topSenso topCam 6500 User manual

- 1 -

Manual topCam 6500 (Ver. > 3.5.4)

topSenso GmbH

Platanenring 10

D - 61352 Bad Homburg

Germany

Contact:

Tel. +49 6172 944606

Fax +49 6172 944607

E-mail [email protected]

Internet www.topSenso.de

- 2 -

Table of content

Manual topCam 6500 (Ver. > 3.5.4) .....................................................................................1

1. EMV test ....................................................................................................................3

2. Technical specifications..............................................................................................3

2.1. Scanning field:........................................................................................................3

2.2. Inputs/Outputs:........................................................................................................3

2.3. Interfaces: ...............................................................................................................3

topCam6500 connection panel............................................................................................4

2.4. Dimensions.............................................................................................................4

3. Connector pin assignment HD-15 connector ..............................................................4

4. Connector pin assignment Video output (round socket)...............................................5

5. topCam 6500 lenses....................................................................................................5

6. Symbologies: ..............................................................................................................5

6.1. Data matrix code ECC200 scanning:.......................................................................6

6.2. Bar code scanning: horizontal, vertical or omnidirectional.....................................6

6.3. OCR/OCV ..............................................................................................................6

6.4. Gauge pin (contour tracing).....................................................................................6

7. Installation..................................................................................................................7

7.1. Positioning and scanning distance ...........................................................................7

8. Electrical connection...................................................................................................7

8.1. Power supply ..........................................................................................................7

8.2. In and outputs .........................................................................................................7

8.3. Serial interfaces.......................................................................................................8

8.4. TCP/IP connector....................................................................................................8

9. Control monitor ..........................................................................................................9

10. Code sizes of the data matrix code ..........................................................................9

11. Print quality parameters and their classifications ...................................................10

12. Operation..............................................................................................................10

12.1. The topControl user interface l.........................................................................10

Selection window (window function)............................................................................12

Settings of the data matrix code scan ................................................................................12

Settings bar code scanning................................................................................................13

OCR/OCV scanning settings...........................................................................................14

MICRO PDF 417 (stacked bar code).................................................................................18

Function window..............................................................................................................19

Interface settings...............................................................................................................19

Options.............................................................................................................................20

Output format...................................................................................................................21

Format..............................................................................................................................21

Lighting adjustment from 1-99 .............................................................................................22

13. The user interface topControllite...........................................................................23

14. Error status data matrix code:................................................................................26

15. Error status bar code: ............................................................................................26

16. Trouble shooting...................................................................................................27

17. Scanning the data matrix code in envelope windows .............................................28

- 3 -

1. EMV test

2. Technical specifications

2.1.Scanning field:

HD: Image area 21 x 17 mm (high density) scanning distance 55 mm

SD: Image area 32 x 25 mm (default density) scanning distance 80 mm

ED: Image area 40 x 30 mm (expanded scanning area) scanning distance 100 mm

Optional: Various focal length and scanning windows

Scanning distance:55 mm/80 mm +/- 5 mm

Lighting:Internal LED flash red (optionally white)

Optional: external lighting

2.2.Inputs/Outputs:

2 potential-free inputs (trigger,

input 2)

2 potential-free outputs, short-circuit-

proof

(continuous current max. 200 mA)

2.3.Interfaces:

1 RS232 process interface

(2400 - 115200 baud)

1 RS232 controlling interface

115200 baud (optional 9600 baud)

1 Ethernet adaptor TCP/IP 100 MB/sec auto negotiation

- 4 -

topCam6500 connection panel

2.4.Dimensions

Casing: 127 x 68 x 48 mm

3. Connector pin assignment HD-15 connector

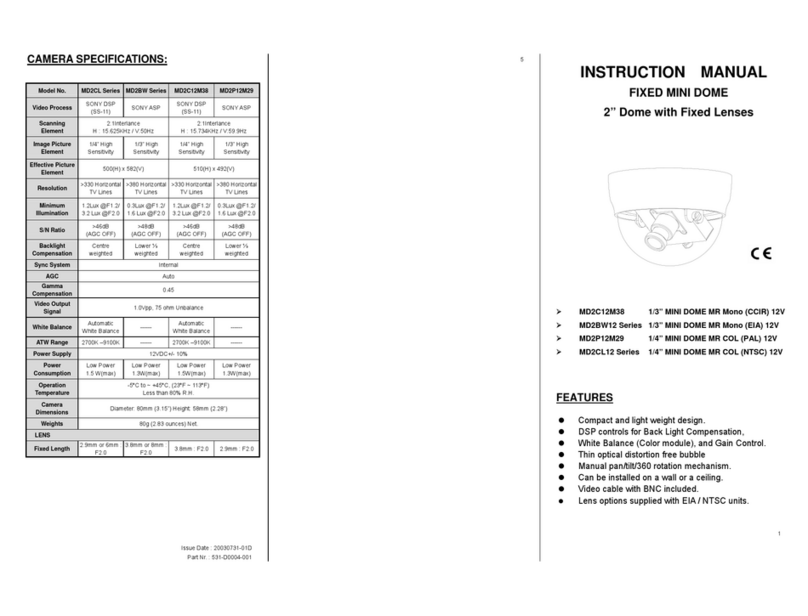

HD 15 connector Signal name Description RS-232

connector

with

process

Sub-D 9

RS 232

connector

service

interface

1GND Reference potential

for power supply

2TXD Process interface 2

3RXD Process interface 3

4IN 2 (unused)

