Truper MOTE-18 User manual

Manual

Electric

Chainsaw

MOTE-18

ModelCode

MOTE-18

Applies for:

16295

2.2 Hp

ENGLISH

ESPAÑOL

Read the user’s manual thoroughly

before operating this tool.

CAUTION

Use and care recomendations

Perform periodic MAINTENANCE to your machine (page 17).

A HEAVY DUTY EXTENSION CORD 16 AWG is recommended

Using extensions with smaller gauges can damage the product.

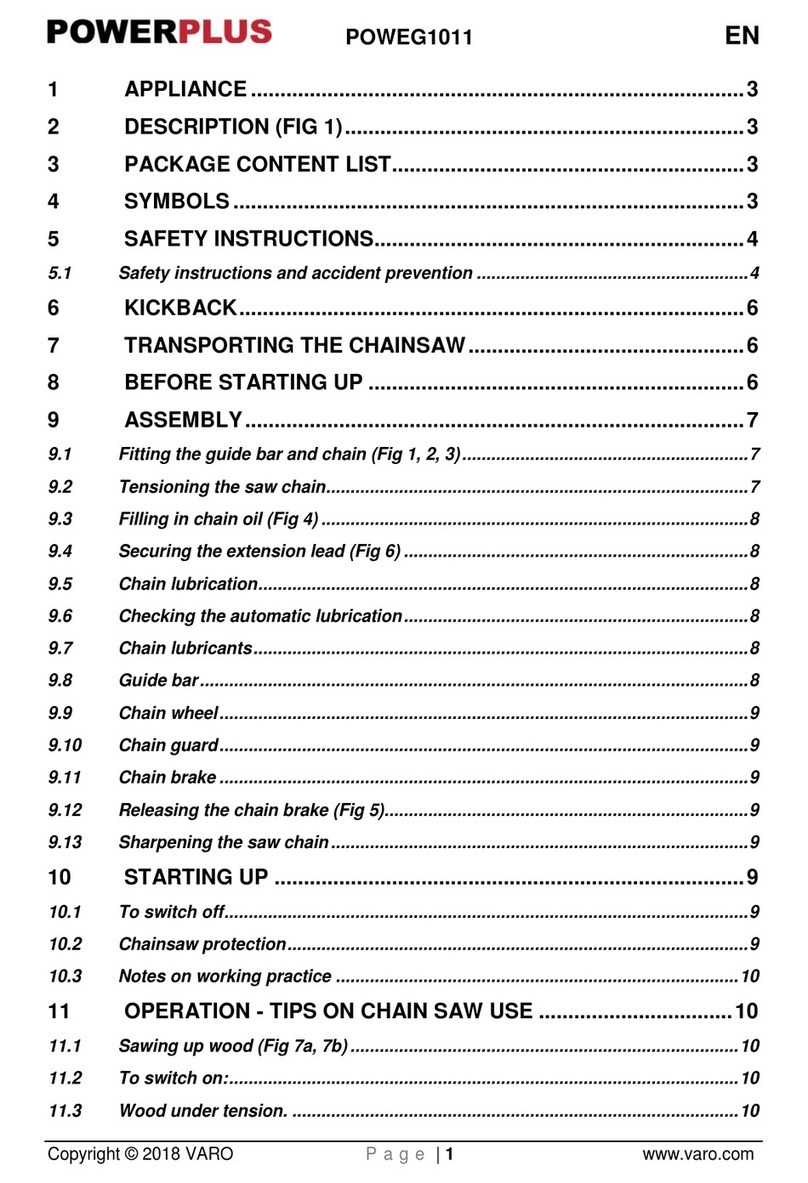

2

Technical Data

Power requirements

Safety warnings for electric tools

Safety warnings for using Chainsaws

Parts

Safety Devices

Oil Supply

Bar and Chain Assembly

Start Up

Cutting Operation

Felling and Bucking

Cutting Branches and Pruning

Adjustments and Maintenance

Troubleshooting

Notes

Authorized Service Centers

Warranty policy

3

3

4

5

7

8

9

10

12

13

14

16

17

19

20

21

22

ENGLISH

Contents

CAUTION

Keep this manual for future references.

The illustrations in this manual are for reference

only. They might be different from the real tool.

To gain the best performance of

the tool, prolong the duty life,

make the Warranty valid if

necessary, and to avoid hazards

of fatal injuries please read and

understand this Manual before

using the tool.

Power cord grips used in this product: Type “Y”.

Build quality: Reinforced insulation

Thermal insulation on motor winding: Class B

Power Requirements

3

Code

Description

Voltage

Frequency

Current

Power

Axis Speed

Advance Speed

Bar

Oil Tank

Chain Pitch Chain Gauge

Work Cycle

Conductors

MOTE-18

16295

127 V

Electric Chainsaw

6 000 RPM

43.6 ft/s

6.7 oz

3/8”

30 minutes’ work and 15 minutes idle. Maximum 6 hours per day.

