THROTTLE

CONTROL

ADJUSTMENTS

The throttle control settings are

factory adjusted and unnecessary

adjustments should not be made.

However,

if

the engine does not

start

or

stop, or

if

it does not re-

spond to various throttle lever set-

tings' then the following adjust-

ments may be necessary.

DANGER

To

prevent personal injury,

stop

the

engine,

disconnect

the

spark

plug

wire,

and

let

the

engine

and

muffler

cool

before

inspecting

or

adjust-

ing

the

throttle

control.

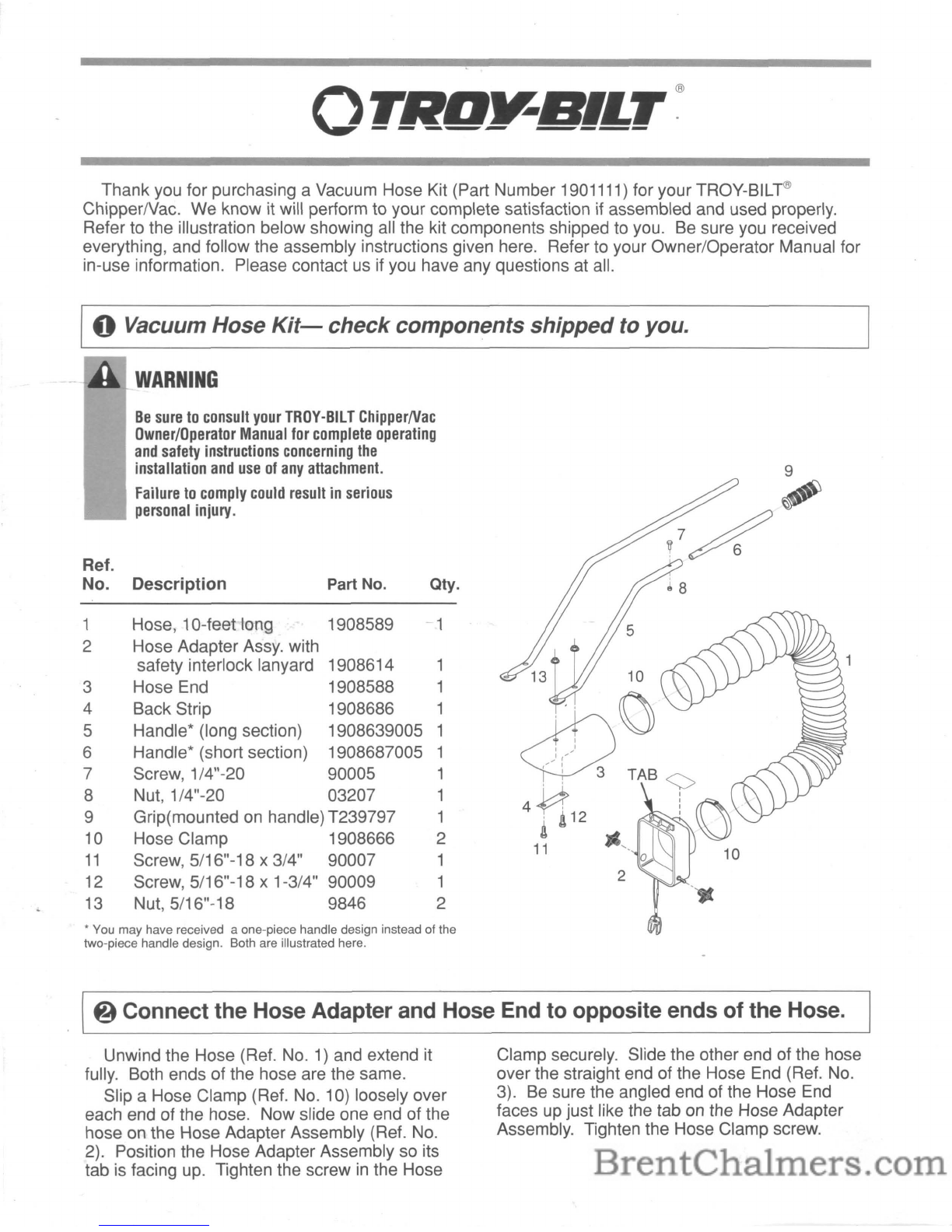

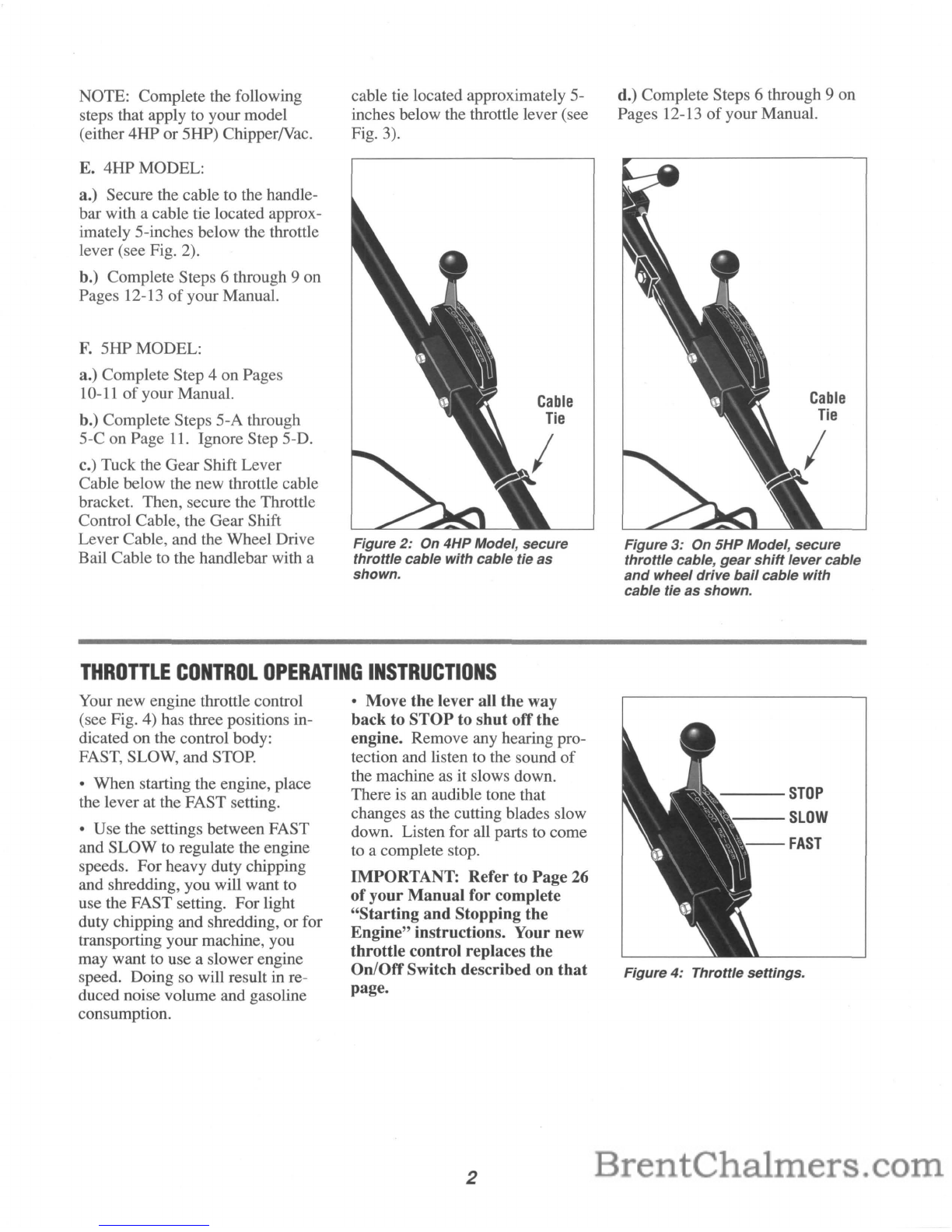

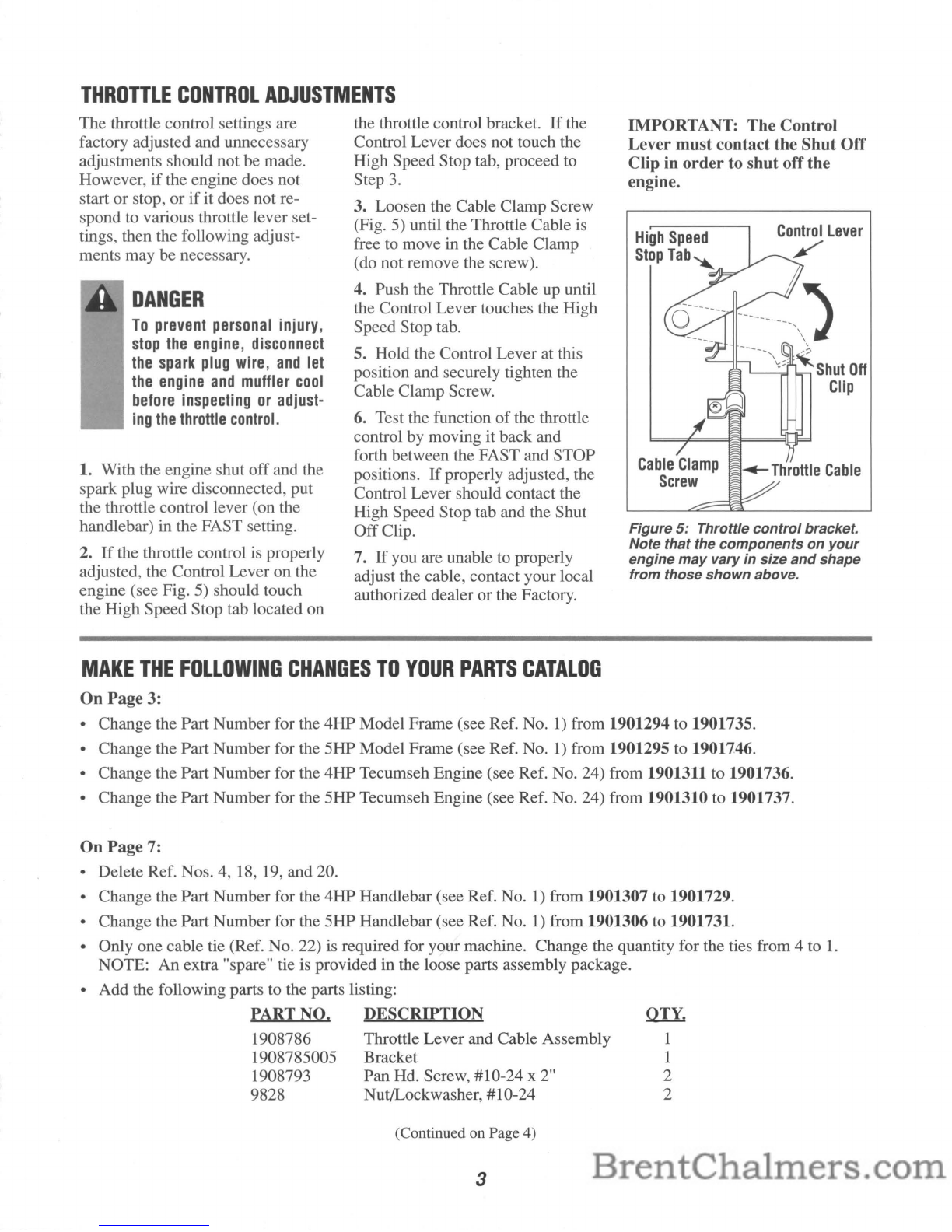

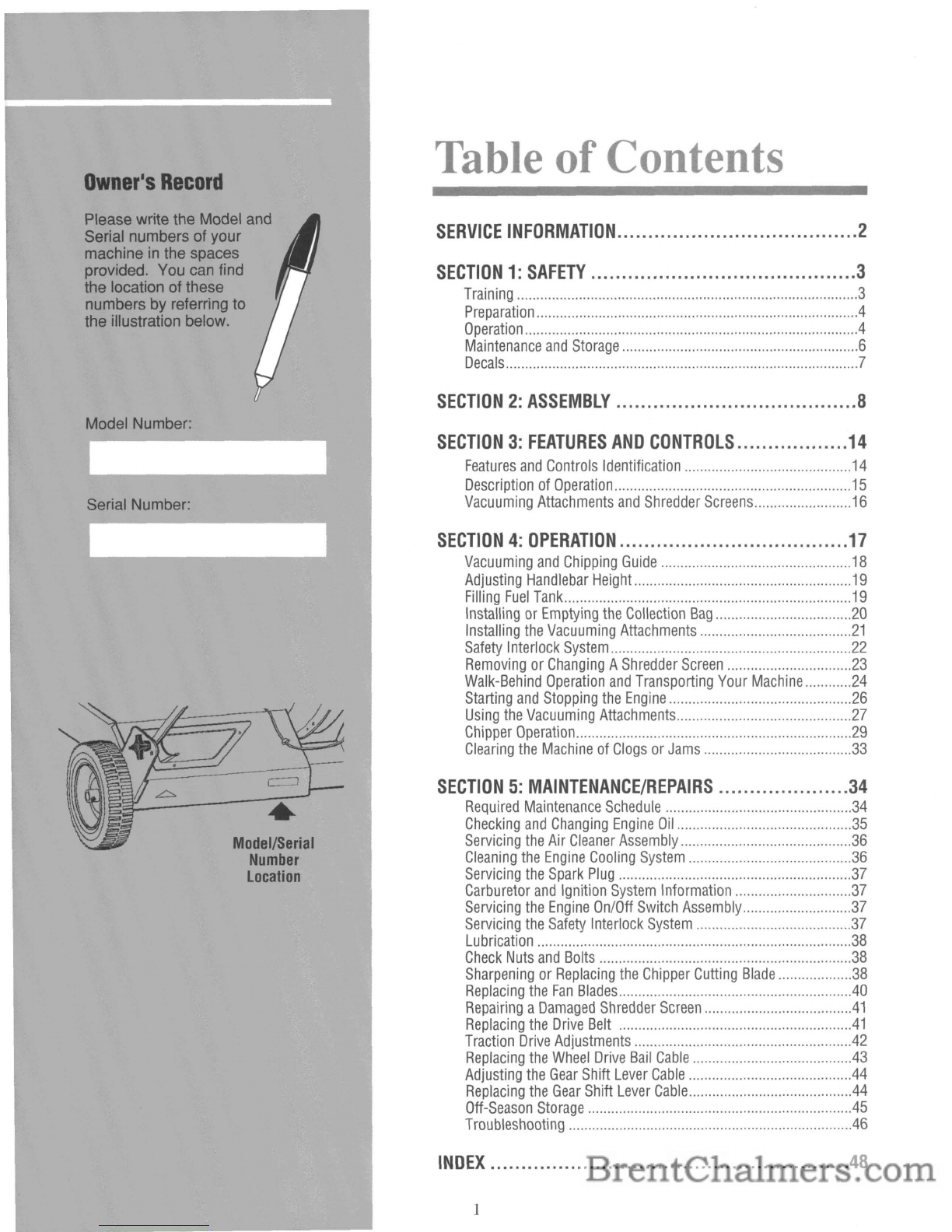

1. With the engine shut

off

and the

spark plug wire disconnected, put

the throttle control lever (on the