5 12-24 volts Power supply

6assigned

7RXD Service interface 3

8assigned

9TXD Service interface 2

10 RS 232 GND Reference potential of

the RS-232 interfaces 5 5

11 IO 12-24 Volt Supply of the

insulated outputs

12 OUT 1 (READ) Output current max.

200 mA

13 OUT 2 (NOREAD) Output current max.

200 mA

- 5 -

14 IN 1Trigger input

15 IO GND Reference potential

for insulated inputs

4. Connector pin assignment video output (round socket)

The plug is screwable (plug in and tighten)

7-pole miniature socket Signal name HD-15 VGA socket

1 H-Sync 13

2 V-SYNC 14

3GND 6

4GND 10

5Blue 3

6Red 1

7Green 2

5. topCam 6500 lenses

Focal length Distance to codeScanning window

8mm 55 mm 36 x 27 mm

80 mm 56 x 42 mm

12 mm 55 mm 21 x 17 mm

80 mm 32 x 25 mm

100 mm 40 x 30 mm

120 mm 60 x 45 mm

9.5 mm 55 mm 24 x 18 mm

80 mm 34 x 25 mm

95 mm 40 x 30 mm

6. Symbologies:

-Data matrix code ECC 200 (max 35 Hz), max 6m/sec), micro PDF 417, EAN data matrix

-Bar code scanning (code I 2of5, Code 39/32, code 128 A,B,C, EAN 8/13, UPC A/E)

Pharma code (max 40 Hz, max 6m/s)

-OCR/OCV scanning (2 windows max 30 objects (Optional: 2 windows with max 30

objects), window, 1 x adjusting window)

-Gauge-pin recognition (object recognition)

-Label position, distance measurement, print image control

- 6 -

-Area measurement

6.1.Data matrix code ECC200 scanning:

-dark code on light background (automatic or configurable)

-light code on dark background

-code sizes from 10 x 10 to 48 x 48 square

-all rectangular codes up to 16 x 48

-aligned, 90 degrees aligned +- 30 degrees, independent from rotation position

-evaluation speeds: < 40 Hz

-movement speeds : 6m/s

- data formats data matrix: ASCII,C40,text, X12, Edifact, Base 256, extended Base 256

-maximum data capacity: 348 numerical, 259 ASCII, 172 Bytes

-printing quality parameters (contrast, grid non-uniformity, error correction)

6.2.Bar code scanning: horizontal, vertical or omnidirectional

- code interleaved 2 of 5

- code 39/32

- code 128 A,B,C

-EAN 8/13

-UPC A/E

- pharma code

- optionally with or without check sum

-length specifications

6.3.OCR/OCV

-character set teachable (max 40 characters)

-mask generator

-product storage up to 25 different products

-scanning, verification or pixel counter

- up to 2 different scanning windows

- up to 30 objects per window

- 1 adjusting window

-scalable objects

-adjustable parameters

-light objects on dark background

-dark objects on light background

-also suitable for inkjet code

-scanning speed approximately 3ms/object + image import17ms

-overlay representation

-guided user interface

6.4.Gauge pin (contour tracing)