0.05”

14 AWG x 2C with 176 °F insulating temperature.

Insulating Class II

60 Hz

13 A

2.2 Hp

18”

Technical Data

ENGLISH

WARNING

WARNING Avoid the risk of electric shock or severe injury. When the power cable gets damaged

it should only be replaced by the manufacturer or at a Authorized Service Center.

The build quality of the electric insulation is altered if spills or liquid gets into the tool while in use.

Do not expose to rain, liquids and/or dampness.

Before gaining access to the terminals all power sources should be disconnected.

from 0 A and up to 10 A

from 10 A and up to 13 A

from 13 A and up to 15 A

from 15 A and up to 20 A

18 AWG(*)

16 AWG

14 AWG

8 AWG

16 AWG

14 AWG

12 AWG

6 AWG

3 (one grounded)

from 5.9’ to 49.2’ | higher than 49.2’

Ampere

Capacity Number of

Conductors Extension gauge

*It is safe to use only if the extensions have a built-in artifact for over current protection.

AWG = American Wire Gauge. Reference: NMX-J-195-ANCE

WARNING When operating power tools outdoors, use a grounded

extension cable labeled “For Outdoors Use”. These extensions are specially designed for

operating outdoors and reduce the risk of electric shock.

Tools with double insulation and reinforced insulation are

equipped with a polarized plug (one prong is wider than the other). This plug will

only fit in the right way into a polarized outlet. If the plug cannot be introduced into

the outlet, reverse the plug. If it still doesn’t fit, call a qualified electrician to install

for you a polarized outlet. Do not alter the plug in any way. Both insulation types

eliminate the need of both a grounded third power cord with three prongs or a

grounded power connection.

When using an extension cable, verify the gauge is enough for

the power that your product needs. A lower gauge cable will cause voltage drop in the line, resulting in power loss and

overheating. The following table shows the right size to use depending on cable’s length and the ampere capability shown in

the tool’s nameplate. When in doubt use the next higher gauge.

WARNING

WARNING

4

Safety warnings for

electric tools

ENGLISH

Work area

Keep your work area clean, and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Sparks generated by power tools may ignite the flammable material.

Keep children and bystanders at a safe distance while operating

the tool.

Distractions may cause loosing control.

Electrical Safety

The tool plug must match the power outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools.

Modified plugs and different power outlets increase the risk of electric shock.

Avoid body contact with grounded surfaces, such as pipes,

radiators, electric ranges and refrigerators.

The risk of electric shock increases if your body is grounded.

Do not expose the tool to rain or wet conditions.

Water entering into the tool increases the risk of electric shock.

Do not force the cord. Never use the cord to carry, lift or unplug

the tool. Keep the cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a tool outdoors, use an extension cord suitable

for outdoor use.

Using an adequate outdoor extension cord reduces the risk of electric shock.

If operating the tool in a damp location cannot be avoided, use

a ground fault circuit interrupter (GFCI) protected supply.

Using a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense

when operating a tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication.

A moment of distraction while operating the tool may result in personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as safety glasses, anti-dust mask, non-skid shoes,

hard hats and hearing protection used in the right conditions significantly

reduce personal injury.

Prevent unintentional starting up. Ensure the switch is in the

“OFF” position before connecting into the power source and /

or battery as well as when carrying the tool.

Transporting power tools with the finger on the switch or connecting power

tools with the switch in the “ON” position may cause accidents.

Remove any wrench or vice before turning the power tool on.

Wrenches or vices left attached to rotating parts of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at all times.

This enables a better control on the tool during unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep

hair, clothes and gloves away from the moving parts.

Loose clothes or long hair may get caught in moving parts.

If you have dust extraction and recollection devices connected

onto the tool, inspect their connections and use them correctly.

Using these devices reduce dust-related risks.

Power Tools Use and Care

Do not force the tool. Use the adequate tool for your

application.

The correct tool delivers a better and safer job at the rate for which it was designed.

Do not use the tool if the switch is not working properly.

Any power tool that cannot be turned ON or OFF is dangerous and should be

repaired before operating.

Disconnect the tool from the power source and / or battery

before making any adjustments, changing accessories or

storing.

These measures reduce the risk of accidentally starting the tool.

Store tools out of the reach of children. Do not allow persons

that are not familiar with the tool or its instructions to

operate the tool.

Power tools are dangerous in the hands of untrained users.

Service the tool. Check the mobile parts are not misaligned or

stuck. There should not be broken parts or other conditions that

may affect its operation. Repair any damage before using the

tool.

Most accidents are caused due to poor maintenance to the tools.

Keep the cutting accessories sharp and clean.

Cutting accessories in good working conditions are less likely to bind and are

easier to control.

Use the tool, components and accessories in accordance with

these instructions and the projected way to use it for the type of

tool when in adequate working conditions.

Using the tool for applications different from those it was designed for, could

result in a hazardous situation.

Service

Repair the tool in a Authorized Service Center

using only identical spare parts.

This will ensure that the safety of the power tool is maintained.

WARNING! Read carefully all safety warnings and instructions listed below. Failure to comply with any of

these warnings may result in electric shock, fire and / or severe damage. Save all warnings and instructions for

future references.

This tool is in compliance with

the Official Mexican Standard

(NOM - Norma Oficial Mexicana).

