Contents

Safety.......................................................................4

GeneralSafety...................................................4

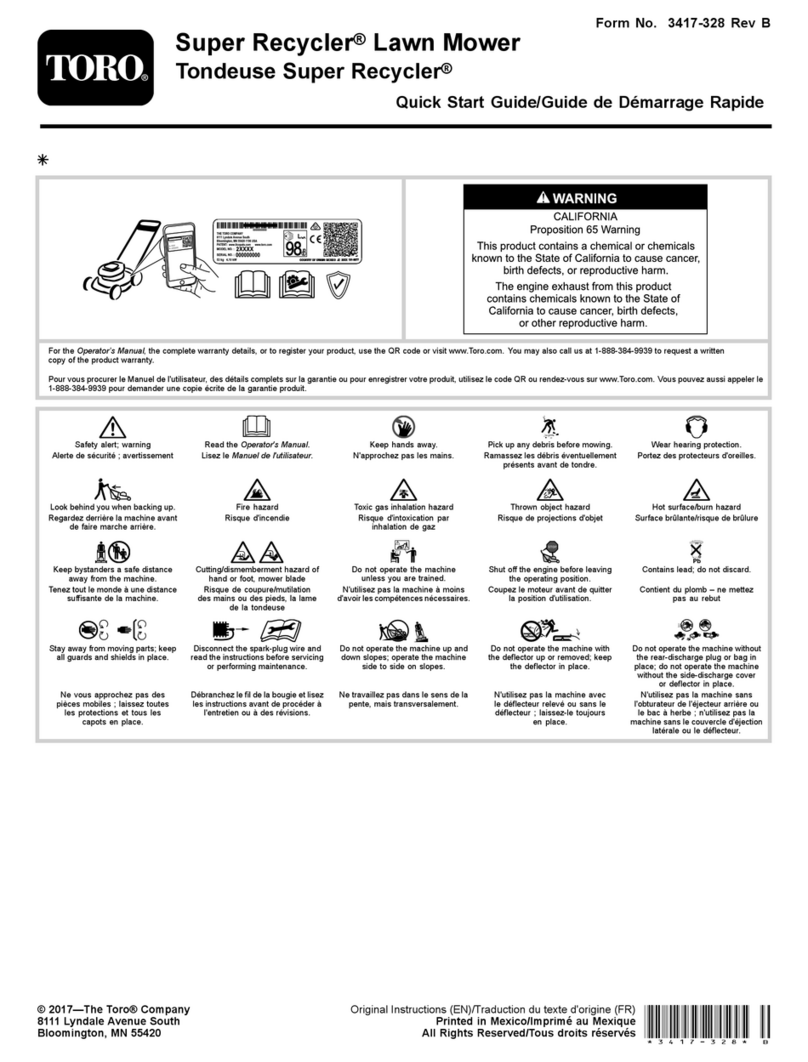

SafetyandInstructionalDecals..........................4

Setup........................................................................7

1PreparingtheTractionUnit..............................8

2InstallingtheCuttingUnittotheTraction

Unit.................................................................8

3InstallingtheHandleRetainers........................9

4InstallingtheTransportWheels........................9

5CheckingtheEngine-OilLevel.......................10

6InstallingtheProduction-YearDecal...............10

7InstallingtheGrassBasket..............................11

8BreakingintheMachine..................................11

ProductOverview...................................................12

Controls...........................................................12

Specications..................................................16

Attachments/Accessories.................................16

BeforeOperation.................................................17

BeforeOperationSafety...................................17

PerformingDailyMaintenance..........................17

CheckingtheEngine-OilLevel..........................17

FuelSpecications...........................................17

FillingtheFuelTank..........................................18

SettingtheMachinetoMatchTurf

Conditions.....................................................19

AdjustingtheHandleHeight.............................20

AdjustingtheHandleAngle...............................20

AdjustingtheThrottleControl...........................20

CheckingtheOperationoftheInterlock

Switches......................................................21

TransportingtheMachinetoaJob

Site................................................................22

DuringOperation.................................................22

DuringOperationSafety...................................22

StartingtheEngine...........................................23

ShuttingOfftheEngine.....................................23

ReleasingtheTransmission..............................24

OperatingTips..................................................24

AfterOperation....................................................25

AfterOperationSafety......................................25

TransportingtheMachine.................................25

Maintenance...........................................................26

RecommendedMaintenanceSchedule(s)...........26

DailyMaintenanceChecklist.............................27

Pre-MaintenanceProcedures..............................28

Pre-MaintenanceSafety...................................28

EngineMaintenance...........................................28

EngineSafety...................................................28

ServicingtheEngineOil....................................28

ServicingtheAirCleaner..................................29

ServicingtheSparkPlug...................................30

FuelSystemMaintenance...................................31

CleaningtheFuel-TankScreen.........................31

ReplacingtheFuelLine....................................31

ReplacingtheBreatherHose............................31

ElectricalSystemMaintenance...........................31

ServicingtheTraction-InterlockSwitch

......................................................................31

ServicingtheBrake-InterlockSwitch.................32

BrakeMaintenance.............................................32

AdjustingtheService/ParkingBrake.................32

BeltMaintenance................................................33

InspectingtheReel-DriveBelt...........................33

VisuallyInspectingtheReelClutch...................33

Engaging/Disengagingthe

Transmission-BeltT ensioner.........................34

ControlsSystemMaintenance.............................34

AdjustingtheTractionControl...........................34

AdjustingtheReelControl................................35

Storage...................................................................36

StorageSafety..................................................36

StoringtheMachine..........................................36

3