2

General

Information/Foreword

This Service Manual contains service, maintenance, and

troubleshooting information for the 2020 XTR1000 model.

The complete manual is designed to aid service personnel

in service-oriented applications.

This manual is divided into sections. Each section covers a

specific vehicle component or system and, in addition to

the standard service procedures, includes disassembling,

inspecting, and assembling instructions. When using this

manual as a guide, the technician should use discretion as

to how much disassembly is needed to correct any given

condition.

This service manual is designed primarily for use by a

basic level technician. The procedures found in this man-

ual are of varying difficulty, and certain service proce-

dures in this manual require one or more special tools to

be completed. The technician should use sound judgment

when determining which procedures can be completed

based on their skill level and access to appropriate special

tools.

NOTE: Whenever a part is worn excessively, cracked,

or damaged in any way, replacement is necessary.

When replacement of parts is necessary, use only genuine

parts. They are precision-made to ensure high quality and

correct fit. Refer to the appropriate Illustrated Parts Manual

for the correct part number, quantity, and description.

All publications and decals display the words Warning,

Caution, Note, and At This Point to emphasize important

information. The symbol !WARNING identifies

personal safety-related information. Be sure to follow the

directive because it deals with the possibility of serious

personal injury or even death. A CAUTION identifies

unsafe practices which may result in vehicle-related dam-

age. Follow the directive because it deals with the possi-

bility of damaging part or parts of the vehicle. The

symbol NOTE: identifies supplementary information

worthy of particular attention. The symbol AT

THIS POINT directs the technician to certain and

specific procedures to promote efficiency and to improve

clarity.