-gauge pin teachable as object

-tolerance specifications

-display of coordinates

-light or dark object

- Windowsprogramme for representation and teaching of gauge pin

- 7 -

7. Installation

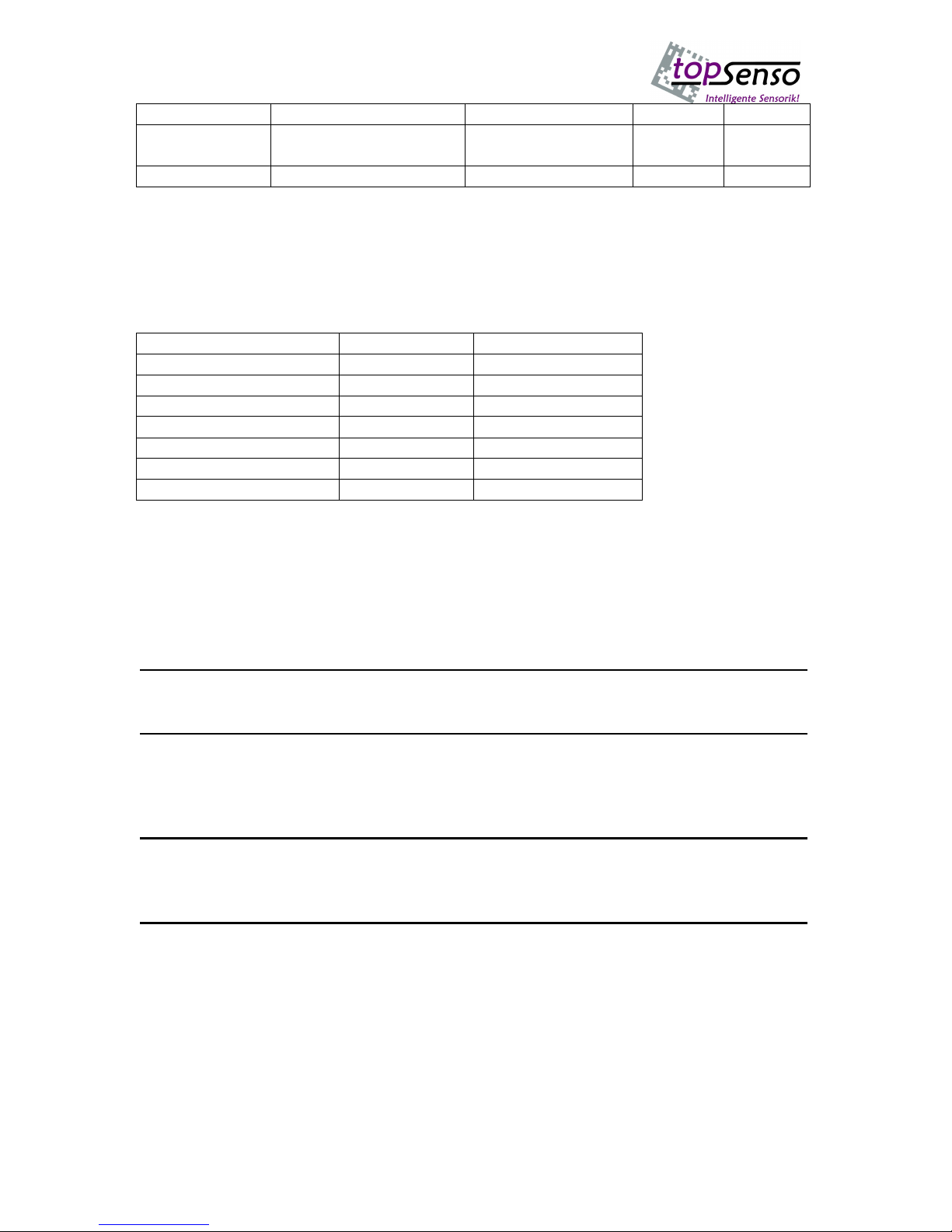

7.1.Positioning and scanning distance

The topCam6500 is fitted at a distance of 80mm (SD version) from the surface. In case of

reflecting surfaces (e. g. labels) the topCam6500 should be mounted in an inclined position, as

shown in Figure 1, in order to eliminate direct reflections.

55

Figure 1: Scanning distance and incline of the topCam6500

8. Electrical connection

8.1. Power supply

The topCam6500 is supplied with a direct voltage of 18 volts to 24 volts. The supply voltage

is impressed between pin 5 (+10..24 volts) and pin 1 (GND). The topCam6500 is protected

against incorrect polarity of the supply voltage.

8.2. In and outputs

The optically insulated in and outputs of the topCam6500 have their own supply connections.

The outputs receive their supply voltage of 18-24 volts from pin 11 of the HD-15 connector.

The output signals are PNP signals.

Reference position for the inputs is pin 15 of the HD-15 connector.

The outputs are short-circuit proof. They switch off automatically in case of overload. In

order to reactivate the outputs after such an overload turnoff, switch the supply voltage at the

outputs off and on.

Output 1 (pin 12 of the HD-15 connector) is activated when a code has been scanned

correctly.

Output 2 (pin 13 of the HD-15 connector) shows a scanning error. Polarity and duration of

activation of the outputs are configurable.

Input 1 (pin 14 of the HD-15 connector) serves as a trigger input. The polarity of the trigger

signal is configurable.

Input 2 resets the statistical counters if a voltage is applied on the input for approximately 3

seconds.

If the trigger delay is to be realized by means of an incremental encoder the signal of the

incremental encoder is to be applied on input 2.

- 8 -

8.3. Serial interfaces

The topCam6500 has two serial interfaces. A process interface and a diagnosis interface. If

the topCam 6500 is integrated in the machine and the process interface is connected the

scanning can be recorded by means of the diagnosis report during the operation. An in process

control is possible.

In addition, simultaneous output of the data to the process port and the diagnosis port is

possible.

The two serial interfaces of the topCam6500 are galvanically isolated from the residual

device, therefore they have their own point of reference (pin 10 of the HD-15 connector).

The first serial interface (pin 2 und 3 of the HD-15 connector) links the topCam6500 with the

process environment.

The second serial interface (pin 7 and 9 of the HD-15 connector) serves as a link between the

topCam6500 and a PC. This interface works with a fixed data rate of 115200 baud, the data

format is 8 data bits, 1 stop bit, no parity.

8.4. TCP/IP connector The TCP/IP allows direct connection by

means of the IP address. The MAC

address is associated with the serial

number of the device which allows

parallel connection of several topCams

with different IP addresses on one

switch. The MAC address cannot be

changed. The IP address can be changed

by a command.This new IP address

will not be activated until a reset is

made. Note! The settings must be saved.

When the topCam 6500 is switched on

the monitor will show the IP address.

Also the process port can be determined

if output of the scanned data is to be made via the RS232 or the TCP/IP port. The Windows

user interface can be operated via the TCP/IP and the RS232 Port. The following commands

can be entered in the command line of the topControl programme:

Changing of the IP address is possible in the menu item SYSTEM ENTER COMMANDO

which will open a window.

