Treedental TR-DWD01 User manual

Instrument Washing Machine

TR-DWD01

01 Overview

Product Brief Introduction & Feature

The machine accord with the new oral disinfection

technical specification requirements, touch screen realized fully automatic

washing, simple operation, energy conservation and environmental

protection. the machine could show & print temperature at any time.

When setting the washing temperature to be 93°C, the A0 value reach and

above 3000, meeting the moist heat sterilization standard. The design of 2

layers mesh basket plus professional hand piece cleaning bracket and

super capacity can satisfy one-time cleaning of dental hand pieces,

appliance, surgical instruments and other experimental vessels. According

to the instruments type, our machine is optimized to provide six smart

washing procedures to meet the diversification of cleaning .

TR-DWD01

02 Safe Handling Attentions

Warning

Please read the instruction before using to avoid accidents

Incorrect grounding lead connection may take you dangerous.

Please check the reliability of the grounding lead connection. Do not use

self-buying power cord. If your socket is not match with our machine’s power

cord, please find a qualified electrician to match it for you

Do not use the washer before installing it properly

if the soft wire of power supply is damaged, in order to avoid danger, must ask

maker’s professional person to change for you.

Please do not use the function if the machine without.

When installing, do not over bend and squeeze the power cord.

Do not change the connection of the circuit board.

If overflow occurs, turn off the tap before repairing.

If the chassis is flooded due to overflow or leakage, the water must be wiped up

before starting the machine.

The machine must be used indoor.

Attentions

1.When the machine is working, please do not open the door to avoid burning

by the steam. If you need open the door midway, please press the "pause" button and

take safeguard protective, then open the door slowly.

2.Do not place any heavy object on the opening door of the machine. The door

should not keep in open status all the time.

3.Must be sure that the power cord of the machine is properly grounded. The

machine is with grounded lead’s connection terminal, so please use the matched

socket with the terminal. Please make sure that the power cord is connected, the

machine’s grounding wire can be effectively connected with public power of the

ground wire.

4.Do not place instruments over the cleaning tank.

5.Do not plug or pull the power plug by wet hand .

6.Do not wipe the surface of the machine by something with solvent and

abrasive.

7.Must avoid Strong electromagnetic interference when using.

8.Must use special Multi-enzyme detergent ,other products cannot instead of it.

9.The machine with water softener must use special salt, and it is not allowed to

replace the salt with edible salt. After adding salt, must run the washing program to

prevent the salt water overflow from corroding the filter, inner and other important

parts.

10.When maintenance the machine or long-term not using, must unplug the

power plug and turn off the faucet.

03 Technical Feature

Product Parameters

1.Power supply:220V 50Hz;Rated power:≤1760W

2.Rated external water pressure: 0.04-1.00MPa.

Supporting cold/hot water;

3.Internal flow pressure:0.3-0.4MPa;

4.Collocating intelligent water softener:Adding special salt can improve water

quality and enhance cleaning effect;

5.Safety device:Automatic fault diagnosis (prompt) and emergency shutdown;

6.Water inlet filter:Porosity 96%;The filter speed:20-85m/h

7.Lumen volume:160L;

8.Dry method:hot wind dry

9.Dimension-Main Unit:590*570*830(L*W*H mm);

10.Packing size:680*680*930(L*W*H mm);

11.Net weight:≤44.5kg;

12.Working Noise:≤50dB

Packing List

1.Mainframe 1 piece 7.Drain pipe 1strip

2.Cleaning basket 2 pieces 8.Specification 1 piece

3.Salt hopper 1 piece 9.Rubber Isolators 32pieces

4.Cleaning rack 1 piece 10.End cap 32pieces

5.Accessories basket 2 pieces 11.Measuring cup 2 piece

6.Water inlet 1 strip 12.Upper rack 1 piece

04 Installation Instructions

Remove the packing and install mounting plate.

Remove the packing, then open the front door of the machine and remove

accessories . It is strictly prohibited to test the machine on foam bottom mat or

cleaning it.

Place the washer

The ground should be solid and flat, you could the height of the machine can be

adjust the height through rotating the stand bar to

keep it in level.