• Keep this in mind. Safety is a combination of common

sense, alert mind and knowledge of the tool operation.

• Please read carefully the manual before

using the chainsaw. Be aware of the safety measures, the

Alert symbols and the Danger, Warning and Attention

Symbol labels pasted on the tool. These safety measures

are alert you and to help you avoid possible injuries or

fatal accidents. However, they do not eliminate the

danger involved in mishandling the chainsaw. The tool

when used with care and for the job it is intended will

render many safe and reliable services.

• Aided with this manual get familiar with the chainsaw.

Keep it in a safe and handy place to consult frequently

and to teach other chainsaw users. Learn its uses,

limitations and also the possible specific dangers.

• Chainsaws are specifically designed to

cut wood. Do not try to cut any other materials.

• Never allow untrained people to use

the chainsaw.

• Operate the chainsaw only when visibility and light

conditions are adequate to see clearly.

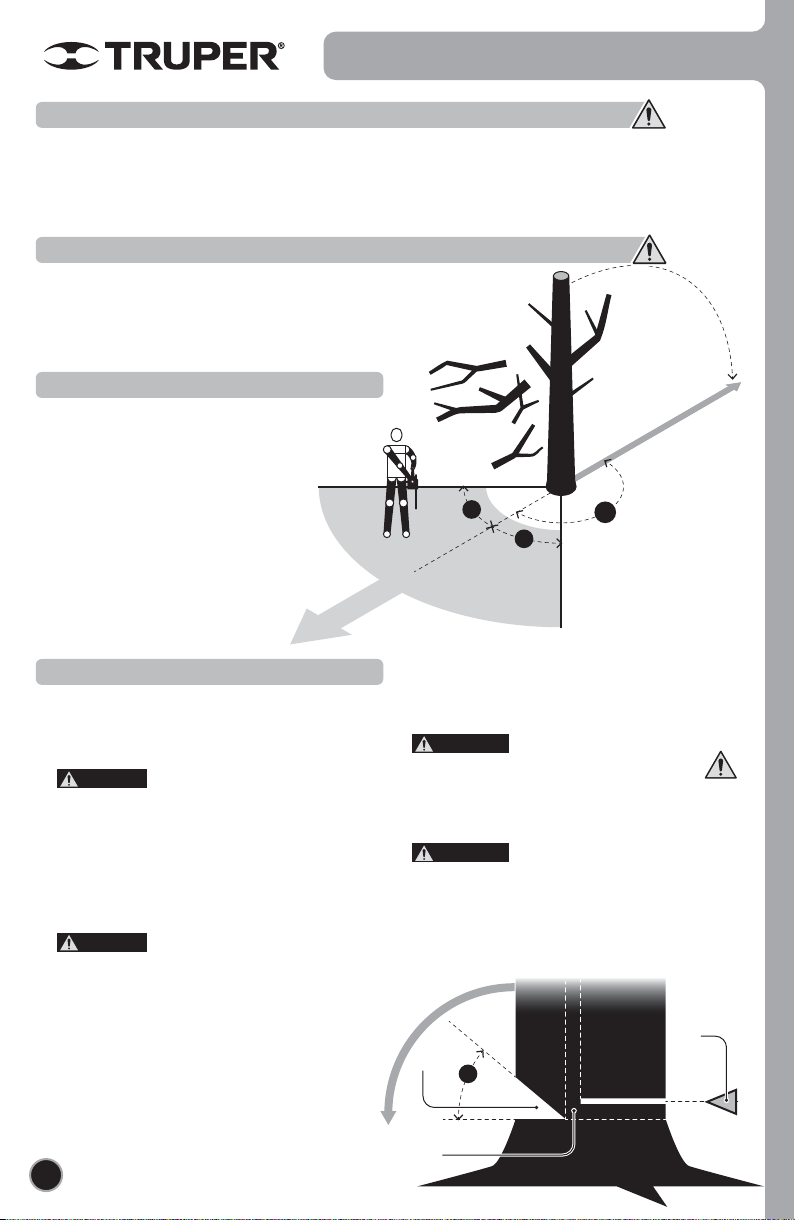

Kickback is the sudden and strong movement off the cut

and towards the operator made by the running tool. It

can make the operator losing control or even severe

personal injury. Usually, kickback happens when the nose

of the cut bar touches an object or the cutting chain is

pinched into the material to be cut. To avoid this

dangerous situation the following measures must be

used:

• Keep all the guards and safety devices incorporated to

the chainsaw well-kept and in place.

• When operating a chainsaw be always alert and avoid

being used to the tool make you stop paying attention to

the cutting job.

• With the chainsaw switched on, hold it

firmly with both hands. Set the right hand in the rear handle

and the left hand in the front handle. Both handles need to

be encircled by your fingers and with your thumbs bent

under the handles (A). This way of holding has the least

chance of failing when kickback occurs. By keeping the

thumbs in the same side of the other fingers is dangerous

because it greatly diminishes your control over the tool if

kickback occurs.

• Operate the chainsaw with your left arm totally straight

and outstretched.

