TopCold ISLA Instruction manual

Integral Promotional Serve Over -

Installation, Operation & Maintenance Manual

Integral Promotional Serve Over Cabinet

ISLA

Integral Promotional Serve Over - ISLA

Introduction and Index

Contents

1 Warning

2 Definition of Cases and Models

3 Sectional Drawings

4 Technical Data Sheet

5 Transport and Delivery

6 Location of your Display Case

7 Installation

8 Operation

9 Usage

10 Setting parameters on the PJEZS

11 Controller Error and Alarm Messages

12 Maintenance

13 Check Plan

14 After Sales Service

15 Troubleshooting

16 Electrical Wiring Diagram for Akdeniz

17 Declaration of Conformity

Integral Promotional Serve Over - Akdeniz

1. WARNING !!!

Do not start to installation and to use before you read this user manual.

HIGH VOLTAGE RISK!!!

If you have no licence install electrical components, do not interfere to the cabinet or

control board.

Contact with the qualified persons or with Topcold Technical Service when you

purchase a new cabinet or meet with a failure of the cabinet.

Do not open and do not touch to insulated connection.

Integral Promotional Serve Over - Akdeniz

2. Definition of Cases and Models

The Akdeniz is attractively designed to optimise display of chilled products. Case is coming

with wheels, aluminium bars and condensate water evaporator, makes merchandising quick,

simple and durable.

DECODING

Model Name

Case Length

Akdeniz

977,5/1290

Do not load each tray with merchandises heavier than 100 kg/m²

Integral Promotional Serve Over - Akdeniz

3. Sectional Drawings

Integral Promotional Serve Over - Akdeniz

Characteristics

Electrical Components

N / A

N / A

1/1

2 x 24

120 x 120 X 38

Shelf Lighting (T5)

Refrigerant

50

Tickness of Side Walls

Trim Heater

Anti-Condensation Fan

1/1

N / A

(V)

(Hz)

Voltage

Frequency

N / A

(3M2)

Lighting ( W )

N / A

N / A

(mm)

n x W

mm

W

Defrost Heaters

TECHNICAL DATA SHEET

1250

Condensate Heater

Climate Class 3: 25 ºC - %60 RH ( EN ISO 23953-1 / EN ISO 23953-2 )

Unit

1014

R449a

Refrigeration Data

Exp. Valve Orifice No.(Danfoss TEV)

Evaporator Fan Motors

Diameter / incl. Blade

Length

Height

Heaters ( W )

400

937

2 x 25

55

N / A

Canopy Lighting (T5)

Shelf Lighting (T8)

Condenser Fan

220 - 240

Canopy Lighting (T8)

4. Technical Data Sheet

Data specified in the above table is based on the following parameters: ISO 23953

Class III, 25°C ambient temperature, 60%RH, 0,2 m/s air flow rate.600 lux

fluorescent lighting.

Integral Promotional Serve Over - Akdeniz

5. Transport and Delivery

Transport:

Cases always should be transport in the upright position. Cases should be handled with care.

Avoid dropping or jolting the case, which may cause damage.

Remove packaging carefully

Special packing style

with bubbled nylon helps

to protect sensitive

surfaces

Integral Promotional Serve Over - Akdeniz

6. Location of your Display Case

Sitting:

Cases should be located on a flat an even surface. Feet may be adjusted as required to

ensure that the case is level. Castors are fitted for ease of movement. You can stop the case

with black brakes on castors or by unscrewing the legs longer then castors.

Adjustable feet and castors with brake

Do not expose the case direct sunlight or other sources of heat. Avoid incandescent lighting.

Avoid locations where the case may be knocked by cleaning machines and pallets.

Access:

Ensure that the case is easily accessible for loading and unloading.

Place the in a prominent position within the store the maximise visibility of merchandise,

promoting impulse purchases.

Integral Promotional Serve Over - Akdeniz

Ventilation :

Make sure that air return grille was almost open. Do not put the merchandising on to the air

return grille. Closed air return grilles decrease the performance.

Do not locate the case close draught, such as doors, open windows or air conditioning vents.

Make sure air return grille is open Make sure air off grille is open

7. Installation

Assembly:

Assembly, installation and connection of the case should always be undertaken by

appropriately qualified personal.