Inlet pipe installation

The inlet pipe need connect to the inflow blast hole on the back machine, and the

inflow pipe’s elbow should be horizontal and same direction as the inlet water.

Drain-pipe connection

Put the outlet water end of the drain pipe into the sink or sewer line. In order to ensure the

washer’s performance , the length of

drainage pipe should be not exceed 5

meters, the hanging height of the drainage

pipe should be not higher than 600mm ,

not lower than 300mm.

Power connection

Connect the power socket well. The power voltage and frequency should be same as the

parameters of the product.

Power line

Inlet pipe

Inlet pipe nut Drain-pipe

Two t

y

pes

Type 1

Type 2

Max600mm

Detergent

drawer

Brightener

Open

05 Direction For Use

Dispenser Using

Gently press the open cover button to push outward along the direction of the

arrow. As the picture showing to open the drawer and add the needed

multi-enzyme detergent and brightener. Then you can push it to close it until the

“Ka”sound.

Detergent: The main washing water intake is about 3~3.5L, please add cleaning

enzyme at a ratio of 300:1 (that is, 300ml of water needs to add 1ml of cleaning

enzyme). also pls follow the instruction from detergent factory.

To fill the brightener about 70ml, it can be used for many times. And close the cover

of the brightener drawer.

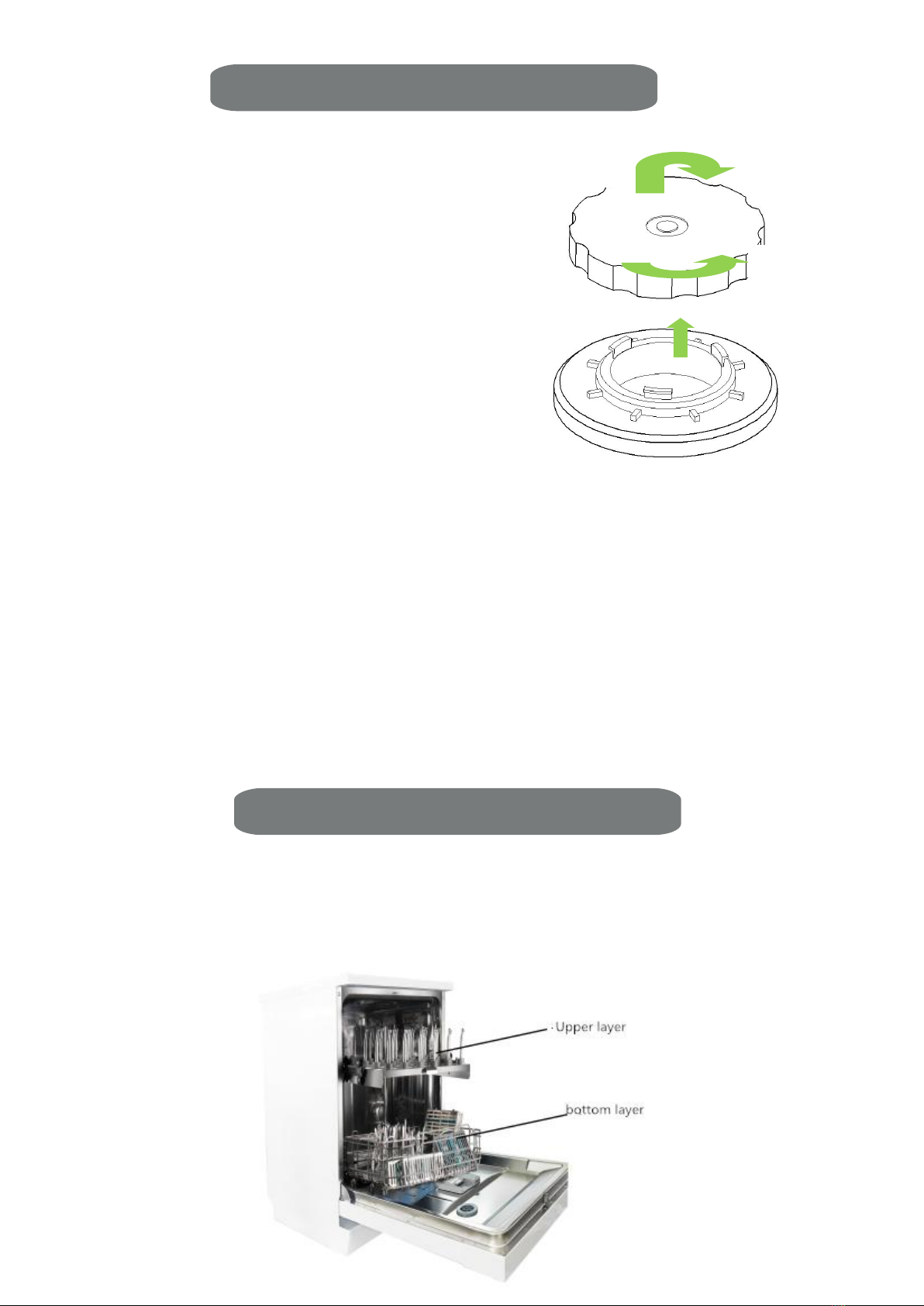

Special Salt Addition

The salt to be soft the hardness of the water. If you

use the pure water. Pls do not need to add the salt.

Counterclockwise open the cover of the

water softener and insert the salt hopper.

Need add about 70g (10 pieces of special salt for

each machine, which can be used many times

for one addition. After adding salt, add water to

the water softener, do not overflow; clockwise rotate the softener cover to prevent

salt leakage from corroding the inner tank. If salt is spilled on the bladder, the

