8

Chain Tension

Air Powered Chain Saw

Air Saws • Gas Saws • Pipe Saws • Concrete Saws • Hydraulic Saws

Diamond Blades • Abrasive Blades • Diamond Wire • Electroplated Blades

Quality Saws, Blades, and Services

1 866 987 7297

Visit our website at www.ussaws.com

3317 W. Warner Avenue 11 High Street 8004B E Broadway Ave

Santa Ana, CA 92704 Sufeld, CT 06078 Tampa, FL 33619

Local 714 434 7297 Local 860 668 2402 Local 813 621 8015

Fax 714 434 7299 Fax 860 668 2404 Fax 813 621 7125

01312013

IMPORTANT

A properly tensioned chain will optimize cutting performance. The tensioning rule of thumb for

a concrete cutting chain saw is that a properly tensioned diamond chain must not be bowstring

tight and can be pulled freely around the guide bar by hand easily without binding.

PROPER CHAIN TENSION

If the chain is too loose, it could come off the bar, or it will allow the drive

sprocket to spin without turning the chain, which can chew up the chain drive

links. If the chain is too tight, a lot of the saw’s power goes into turning the

chain rather than into the cut. In extreme over-tightened cases, the saw may not

be able to turn the chain at all. In addition, damage can occur to the bar nose

and premature stretch may occur.

HOW TO CHECK

Before cutting, check for proper tension by pulling the chain around the bar

by hand. If you cannot easily pull by hand, the chain is too tight and needs to

be loosened.

WHEN TO TENSION

All chains have a tendency to stretch when used. Diamond chains stretch

more than wood cutting chains because of the abrasive materials they are

cutting. When a chain stretches to a point where the drive links are hanging

approximately 1/2 in- 3/4 in (12 - 18 mm)below the bar, it’s time to tension

the chain.

HOW TO TENSION

To tension the chain, first loosen the side cover nuts, then while holding the nose of

the bar up, use a screw driver to turn the tensioning screw clockwise until the chain

drive links hanging below the bar are just beginning to enter the bar groove. Continue

to hold up on the nose of the bar and firmly tighten the side cover nuts, (20 ft-lbs,

27 Nm). And remember, it’s the side cover nuts that hold the bar in position.

HOW TO PREVENT CHAIN TENSIONER BREAKAGE

Do not attempt to adjust the tensioner without first loosening the side cover nuts. Do

not use the saw without making sure the side cover nuts are tight. If the side cover nuts

are not tight, the bar can slip backwards during cutting and break the tensioner pin.

