Torrot KIDS10/12 Operating instructions

REPAIR MANUAL FOR THE ELECTRICAL SYSTEM / ELECTRONIC

MOTORCYCLES TORROT KIDS10/12

(Rev.1.0)

2 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

3 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

INDEX

Connection scheme V1.0 (P.4)

Connection scheme V1.1 (P.5)

System elements V1.0 (P.6)

System elements V1.1 (P.8)

Troubleshooting V1.0 (P.10)

Troubleshooting V1.1 (P.12)

Battery check (P.14)

Correct use of the battery (P.15)

Installation modifications (P.17)

Sequence of motor sensors (P.19)

4 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

CONNECTION SCHEME (V1.0)

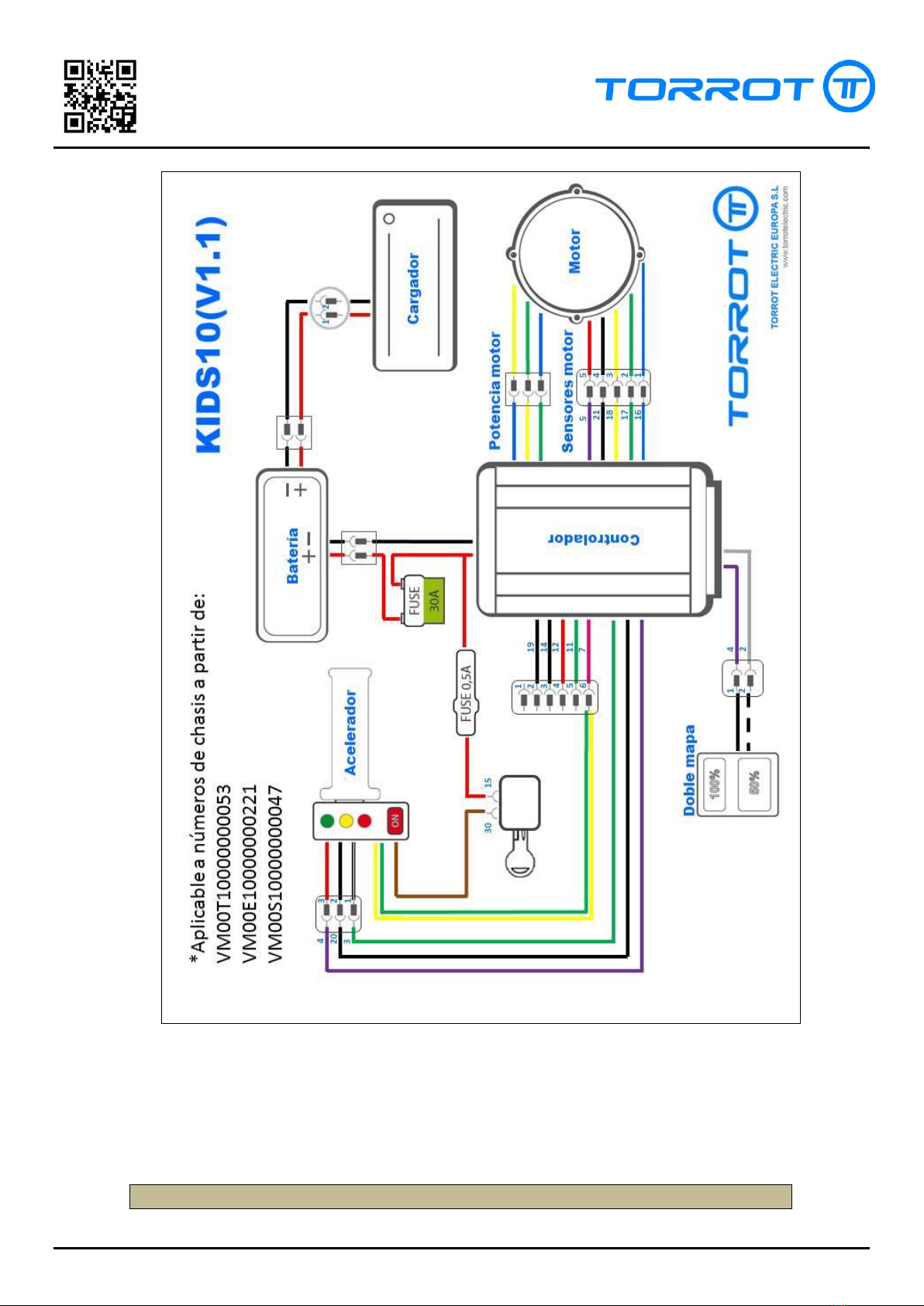

CONNECTION SCHEME (V1.1)