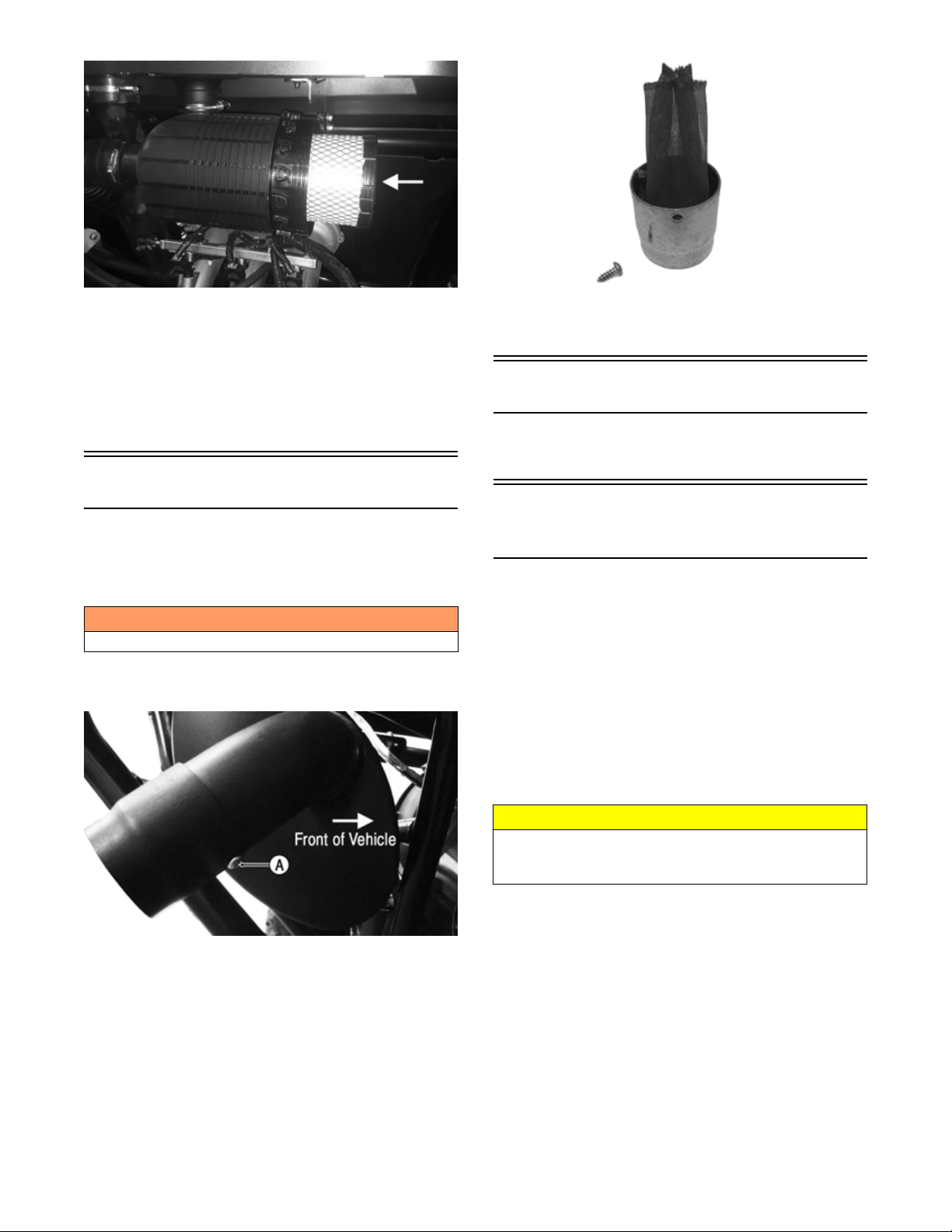

At the time of publication, all information, photographs,

and illustrations were technically correct. Some photo-

graphs used in this manual are used for clarity purposes

only and are not designed to depict actual conditions.

Because products are constantly refined and improved,

no retroactive obligation is incurred.

All materials and specifications are subject to change with-

out notice.

