Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

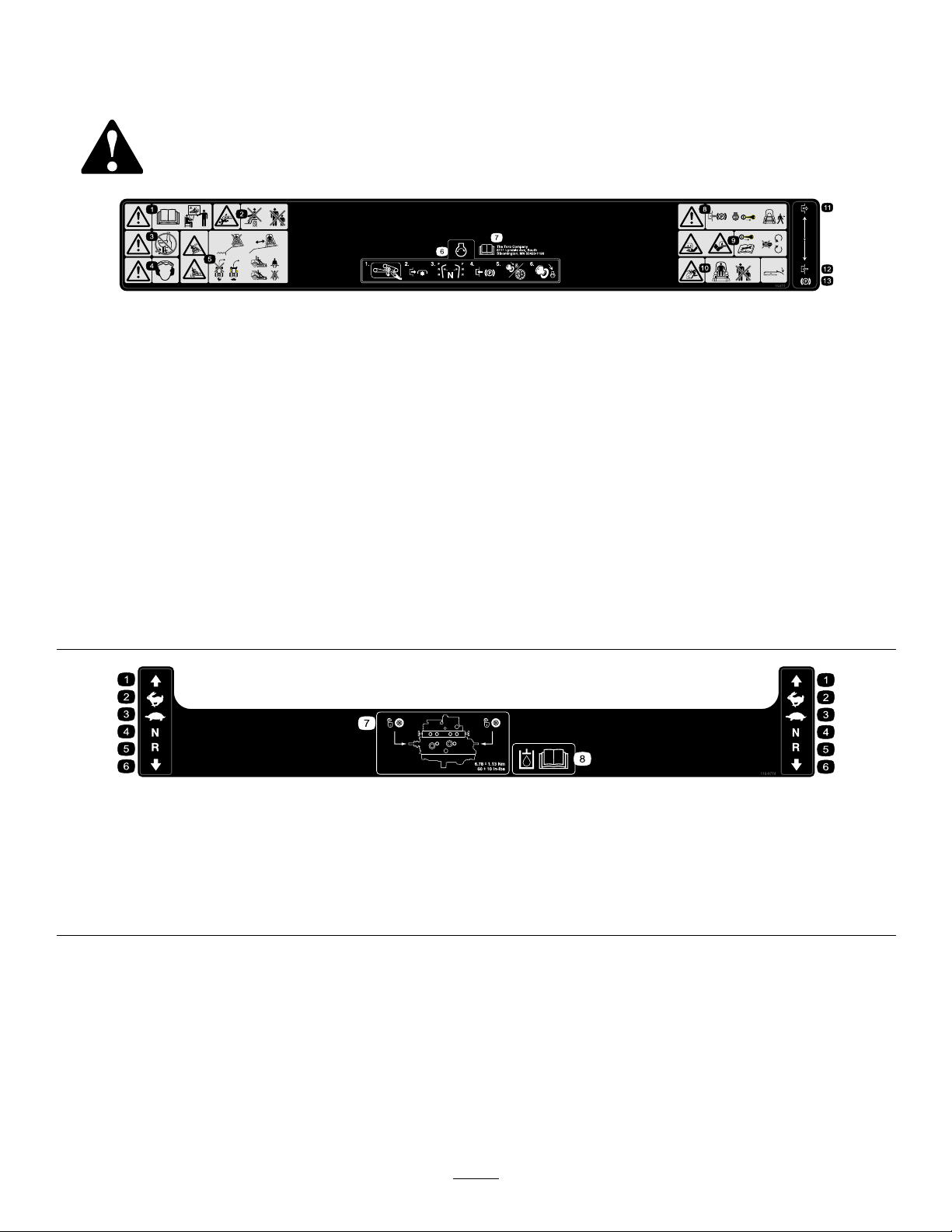

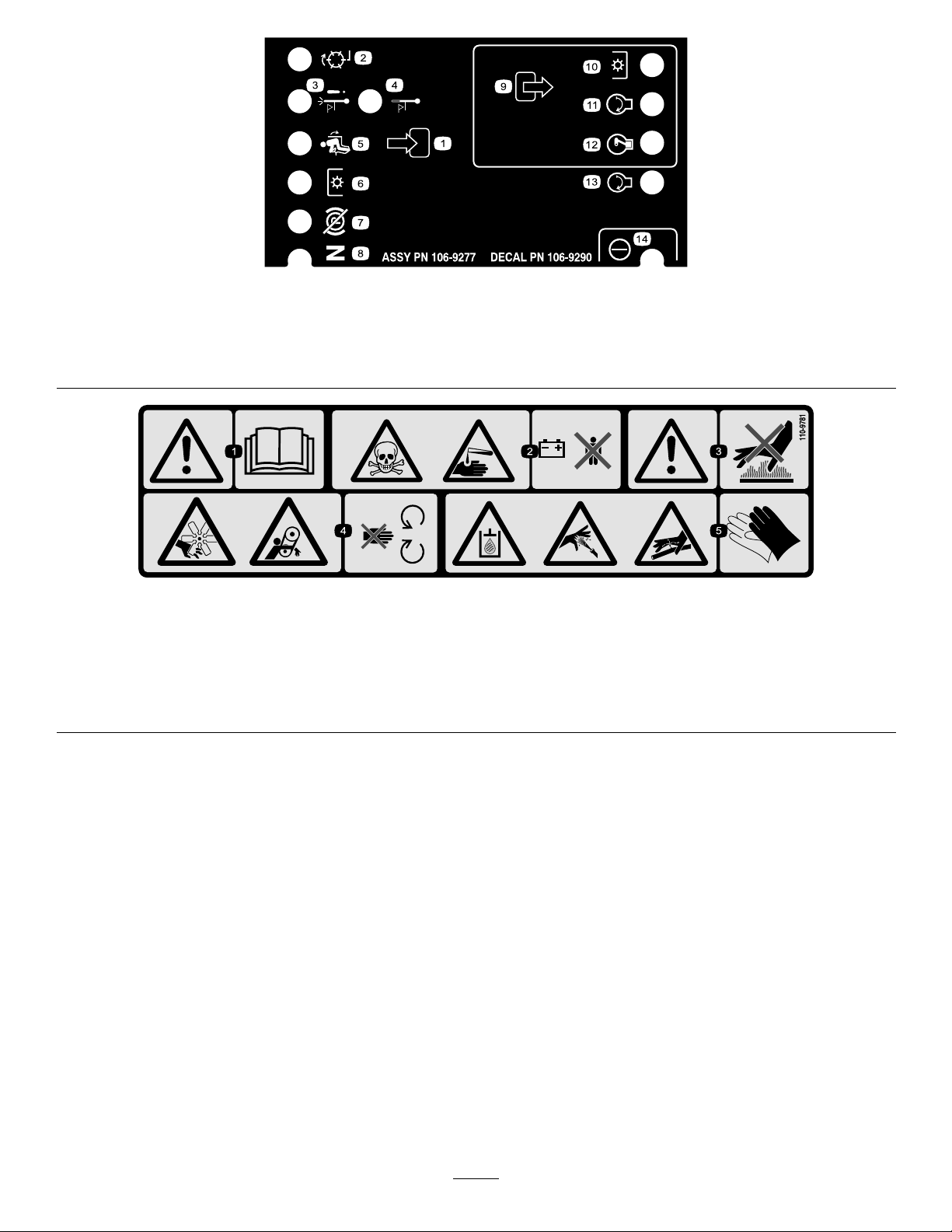

SafetyandInstructionalDecals.............................6

Setup............................................................................9

1CheckingFluidLevels........................................9

2ActivatingandChargingtheBattery....................9

3InstallingtheMowerDeck/Polar

Trac................................................................11

ProductOverview......................................................19

Controls.............................................................19

Operation...................................................................21

AddingFuel.......................................................21

CheckingtheEngineOilLevel............................22

CheckingtheCoolingSystem..............................22

CheckingtheHydraulicSystem...........................22

ThinkSafetyFirst...............................................22

OperatingtheParkingBrake...............................23

StartingtheEngine.............................................23

DrivingtheMachine...........................................24

StoppingtheMachine/Engine............................25

TheSafetyInterlockSystem................................25

PositioningtheSeat............................................26

UnlatchingtheSeat.............................................27

MovingaNon-functioningMachine...................27

LoadingMachines..............................................28

TransportingtheMachine...................................28

OperatingFrontAttachmentswiththePolar

TracKitInstalled............................................29

Maintenance...............................................................31

RecommendedMaintenanceSchedule(s)................31

DailyMaintenanceChecklist...............................32

PremaintenanceProcedures....................................33

Lubrication.............................................................33

GreasingtheBearingsandBushings....................33

EngineMaintenance...............................................34

AirCleanerMaintenance....................................34

ServicingtheEngineOil.....................................34

FuelSystemMaintenance.......................................36

ServicingtheWaterSeparator.............................36

CleaningtheFuelTank.......................................36