The IP address is set to 192.168.120.102 on delivery and can be changed as follows: Enter:

IN:M:t192.168.120.103 in the command window. With the command IN:Q:n n= 0 process

port the RS232 is, n=1 process port is the TCP/IP port.

All changes must be saved in the Flash and will be activated after switching off and switching

on again.

Important!!!! The port address for TCP/IP is port 23

- 9 -

9. Control monitor

A commercially available VGA monitor can be connected to the 7-pole miniature port. It

displays the image which was recorded last. A compatible link cable is also included in the

delivery of the topCam6500.

Inverse DM code rectangular DM code EAN13 code DM code

This figure shows and image of a VGA monitor with a varying code

10. Code sizes of the data matrix code

Symbol size Data region Data bytes error correction Data capacity max rectifiable

vert horiz. num alpha byte bytes

10 10 8 x 8 3 5 6 3 1 2

12 12 10 x 10 5 7 10 6 3 3

14 14 12 x 12 8 10 16 10 6 5

16 16 14 x 14 12 12 24 16 10 6

18 18 16 x 16 18 14 36 25 16 7

20 20 18 x 18 22 18 44 31 20 9

22 22 20 x 20 30 20 60 43 28 10

24 24 22 x 22 36 24 72 52 34 12

26 26 24 x 24 44 28 88 64 42 14

32 32 28 x 28 62 36 124 91 60 18

36 36 32 x 32 86 42 172 127 84 21

40 40 36 x 36 114 48 228 169 112 24

44 44 40 x 40 144 56 288 214 142 28

48 48 44 x 44 174 68 348 259 172 34

8 18 6 x 16 5 7 10 6 3 3

8 32 6 x 28 10 11 20 13 8 5

12 26 10 x 24 16 14 32 22 14 7

12 36 10 x 32 22 18 44 34 20 9

16 36 14 x 32 32 24 64 46 30 12

16 48 14 x 44 49 28 98 72 47 14

- 10 -

11. Print quality parameters and their classifications

Quality class Contrast error correction Grid non-uniformity Axial non-uniformity

A>=70 >=62 <=38 <=6

B>=55 >=50 <=50 <=8

C>=40 >=37 <=63 <=10

D>=20 >=25 <=75 <=12

F< 20 < 25 > 75 > 12

12. Operation

All parameters relevant for the operation of the topCam6500 can be easily set by means of the

operation programme topCamControl. In addition, this programme allows to store device

settings and to save recorded images.