Tempered Glasses Epos glass should be put in to the canal in

front of the air return grill

Integral Promotional Serve Over - Akdeniz

Power Supply :

As Standard the case is supplied at 220-240 V/ 50 Hz. Please ensure that the local power

supply is appropriate. If the case is hard wired to the mains supply, a means of isolation

must be provided.

The power point should be accessible after the case is positioned.

The case should be earthed. An equipotential earth bonding terminal is also supplied,

allowed the case to be bonded to a building surge earth or adjacent equipment.

8. Operation

Switching on :

Ensure that the main power supply is connected and switched on also refrigeration works

finished.

The case’s fan will operate as soon as the power is switched on and digital thermostat

screen will start to blinking.

Case temperature will begin to drop to its pre-set value. For the pre-set temperature for

your specific model, please refer to the Technical Data Sheet Section.

Turn on the light switch on the control panel.

The light and refrigeration switch are located

onto the front canopy at the right hand of

cabinet.

The light switch is next to the refrigeration

switch.

The digital controller is located next to the

power switch.

Merchandising:

Allow the case for operate for at least two hours before loading merchandise. When loading

cases do not exceed loading limits or allow product to overhang shelf front edges or obstruct

air return grilles.

A tidy, well merchandised case will function more efficiently than a badly loaded one.

Ensure free air flow around the merchandise and between the air discharge and return ducts

designed to maintain not reduce temperature. If warm product loaded within the case, there

may be a delay in the case reaching its normal operating temperature.

Integral Promotional Serve Over - Akdeniz

9. Usage

The Akdeniz is designed and produced in latest technology to preserve dairy, prepacked

meat product temperature class M2.

Always load cases within conservation product temperature.

Before turning it on, clean inside and outside of the cabinet with soft tissue, moistened by

water which contains detergent harmless for surfaces.

Place the foodstuffs steady and accurate onto shelves.

P.S : Never exceed maximum loading limit sign which is shown in the picture.

Integral Promotional Serve Over - Akdeniz

Fans off during defrost

Parameter Definition

AKDENIZ M2

1

2 °C

0

-5 °C

+25 °C

12 °C

45 minutes

4 hours

+2 °C

+7 °C

SEt

Low Temperature Alarm

Temperature Set Point

DEFROST PARAMETERS

F3

FAN PARAMETERS

Time between Defrosts

Set Point Minimum

SET POINT

dt

AL

Display on LED

dl

Maximum Defrost Duration

dp

CONTROLLER PARAMETERS

rd

Control Differential

Set Point Maximum

r2

r1

End of Defrost Temperature

ALARM PARAMETERS

High Temperature Alarm

AH

Usage(continued)

As standard the case is supplied with a Carel PJEZ-S

full functional electronic controller, incorporating

an LED thermometer, which displays average case

operating temperature.

The controller is factory pre-set, but parameters may

be programmed as detailed below.

Reprogrammed parameters take immediate effect and

will be saved in the event of loss of power to the

controller.

Pressing 5 seconds to "UP" arrow supplies manual defrosting

when you determine icing up on the evaporator. !!!

Integral Promotional Serve Over - Akdeniz

10.Setting parameters on the PJEZ-S

The Carel PJEZS electronic controllers comprise a three digit LED display, 'Ф', '*',

Set' and buttons which allow parameters to be set or reprogrammed.

To set or check temperature :

Ensure that the case is switched on and the lights, fans

and compressor are running.

Press ‘SET’ button to display SET on led.

Press ‘SET’ button again and set point value of ‘22’

should be displayed on led .

To change the set point, use down and up buttons within 5 seconds. New parameter has

been set.

To set minimum temperature limit parameter:

Ensure that the case is switched on and lights, fans and compressor are running. Press SET

button for a count of more 5seconds until P5 is displayed on LED.

Press SET button again. 0 appears on the screen. Use up and down buttons until 22

displayed on LED. Press SET button and see d0. Change the value with up and down

buttons. Press SET again and see d0 on the LED. Press SET button once and new parameter

has been set.

To set maximum temperature limit parameter:

The same applies for the maximum temperature. But unlike press SET button and see d1.

Change the value with up and down buttons. Press SET again and see d1 on the LED. Press

SET button once and new parameters has been set.