• DO NOT allow the nose of the cut bar

make contact with both the material you are about to cut

and obstacles such as logs, branches, fences or any other

material that could touch the cut bar while operating the

chainsaw.

• Always cut with the engine running at maximum speed.

Press the trigger switch all the way and keep a stable

cutting speed.

• Do not overreach or cut objects out of

reach or higher than your chest.

• Keep the cutting chain sharp and in optimal conditions.

• Use only spare bars and chains specified by

.

Right way to hold

the chainsaw

Wrong way to hold

the chainsaw

5

DANGER

DANGER

DANGER

Safety warnings for

Using Chainsaws

WARNING

CAUTION

WARNING

General To Prevent Kickback

A

ENGLISH

• Keep co-workers away when starting or operating the

chainsaw. A safe distance is15 feet between every worker.

Make sure passersby or animals are further away from the

work area when you start and operate the machine. A

safe area is at least double the height of the tallest trees in

the felling zone.

• After starting the motor, verify the cutting chain in not

coming into contact with any object.

• Set both feet firmly in the ground. Do

not operate the chainsaw if standing in an unstable area,

such as scaffolding, ladders, trees, etc. Only highly

qualified people and adequate safety gear can operate a

chainsaw up in a tree.

• Do not start cutting until the work area is clear, feet

perfectly stable on the ground and an escape route that

takes into account the felled tree.

• Never operate the chainsaw

single-handedly. Otherwise the operator and third parties

will get injured.

• Keep every part of your body away from the cutting

chain when the motor is running.

• Do not cut small vines or shrubs (smaller than 3”

diameter).

• Use extreme caution when cutting

small shrubs and young trees. The slim material could get

pinched in the saw chain and be thrown with great force

towards you.

• Use extreme caution when cutting

branches under pressure. When cutting, the branch

might whiplash back to its original position, therefore

hitting the operator. Take this in mind and stay away from

the branch trajectory.

• Stay alert to the chainsaw reaction when

cutting big trunks. Because of reaction forces dependent of

the direction of the chain movement and (the upper or lower)

edge of the cut bar used, the chainsaw might be pushed

towards the operator (B), or could be pulled towards the

trunk (C).

• Never use the chainsaw when tired, sick or under the effects of drugs, alcohol o medication.

• Wear clothes adequate for chainsaw operation: tight fitting clothes, thick slacks, safety non-skid

boots, heavy-duty protective gloves, safety goggles or protective lenses with side protection compliant

with the ANSI Z87.1 Standard, head and hearing protectors. Also recommended are overalls, jeans

and chaps, as well as wide vision full masks.

• Remove from your person any accessory or lose clothing that could get caught into the moving chain.

Hold long hair up above your shoulders.

• Verify the chainsaw is in perfect conditions. Do not turn it on is not well adjusted or not completely assembled so it will

work safely.

• Verify the cutting chain stops moving when releasing the trigger switch. In the event the chain is not stopping when

releasing the trigger switch, turn off the chainsaw and go to a Authorized Service Center to fix the

problem.

• Do not turn on the chainsaw if assembled with any device or accessory not specified in this Manual.

• Verify the chainsaw handles are clean, dry and free of oil or fuel.

• Make sure the work area is an open and well-ventilated area.

• Always carry the chainsaw switched off

and with the chain brake engaged, the cut bar facing back

and sheathed and the muffler away from the body.

• Turn off the chainsaw and apply the

chain brake before setting it idle. DO NOT leave it running

while unattended.

• Service and repairs on the chainsaw

have to be carried out only by highly trained staff. A bad

service job may cause an accident with fatal consequen-

ces. (For example; if when disassembling or supporting

the flywheel to remove the clutch, a structural damage

may happen and make it burst).

6

DANGER

DANGER

DANGER

Safety warnings for

Using Chainsaws

WARNING

WARNING

WARNING

WARNING

Before operating the Chainsaw

When operating the Chainsaw After Operating the Chainsaw

CAUTION

CAUTION

CAUTION

B

C

ENGLISH

Chain

Cover

Sprocket

Wheel

Oil Level

Window

Trigger

Switch

Oil Level

Window

Motor

Cover Rear Handle

Base

Chain

Tightening Knob Chain Cover

Locking Knob

Chain

Cover

Cable

Fastener

Mounting

Surface

Power cord

protector

Power

Cable

Rear

Handle Low Kickback

Chain

Oil Deposit

Cap

Front

Handle Switch

Lock

Cut Bar

Cut Bar Scabbard

Front Guard /

Chain Brake

7

Parts

ENGLISH

K

i

c

k

b

a

c

k

• The chain brake (A) function is to stop quickly the chain

movement and protects the hand in case of kickback.

(See page 5). It is designed taking in consideration the

predictable movement of kickback, which sends the cut

bar upwards and towards the operator, so when the brake

is pushed with the left hand, the chain stops immediately.

• Test the chain brake every time you

turn on the chainsaw and before you start cutting:

• With the motor running and pressing the trigger switch,

push with the back of your left hand the chain brake

towards the cut bar. When doing this

movement DO NOT let go the front handle. Just turn your

left hand forward until it touches the brake and push it.

