U s e A n d M a i n t e n a n c e I n s t r u c t i o n s

Ch a r g e D i s p l a c e m e n t P ro b e E 9 T r b F o r D u s t C o n t r o l

8 T U R B O s . r . l .

D u s t F i l t e r C o m p o n e n t s

V i a P o / 5 2 0 8 1 1 C e s a n o M a d e r n o ( M B ) I t a l y T e l + + 9 0 6 2 5 7 4 0 2 4 F a x + + 9 0 6 2 5 7 4 0 9 2

I n M n 2 5 S T S C

R e v . 0 0 e n

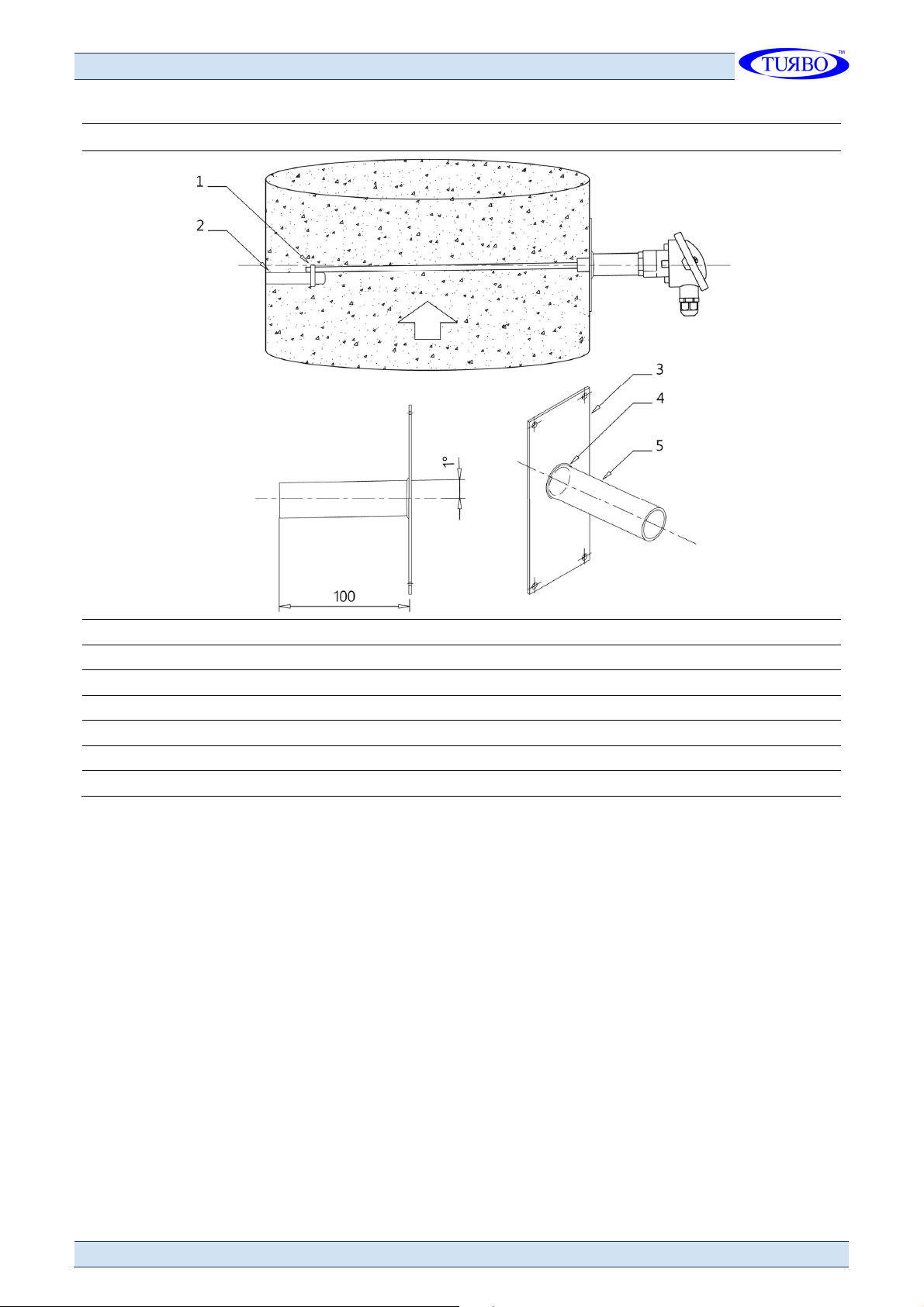

Accessories

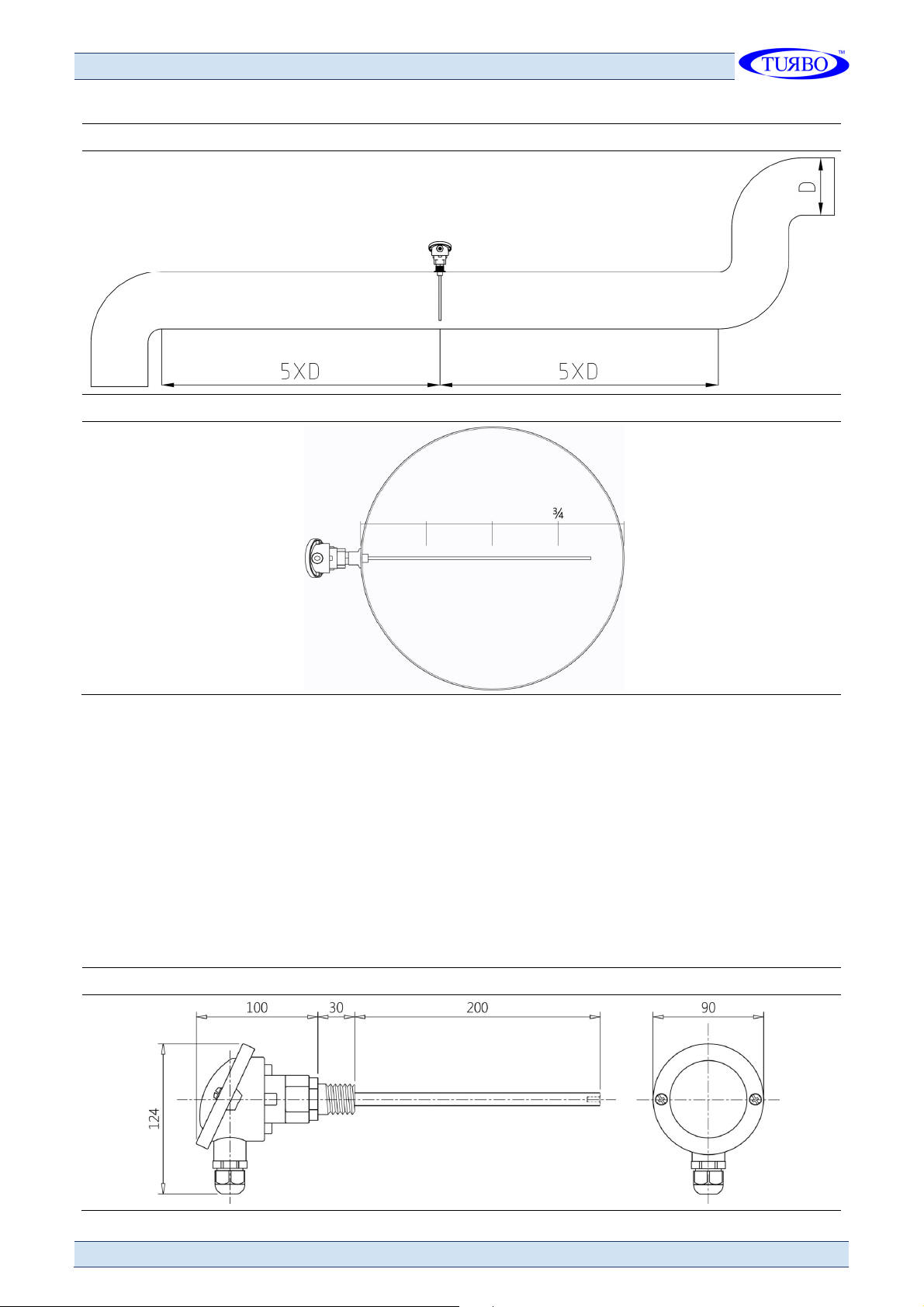

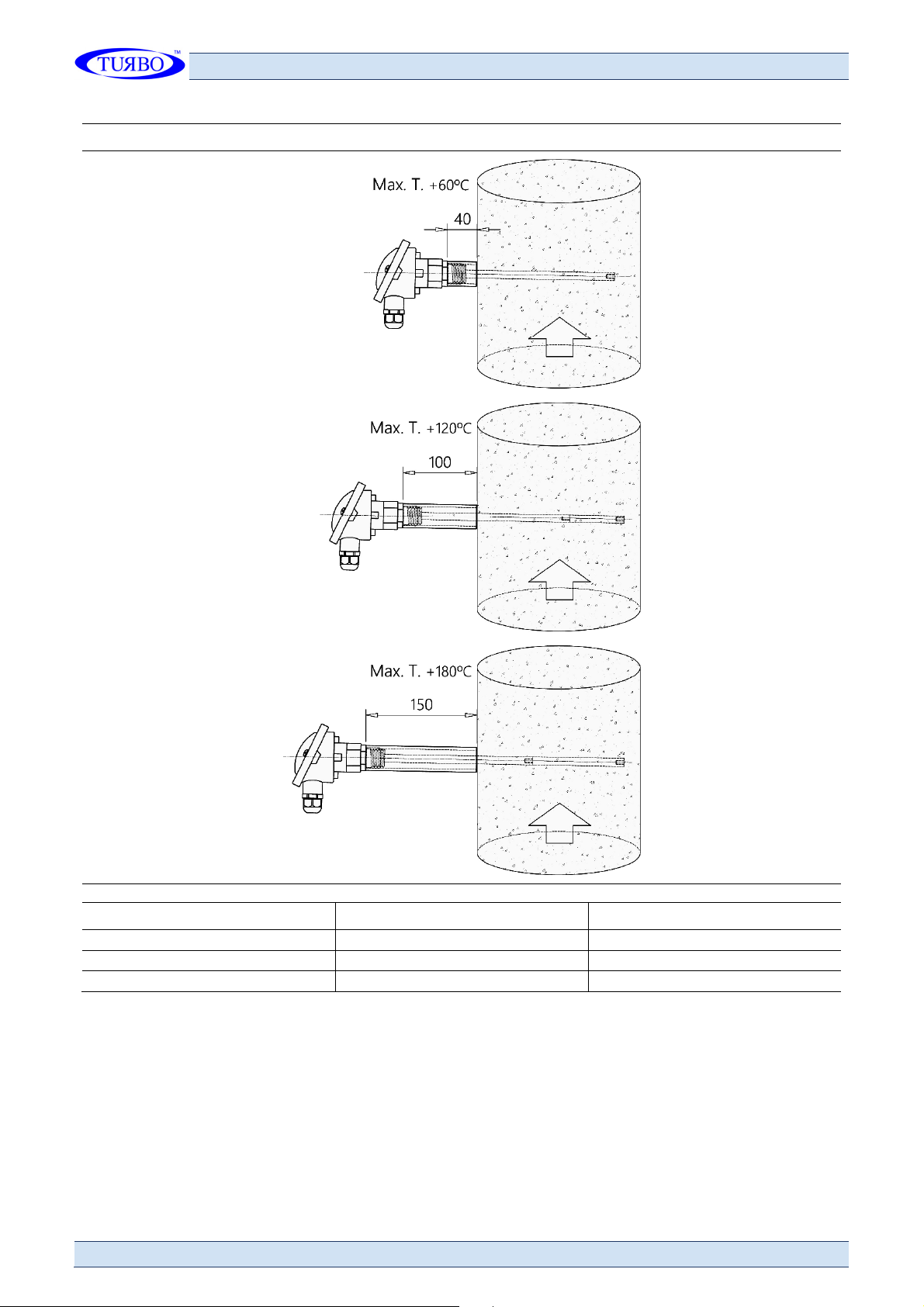

Ex tension s nd dapt atio ns For El ectrode I ns ta ll atio n On Pi pelines Of Variou s Diame te rs

Le ng h t

100 m m

200 m m

400 m m

Th r e ad M4 m 10 mm

Ma te r i al

d. 8 m m

The extensions of the electrodes must be joined together using a medium

strength thread locker to prevent loosening due to vibration, shock and

temperature fluctuations.