Integral Promotional Serve Over - Akdeniz

Setting parameters on the PJEZ-S

Preliminary Configurations

Integral Promotional Serve Over - Akdeniz

11.Controller Error and Alarm Messages

A variety of error and alarm messages may be displayed on the LED of the electronic

controller. The codes are detailed below.

Please note that e2 may not be available in some models.

Integral Promotional Serve Over - Akdeniz

12.Maintenance

Before starting any maintenance or cleaning, disconnect the equipment from the electrical

power supply.

If the power control board and condensing units are placed far from each other(remote),

make sure that the control board is switched-off during the cleaning of the condensation

unit. Do not touch the hot and moving parts. The use of heavy-duty gloves is recommended.

Cut the electric supply off before starting maintenance.

Put gloves on before starting maintenance.

Do not touch hot and moving parts.

Amount of the ice in evaporator must be checked every day in first week after installation

and twice a week after first week. If abnormal amounts of ice are noticed, the cabinet must

be set to regular working conditions by manual defrosting.

12.1 Cleaning :

12.1.1 General:

A regular and thorough cleaning regime is essential for the efficient and hygienic operation

of your display case .

Before undertaking any cleanin operation, always turn the case off and if possible disconnect

from the main supply.

Never use abrasive or caustic cleaning as above.

SHOCK HAZARD !!!

TURN OFF THE POWER BEFORE

START TO CLEANING !!!

Integral Promotional Serve Over - Akdeniz

12.1.2 Exterior / Internal surfaces, shelves and air grilles:

Painted or metal surfaces should be cleaned with a cloath soaked in warm soapy water.

Surfaces should be dried with soft cloth.

Shelves should be removed for cleaning as above.

12.1.3 Glass:

Glass endwalls should be cleaned with a suitable glass cleaner.

Glass surfaces may be buffed with a soft dry cloth.

12.1.4 Case Well:

Lift out deck trays and sweep or vacuum any debris from the case well.

The well may be wiped with a cloth and mild disinfectant.

12.1.5 Fan Deck:

Lift the fan plate allow claening around the

fans.Make sure that fans are not running.Never

take off the fan guards.Never try to stop the fans

with your hands while they are running.

12.1.6 Cooling Fins:

Carefully vacuum dust and air borne debris

from the cooling fins.

Exercise care not to dmage fins.

Beware of the sharp finds and take care when

cleaning this area.

Integral Promotional Serve Over - Akdeniz

12.1.7 Water Outlets:

Outlets for waste water should be cleaned

regularly to ensure a continious flow of waste

water.

12.2 Housekeeping Routines:

12.2.1 Close of Business:

Cases should not be switched off at close of business or overnight.If your princible is moving

of the merchandises to the cold room at the end of the day,switch off the case.But, do not

load the merchandises again without getting enough refrigeration in the case.

12.2.2 Case Inspection:

Operating temperature, as indicate on the controller

mounted in front of the case,should be checked on

dialy basis.

Case should be monitored on a daily basis for any

undue noise, smell or malfunction.

Regularly inspect the case for ice cream spillage or debris in the air grilles and case well.

Remove and clean spillages and debris.

12.2.3 Cleaning of the Condenser unit:

Ensure that the condensing unit is switched off and if

possible disconnected from the main power supply.

Carefully vacuum dust and air borne debris from the

condenser fins.

Exercise care not to damage fins.

Integral Promotional Serve Over - Akdeniz

13.Check Plan:

Customer is liable on these opeations!!!

Check or Maintenance

Daily

Weekly

Monthly

Cleaning of condenser

X

Cleaning of evaporator

X

Checking of the digital controllers display

X

Checking of icing up of the evaporator

X

Cleaning of the case drain

X

Checking of the case circulation fans

X

Checking of the condenser fan(s)

X

Checking of the air off at grilles

X

Condenser Evaporator Display

Drain and circulation fans Air off and air return grilles

Integral Promotional Serve Over - Akdeniz

General instruction while maintenance processing:

Do not step on bottom shelves and the cabinet.

Inside of the cabinet is wet and slippery.

Inside of the cabinet has cold surfaces right after refrigeration process.Wait until

its warm up.

In maintenance the first job of the trained stuff , check the cabinets and their operating

temperatures and note them.

Any maintenance operation not included among the former steps must be carried out by the

authorised after-sales service or by qualified personel.You can refer the troubleshooting

tables in this document.