handlebar) in the FAST setting.

2.

If

the throttle control is properly

adjusted, the Control Lever on the

engine (see Fig. 5) should touch

the High Speed Stop tab located on

the throttle control bracket.

If

the

Control Lever does not touch the

High Speed Stop tab, proceed to

Step 3.

3. Loosen the Cable Clamp Screw

(Fig. 5) until the Throttle Cable is

free to move in the Cable Clamp

(do not remove the screw).

4. Push the Throttle Cable up until

the Control Lever touches the High

Speed Stop tab.

5. Hold the Control Lever at this

position and securely tighten the

Cable Clamp Screw.

6. Test the function

of

the throttle

control by moving it back and

forth between the FAST and STOP

positions.

If

properly adjusted, the

Control Lever should contact the

High Speed Stop tab and the Shut

Off

Clip.

7.

If

you are unable to properly

adjust the cable, contact your local

authorized dealer or the Factory.

IMPORTANT: The Control

Lever must contact the Shut Off

Clip in

order

to shut offthe

engine.

High

Speed

Stop

Tab

.........

----------,

1

,,,,

~Shut

Off

Clip

Figure

5:

Throttle

control

bracket.

Note that the components on

your

engine

may

vary

in

size

and

shape

from those

shown

above.

OTY.

1

1

2

2

MAKE

THE

FOLLOWING

CHANGES

TO

YOUR

PARTS

CATALOG

On

Page 3:

•Change the Part Number for the

4HP

Model Frame (see Ref.

No.1)

from 1901294 to 1901735.

•Change the Part Number for the 5HP Model Frame (see Ref.

No.1)

from 1901295 to 1901746.

•Change the Part Number for the

4HP

Tecumseh Engine (see Ref. No. 24) from 1901311 to 1901736.

•Change the Part Number for the 5HP Tecumseh Engine (see Ref. No. 24) from 1901310 to 1901737.

On

Page 7:

•Delete Ref. Nos. 4, 18, 19, and 20.

•Change the Part Number for the

4HP

Handlebar (see Ref.

No.1)

from 1901307 to 1901729.

•Change the Part Number for the 5HP Handlebar (see Ref.

No.1)

from 1901306 to 1901731.

•Only one cable tie (Ref. No. 22) is required for your machine. Change the quantity for the ties from 4to

1.

NOTE:

An

extra "spare" tie is provided in the loose parts assembly package.

•Add the following parts to the parts listing:

PART NO. DESCRIPTION

1908786 Throttle Lever and Cable Assembly

1908785005 Bracket

1908793

Pan

Hd. Screw, #10-24 x2"

9828 Nut!Lockwasher, #10-24

(Continued on Page 4)

3