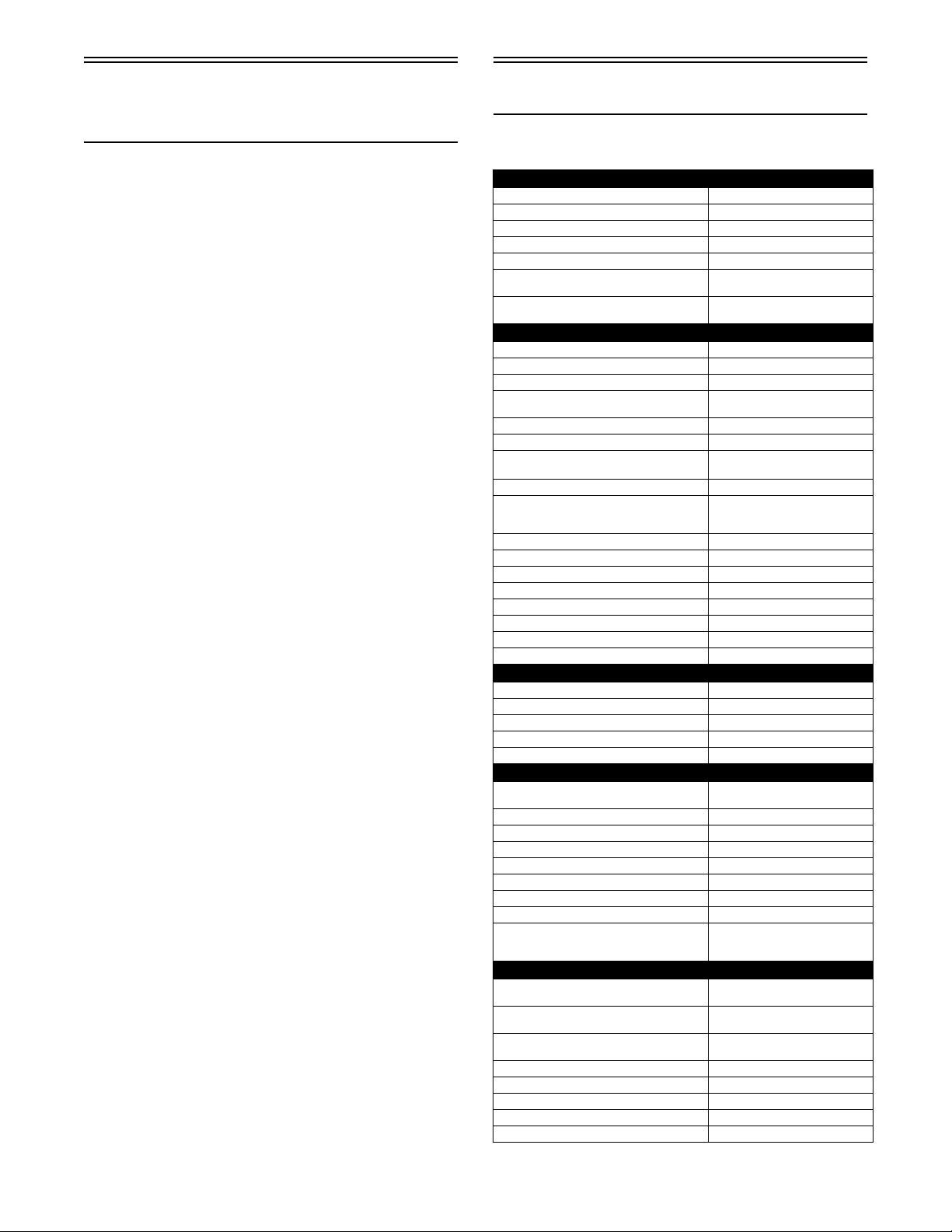

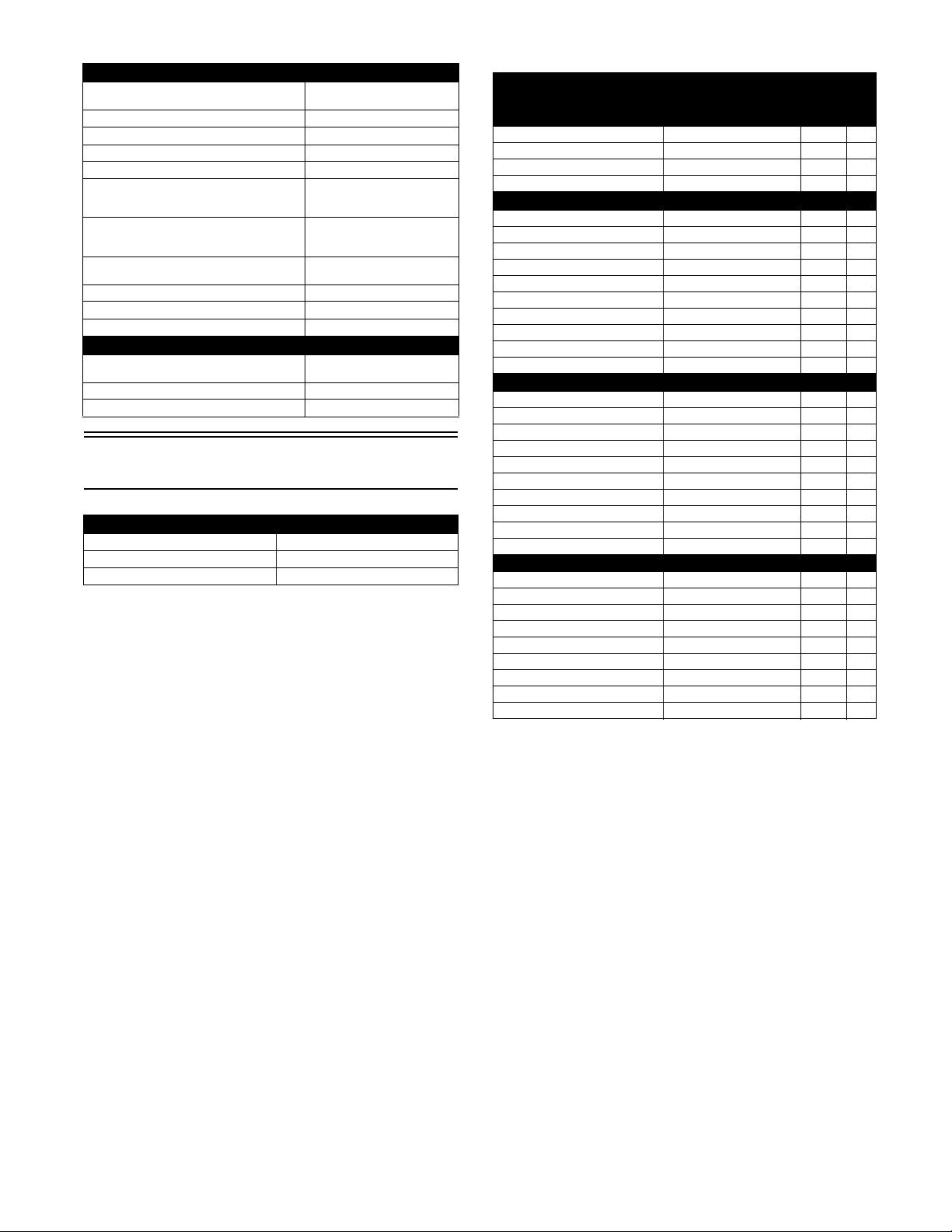

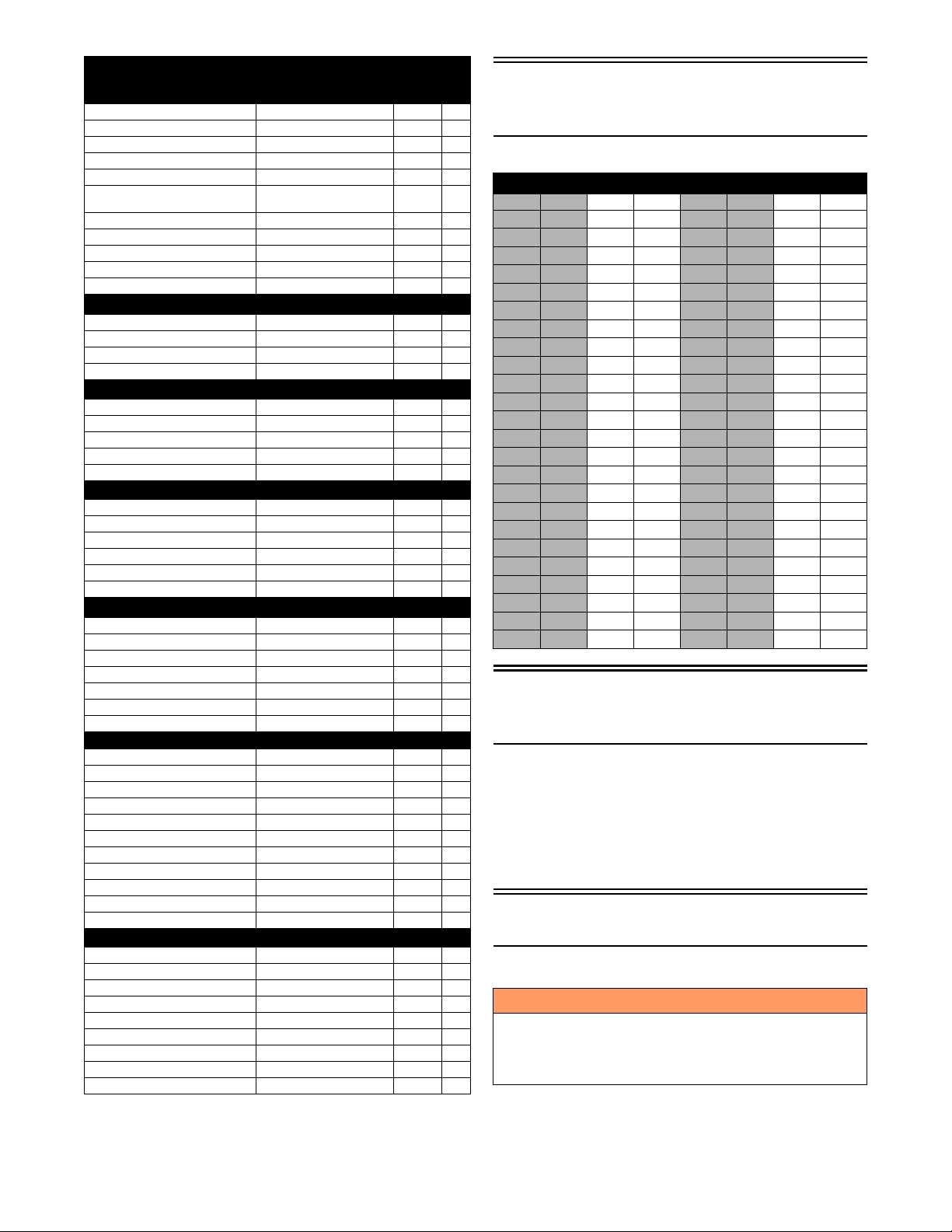

Specifications

NOTE: Specifications subject to change without notice.

* Visible at plug threads.

CHASSIS

Dry Weight (approx) 821 kg (1812 lb)

ROPS Tested Curb Weight 1179.4 kg (2600 lb)

Length (overall) 345.4 cm (136 in.)

Height (overall) 172.7 cm (68 in.)

Width (overall) 162.6 cm (64 in.)

Tire Size 30 x 10-15 — front

30 x 10-15 — rear

Tire Inflation Pressure 14 psi (96.5 kPa) — front

22 psi (151.7 kPa) — rear

MISCELLANEOUS

Spark Plug Type NGK CR9EB

Spark Plug Gap 0.7-0.8 mm (0.028-0.031 in.)

Gas Tank Capacity 37.85 L (10 U.S. gal)

Coolant Capacity (60% Antifreeze/40%

Water Mixture)

9.5 L (2.5 U.S. gal)

Front Differential Capacity 400 ml (13.5 fl oz)*

Transaxle Capacity 1.2 L (40.5 fl oz)

Engine Oil Capacity

(Approx. Capacity at oil change)