14.After-Sales Service

Contact your agent when you need technical assistance.If you need parts contact your after-

sales service.Manufacturer recommends using genuine parts for cabinet to operate

properly.Manufacturer undertakes no responsibility for damaging resulting from the use of

non-genuine parts.

Table of contents

Popular Merchandiser manuals by other brands

VALERA

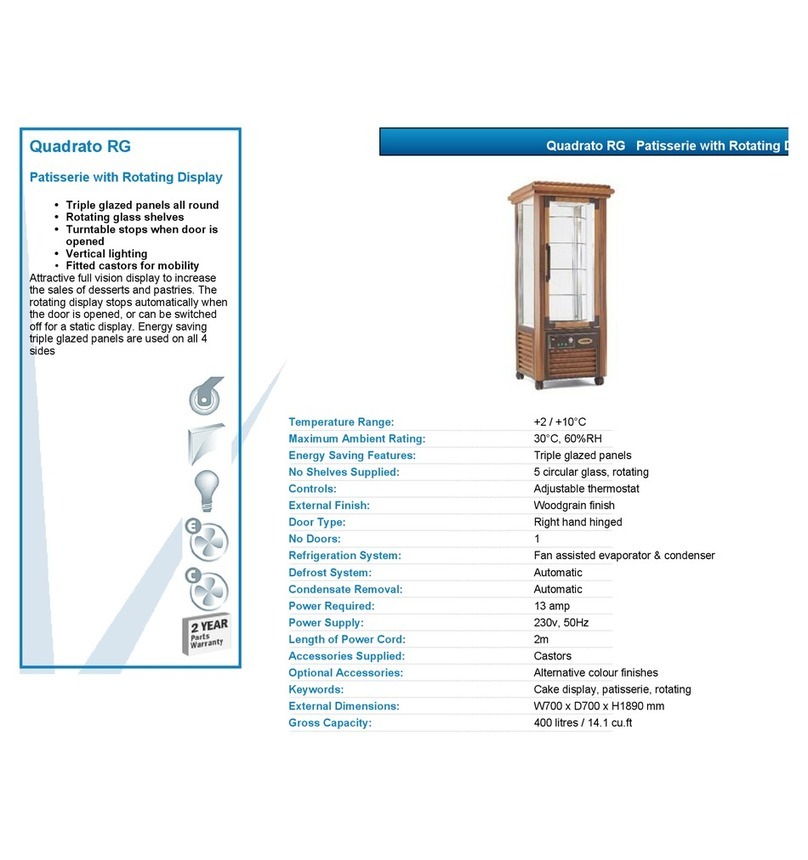

VALERA QUADRATO RG datasheet

Summit

Summit SCR312L owner's manual

VALERA

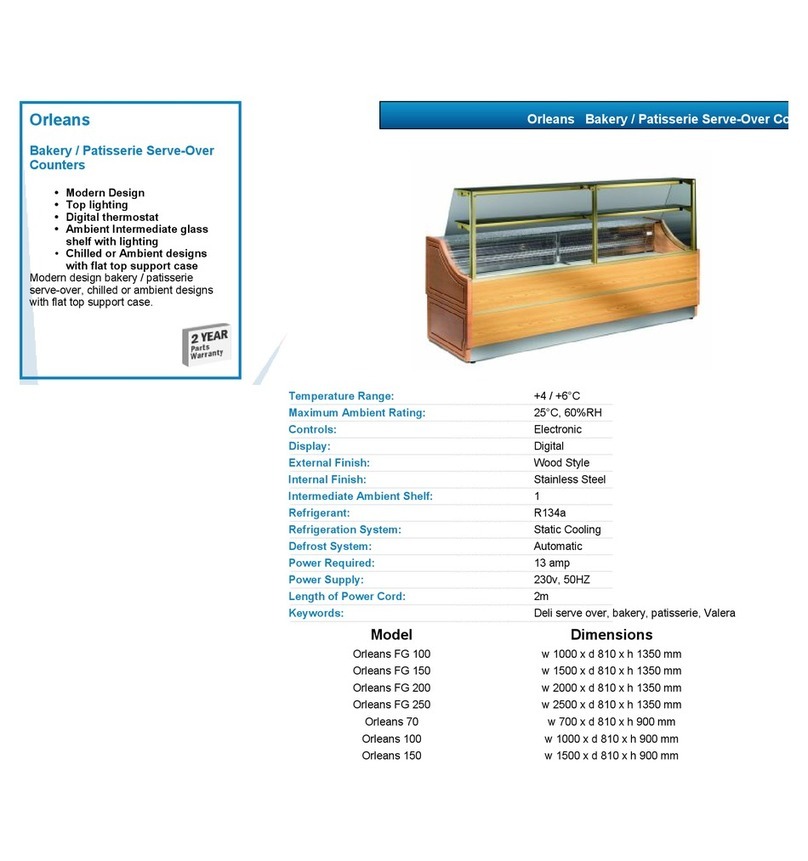

VALERA ORLEANS 100 datasheet

Hussmann

Hussmann Q1-DC Wedge Installation and operation guide

