Contents

Safety.......................................................................4

GeneralSafety...................................................4

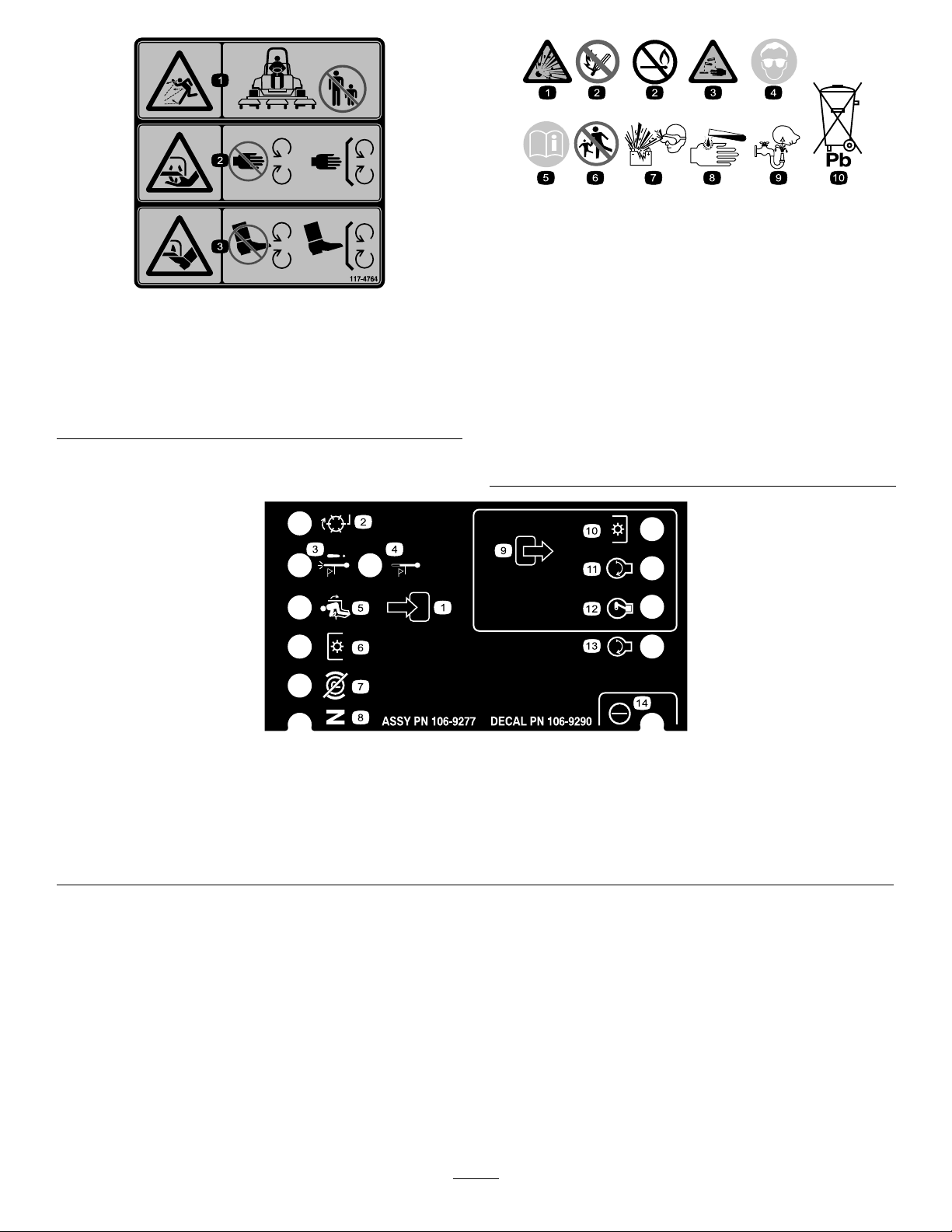

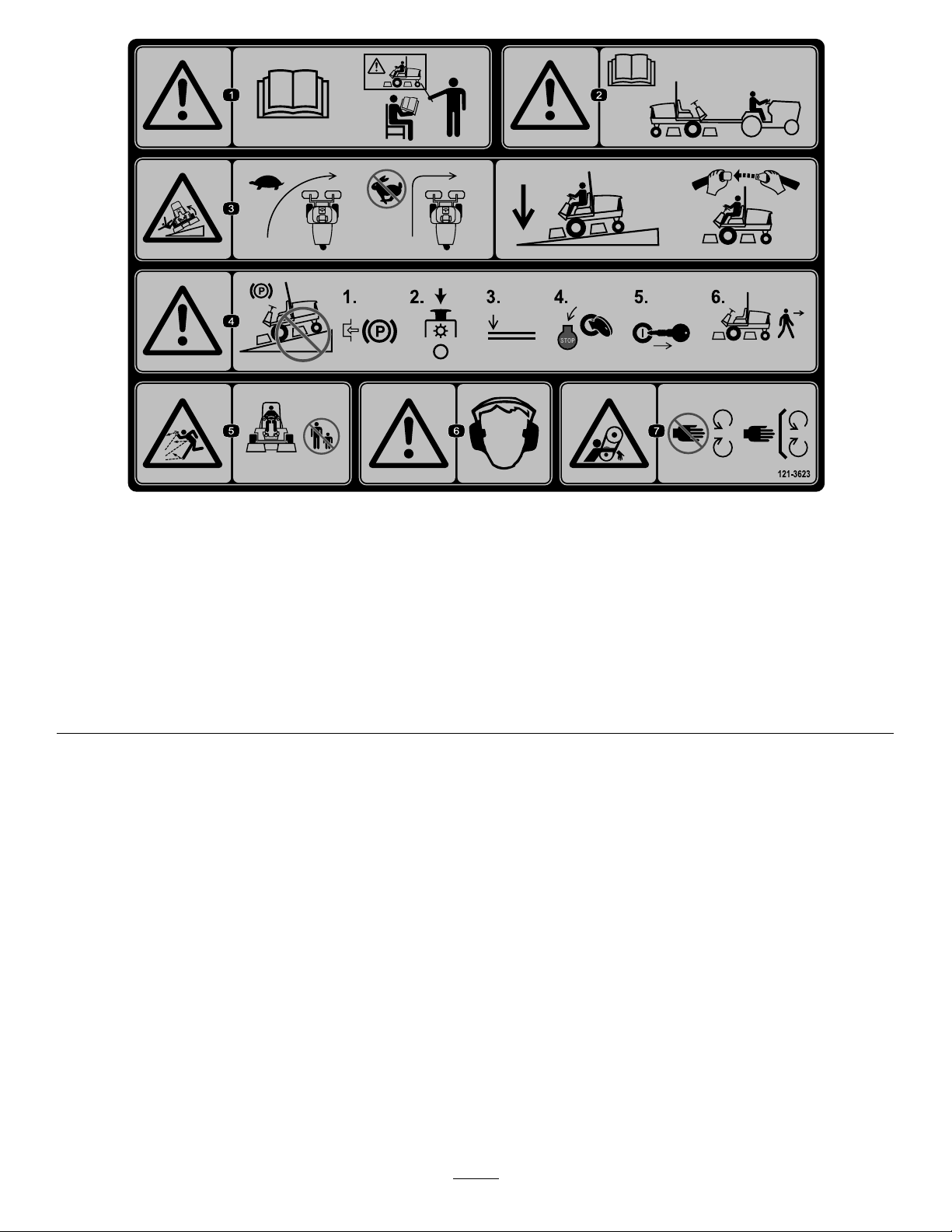

SafetyandInstructionalDecals..........................5

Setup......................................................................10

1Activating,Charging,andConnectingthe

Battery...........................................................11

2InstallingtheCEDecal...................................12

3InstallingtheHoodLatch................................12

4InstallingtheExhaustGuard..........................14

5AdjustingtheLiftArms...................................15

6AdjustingtheCarrierFrame...........................16

7AdjustingtheHeightofCut.............................17

8AdjustingtheRollerScraper...........................18

9InstallingtheMulchingBafe..........................18

ProductOverview...................................................19

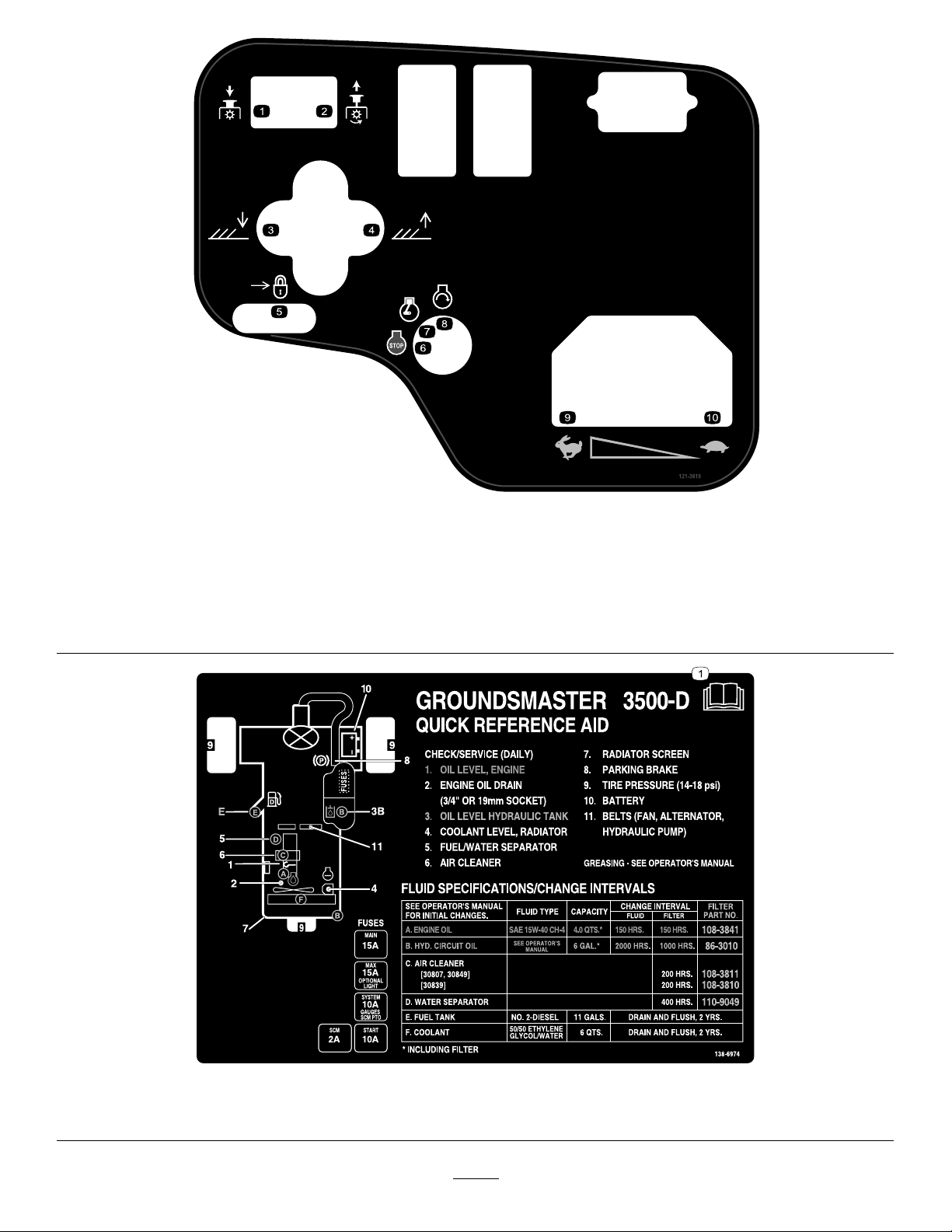

Controls...........................................................19

Specications..................................................22

Attachments/Accessories.................................23

BeforeOperation.................................................23

BeforeOperationSafety...................................23

AddingFuel......................................................24

CheckingtheEngine-OilLevel..........................25

CheckingtheCoolingSystem...........................25

CheckingtheHydraulicSystem........................25

SelectingaBlade..............................................25

ChoosingAccessories......................................26

CheckingtheSafety-InterlockSystem..............26

DuringOperation.................................................27

DuringOperationSafety...................................27

