i

Table of contents

1. Technical Information ......................................................................................................... 1

1.1. Coils Information ......................................................................................................... 1

1.2. Tool Intented Use ........................................................................................................ 1

1.3. Working conditions ..................................................................................................... 1

1.4. Fan Information ........................................................................................................... 2

2. Transport and Storage ......................................................................................................... 2

2.1. Transport ..................................................................................................................... 2

2.2. Storage......................................................................................................................... 3

3. Installation and Location ..................................................................................................... 4

3.1. Installation ................................................................................................................... 4

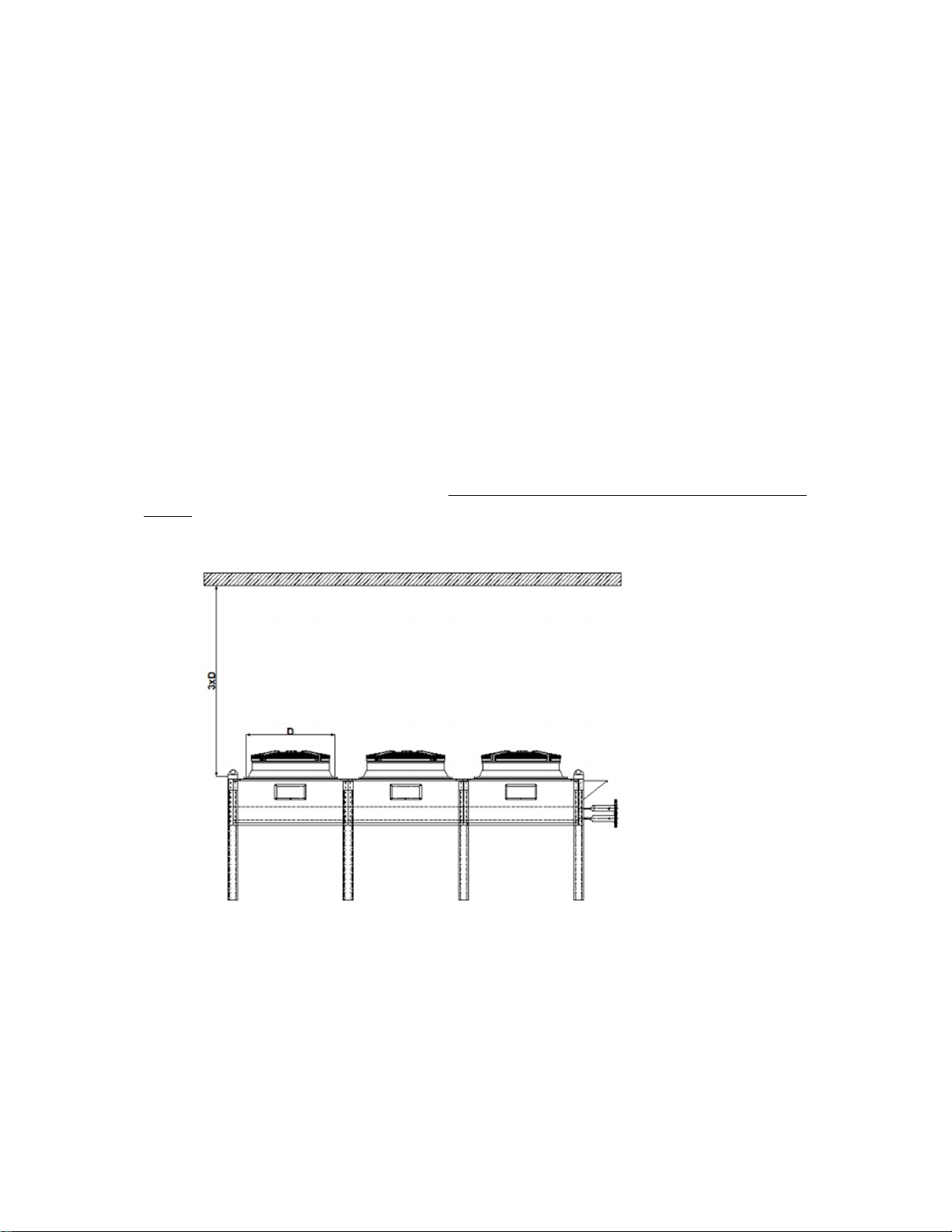

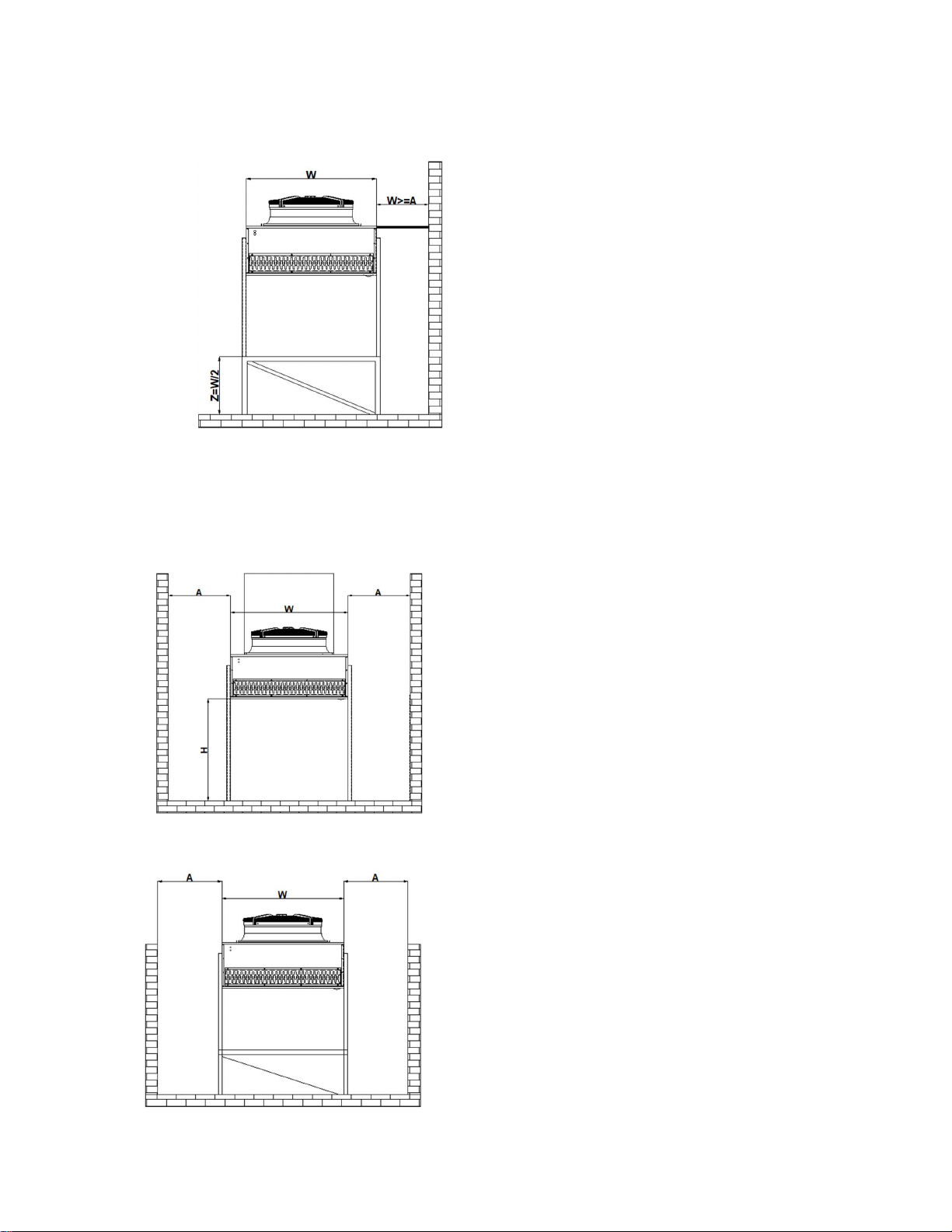

3.1.1. Horizontal Use of Products .................................................................................... 4

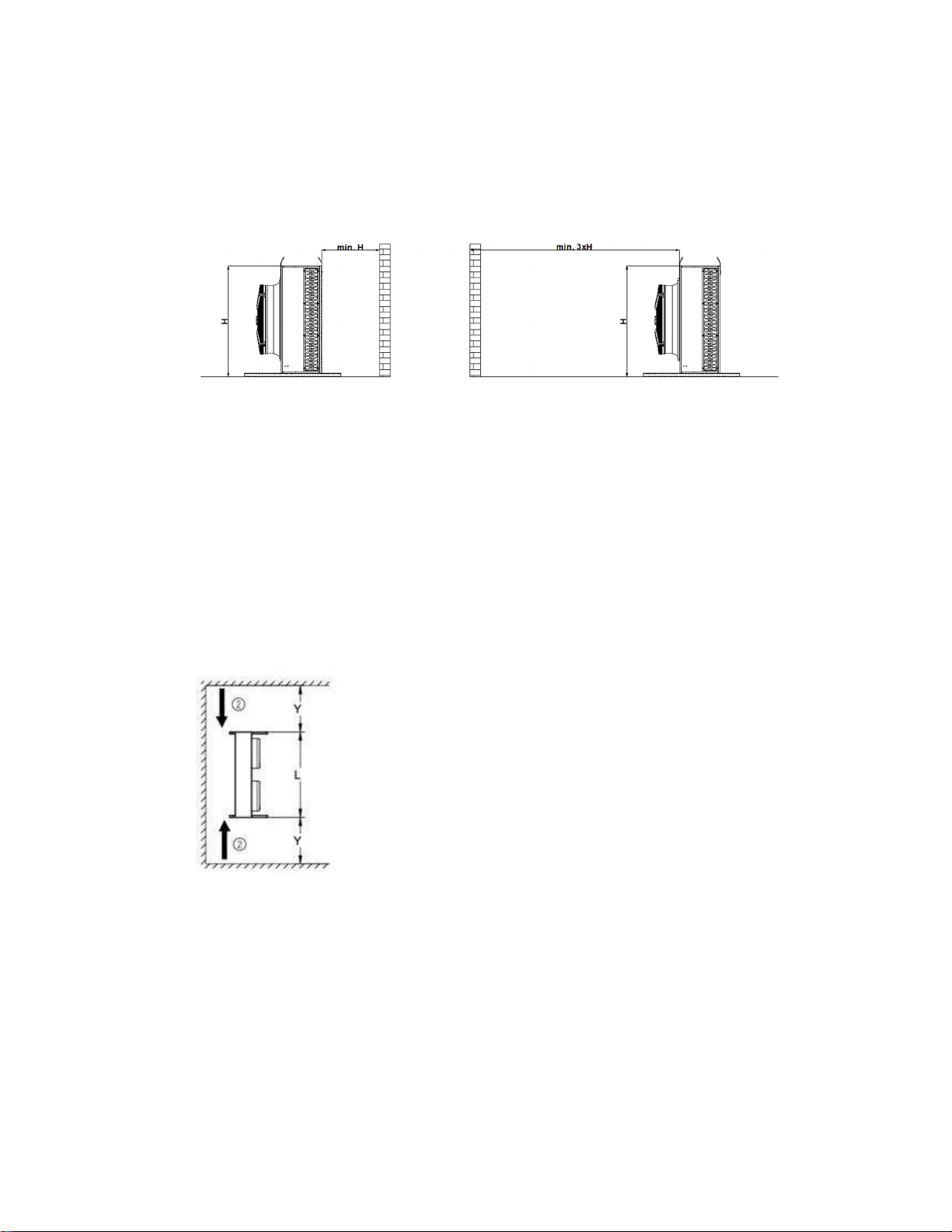

3.1.2. Vertical Use of Products ........................................................................................ 7

3.2. Installation and Assembly ............................................................................................ 8

3.2.1. Leg Installation ...................................................................................................... 8

3.3. Test and Final Control .................................................................................................. 8

4. First Run ............................................................................................................................... 8

5. Maintenance and Cleaning .................................................................................................. 9

5.1. Maintenance of Fans ................................................................................................... 9

5.2. Checking the Unit Battery Section ............................................................................... 9

6. Troubleshooting ................................................................................................................ 10

7. Electrical Wiring Diagrams ................................................................................................. 11

7.1. Fan Connection .......................................................................................................... 11