• If for any reason the brake does not stop the chain, DO NOT

operate the chainsaw. Turn it off and have it repaired in a

Authorized Service Center..

• If the brake is working properly, the cutting chain will stop immediately. To

disengage the brake, hold the upper side of the guard and pull towards you until

you hear it snap.

• Remember the chainsaw brake does not prevent the kickback. It

is a safety device to avoid possible injury after the kickback happens.

• Keep in mind that even with the proper maintenance, in field use

conditions, the chain brake function cannot be considered totally safe. Be alert at all

times. Use adequate cutting techniques and always use the rest of the safety devices.

• This type of chain has cleaning teeth (depth gauge) placed before each cutting

tooth to prevent it enters too deeply into the wood and gets pinched causing the

kickback.

• To replace worn chains, use only Low-Kickback certified chains.

• Take into consideration that the chain wears out with regular

use or with the filing process. It loses its capability to lessen the possibility of

kickback, therefore; you need to use extra caution.

• When the working life of the cut bar (C) is finished, replace it

with an identical bar.

• The smaller the nose radius in the cut bar is, the capacity to

decrease the possibility of kickback will be less.

Changing Direction

of the Left Hand

to Activate the

Chain Brake

8

Cut Bar

Chain Brake

Low Kickback Chain (B)

Safety Devices

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

CAUTION

A

C

B

ENGLISH

9

Oil Supply

• Use oil for bars, chains and their lubrication systems,

specially designed to work in a wide range of

temperatures without any dilution. Using SAE-20 oil is

recommended.

• Oil level should be checked every 20 minutes through

the oil level window (E). The tank should be filled up

when the level is below the MIN mark.

• Do not use dirty, used or

contaminated oil. The oil pump, the bar or the chain

might get damaged.

• Clean the surface around the oil tank cap to avoid

contamination.

• Loosen slowly the oil tank cap.

• By carefully avoiding spills pour oil in the tank with the help

of an oil funnel.

• Before re-capping the oil tank, check and clean the joints.

• Place immediately the oil tank cap and tighten by hand.

• Clean any spilled oil.

CAUTION

Oil Supply for Cut Bar and Chain

E

ENGLISH

• Never start the motor before having

first assembled the cut bar, chain and chain cover.

Otherwise, the operator would be exposed to severe

personal injury.

• Set the switch in the off position.

• Pull back the chain brake to be sure it is in the operating

position (see page 8).

• To handle the chain safely and to avoid

cuts, use heavy-duty protective gloves.

• Loosen the knob to fasten the chain cover (D).

• Remove the chain cover (E).

• Set the chain flat on a flat and clean surface making an

oval shape near the cut bar and straighten any crooked

link. The cutting teeth should face the chain movement

direction, otherwise reverse the chain position.

Traction

Sprockets

Streighten

Displacement Direction

Cut

Sprockets Advance

Slot

Advance

Cut Bar

Bar and Chain Assembly

10

WARNING

CAUTION D

E

• Set the chain traction sprockets in the bar groove.

• Place the chain so that is set loose in the rear side of the

bar.

• Lift the bar with the chain and set it into the saw. Pass

the mounting knob (F) through the bar groove and the

loose space between the bar and the chain around the

sprocket wheel (G). Upon setting the bar in the knob,

double check that the tension pin enters into the

corresponding orifice in order to tighten the chain (H).

• Mount the chain cover and tighten the knob just a

little bit to secure the chain cover. This way the bar is

released and then you can proceed with the chain

tightening.

Loose Chain

Adjusted Chain

Right tightness with

dilated chain

Bar and Chain Assembly

11

F

G H

Chain Tightening

• Turn the chain tightening knob until the chain is snug

against the bar and with the traction links inserted in the

bar groove.

• Lift the nose of the cut bar to look for any looseness in

the chain. If so, turn the knob again ½ turn to give more

tension to the chain. Repeat this process until no

looseness is present between the chain and the bar.

• Tighten the knob firmly to secure the chain cover.

• To verify if the chain is not too tight, try moving it by

hand. If the chain gets stuck or is hard to move you need

to slightly loosen the knob to tighten the chain, only ¼ of

a turn. Lift the nose of the bar and tighten back the knob

to secure the chain cover before checking again the chain

tightness.

• To verify if the tightness of a chain that was dilated by the

heat produced while cutting is adequate, the distance

between the lower side of the cut bar and the chain links

must be 0.05” (3).

30.05”

When tensing a hot chain, it can tighten in

excess when it cools down. Verify the “cold tension”

before using it again.

ENGLISH

NOTICE

12

Start Up

A

• Use the cable holder (A) to prevent the chainsaw will

get unplugged accidentally from the extension cable while

in use.

• Make a loop in the extension end and pass it through

the orifice in the rear handle base.

• To secure it, pass the cable holder through the loop and

pull the extension out off the handle.

• Connect the chainsaw to a 1-outlet 16 AWG heavy duty

extension cord.

Connection

• Double check the chain is not making contact with any

object.

• Connect the extension cable plug to the power supply.

• Keep the switch lock pressed (C) to unblock it (B).