5 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

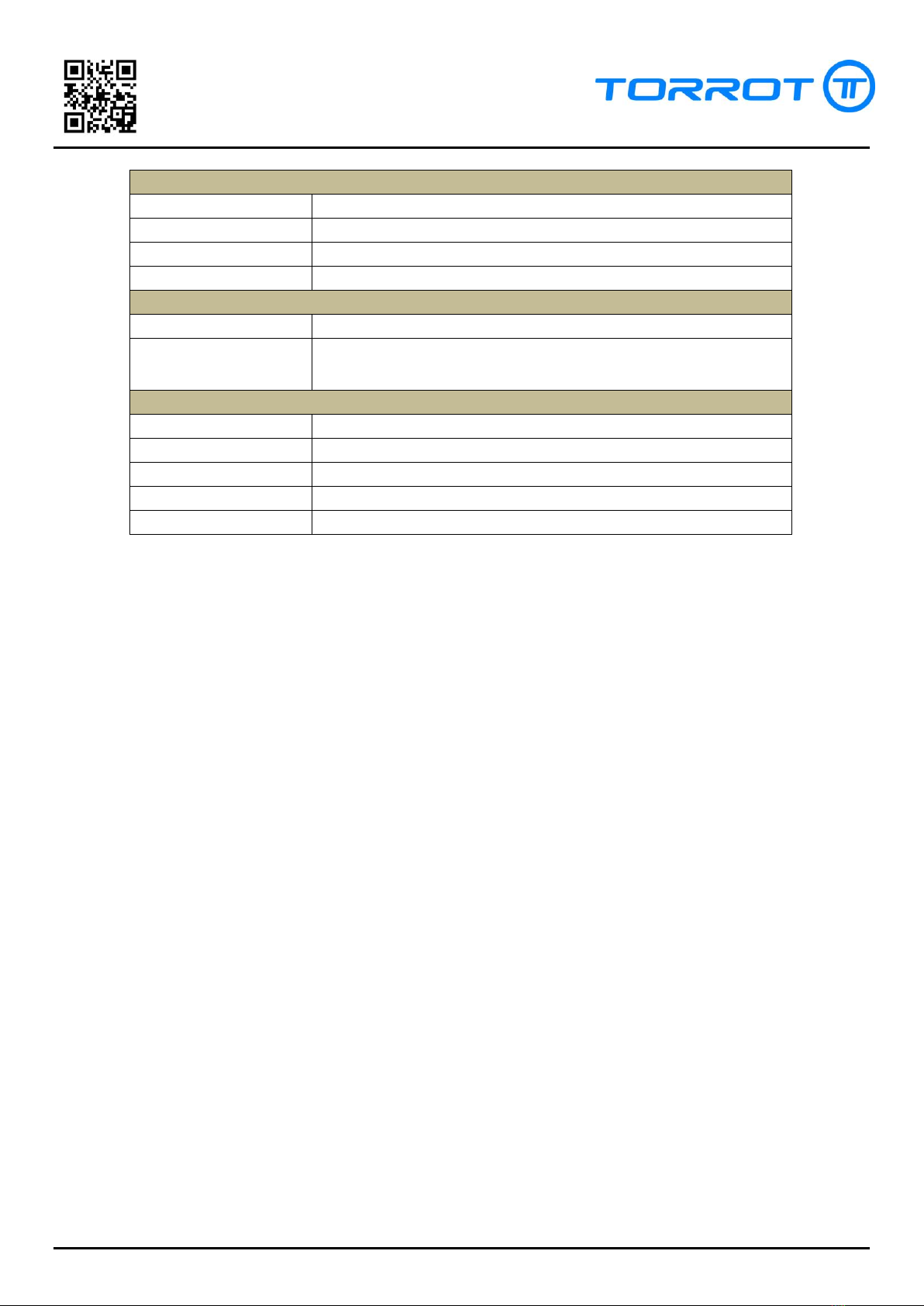

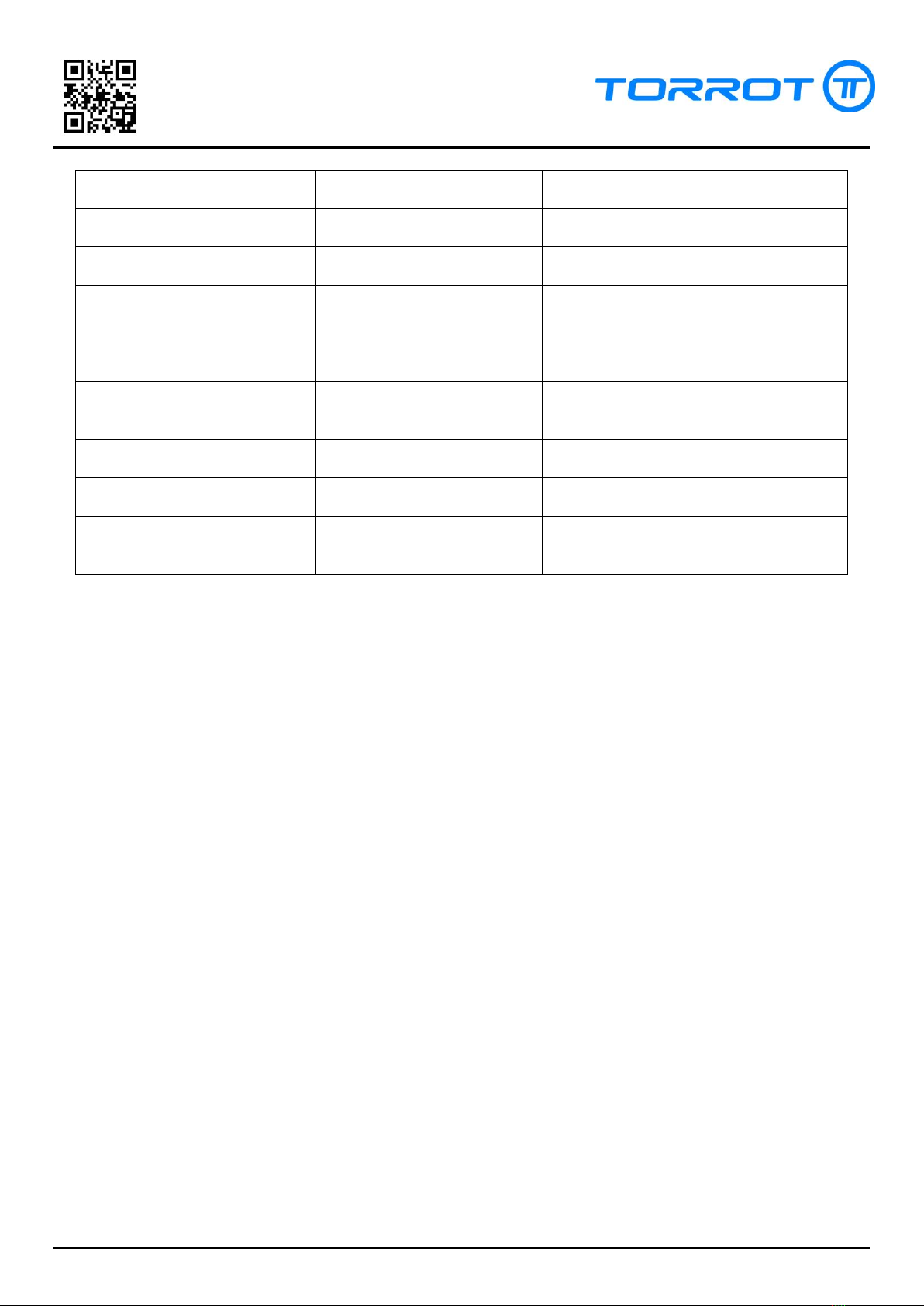

RESUMEN DE ELEMENTOS (V1.0)

1: BATTERY

6 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

Cables:

Red 1 and 2: Output, 48V

Cables:

Black 1: Common discharge

Cables:

Black 2: Common charge

2: CONTROLLER

Power

Cables:

Red: Input , direct battery voltage

Black: Common

Double map

Cables:

Yellow (4): Output, 4.3V

White (2): Common

Hall connector

Cables:

Yellow (4): Output, 4.5V

Black (21): Common

Yellow (18): Input Hall C, 4.5V

Green (17): Input Hall B, 4.5

Blue (16): Input Hall A, 4.5V

Motor phases

Cables:

Yellow: Output, Phase C

Green: Output, Phase B

Blue: Output, Phase A

Throttle

Cables:

Yellow (4): Output, 5V

Black (20): Common

Grey (3): Input, 0.8-4.2V

Connector E/S

Cables:

Black (19): Not connected

Black, Blue (14): Not connected

White (12): Not connected

Grey (11): Not connected

Pink (7): Input Start, Direct battery voltage

Start Line

Cables:

Red: Direct battery voltage

3: FUSES

Main fuse

Calibre

30A

Starting fuse

Calibre

0.5A

4: MOTOR

Hall connector

Cables:

Red: Input, 4.5V

Black: Common

Yellow (Output Hall C, 4.5V)

Green (Output Hall B, 4.5V)

Blue (Output Hall A, 4.5V)

7 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

Motor phases

Cables:

Yellow (Input, Phase A)

Green (Input, Phase B)

Blue (Input, Phase C)

Winding resistance:

0,2-0,3 Ohms between terminals

5: DOUBLE MAP SELECTOR

Cables:

Black: Input, 4.5V

White / Black: Common

6: THROTTLE

Cables:

Red: Input, 5V

Black: Common

White: Output, 0.8-4.2V

Green: Output Start, direct battery voltage.

Yellow: Input Start, direct battery voltage.