12.1. The topControluser interface

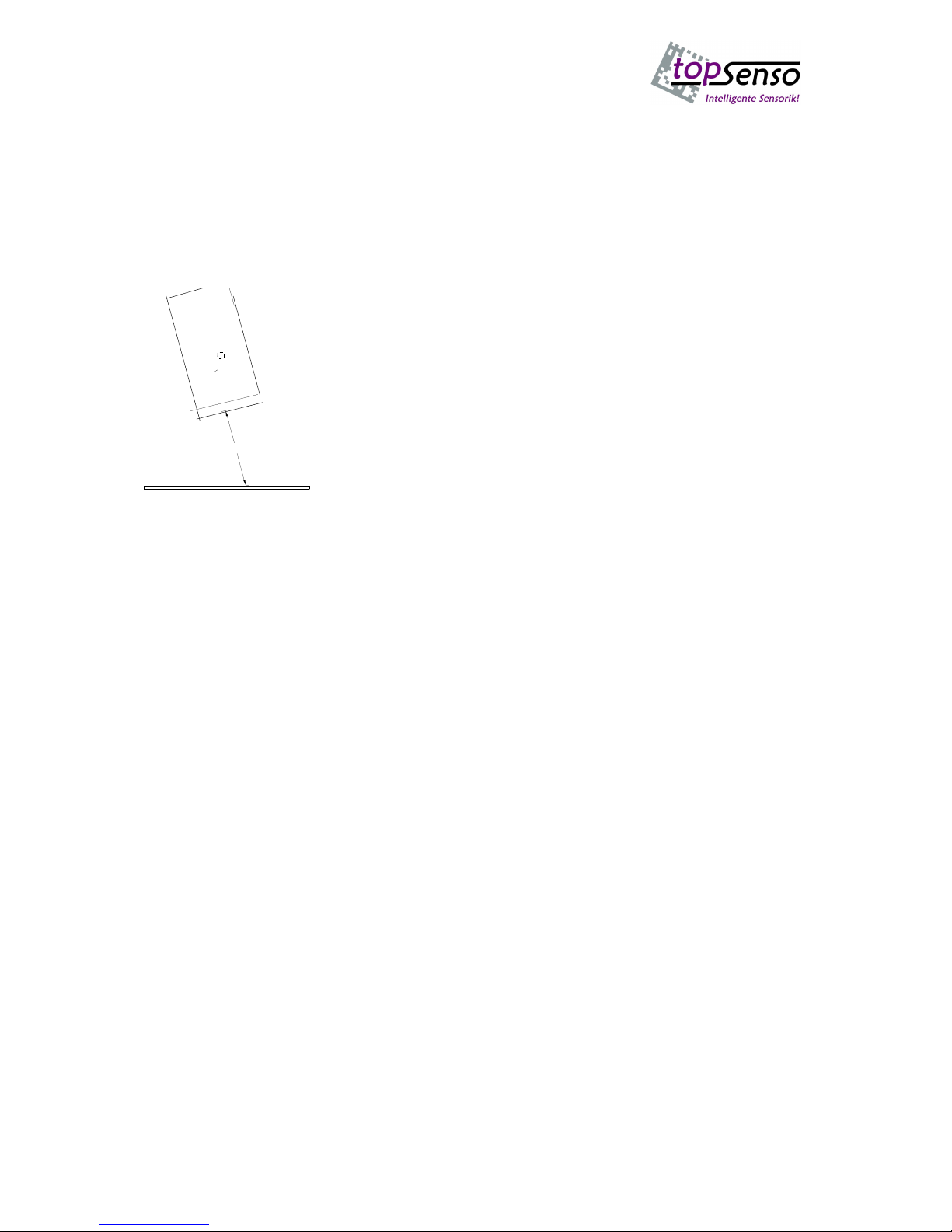

The topControl user interface allows operation of the topCam6500 via a PC COM port or to

establish a communication via Ethernet for the topCam using an Ethernet adapter.

When the programme is started for the first time it will be asked if the topCam is to be

controlled via the RS232 or the TCP/IP Ethernet connection.

Selecting the connection

If the COM port connection is selected the system’s available COM interfaces will be

scanned; if more than one interface is available the programme will scan for the COM port to

which the topCam is connected when being started for the first time.

Connection to RS232 with adjustable parameters

- 11 -

When selecting the TCP the menu will request the IP address.

NOTE! The PORT number mustalways be entered with 23. (PORT for TELNET)

After the port has been selected the programme will start and establish the required

connection with the topCam6500.

Establishment of connection

The setup parameters are loaded from the topCam6500. Then, the basis interface will be

displayed.

On the right 4 different tabs can be opened.

-Interfaces

-Output format

-Options

-Window functions

- 12 -

When the programme is started the

“window function” will be opened

automatically.

Up to 4 evaluation windows can be

configured here. For every evaluation

window one type of evaluation can be

selected.

Selection window (window function)

Settings of the data matrix code scan

After selection of an evaluation type the settings

typical for this type of evaluation can be made

with the button “Einstellungen”(settings).

The following example shows the setting of the

data matrix code: “invers”= light code on dark

background, if auto is selected the system will

automatically search if light or dark code.

“Codegröße“(Code size) is used to specify the

exact code size or if to be found automatically.

“Orientierung“ (Orientation) defines the rotation

in which the DM code is to be scanned. (3 options:

fixed position, rotated by 90 degrees or

independent from position of rotation).

“Ruhezone“(Clear area) defines the number of

pixels to be left clear around the code.

“Grauwertschwelle” (Grey scale value threshold)

defines a value for which the grey scale value

jump is recognized as ramp.

“Störungskompensation” (Disturbance

compensation) skips holes in the finder. “automatische Videoverstƒrkung“ is used to set the

video amplifier at first to the lower value in order to be increased after every scanning

attempt. This function can be used to compensate contrast variances for strong background or

the lighting conditions for code on changing surfaces.

- 13 -

Settings bar code scanning

If bar code scanning is selected as window function

the settings on the left can be made for this

evaluation.

“inverser Code, mit Prüfsumme“ (inverse code with

checksum), “Ausgabe der Prüfsumme“(Output of

checksum), “Code 39 oder Code32“(code 39 or code

32), “EAN oder UPC“(EAN or UPC), “Pharamacode

oder Multicode“(Pharma code or multi code).

“Horizontales oder vertikales Scannen”(Horizontal

or vertical scanning). “Omnidirektionales Scannen”

(Omnidirctional scanning).

Auto-discriminating or individual code types should

be scanned.