Turboair

Turboair TOM-40 User's installation and operation manual

Hussmann

Hussmann Specialty Products R3H Installation and operation guide

Hussmann

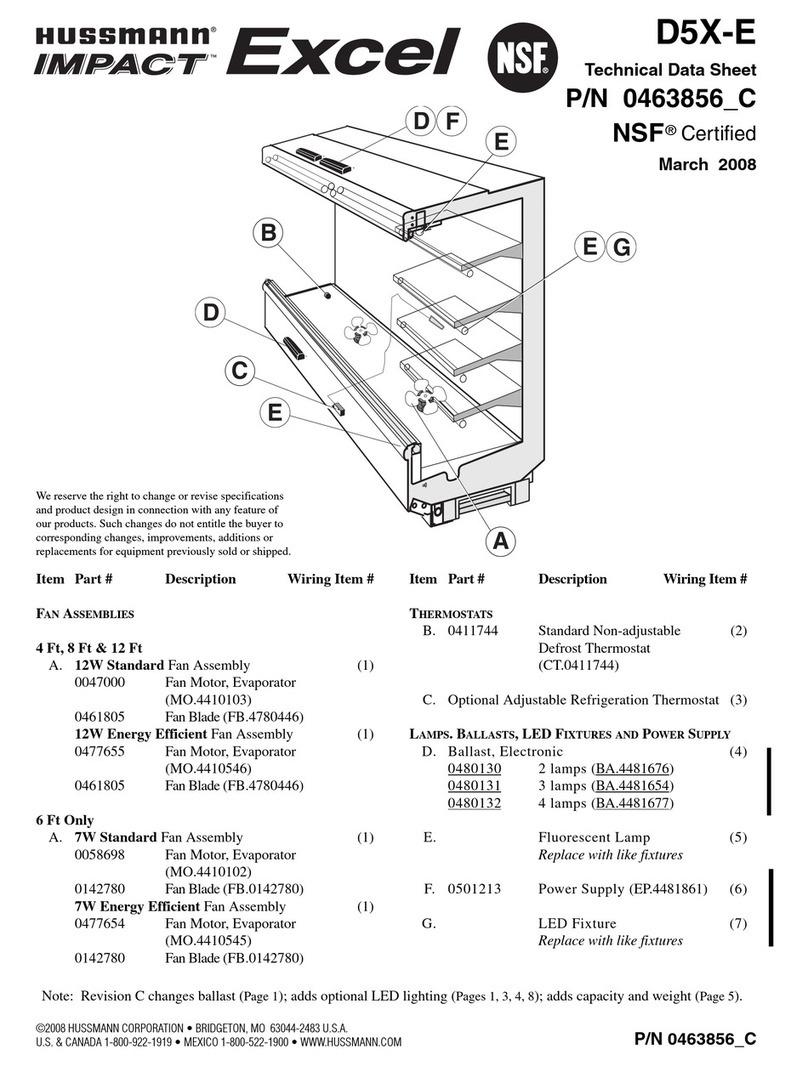

Hussmann D5X-E Technical data sheet

Hussmann

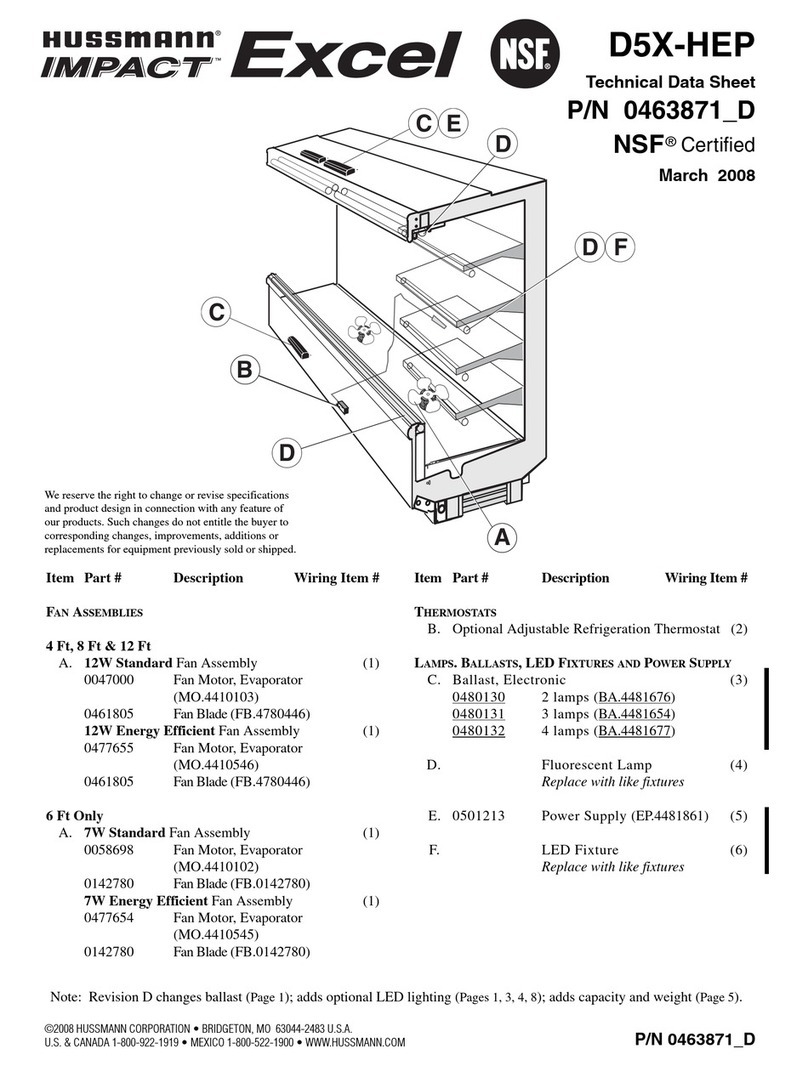

Hussmann D5X-HEP Technical data sheet