8 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

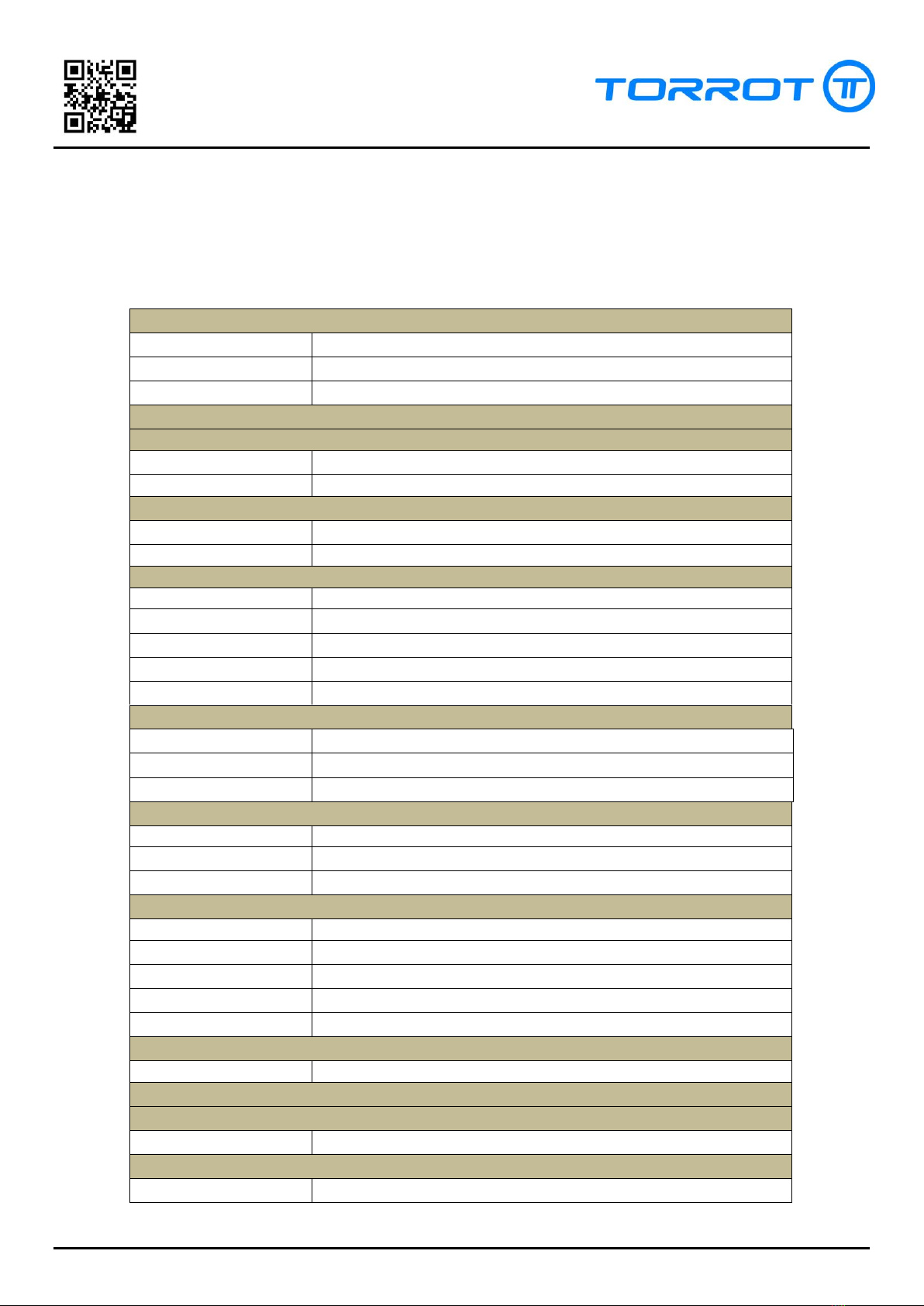

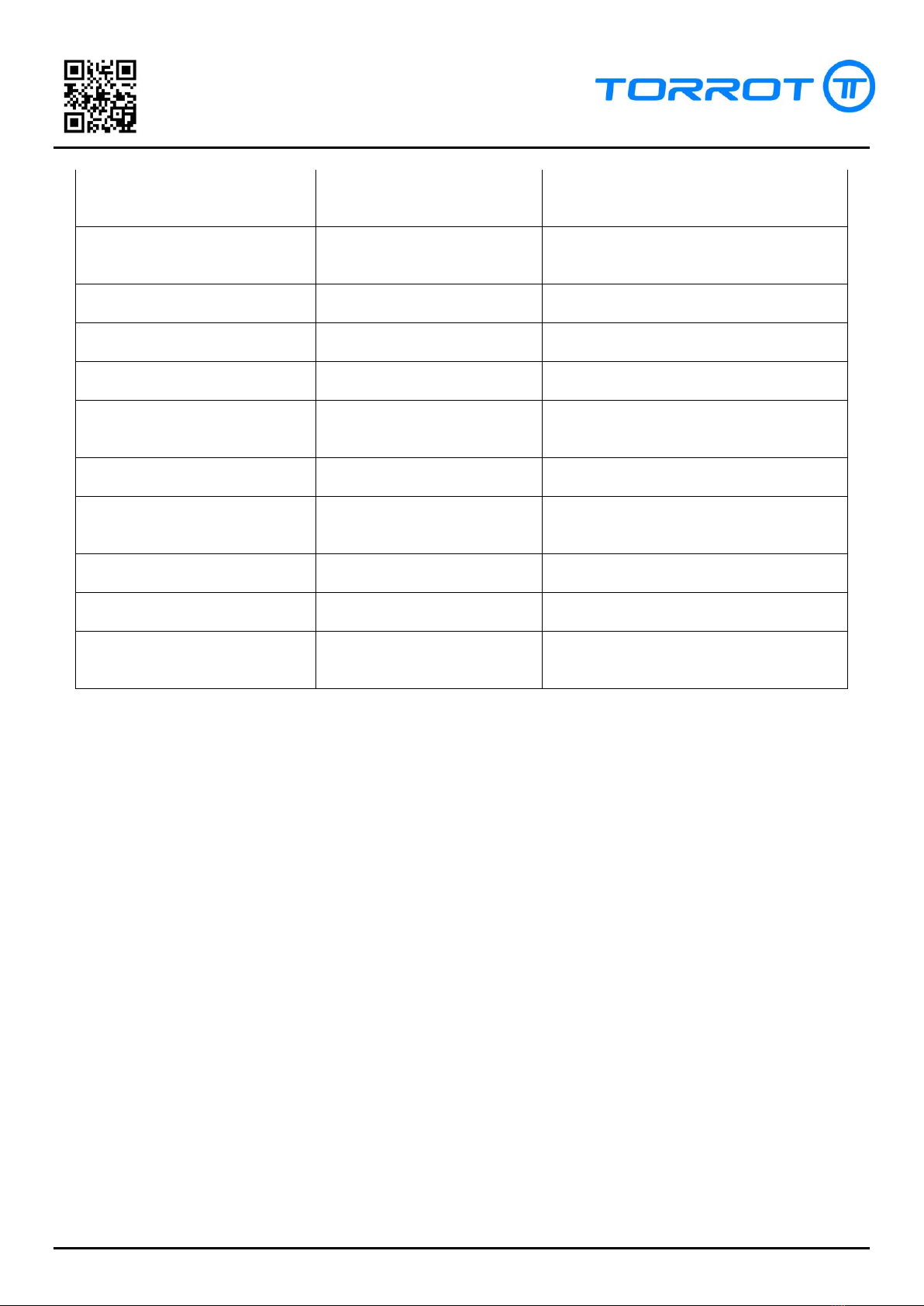

RESUMEN DE ELEMENTOS (V1.1)

1: BATTERY

Cables:

Red 1 and 2: Output, 48V

Cables:

Black 1: Common discharge

Cables:

Black 2: Common charge

2: CONTROLLER

Power

Cables:

Red: Input, direct battery voltage

Black: Common

Double map

Cables:

Violet (4): Output, 4.3V

Grey: Common

Hall connector

Cables:

Violet (4): Output, 4.5V

Black (21): Common

Yellow (18): Input Hall A, 4.5V

Green (17): Input Hall B, 4.5

Blue (16): Input Hall C, 4.5V

Motor phases

Cables:

Yellow: Output, Phase A

Green: Output, Phase B

Blue: Output, Phase C

Throttle

Cables:

Violet (4): Output, 5V

Black (20): Common

Green (3): Input, 0.8-4.2V

Connector E/S

Cables:

Black (19): Not connected

Black (14): Not connected

Red (12): Not connected

Green (11): Not connected

Pink (7): Input Start, direct battery voltage

Start Line

Cables:

Red: Direct battery voltage

3: FUSES

Main fuse

Calibre

30A

Starting fuse

Calibre

0.5A

9 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

4: MOTOR

Hall connector

Cables:

Red: Input, 4.5V

Negro: Common

Amarillo (Output Hall A, 4.5V)

Green (Output Hall B, 4.5V)

Blue ( Output Hall C , 4.5V)

Phases motor

Cables:

Yellow (Input, Phase A)

Green (Input, Phase B)

Blue (Input, Phase C)

Winding resistance:

0,2-0,3 Ohms between terminals

5: DOUBLE MAP SELECTOR

Cables:

Black: Input, 4.5V

White / Black: Common

6: THROTTLE

Cables:

Red: Input, 5V

Black: Common

White: Output, 0.8-4.2V

Yellow + Green: Output Start + input indicator, direct battery

voltage.

Brown: Input Start, direct battery voltage.

7: KEY SWITCH

Cables:

Contact 15: Input, direct battery voltage

Contact 30: Output, direct battery voltage

10 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

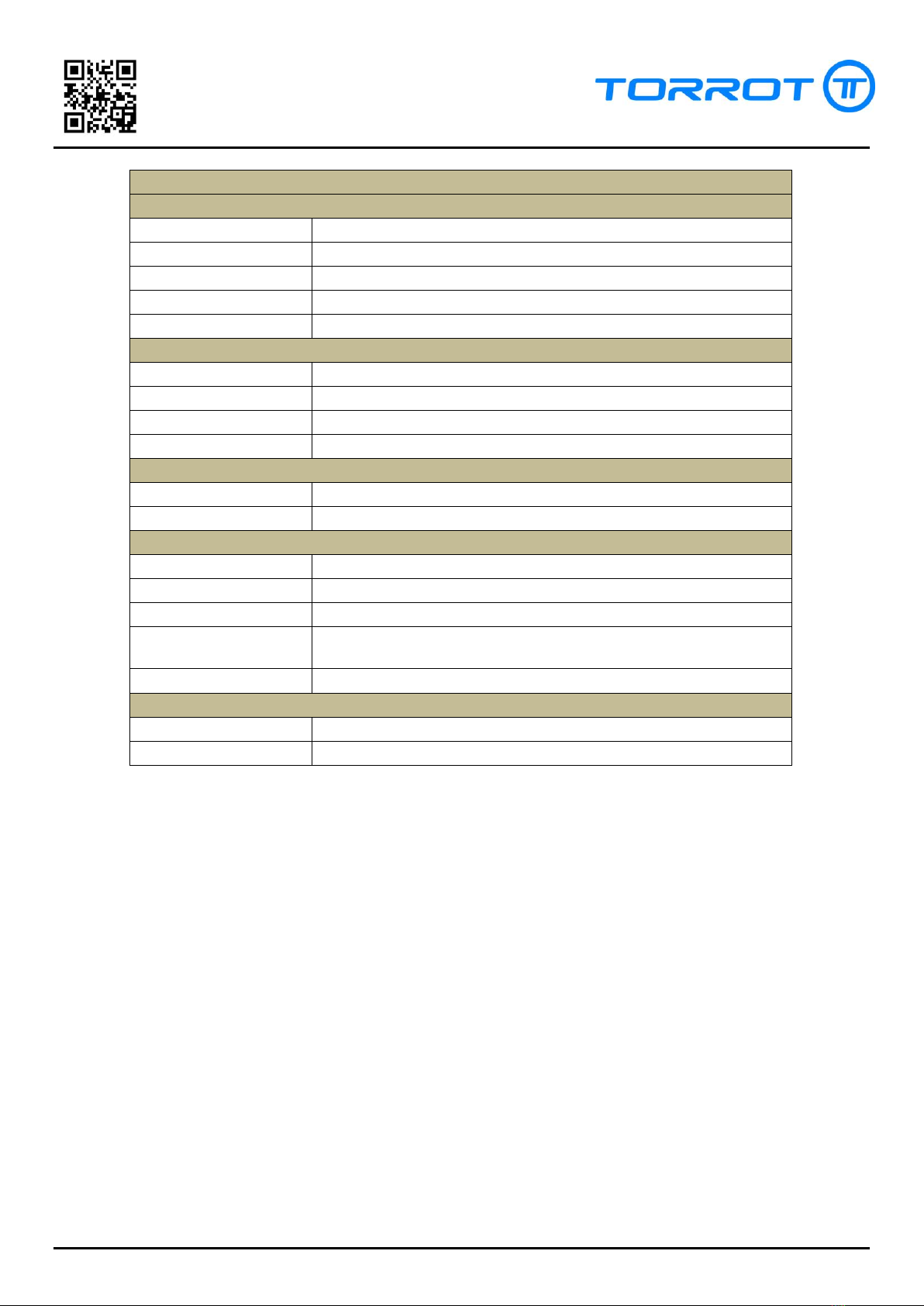

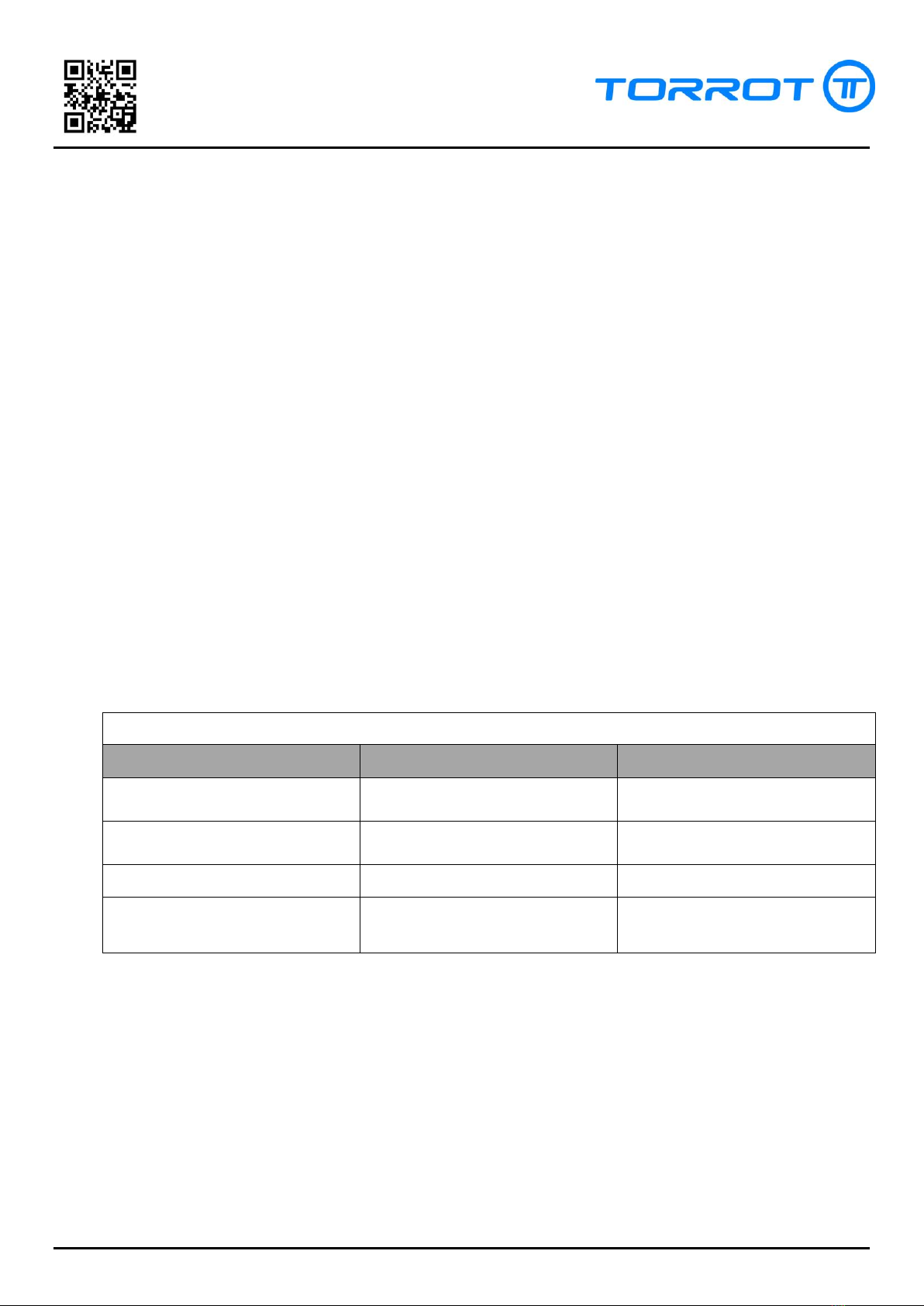

TROUBLESHOOTING (V1.0)

The following table helps you to detect and solve common problems. Before using it and as

a step prior to the solution of problems, make sure that the battery is fully charged and that you

have entered a set of parameters known in the controller, in this order. If you cannot charge the

battery or enter the parameters in the controller, please read first the corresponding possible

causes in the table.