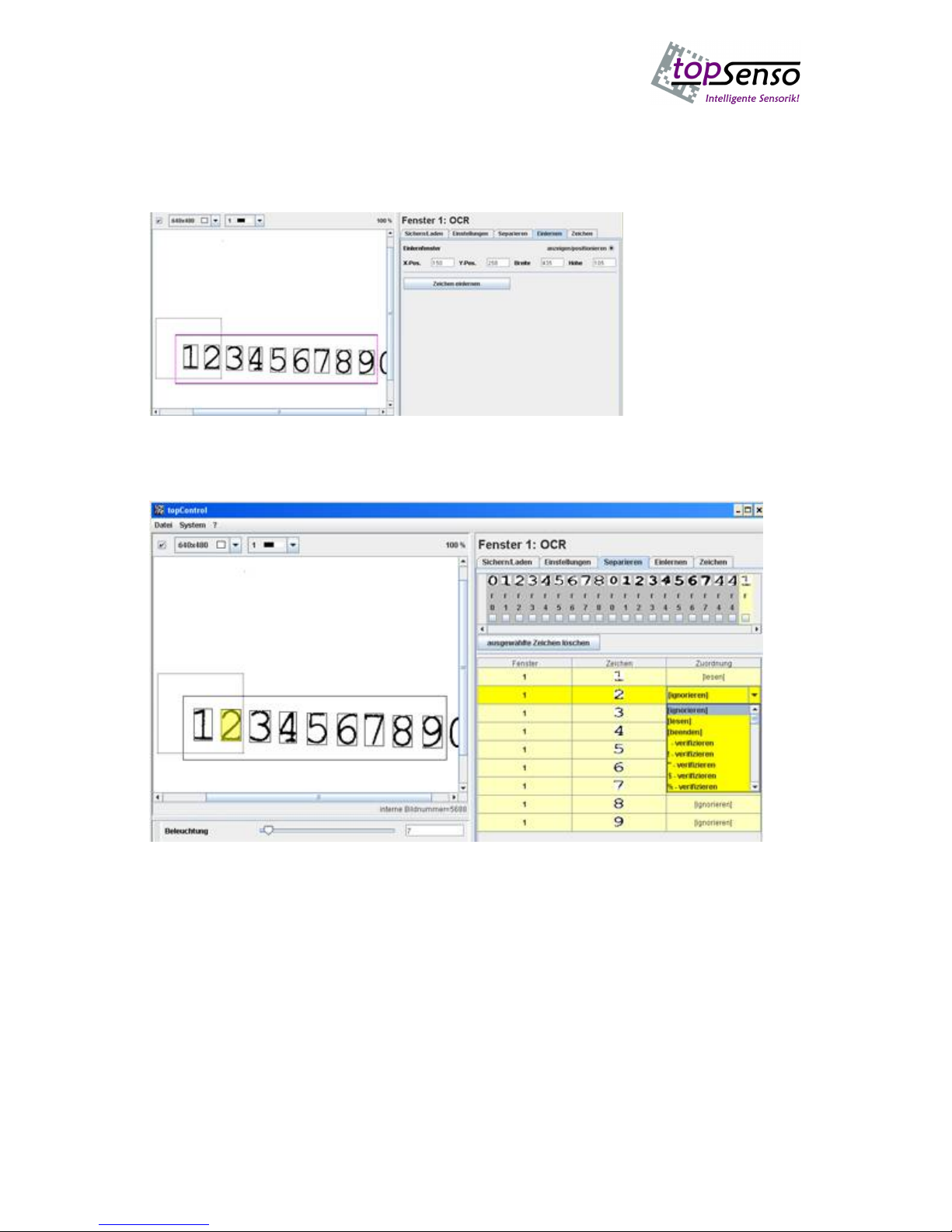

When OCR/OCV scanning is selected first a basic menu

will be opened with different options for

Speichern/Laden (Save/load)-Einstellungen (Settings)-

Separieren (Separate) -Zeichen einlernen (Teach

characters)-Zeichensatz bearbeiten (Edit character set ).

The menu on the left allows storing and loading of the

product data set (window settings, basic settings) or of

the character set.

- 14 -

OCR/OCV scanning settings

Settings of the adjusting window:

Adjusting over X(horizontally) and

from the left and over Y (vertically)

from the top.

Ramp form light to dark.

If amask is selected a mask generator

will assign a function to every

character.If variable length is

selected all characters found in the

scanning window will be scanned.

The output string can be made up

with zeros up to a fixed length, if

required.

The characters are dark on light

background.

The compliance proportion should be

at least 90 %.

The minimum height of the

characters should be at least 20 pixels

and the minimum width 6 pixels.

If inside a character distances of up to

5 pixels are present it will be scanned

as one character.

The minimum distance between the characters should be at least 1 pixel.

The division factor is defined by the proportion height to width * 10.

The grey scale value threshold indicates the minimum contrast that may be present.

The control function is used to insert information in the scanned characters. CNTR and the

mouse are used to add individual control outputs.

In order to edit additional menu items the character string to be scanned should be read and

the display in the window should be set to at least 320 x 240. If separating is selected the

following interface will be displayed. The buttons display (adjusting window or scanning

window) will display the selected window.

In the figure below the adjusting window is shown in green.

Use the mouse to reset or move the window. This is also possible by directly entering the

coordinates.

- 15 -

The image below shows the scanning window 1.

Use the button “Zeichen

Separieren”(Separate

characters) to search and

separate the individual

characters in the

scanning window. All

characters found are

displayed in the user interface.A function can be assigned to every character.The following

functions are available: - “Lesen”(Scanning) (The character on the respective position will be

scanned) – “Verifizieren”(Verify) (Character will only be compared to identical character) –

”Ignorieren”(Ignore) (the character is recognized but ignored) – “Ende”(End) (terminates

the character string).

- 16 -

If a character is highlighted with the mousethe character will be highlighted in yellow in the

image window.Now the required function can be assigned to the character.Using this

procedure a function can be assigned to every single character in the character string. The

current character set of the camera is shown on the top.After all characters have been

assigned the settings are accepted by pressing the button “Übernehmen”(Accept).

In order to be able to scan the characters specified for scanning a character set must be

created.The following describes how to teach the character set.