procedure must be run to flush once.

Note:The indicator light may not be off immediately after adding salt, which is normal

and will not affect normal use (Due to differences of water quality and room

temperature, it will take 2 to 6 days for salt to be dissolved and reach saturated state).

Baskets

The washing area of instruments cleaning machine is divided into two layers, which

can be used as per your demand。

open

Close

Upper hand pieces cleaning rack placement

The hand pieces are inserted directly into the rubber seat of the rack. Please do not put

it to the bottom to prevent water from flowing into the hand pieces. The rack can clean

at most 32 hand pieces each time. when the machine working, you could cover the end

cap on the rubber seat.

Bottom Layer

The sub layer basket can be used matching the accessory basket, It can be placed more

than 100 mouth mirror, 20 tooth forceps, 70 forceps apparatus sterilization box tray

and so on each time.

Description Of Control Panel

Display Screen Introduction

End cap

Hand pieces

Rubber Seat

The interface of the program choose

①

②

④

⑤

⑥

①choose the washing programs as per your requirements.

③

⑦

②Set up the Dry function:the dry function is closed by default. press the dry key,the

dry function is on when the key turn dark.

(not all the machine have the dry function)

③Set up Disinfect function:the disinfect function is closed by default.press the

disinfect key. The disinfect function is on when the key turn dark.

④The display of the water temperature

⑤Start/pause:after choosing the program, press the key . The program

start up. press the key to pause.

Notice: when the program is running, except the start/ pause key. other key are no longer

in force.

⑥Stop the program. Press the key .there will a notice “whether cancel this

program” . press yes, this program will be stop.

⑦when the program stop running, the machine can back to main interface.