StartingtheEngine...........................................28

ShuttingOfftheEngine.....................................28

Standard-ControlModule(SCM)......................29

OperatingTips.................................................31

AfterOperation....................................................32

GeneralSafety.................................................32

HaulingtheMachine.........................................32

LocatingtheTie-DownPoints...........................33

PushingorTowingtheMachine........................33

Maintenance...........................................................34

MaintenanceSafety..........................................34

RecommendedMaintenanceSchedule(s)...........34

DailyMaintenanceChecklist.............................36

Pre-MaintenanceProcedures..............................37

PreparingtheMachineforMaintenance............37

RemovingtheHood..........................................37

UsingtheCuttingUnitServiceLatch

......................................................................37

Lubrication..........................................................38

GreasingtheBearingsandBushings................38

EngineMaintenance...........................................40

EngineSafety...................................................40

ServicingtheAirCleaner..................................40

ServicingtheEngineOil....................................42

FuelSystemMaintenance...................................43

DrainingtheFuelT ank......................................43

ServicingtheWaterSeparator..........................43

BleedingtheFuelSystem.................................44

BleedingAirfromtheInjectors..........................44

ElectricalSystemMaintenance...........................45

ElectricalSystemSafety...................................45

ServicingtheBattery.........................................45

ServicingtheFuses..........................................45

DriveSystemMaintenance..................................46

CheckingtheTirePressure...............................46

CheckingtheTorqueoftheWheel-Lug

Nuts..............................................................46

AdjustingtheTractionDriveforNeutral.............46

CoolingSystemMaintenance..............................47

CoolingSystemSafety.....................................47

CheckingtheCoolingSystem...........................47

CleaningtheCoolingSystem............................48

BrakeMaintenance.............................................49

AdjustingtheParkingBrake..............................49

BeltMaintenance................................................49

ServicingtheEngineBelts................................49

ControlsSystemMaintenance.............................50

AdjustingtheThrottle........................................50

HydraulicSystemMaintenance...........................51

HydraulicSystemSafety...................................51

ServicingtheHydraulicFluid............................51

CuttingUnitMaintenance.....................................54

SeparatingtheCuttingUnitsfromthe

TractionUnit..................................................54

MountingtheCuttingUnitstotheTraction

Unit...............................................................55

ServicingtheBladePlane.................................55

ServicingtheFrontRoller.................................56

BladeMaintenance..............................................57

BladeSafety.....................................................57

ServicingtheBlade...........................................57

Storage...................................................................59

StorageSafety..................................................59

PreparingtheMachineforStorage...................59

StoringtheCuttingUnits...................................59

3