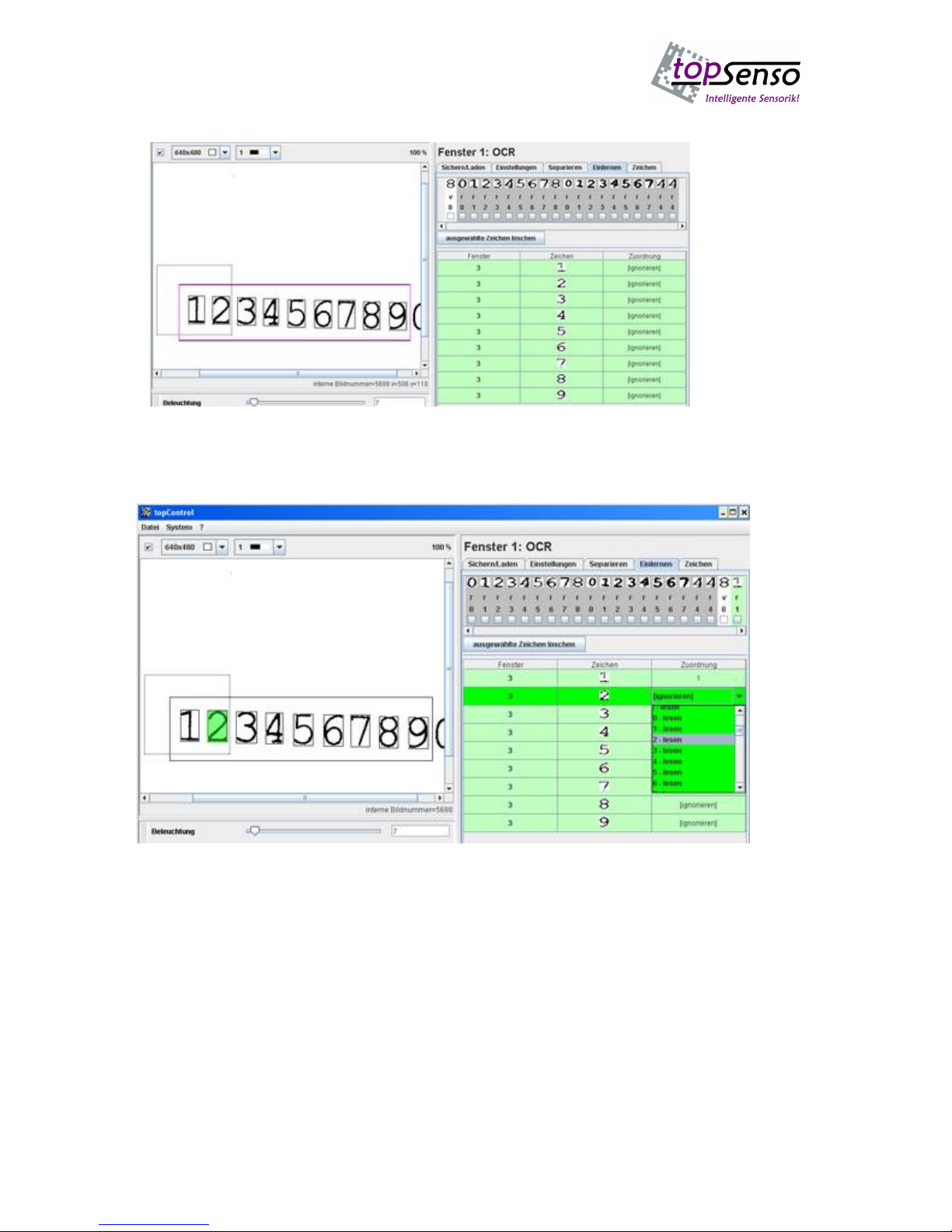

When choosing the tab “Einlernen” (Teaching) a window in red will be displayed.The

characters in this window are scanned and displayed as a list as for separating.

- 17 -

The following list will be displayed:

The existing

character set

will be

displayed in

the top right

corner.The

function

assignments

appear below

the characters

r= scan, v=

verify.

Characters for

scanning within the character set (marked with “r”) can be deleted.

Now an assignment can be made for the list in the table.

The number 1 has already been included in the character set and is contained in the top

right corner in the character set.

An assignment to the characters is only made for the characters which are to be included in

the character set. The assignment can also, for example, be used to assign a letter to a

Japanese character.

Use the button “Übernehmen”(Accept) to accept all data.