PROBLEM

POSSIBLE CAUSES

ERROR DETECTION/ SOLUTION

Pressing the ON button the motor

does not respond

Low battery

Check voltage in the discharge terminals of

the battery. Charge the battery.

Main fuse damaged

Check the 30A power fuse. Check for possible

short circuits in the wiring / controller.

Replace the fuse when it is safe.

Starting fuse damaged

Check the 0.5A starting fuse. Check for

possible short circuits in the wiring /

controller. Replace the fuse when it is safe.

The Start signal does not reach

the E/S connector

Check the wiring of the whole circuit and that

the battery voltage reaches cable 7 (pink) of

the E/S connector. Replace defective points of

the installation.

There is tension in the Start line but

the motor does not respond

The controller does not transmit

voltage to the throttle

Disconnect the throttle and check that there is

supply voltage in the supply line of the

throttle. Replace the controller if necessary.

The throttle is defective

Once checked that there is supply voltage

check the analogue signal of the throttle.

Replace the throttle if necessary.

When the motor is activated, it

emits an unusual sound or vibrates

excessively

Connection error in the Hall

sensors

Check the connection of the Hall sensors.

Check the continuity on both sides of the

connector. Replace the connector if necessary.

Disconnection of any of the

motor phases or error in the

order of the connections.

Check the connectors of the motor phases.

The controller does not supply

voltage to the sensors correctly.

Disconnect the controller and check the

power supply of the Hall sensors. Connect and

check again. Check that the sensors are

correctly supplied with voltage. According to

the results replace controller and/or motor.

One or more sensors do not

generate position signals.

With the motor in start position, turn the

motor manually. Check if the signals of the

Hall sensors vary by turning the motor.

Replace the motor if necessary.

One or more of the phases have

deteriorated.

Check that the resistance of the windings is

the correct one and that there are no

derivations to the chassis.

Excessive resistance to the

rotation of the motor.

Check manually if the wheel can turn easily.

Solve possible problems in the chassis /

braking system.

11 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

Dual map button does not work

Connection error in the switch.

Check connections of the dual map switch.

Replace defective parts.

Dual map switch defective

Check the continuity in the switch. Replace if

necessary.

Programming error.

Programme a parameter set in the controller.

Restart the controller and check the function.

The controller does not supply

voltage to the dual map switch

Disconnect the switch. Check that there is the

necessary voltage in the supply line of the

switch.

When the charger is connected the

indicator light stays green.

Battery is fully charged

Check the battery voltage. If fully charged it

will not accept any more charging.

Wiring error

Check that there is battery voltage in the

circular chassis connector and in the battery

charging connector. Replace defective parts.

The battery is defective

Follow the instructions of the battery check.

Replace battery if necessary.

It is not possible to programme the

controller.

The controller is not supplied with

power and in position Start.

Check all steps of the initial section. Keep the

motor activated in order to programme.

Wrong connection cable

Check that the connection cable is in good

condition and correctly connected and

installed on your PC.

12 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

TROUBLESHOOTING (V1.1)

The following table helps you to detect and solve common problems. Before using it and as

a step prior to the solution of problems, make sure that the battery is fully charged and that you

have entered a set of parameters known in the controller, in this order. If you cannot charge the

battery or enter the parameters in the controller, please read first the corresponding possible

causes in the table.

PROBLEM

POSSIBLE CAUSES

ERROR DETECTION/ SOLUTION

Pressing the ON button the

indicator does not light up and the

motor does not respond

Low battery

Check voltage in the discharge terminals of

the battery. Charge the battery.

Main fuse damaged

Check the 30A power fuse. Check for possible

short circuits in the wiring / controller.

Replace the fuse when it is safe.

Starting fuse damaged

Check the 0.5A starting fuse. Check for

possible short circuits in the wiring /

controller. Replace the fuse when it is safe.

The key switch does not start

Check that the key switch is in the ON

position. Turn the key to the correct position.

The key switch does not work

Check that there is battery voltage in the

terminal before turning the key and that the

terminals 15 and 30 connect when starting the

switch. Replace the switch if necessary.

The Start signal does not reach

the E/S connector

Check the wiring of the whole circuit and that

the battery voltage reaches cable 7 (pink) of

the E/S connector. Replace defective points of

the installation.

The indicator responds and there is

tension in the Start line but the

motor does not respond

The controller does not transmit

voltage to the throttle

Disconnect the throttle and check that there is

supply voltage in the supply line of the

throttle. Replace the controller if necessary.

The throttle is defective

Once checked that there is supply voltage

check the analogue signal of the throttle.

Replace the throttle if necessary.

When the motor is activated, it

emits an unusual sound or vibrates

excessively

Connection error in the Hall

sensors

Check the connection of the Hall sensors.

Check the continuity on both sides of the

connector. Replace the connector if necessary.

Disconnection of any of the

motor phases or error in the

order of the connections.

Check the connectors of the motor phases.

The controller does not supply

voltage to the sensors correctly.

Disconnect the controller and check the

power supply of the Hall sensors. Connect and

check again. Check that the sensors are

correctly supplied with voltage. According to

the results replace controller and/or motor.

One or more sensors do not

generate position signals.

With the motor in start position, turn the

motor manually. Check if the signals of the

Hall sensors vary by turning the motor.

Replace the motor if necessary.

13 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

One or more of the phases have

deteriorated.