FuelLinesandConnections................................36

BleedingtheFuelSystem....................................36

BleedingAirFromtheInjectors..........................37

ElectricalSystemMaintenance................................38

ServicingtheBattery...........................................38

StoringtheBattery..............................................38

CheckingtheFuses.............................................39

CoolingSystemMaintenance..................................39

CheckingtheCoolingSystem.............................39

CleaningtheRadiator.........................................40

BrakeMaintenance.................................................41

AdjustingtheParkingBrakeInterlock

Switch............................................................41

BeltMaintenance....................................................42

CheckingtheAlternatorBeltTension..................42

ControlsSystemMaintenance.................................42

AdjustingtheControlLeverNeutralInterlock

Switch............................................................42

AdjustingtheControlLeverNeutral

Return............................................................43

AdjustingtheTractionDriveforNeutral.............44

AdjustingtheMaximumGroundSpeed..............45

AdjustingtheTracking........................................45

HydraulicSystemMaintenance...............................46

CheckingtheHydraulicFluidLevel.....................46

ChangingtheHydraulicOilAndFilter................47

Storage.......................................................................48

Machine.............................................................48

Engine...............................................................48

Schematics.................................................................49

ConditionsandProductsCovered.......................52

InstructionsforObtainingWarranty

Service...........................................................52

OwnerResponsibilities.......................................52

ItemsandConditionsNotCovered.....................52

Parts...................................................................52

NoteRegardingDeepCycleBattery

Warranty:.......................................................52

MaintenanceisatOwner’sExpense.....................52

GeneralConditions............................................52

Noteregardingenginewarranty:.........................52

CountriesOtherthantheUnitedStatesor

Canada...........................................................52

3