No spare parts, tools, measuring equipment or any other

item shall be stored inside the high voltage enclosure. The

inside of the enclosure, terminals and cables shall be clean

and dry. If dust or water is present, the enclosure shall be

disconnected, earthed, cleaned and measures shall be

taken to prevent further ingress of dust or water. Measures

should be taken to prevent condensation inside the enclo-

sure.

An equipotential bonding wire should always be connected

to the enclosure. This is to ensure any fault current shall be

lead safely to earth, and that the enclosure in no way may

be dangerous to touch. The bonding wire should be of a

suitable cross section so that it may safely lead the fore-

seen fault-current to the ground.

Installation is to be performed by skilled personnel, fa-

miliar with high voltage installations and regulations,

“Ex” regulations, the ATEX Directive and/or IECEx

norms and standards. This includes but is not limited to:

IEC/EN 60079-0, IEC/EN 60079-7, IEC/EN 60079-14, com-

pany routines and national and international regulations.

Ferrules shall always be used on fine-stranded cables.

All clearance and creepage distances shall be according to

IEC/EN 60079-7 after installation.

Regardless of the regulations taking precedence in any in-

stallation, a dielectric strength test is highly recommended

after installation, before the equipment is put in service. In

most cases, this test will be mandatory.

Disposal/Recycling: When the apparatus is disposed of,

the respective national regulations shall be observed.

