•Before operating a machine with roll over

protection be certain the seat belts are attached

and seat is latched to prevent the seat from

pivoting forward.

•Use only Toro-approved attachments. Warranty

may be voided if used with unapproved

attachments.

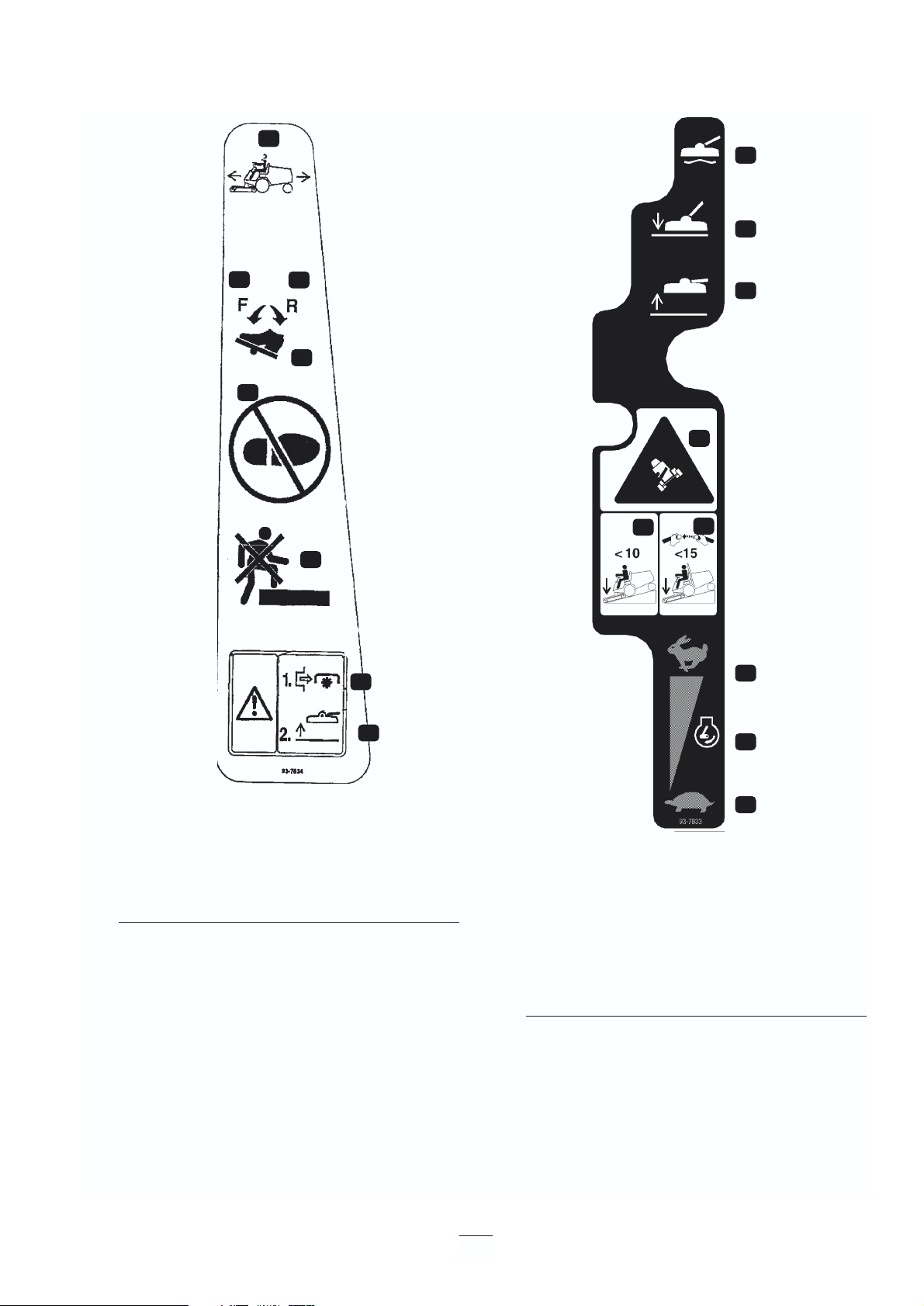

Slope Operation

Slopes and ramps are a major factor related to loss-of-

control and tip-over accidents, which can result in

severe injury or death. All slopes and ramps require

extra caution. If you cannot back up the slope or if

you feel uneasy on it, do not mow it.

DO

•If you must ascend a steep slope, back up the hill,

and drive forward down the hill, keeping the

machine in gear.

•Remove obstacles such as rocks, tree limbs, etc.

from the mowing area. Watch for holes, ruts or

bumps, as uneven terrain could overturn the

machine. Tall grass can hide obstacles.

•Use slow speed so that you will not have to stop

while on the slope.

•Follow the manufacturer’s recommendations for

wheel weights or counterweights to improve

stability.

•Use extra care with other attachments. These can

change the stability of the machine.

•Keep all movement on slopes slow and gradual.

Do not make sudden changes in speed or

direction.

•Avoid starting or stopping on a slope. If the tires

lose traction, disengage the blades and proceed

slowly straight down the slope. Avoid raising the

side decks on a slope.