Check that the resistance of the windings is

the correct one and that there are no

derivations to the chassis.

Excessive resistance to the

rotation of the motor.

Check manually if the wheel can turn easily.

Solve possible problems in the chassis /

braking system.

Dual map button does not work

Connection error in the switch.

Check connections of the dual map switch.

Replace defective parts.

Dual map switch defective

Check the continuity in the switch. Replace if

necessary.

Programming error.

Programme a parameter set in the controller.

Restart the controller and check the function.

The controller does not supply

voltage to the dual map switch

Disconnect the switch. Check that there is the

necessary voltage in the supply line of the

switch.

When the charger is connected the

indicator light stays green.

Battery is fully charged

Check the battery voltage. If fully charged it

will not accept any more charging.

Wiring error

Check that there is battery voltage in the

circular chassis connector and in the battery

charging connector. Replace defective parts.

The battery is defective

Follow the instructions of the battery check.

Replace battery if necessary.

It is not possible to programme the

controller.

The controller is not supplied with

power and in position Start.

Check all steps of the initial section. Keep the

motor activated in order to programme.

Wrong connection cable

Check that the connection cable is in good

condition and correctly connected and

installed on your PC.

14 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

BATTERY CHECK

The lithium-ion battery of KIDS10/12 has an integrated electronic energy

management, different from lead batteries that work without electronic control. This means

that the charging and discharging battery drivers are independent from each other being

able to have supply voltage in only one of them and not in the other.

During normal functioning there must always be supply voltage in the loading port

while the tension of the discharge port is 0V at the time when the battery is fully charged

and it stays like this until the battery is charged above the minimum limit.

There are some checks that can be done in case you think that the battery might not

work correctly.

Checking the battery voltage: Although the battery's nominal voltage is 48V it should

reach 54.6V by the end of the charging process. If at the end of charging the battery

remains below this value it is an indication that there is an internal battery error. Usually this

error occurs with the fact that the LED indicator of the charger changes the colour from red

to blue instead of to green. A third check is to measure the voltage at the charging and

discharging ports. With the values obtained consult the following table:

BATTERY STATES

Voltage at charging port

Voltage at discharging port

State

36V –54.6V (equal to

discharging port)

36V –54.6V (equal to

charging port)

Ok

0V

36V –54.6V

Internal error

36V –54.6V

0V

Battery discharged

0V

0V

Internal error / overheating

15 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

CORRECT USE OF THE BATTERY

1. General

a. The motorcycle battery is composed of lithium-ion cells with high energy

density. In no case it must be manipulated. Non-compliance with this advice

involves electrical and chemical risks and can result in material damage and

serious personal injuries.

b. It is strictly prohibited that personnel not authorized explicitly by the

manufacturer carry out inspection, repair or replacement of the battery or any

of its elements.

2. Damages to the battery

a. All abusive treatment of the vehicle can affect the life of the battery. To keep it

in good condition and to extend its life the following instructions must be

followed:

i. Avoid using the motorcycle in conditions of extreme heat or cold that

exceed the limits specified by the manufacturer.

ii. Avoid charging the battery in conditions of extreme heat or cold that

exceed the limits specified by the manufacturer.

iii. In periods when the vehicle is not used it must be stored in a dry place

away from sources of cold and/or heat as well as from direct sunlight.

iv. Avoid unnecessary blows and vibrations on your motorcycle. Check

regularly that the insulation between the battery and the chassis of the

vehicle is in good condition. If it is not replace it.

v. The auto discharge is a natural characteristic of the battery and must be

controlled. For long periods of inactivity periodically connect the charger

and charge the battery completely.

vi. Avoid partial charges of the battery. For a correct daily use the battery

must always be charged until the charger completes the process

indicating it with the green light.

vii. As a general rule it is recommended to keep the battery connected to

the charger for a few minutes after the completion of charging.

viii. Do not use any charger that has not been directly supplied by the

manufacturer.

ix. Avoid forcing the vehicle in an abnormal way during its use.

16 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

x. The battery is provided with internal protections against electrical

hazards that can work automatically. Go to the section on battery check

to know how to proceed.

xi. Keep the battery clean and in good condition, carefully remove dust, dirt

and other external elements that could get into the battery

compartment during its use.

xii. In case of detecting damage in the drivers of the electrical system,

disconnect the vehicle and remove it from the power supply before

proceeding with the repair. Do not reconnect until you have made sure

that there are no unwanted derivations.

xiii. Avoid direct contact of the electrical system of the motorcycle with

water, mud or similar. If water accidentally gets into any electrical

element of the vehicle disconnect it and wait for it to dry naturally prior

to its inspection/repair.

17 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

MODIFICATIONS IN THE INSTALLATION

To make the modifications listed below check the schemes of both installations and compose the

installation as shown in the document. Pay special attention to the position of the cables in the contacts

and to their type. The diagram shows the types of contacts that are inside the connectors.

Before modifying the installation remove as many elements of the fairing as necessary to work

comfortably and remove the battery

REPLACEMENT OF CONTROLLER V1.0 FOR V1.1

Reference manufacturer kit:

01EL-000A0-ZZ

KIT CONNECTOR WP 2 PINS

01EL-000B0-ZZ

KIT CONNECTOR WP 3 PINS

01EL-000C0-ZZ

KIT CONNECTOR WP 5 PINS

01EL-000D0-ZZ

KIT CONNECTOR WP 6 PINS

01EL-000E0-ZZ

KIT ANDERSON PP30 RED

01EL-000F0-ZZ

KIT ANDERSON PP30

01EL-000G0-ZZ

KIT ANDERSON PP30

01EL-000H0-ZZ

KIT ANDERSON PP30 GREEN

REPLACEMENT OF THROTTLE CONTROL V1.0 FOR V1.1

Reference manufacturer kit:

01EL-00020-ZZ

THROTTLE ELEC. LOAD LEVEL WP.