2.55 L (2.70 U.S. qt)

Compression Ratio 11.3:1

Gasoline (recommended) Regular gas 86 PON, 91 RON or

higher/ethanol content not to

exceed 10%

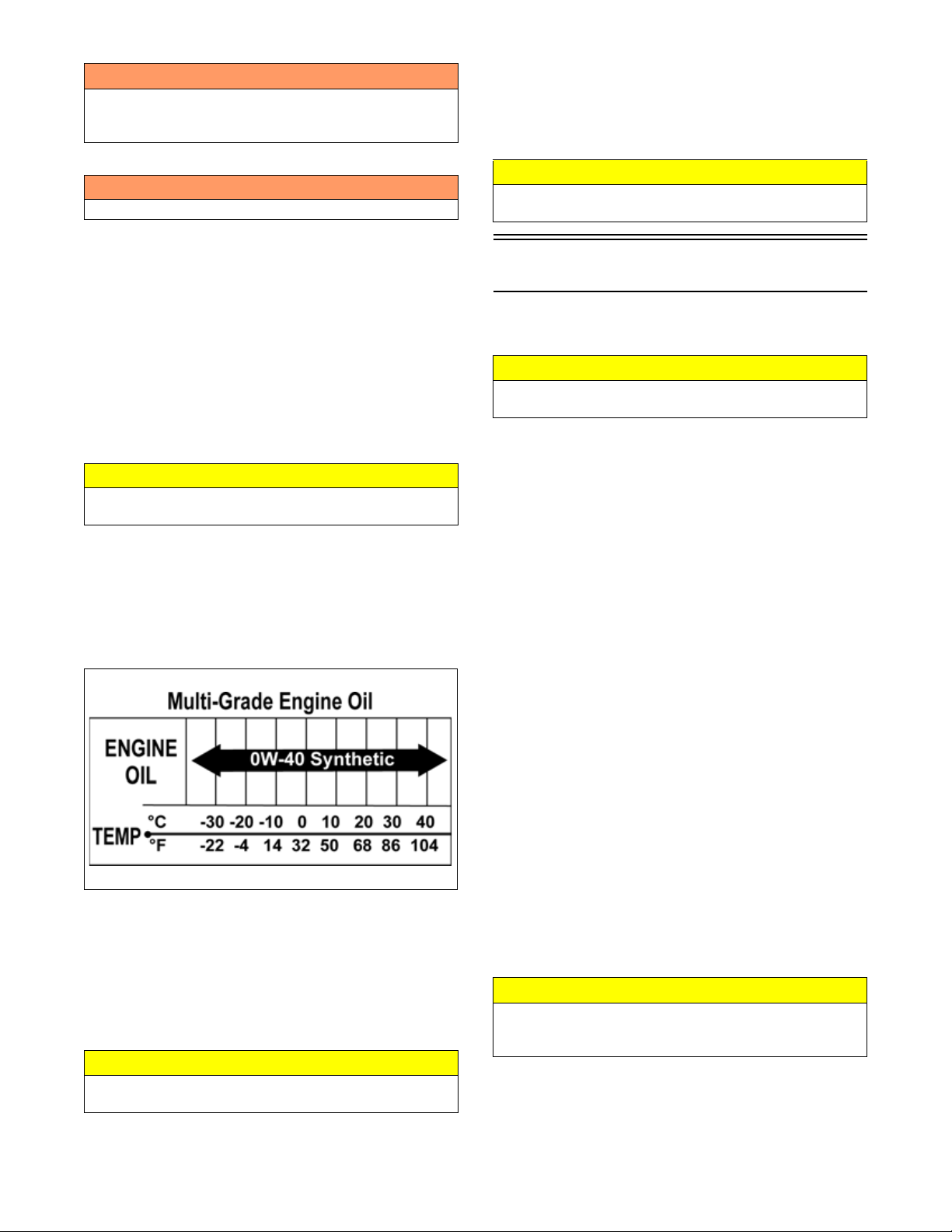

Engine Oil (recommended) ACX All Weather (Synthetic)

Front Differential Lubricant SAE-Approved 80W-90 Hypoid

Transaxle Lubricant Synthetic Transaxle Fluid with EP

Belt Width 38.4 mm

Brake Fluid DOT 4

Taillight/Brake Light LED

Headlight Halogen H13 with LED

Electric Starter Type Constant Mesh

COOLING SYSTEM

Cooling Fan 1 On 194° F (90° C)

Cooling Fan 1 Off 185° F (85° C)

Cooling Fan 2 On 203° F (95° C)

Cooling Fan 2 Off 194° F (90° C)

Thermostat Opening Temperature 156.2-163.4° F (69-73° C)

ELECTRICAL SYSTEM

Ignition Coil Resistance (primary)

(secondary)

1.40 ohm ± 15%

10,000 ohm ± 15%

Ignition Coil Primary Voltage Battery Voltage

Stator Coil Resistance 0.19 ohm ± 20%

Pickup Coil Resistance 495 ohm ± 20%

AC Magnetos Output 14 volts, 39 A @ 5000 RPM

Alternator Output 65 amps

Ignition Timing 8° BTDC @ 1500 RPM

Intake Air Temperature Sensor 315 ohm @ 176° F (80° C)

Coolant Temperature Sensor 5,740 ohm @32° F (0° C)

310-326 ohm @ 176° F (80° C)

183.6 ohm @ 212° F (100° C)

VALVES AND GUIDES

Valve Head Diameter (intake)

(exhaust)

30.90-31.10 mm

25.90-26.10 mm

Valve/Tappet Clearance (intake)

(cold engine) (max) (exhaust)

0.16 mm

0.22 mm

Valve Guide/Stem (intake)

Clearance (max) (exhaust)

0.08 mm

0.10 mm

Valve Guide Inside Diameter (max) 4.550 mm

Valve Head Thickness (min) 2.3 mm

Valve Seat Angle 45° +15’/+30’

Valve Spring Free Length (min) 37.59 mm

Valve Spring Tension @ 34.6 mm 112.30-129.30 N (25.25-29 lb)