Hatco

Hatco GLO-RAY GR3SDS-39DCT Installation and operating manual

Hussmann

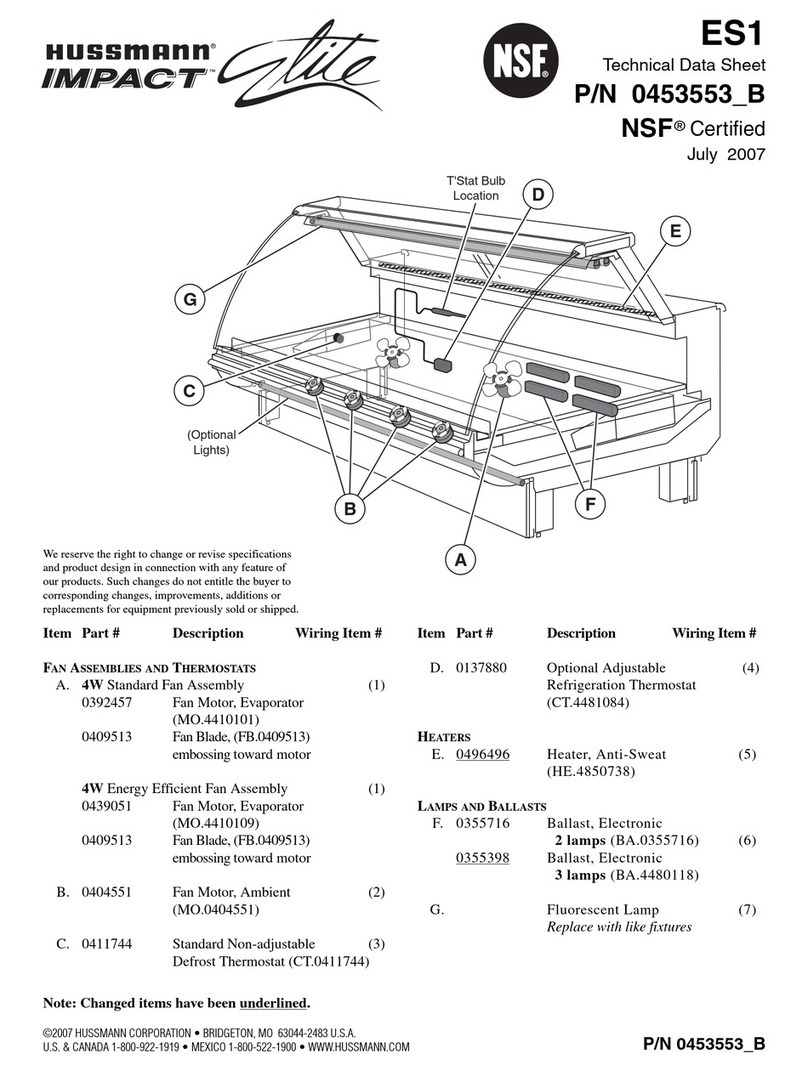

Hussmann IMPACT Elite ES1 Technical data sheet

Hussmann

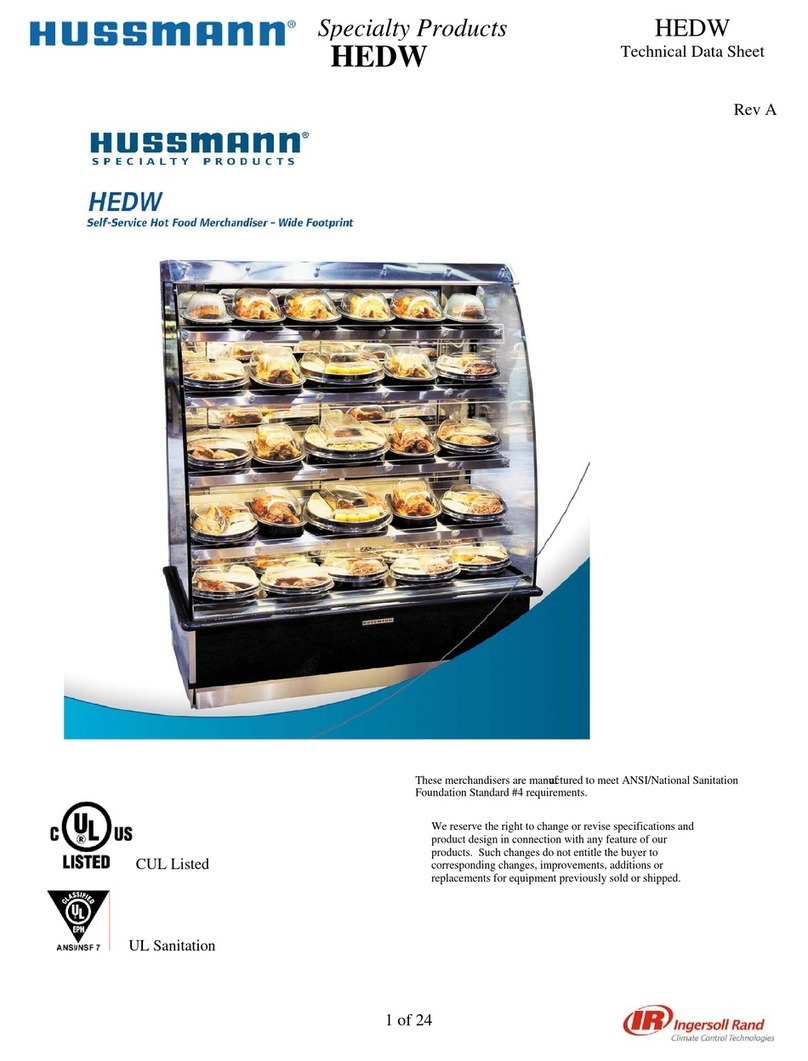

Hussmann HEDW Technical data sheet

Hussmann

Hussmann Q1-SS Installation and operation guide