The switch block prevents accidental startups.

• Press the switch lock (B) so that the chain starts

advancingr.

Turning ON

• To stop the chain, release the trigger switch (B).

• It is normal that the chain keeps moving a couple of

seconds after releasing the trigger switch. As an additional

safety measure, activate the chain brake (see page 8).

Turning OFF

C B

ENGLISH

Cut Axis

13

Cutting Operation

Basic Cutting Procedures

If you lack of previous experience using chainsaws and to

get familiar with its use, it is recommended to practice

sawing small logs (not smaller than 8” in diameter),

supported by a sawhorse and using the following

technique:

• Adopt a right posture facing the log. The chainsaw

should be idle.

• Press the throttle trigger to get to the highest speed.

• Start cutting setting the bar onto the log.

• Keep the motor in high speed all the time.

• Allow the chain to do its job applying slight pressure

downwards with the chainsaw. Never try to force the cut.

Otherwise, the chain, bar or motor might get damaged.

• Release the trigger switch as soon as finishing the cut.

You will avoid unnecessary wear in the chain, bar o motor.

Cutting Correct Position

• Both feet should be evenly set on firm ground. Your

body weight well balanced. The left foot should be slightly

forward from your right foot.

• Hold the chainsaw as indicated in the Safety Standards

for chainsaws section (page 5).

• Keep your right arm straight; to stand the kickback

forces do not bend your elbow.

• Always keep the cut axis to your right; it keeps your

body free from the cut axis in case of kickback.

• To avoid tension in arms and back, keep the chainsaw

close to your body.

• Do not try to hold the chainsaw in a left-handed

position.

Cut Axis

Left arm straight

Cut Axis

ENGLISH

Debris Area

First Cut

Third

Cut

Notch

Wedge

Hinge

Second Cut

45°

40°

180°

45°

Felling and Bucking

14

Preparations to Fell

• Set ahead at least two escape paths. Clear the area from

any obstacle. The optimal escape path is 180° opposite to

the falling tree direction and with a 45° margin in both

sides.

• To estimate the how the tree will drop,

consider wind force and direction. Examine

the tree’s inclination and balance as well as

placement of the largest branches.

• Verify the tree has no dead branches,

which could fall onto you while cutting.

How to Fell Trees

• Cut a notch 1/3 of the trunk diameter on the side of the

tree in the direction of falling.

• The notch takes two cuts. The first one is horizontal and

the second one at 40°.

• It is important to make the cuts in that

order to avoid wood residues pinching and trapping the

bar and being shot with force onto any direction.

• The third cut is made opposite to the notch side. Must

be horizontal and placed at 2” above the horizontal cut in

the notch but not reaching it. Leave 1/10 diameter of trunk

between the notch and the third cut to make a “hinge”.

This guides the falling tree and avoids unexpected

trajectories or violent separation from its stump.

• To avoid the uncontrolled falling of the

tree, never reach the notch with third cut.

• When cutting trees with a large diameter, stop the rear

cut before reaching such a depth that will make the tree

to sit and trap the bar.

• Before going on with the cut, fit a plastic or wood wedge

into the cut to keep it open.

Felling Restrictions. Do not attempt this EVER!

• Do not cut down trees under heavy rain or while strong winds are blowing. Wait for suitable weather.

• Do not cut down trees when people or animals are in the area. The safe distance standards for passersby are explained

in “When Using the Chainsaw” on the Safety Standards for Chainsaws section; page 6.

• Do not cut down trees without estimating first an escape path. Avoid getting crushed by the felled tree!

• Do not cut extremely slender trees.

• Do not cut big trees with dead branches, loose bark or hollow trunks.

Professional loggers operating heavy log pushing or dragging equipment is needed.

• Do not cut trees near power lines or buildings.

Felling Route

Safest Escape Path

Limits for Felling Trees. Leave this job to professionals!

E

s

c

a

p

e

S

c

o

p

e

CAUTION

CAUTION

• Inserting the wedges may be enough to the tree.

Otherwise you need to insert the bar nose to continue to

cut without removing the wedges until the “hinge” is

made.

• Introducing the bar nose into the cut

must be performed only by professionals.

• Once the tree starts to fall, turn off the saw and

immediately set it on the ground. Move down your

optimal escape path. Be alert all the time in case of

contingency.

• While making the third cut pay

attention to the behavior of the crown to verify the tree

falls in the programmed direction. If for any reason the

tree starts falling in the wrong direction or the chainsaw is

pinched in the falling tree, drop it and run for your life!

WARNING

WARNING

F

a

l

l

i

n

g

r

o

u

t

e

1/3 of

theTrunk

1/10 of the trunk

2”

ENGLISH

• While cutting large trunks it is useful to use wedges into

the cut to prevent the bar from being pinched by the

trunk when it sits into place.

• If the trunk diameter is too large, it will be necessary to

fit the bar nose into the trunk to keep on cutting without

removing the wedges until finishing.

Introducing the bar nose into the cut

must be performed only by professionals.

• Bucking is when cutting a tree limb after being felled.

• While bucking, cut only one trunk at a time.