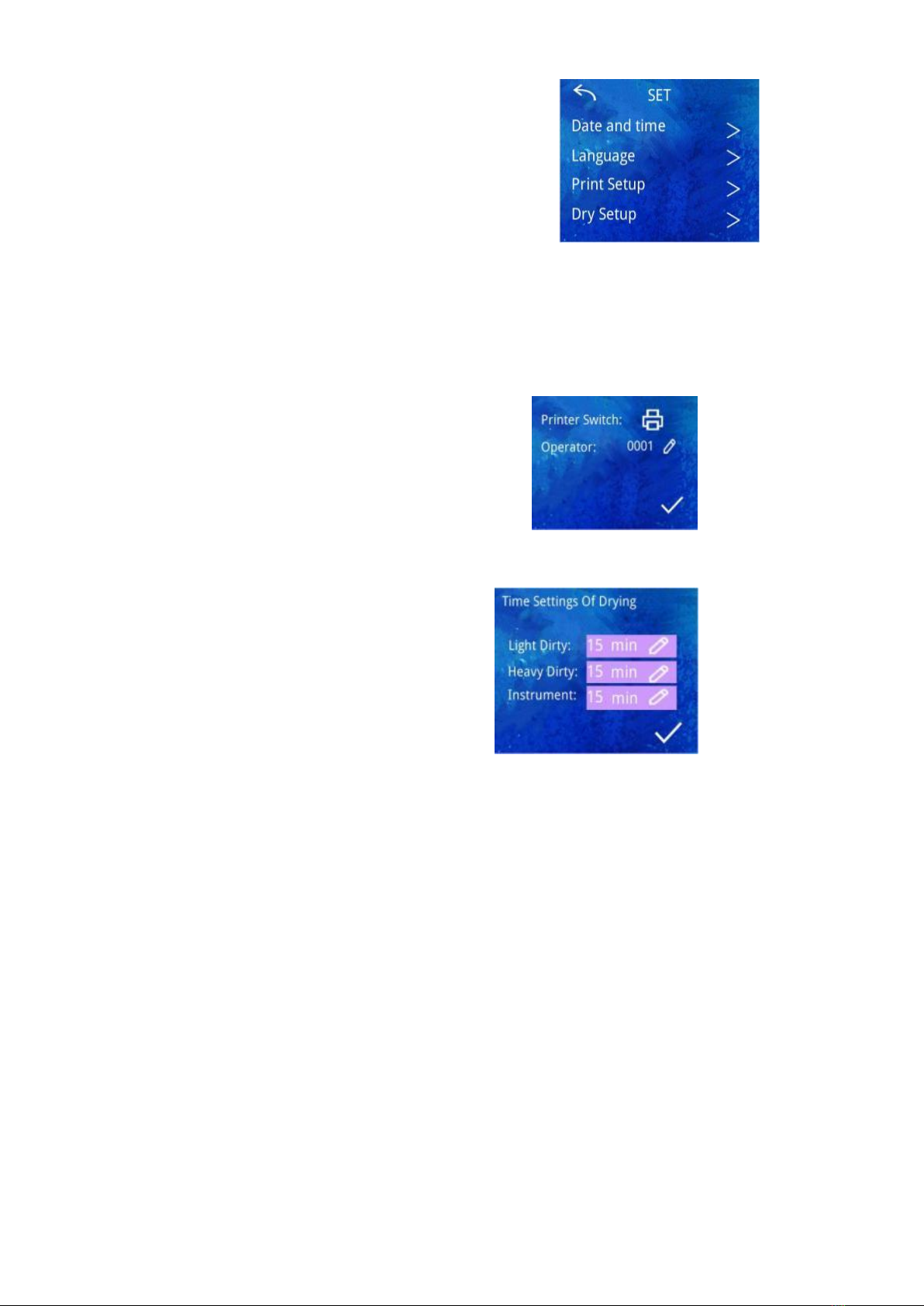

Time

Operator

Set up system

Choose the programs

Back to interface:you can back to main interface

after setting up.

Set up the Date and time:touch it. you can edit

the date and time.

Set up the language: you can choose English or Chinese

Set up the printer:

You can set up open the printer

Or close the printer

Also you can edit the operator number

Set up the dry function:

You can set up the different dry time

As per the different programs.

Notice:The quick washing no the

dry function.

1

It could print the washing date,program,operator and the time with temperature on the

paper.

Press the ON/OFF button, enter ready mode;then press program button to select

washing mode you need on display screen interface, then press Start/Pause button, the

display screen will show the present program by words and enter washing status.

Note: when the washing program is running, the main setting interface is

forbidding using status.

Using Introduction

1. Connect the water inlet pipe and water drain pipe.

Date:2019/07/01

Program:Heavy pollution(70)

Operator:10000001

--------------------------------

09:21:35 30℃

09:26:35 35℃

09:31:35 39℃

09:36:35 40℃

09:41:35 38℃

09:42:52 Pause

09:58:31 Continue

30℃

10:03:35 32℃

10:08:35 38℃

---------------End-------------

①

③②

④⑤

2

3. Turn on the tape. Open the water valve (keep the water be on during washing).

2. Connect the power plug.

3. Open the machine’s door, press the button left as per the arrow indicating, open the

dispenser cover, pour the multi-enzyme detergent into the box then close it.