•When operating the machine on slopes, banks or

near drop offs, always have roll-over protection

installed.

•When operating a machine with roll-over

protection always use seat belt.

•Be certain that the seat belt can be released

quickly if the machine is driven or rolls into

ponds or water.

•Check carefully for overhead clearances (i.e.,

branches, doorways, electrical wires) before

driving under any objects and do not contact

them.

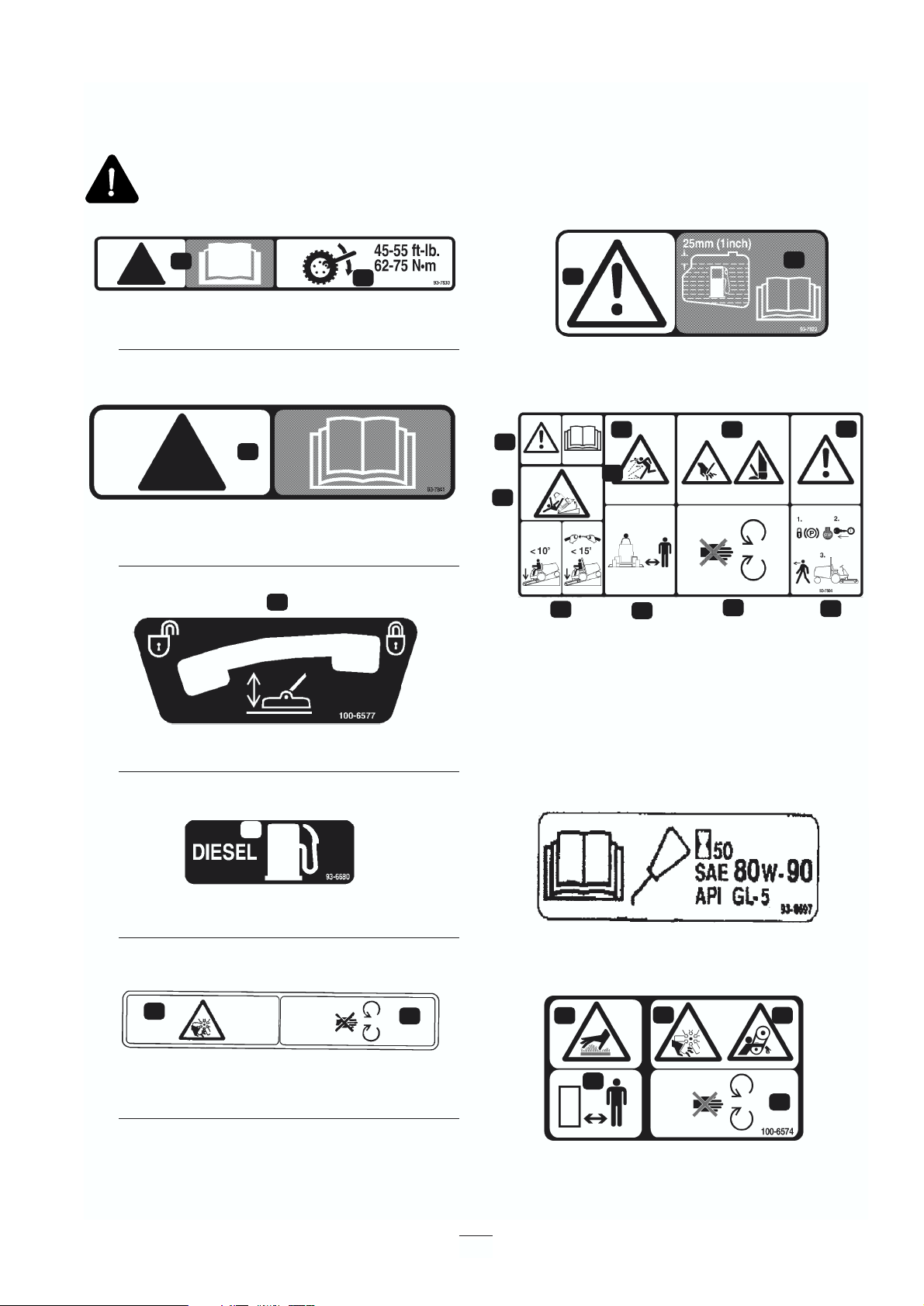

DO NOT

•Do not mow slopes exceeding 15 degrees.

•Avoid turning on slopes. If you must turn, turn

slowly and gradually downhill, if possible.

•Do not mow near drop-offs, ditches, or

embankments. The machine could suddenly turn

over if a wheel goes over the edge of a cliff or

ditch, or if an edge caves in.

•Do not mow on wet grass. Reduced traction

could cause sliding.

•Do not try to stabilize the machine by putting

your foot on the ground.

Service

•Never store the machine or fuel container inside

where there is an open flame, such as near a

water heater or furnace.

•Keep nuts and bolts tight, especially the blade

attachment bolts. Keep equipment in good

condition.

•Never tamper with safety devices. Check safety

systems for proper operation before each use.

•Use only genuine replacement parts to ensure

that original standards are maintained.

•Check brake operation frequently. Adjust and

6