01EL-000B0-ZZ

KIT CONNECTOR WP 3 PINS

ADDITION OF KEY SWITCH TO INSTALLATION V1.0

Reference manufacturer kit:

01EL-00110-ZZ

KEY SWITCHED ON

CHANGE OF ALL CONNECTORS V1.0 FOR V1.1 (WATERPROOF)

Reference manufacturer kit:

18 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

01EL-000E0-ZZ

KIT ANDERSON PP30 RED

01EL-000F0-ZZ

KIT ANDERSON PP30 BLACK

01EL-000G0-ZZ

KIT ANDERSON PP30 YELLOW

01EL-000H0-ZZ

KIT ANDERSON PP30 GREEN

01EL-000I0-ZZ

KIT ANDERSON PP30 BLUE

01EL-00110-ZZ

KEY SWITCHED ON REF. 6553

01EL-00210-ZZ

FUESE HOLDER RUBBER WP. 30A

01EL-000A0-ZZ

KIT CONNECTOR WP 2 PINS

01EL-000B0-ZZ

KIT CONNECTOR WP 3 PINS

01EL-000C0-ZZ

KIT CONNECTOR WP 5 PINS

01EL-000D0-ZZ

KIT CONNECTOR WP 6 PINS

INSTALLATION OF REMOVABLE BATTERY IN INSTALLATION V1.0

Reference manufacturer kit:

01EL-000E0-ZZ

KIT ANDERSON PP30 RED

01EL-000F0-ZZ

KIT ANDERSON PP30 BLACK

REPLACING OF CHARGING CONNECTOR V1.0 FOR V1.1

Reference manufacturer kit:

01EL-000A0-ZZ

KIT CONNECTOR WP 2 PINS

01PW-00041-ZZ

BATTERY CHARGING CABLE WAT.

19 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

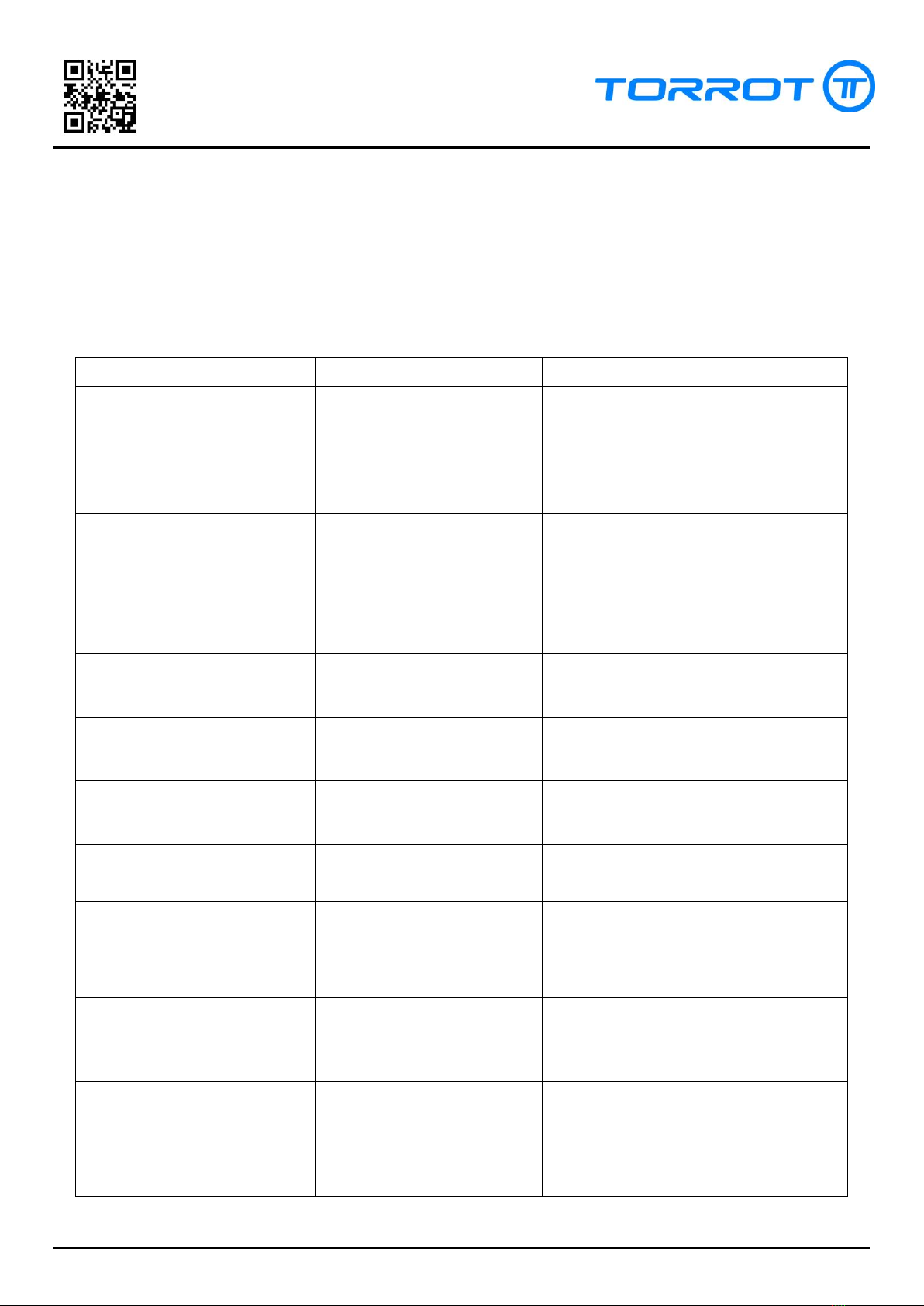

ANNEX 1: SEQUENCE OF MOTOR SENSORS

Sequence of the motor Hall sensors (1= On, 0=Off)

Hall A (Blue)

Hall B (Green)

Hall C (Yellow)

1

0

0

1

1

0

0

1

0

0

1

1

0

0

1

1

0

1

20 of 20 www.torrotelectric.com Rev. 1.0

REPAIR MANUAL

KIDS10/12

fdsafasdfasdf

R

Table of contents

Other Torrot Motorcycle manuals

Popular Motorcycle manuals by other brands

KTM

KTM 250 EXC-F EU 2012 Setup instructions

BMW Motorrad

BMW Motorrad R 1250 RT special vehicle 2018 Rider's manual

MOTO GUZZI

MOTO GUZZI Stelvio 1200 NTX ABS MY10 Service station manual

Yamaha

Yamaha 2001 V Star XVS1100AN owner's manual

Yamaha

Yamaha XSR 700 owner's manual

Zontes

Zontes ZT310T-M Maintenance manual