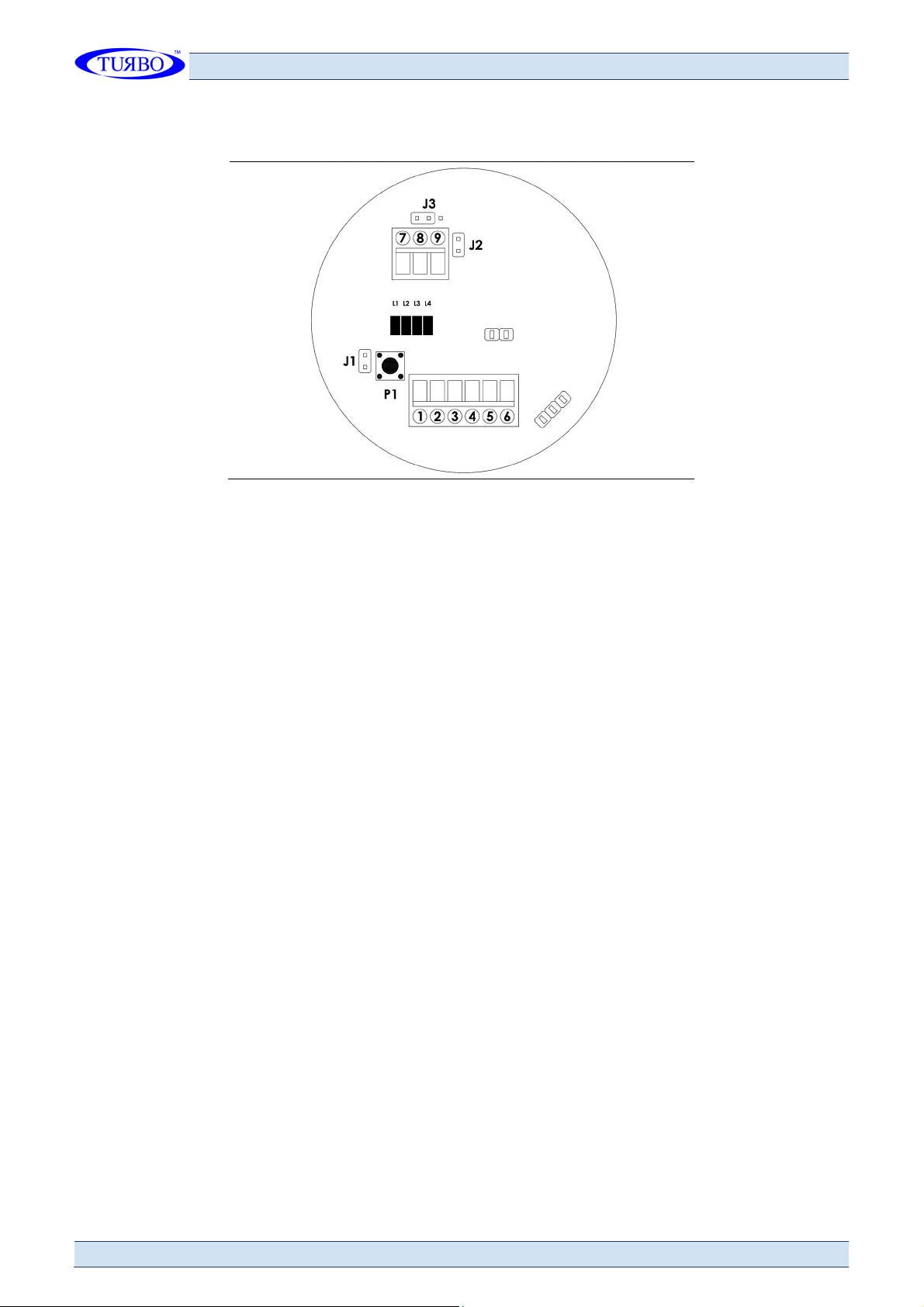

Startup

After powering up the probe and verified the green led L1, it is necessary to wait

for a warm-up time of minutes, during which the probe is measuring but the

outputs are disabled.

After this period of time, if the jumper J1 is left OFF, disengaged, the probe will

operate in manual mode with preset thresholds from the default settings.

If the jumper J1 is inserted, the probe will work with thresholds set

automatically. in this condition, the probe will wait for the press of the button

P1, this state will be indicated by the led L2 mode "a" that is slowly blinking.

To start the self-acquisition: hold down P1 button for 5 seconds, the led will light

steadily L2 (mode "b"), and wait until the led turned off after about 4 minutes,

at this point the acquisition will be completed and the values will be stored in a

solid-state memory, which will keep them even if the probe will be de-energized.

N. B . v al ue s a r e, obtai ne d for t he pr o b e , th e r efe renc e for t h e a c t i v at io n o f t h e o ut p ut s , the n b e

und er s to od a s o p er at i ng va l ue s w it h "r eg u l a r " q uan tit y o f d us t, s o i t i s re co m m en d ed to p er fo r m

the s el f- ac q uis i ti on by c ho o s i ng the m o m e nt con s id er e d m o s t s uit ab le du r i ng pr oc es s in g .

If you want to store new values (eg. changes of working conditions), run new self-

acquisition by pressing P1 as described above.