• To cut small branches support them on a sawhorse or

between two larger trunks.

• If the ground in the bucking area is

uneven stand in the higher side to avoid being run over

by the cut branches.

• Stay alert all the time. Oftentimes it is

difficult to predict the direction the branches will take

when cut. Also, sometimes it is not possible avoid the bar

from being pinched.

First Cut

Second Cut

Anchor Root

Sawhorse

Wedge

Load

Load

Felling and Bucking

15

Anchor Root Cutting

• Anchor roots are those roots that stick out too much

from the ground. When they are too big may make the

felling job too difficult. They must be removed before

felling.

• First, make a horizontal cut through the root, some

centimeter up the ground.

• Then make a downward vertical cut and leveled to the

trunk to separate the root and to the bar from being

pinched.

• It is important to make the cuts in that

order to avoid wood residues pinching and trapping the

bar, and being shot with force onto any direction.

WARNING

WARNING

WARNING

CAUTION

Bucking

Bucking with a Wedge

• Make the first cut at 1/3 depth of the trunk diameter. Then make a 2/3 depth cut on the opposite side. See the diagram to

determine where to make the first cut and to avoid the bar from being pinched by the trunk weight.

Bucking Trunks under Tension

First Cut

(1/3)

Final

Cut

Final Cut

First Cut

(1/3)

ENGLISH

Bucking the

Top of the Trunk Bucking Below

the Trunk

Reaction Reaction

16

Felling and Bucking

Cutting Branches and Pruning

T

e

n

s

i

o

n

R

e

l

e

a

s

e

Bucking the Top of the Trunk

• Setting the lower side of the bar against the trunk, start

cutting the upper side of the trunk.

• Apply pressure downwards.

• Stay alert to the chainsaw reaction force. It

will pull it towards the trunk.

• Felling, the same as trimming and pruning, should be

done slowly and very carefully and following the Safety

Standards (see pages 5 and 6).

• When cutting a branch keep the tree between you and

the chainsaw.

• Never cut branches standing on top of

a ladder, hanging from the tree or standing onto a

platform or trunk. It is extremely dangerous. Let the

professional people take care of the branches you cannot

reach standing on the ground and above your chest.

CAUTION

Bucking Below the Trunk

• Setting the upper side of the bar against the trunk, start

cutting the lower side of the trunk.

• Apply slight pressure upwards.

• Stay alert to the chainsaw reaction force. It

will pull it towards the trunk.

Cutting Operation

• To avoid the falling branch to pull out the bark from the

tree do not cut level with the trunk.

• Make the first cut at 1/3 depth of the branch diameter.

Then make a second cut at 2/3 depth of the branch

diameter in the opposite side.

• Finish cutting the branch with a third cut, this time level

with the trunk to allow the bark to grow back and seal the

cut.

• When the branch is too thick cut sections to avoid a

violent detachment.

Spring Poles

• Spring poles are any trunk, branch or young tree being

held down by the pressure of a second trunk or branch,

accumulating tension and releasing great force if the

pressure is released.

• Spring poles are very dangerous. They

can hit the operator causing severe injury and/or causing

to lose control of the chainsaw. Be always aware of that

possibility.

CAUTION

DANGER

DANGER

First Cut

(1/3) deep

Spring Pole

Final

Cut

Second cut

(2/3) deep

Load

ENGLISH

Chainsaw Chain Maintenance

Sharpening of the Chain

• The chain needs sharpening if the wood shavings

generated when cutting are small and dusty; when

needing to force the bar trough the wood or when the

chain is cutting sideways.

• Sharpening of the chain must be done with the chain

mounted and tight on the bar (see page 11) and with the

chainsaw shut off.

• Use a 5/32” round file.

• Be careful to file all the teeth to the

angles specified in the image being careful to give them

the same length. Only uniform teeth get a safe and right

cut.

• Sharpen all the teeth, one by one. First those on the

right side, then, those on the left side. To travel from one

tooth to the other move the chain little by little so each

time you file a tooth it should sit in the middle of the bar.

• Keep the file level with the upper top-plate in the tooth.

Keep the file from leaning or balancing. Apply slight but

firm pressure moving only to the front of the tooth.

Remove the file each time you move back.

• Give each tooth a few passes.

• Remove the steel shavings produced while filing with a

wire brush.

• Using the chainsaw with a badly

sharpened or dull chain at high speed could damage the

motor.

• Operating the chainsaw with the

wrong or blunt chain increases the risk of kickback.

• Using the chainsaw with a damaged

chain may cause severe injury.

• The chain is very sharp. Use

heavy-duty protective gloves.

• If the cutting chain is dull due to

contact with nails, stones or sand and mud present in the

wood, have it re-sharpened by a

Authorized Service Center.

• To make smooth and fast cuts, the cutting chain needs

maintenance periodically.

• Shut off the chainsaw before maintenance and service.

• Use heavy-duty protective gloves.