4. Place the instruments properly into the washer.

Then close the washer door and confirm the door

is closed and locked(A snap can be heard when

the lock is tight).

3

5. Press the ON/OFF, start power supply.

6. Select the washing procedure, then press the start/pause button for cleaning.

7. The machine will finish the washing work when the buzzer give the sounds like

“Di Di....” 6 times. The dry procedure will start to work.

8. Open the machine door after finish washing 5 minutes and remove the instruments.

Note: when the program is running, if you need change program, please press power

button and re-start to enter program selecting main interface.

There are small amount of steam once the water temperature up to 90℃. in order to

help the machine to Difuse the steam. Pls open the door in time after the machine

finish the program.

4

Washing Procedure Introduction

Notes: For example, with the "+disinfection" function, the running time will be

extended by about 30 minutes; with the "+drying" function, the duration can be set by

yourself. The total cleaning time is the running time of each program + disinfection

time + drying time.

The running time values provided in the table are for reference only, and there may be

differences in actual use due to differences in ambient temperature, tap water

temperature, pressure and cleaning equipment.

06 Malfunction Analysis & Exclusion

Common Fault Solving

When the washer break down, you check the Malfunction Analysis & Exclusion to

help you deal with some common faults. If you cannot solve the problem by yourself,

please ask a professional for help.

programs Description Detergent

Running time

(minutes)

Extra

program

Heavy dirty

Heavy pollution or stored

long time

10ml 65

+dry

+disinfect

Light dirty

Light pollution or

immediately washing

10ml 50

+dry

+disinfect

Handpiece

Short washing time for

hand piece

10ml 40

+dry

+disinfect

Quick

washing

Short time washing with

cold water

0ml 12 ——

5

Malfunction Possible Cause Solutions

The washer

can not

operate

Fuse blowout,

Breaker off.

Replace the fuse or reset the circuit breakers

and disconnect other devices that share same

line with the washer.

The power is not

on.

Make sure the power is turned on and the

door is closed. Make sure the power plug is

properly connected to the socket.

Water pressure is

too low.

Check the water inlet equipment to make it

connected ok and the faucet turned on.

The

drainage

pump cannot

stop.

Overflow occurs

The washer with overflow protector, When

overflow occurs, the circulating pump will be

closed and the drain pump will be opened.

Noisy

The internal

instruments were

not placed correctly

Make sure each instrument in the washer is

properly placed.

The pump hum

If the washer is not used regularly, need make

sure the water inflow and drain every week,

which could keep the sealing strip moist.

There is

foam

Incorrect use of the

detergent

Please use special detergent. If foam occurs,

running the cleaning process until the foam

cleared away.

There is

steam

Normal

phenomenon

When draining, a bit amount of steam leaks

through the door

Water

remains on

the inner

bottom

Normal

phenomenon

A bit amount of water on the inner bottom

could keep the sealing strip moist.

Leak water Uneven installation

of machine Make sure the washer is in level.

Error code: in case of failure, the washer control LCD section will display as

follows:

Display usage Implication Possible cause Solutions

The prerinse

indicator

flashes quickly

Water inflow

anomalies

The water

pressure is too

low;

Inlet pipe

clogging;

Check whether the faucet is

open and check the water

pressure or ask professional

maintenance person to repair.

6

Faucet is not

open.

The instrument

indicator

flashed quickly

Overflow

occurs

some parts of the

washer is leaking

Please turn off the tap and ask

professional maintenance

person to repair it

07 Maintenance

Maintenance

1.Wipe the washer door’s edge with a soft wet cloth every day.

2.Cut off the water and open the door slightly to prevent moisture and odor.

3.Clean the filter.

In order to maintain a good performance and washing effect, you should clean

the filter components regularly. Remove the coarse filter after each washing and rinse

under running water, Unscrew the lifting cup, then lift up to remove the lifting cup

and filter components. the filter components should be cleaned each week, Brush can

be used to clean the coarse filters and micro-filters.

Storage Conditions

The washer should be stored in a cool and dark place that the relative humidity

not more than 80% without corrosive gas and good ventilation after packing.

7

Transport Conditions and Methods

The washer can be transported by common vehicle after packing, but we should

prevent the violent impact, vibration, rain or snow splash in transportation.

Table of contents