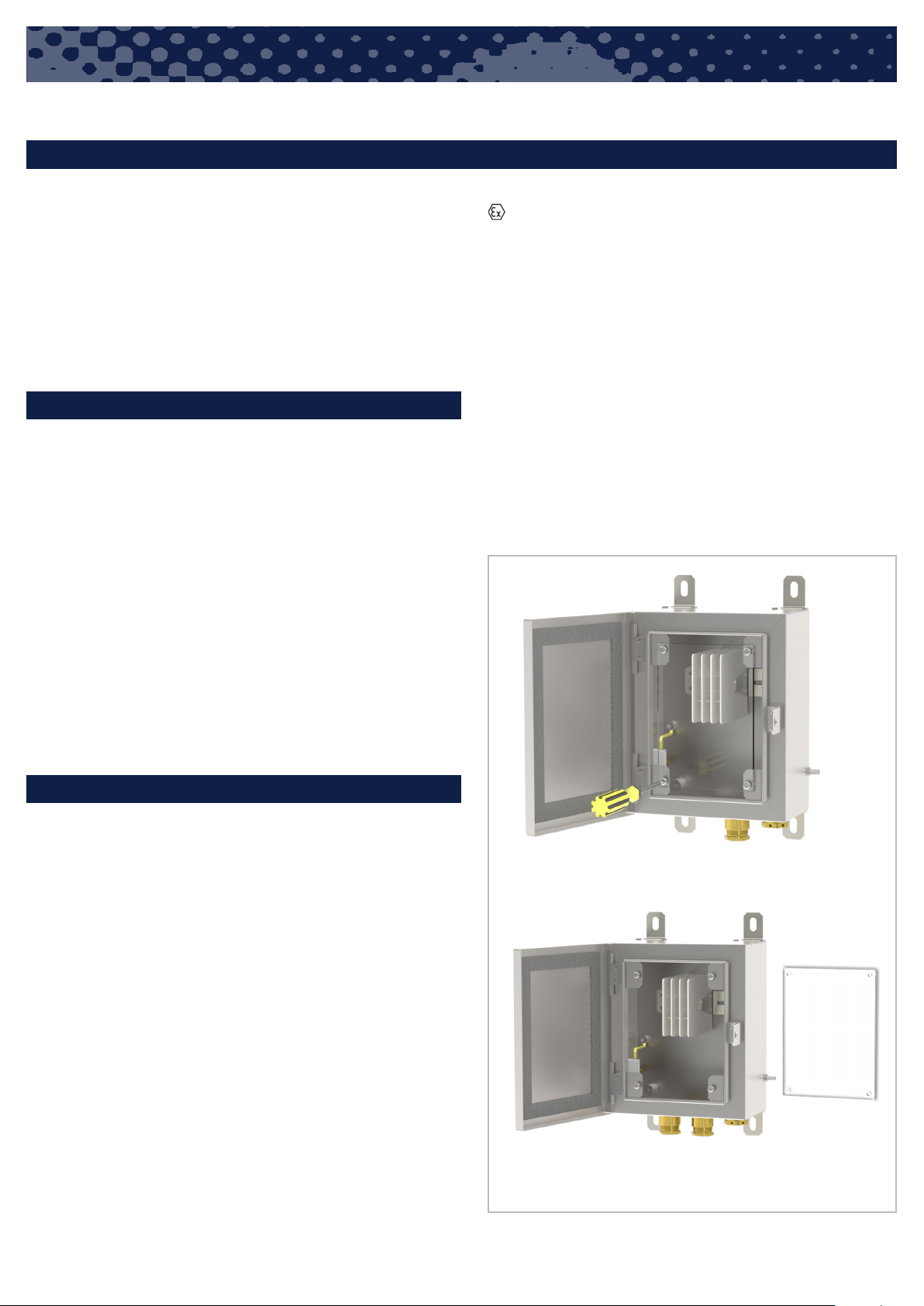

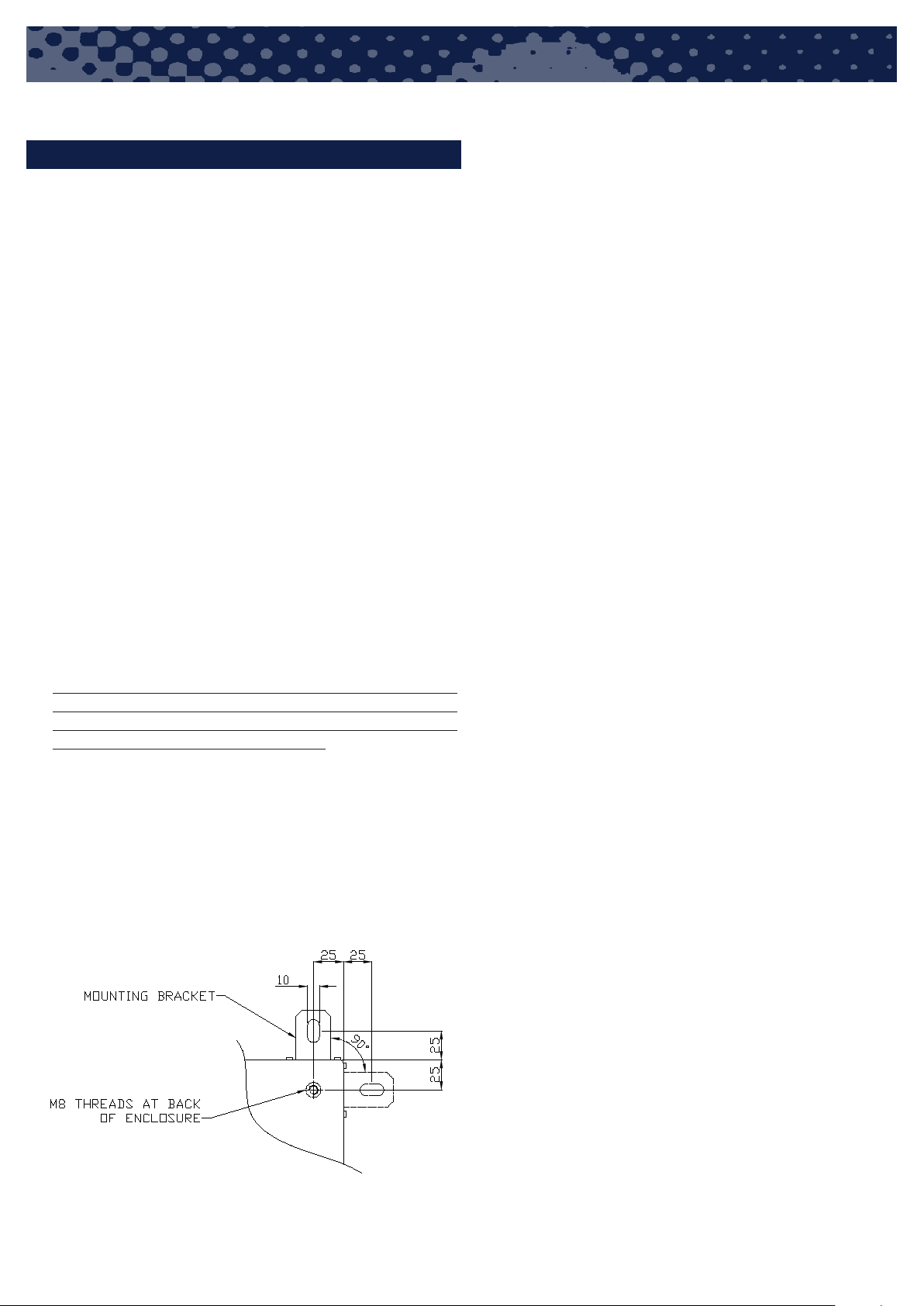

Mounting

The 1060 enclosure must be fastened by 4 pcs. of M10

bolts, or M8 bolt at holes in back of enclosure

TEF 1060 HIGH VOLTAGE ENCLOSURE WITH A-BLOCK USER MANUAL

INSTALLATION

Connection

In order to maintain the mode of protection, the conductors

will have to be connected with special care. The insulation

must reach up to the terminal and the conductor must not

be damage. All screw and nut of the terminals, also those

remaining vacant, must be tighten down. For earth connec-

tion to stud or bar, cable shoes will have to be used.

Only certified cable entries and blinds may be used. Gland

has to be chosen according to cable diameter used.

To ensure the required minimum protection category glands

has to be tighten properly and unused holed has to be

closed with certified blinds according to hole diameter.

Close and lock door / lid. In case of bolt tight these firmly

with suitable tool by hand force. Over tightening may impair

the protection category.

Important

The panel must be mounted vertically to a wall or structure.

Make sure to use all four (and sometimes more) fixing

points, as the weight of the panel with components inside

may be considerable.

It is also very important that the rear of the panel stays level,

meaning that the fixing points on the structure must be in

the same plane. If one or more of the fixing points are out of

line, the panel is likely to be bent when fixed to the structure.

If the panel is bent it may result in several problems, such

as:

• Fault on IP degree of ingress protection, due to

certificate.

• Water intrusion (uneven pressure on door gaskets)

• Doors may not close completely or become difficult to

open

• The load on the fixing bolts may not be fully distributed

(excessive load on some points)

• Permanent deformation of the panel