17

Adjustments and Maintenance

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

Top Plate Top Plate

Right Hand

Cutting Edge

Top Plate

Cutting Edge

Top Plate

Cutting Edge

Left Hand

Cutting Edge

Toe

Chain Axis Chain Axis

Chain Direction

Rivet

Depth

Gauge

Groove Groove

Basic

Tooth

Body

Basic

Tooth

Body

Heel Heel

Toe

Depth

Gauge

Right Hand

Cutter Link

Top Plate

Cutting Edge

Correct Filing Angle

Filing

Direction

Left Hand

Cutter Link

30°

30°

80°

Any angle different from the one

specified causes damage to the motor, bar and chain, and

increases the risk of violent kickback.

ENGLISH

Direction

Cutting Link

Depth Gauge Depth

Gauge

Flat

File

Depth Gauge

Jointing Tool

Adjustments and Maintenance

18

A

B

Chain Depth Gauge

Bar Maintenance

• The chain has cleaning teeth (Depth Gauge) placed in

front of each tooth. Their design avoids getting too deep

into the wood getting pinched and causing kickback.

• Depth gauges should be checked each time you file the

chain in order to get the correct height in the top plate.

• The difference in height on the depth gauge and the top

plate should always be 0.025”.

• If due to normal wear / or filing of the chain the

difference is less, use a calibrating instrument and a flat

file to even and verify the difference to 0.025”.

• File only the depth gauges. Do it towards the same

direction as of the adjacent tooth being careful not to

touch its cutting edge.

• After matching the difference on all the cleaning teeth,

file each one and restore the original rounded shape (A).

• The cutting bar has to be cleaned in the end of the work

day and checked closely to identify wear and possible

damage.

• The appearance of minute grooves or bumps in the bar

rails is due to normal wear and should be smoothed

down with a file as soon as identified.

• Clean debris from the lubrication orifice and the chain slot.

• After a week working with the chainsaw, reverse the bar to

distribute its normal wear and maximize its useful life (B).

• After a week working with the chainsaw lubricate the bar

if it has a sprocket wheel in the nose. Use a grease syringe

to apply the lubricant into the lubrication orifice.

• If the rail has such wear that is not allowing the chain to

rest in its side, if widened or broken; or the bar is bent,

replace it with a new one.

0,025”

ENGLISH

Adjustments and Maintenance

19

Troubleshooting

Chainsaw Storage

Carbon Replacement

When storing the chainsaw for a month or longer

consider the following:

• Drain the bar and chain oil tank completely into an

approved oil container.

• Clean the chainsaw thoroughly.

• Store the unit in a ventilated area, away from corrosive

agents such as garden chemical products or deicing salts.

Keep it away from children.

Lubrication

The tool bearings have high grade lubricant and when

used under regular conditions it lubricates for life. No

lubrication needed.

• Never try to start the motor if ALL the

chainsaw parts are not assembled in place. Otherwise, the

parts may fracture and be shot towards the operator. It

also damages the tool and makes the warranty void.

WARNING

• Remember to disconnect the tool before cleaning or

maintenance.

• All the tool components are an important part of the

insulating system and should only receive maintenance in

a Authorized Service Center.

• EVERY TIME you service the tool ask for original

spare parts.

• When cleaning the plastic parts, do not use solvents.

Most of the plastic materials are susceptible to damage

when using commercial solvents.

• To clean sooth, coal or dust; use a clean cloth or

pressurized air.

A DVERTENNEVER expose to brake fluid,

petroleum based products, penetrating oils, etc. They are

made of chemical substances that could damage or

destroy plastic.

When using pressurized air to clean

particles ALWAYS use safety eyeglasses with lateral

protection or a facemask. If there is too much dust, use a

dust mask as well.

• It is not advisable to use this tool for large jobs with

fiberglass, gypsum wallboard, plaster or gypsum. Their

particles are highly abrasive to components on any power

tool.

• Check periodically the carbons. If worn have them

replaced in a Authorized Service

Center. After being replaced, ask to check if the new

carbons can move freely in the carbon housing. Ask to

turn on the tool during 5 minutes’ to even the contact of

the carbons with the commuter.

• Use only original spare carbons designed specifically with

the electric roughness and resistance for each type of

motor. Carbons that are out of specification may damage

the motor.

• When replacing carbons, always replace both.

WARNING

WARNING

Bar and chain are too

hot and give off

smoke.

The motor starts and

runs but the chain is

not moving.

The motor starts and

runs; the chain moves

but is not cutting.

• The oil tank in the chain is empty.

• Too much tension in the chain.

• The chain brake is activated.

• Too much tension in the chain.

• The chain and the cutting bar are not

properly assembled.

• The chain and / or bar is damaged.

• The chain is dull.

• The chain is assembled the wrong way.

• Fill up the oil tank. Remember too fill up every

time the level is below the “MIN” mark.

• Reduce the chain tension. (See page 11).

• Release the chain brake. (See page 8).

• Reduce tension in the chain. (See page 11).

• Chain and bar need to be assembled correctly.

(See pages 10 and 11).

• Replace and assemble similar chain and / or bar.

• File the chain. (See page 17).

• Assemble the chain in the right direction.

Problem Cause Solution

ENGLISH

20

Notes

ENGLISH

This manual suits for next models

1

Table of contents

Other Truper Chainsaw manuals