- 18 -

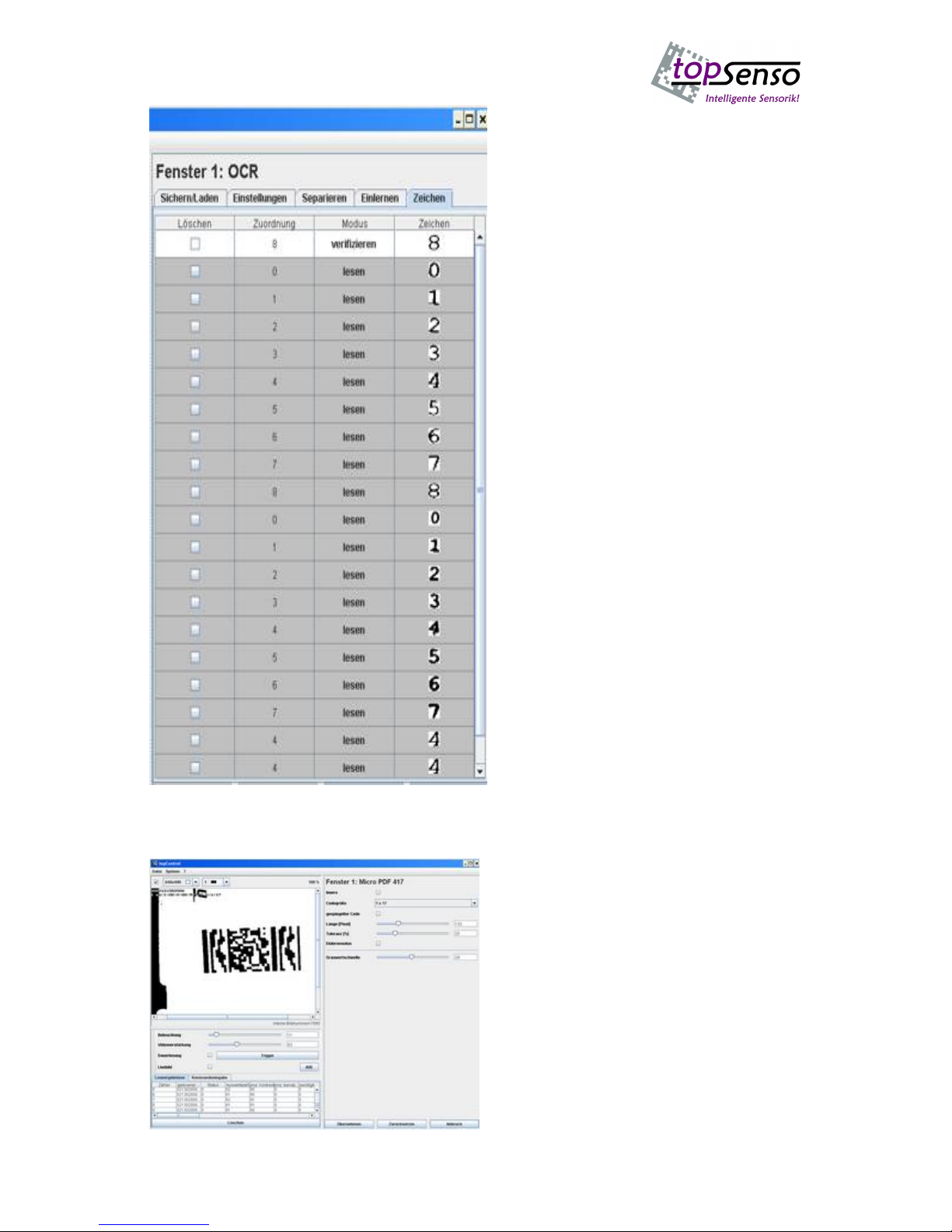

Use the window “Zeichen” (Characters) to

display and edit (delete) the current

character set.

All characters can be deleted apart from

the characters which only have a fixed

position and assignment for verification.

This function is described in modus.

The character set can be up to 40

characters long.

Additional special settings can be set in

the camera. However, they are not

supported by the Windows user interface.

MICRO PDF 417 (stacked bar code)

Another evaluation window is the scanning

of the micro PDF 417 code.

- 19 -

Function window

If more than one evaluation windows

are active AND or OR interconnections

can be made.

If AND is selected all function

windows must have reached a

successful scanning for the successful

signal to be set. If OR is selected only

one function window must have

effected a successful scanning for a

successful signal to be set.

In addition triggering for every

individual window by means of the 2

trigger inputs is possible. Example: If 2

windows are active the different trigger

inputs can be used to initiate a

triggering.In the centre of the picture

below either trigger 1 or trigger 2 can

be selected. This allows realization of

different evaluations at two different

positions.

Interface settings

With selection of the tab

“Schnittstelle”(Interface) the

following settings are possible for

the process interface.

Process interface

Baud rate

Data bits

Parity

Stop bits

Trigger

Polarity

Trigger delay up to

2000 ms

Trigger string (start)

Trigger string (end)

Output signals

Polarity

Pulse length

Output time

- 20 -

A number of options is available for scanning the image and its subsequent evaluation.

1. When applying a trigger signal an evaluation is made by means of a serial trigger

string which can be defined freely.

2. When a certain period has passed after the trigger signal the scanning of the image

starts.

3. After a number of pulses after the trigger input has been set.

4. Within a scanning gate starting with the trigger input

5. Within a scanning gate via soft trigger string start until one soft trigger string is sent

which terminates the scanning procedure.

When the values are on 0 the action is deactivated. Up to 6 unassigned characters can be

selected for the soft trigger start. Also up to 6 characters can be defined for the trigger end

string.

As a default option, a scanning can be initiated by sending the command <STX>TR<CR>.

Options

By selection of the tab “Optionen” (Options) the following basic system settings can be

realized.

Suspending the start-up message

„Trace data matrix code“ after every

successful scanning of the data matrix

code a frame is drawn around the code

and the individual modules are

represented by a dot and the error

correction by a red cross.

Monitor output:

monitor rotated by 90 degrees.

Flash on/off:

the individual flash LEDs can be

switched on or off individually.

Overlay on/off:

permanent scanning, display only

successful scannings

Permanent scanning, but only the

different ones Codes are displayed only

once

Scanning as long as trigger is active

Timeout in ms if value exceeds 0 a

successful scanning must be made

within the time in ms. If not a NIO

signal is emitted.

Match code entry: If the match code is

active the scanned code will be

compared to the reference code. The

reference code can be specified or

taught during the first valid scanning.

Table of contents