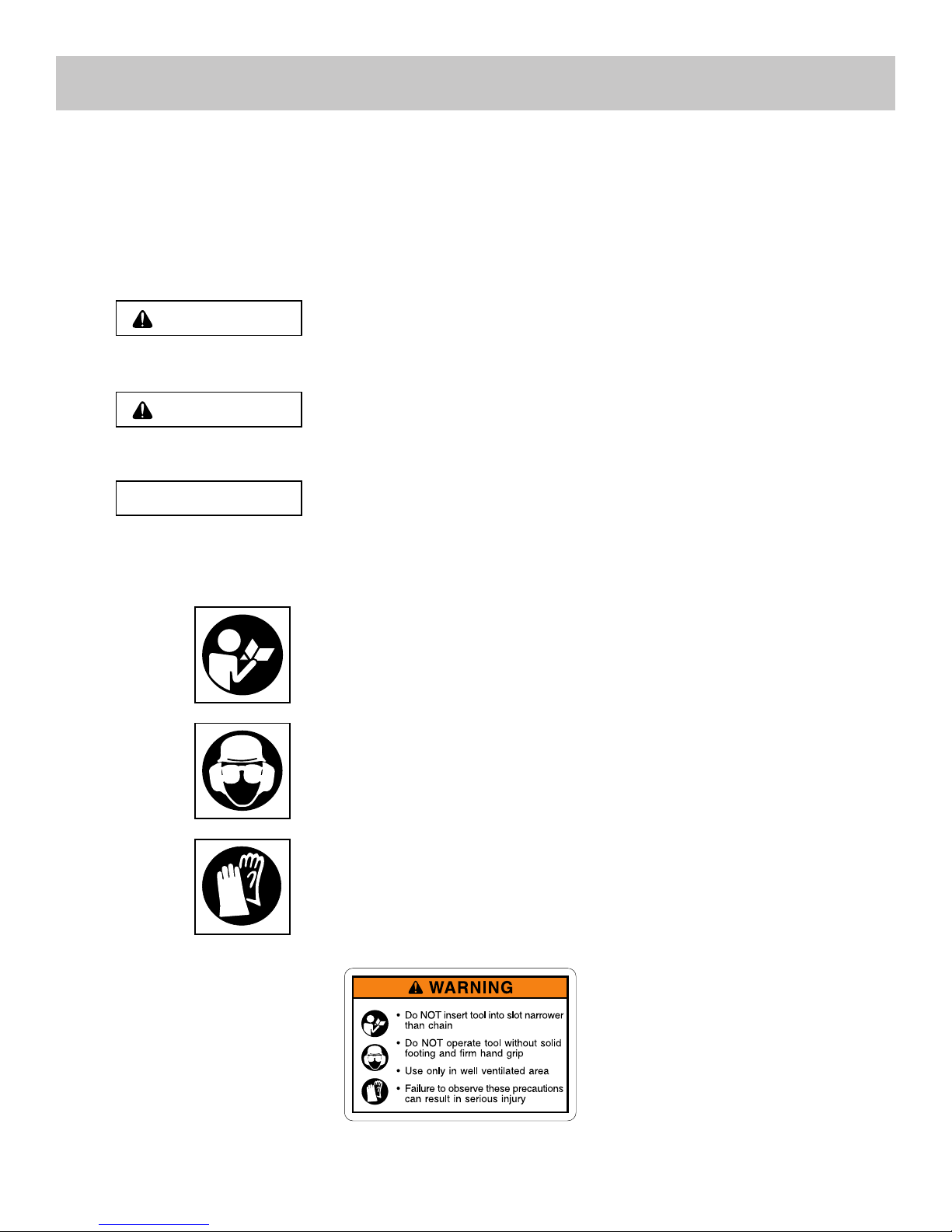

correct chain tension

chain chain

too loose too tight

Proper Chain Tension

If the chain is too loose, it could come off the bar, or it will

allow the drive sprocket spin without turning the chain

which can damage the chain drivel inks. If the chain is

too tight, much of the saw’s power goes into turning the

chain rather than into the cut. In extreme over-tightened

cases, the saw may not be able to turn the chain at

all. In addition, damage can occur to the bar nose and

premature chain stretch may occur.

How To Check

Before cutting, check for proper tension by pulling the

chain around the bar by hand. If you cannon easily pull by

hand, the chain is too tight and needs to be loosened.

When to Tension

All chains have a tendency to stretch when used.

Diamond chains stretch more than wood cutting chains

because of the abrasive materials they are cutting. When

a chain stretches to a point where the drive links are

hanging approximately 1/2 inch to 3/4 inch below the

bar, it’s time to tension the chain.

How to Tension

To tension the chain, rst loosen the side cover nuts, then

while holding the nose of the bar up, use a screwdriver to

turn the tensioning screw clockwise until the chain drive

links hanging below the bar are just beginning to enter

the bar groove. Continue to hold up on the nose of the bar

and rmly tighten the side cover nuts. And remember, it’s

the side cover nuts that hold the bar in position.

How to Prevent Chain Tensioner Breakage

Do not attempt to adjust the tensioner without rst

loosening the side cover nuts. Do not use the saw without

making sure the side cover nuts are tight. If side cover

nuts are not tight, the bar can slip backwards during

cutting and break the tensioner pin.

Air Saws • Gas Saws • Pipe Saws • Concrete Saws • Hydraulic Saws

Diamond Blades • Abrasive Blades • Diamond Wire • Electroplated Blades

Quality Saws, Blades, and Services

1 866 987 7297

Visit our website at www.ussaws.com

3317 W. Warner Avenue 11 High Street 8004B E Broadway Ave

Santa Ana, CA 92704 Sufeld, CT 06078 Tampa, FL 33619

Local 714 434 7297 Local 860 668 2402 Local 813 621 8015

Fax 714 434 7299 Fax 860 668 2404 Fax 813 621 7125

01312013

IMPORTANT

A properly tensioned chain will optimize cutting performance. The tensioning rule of thumb for

a concrete cutting chain saw is that a properly tensioned diamond chain must not be bowstring

tight and can be pulled freely around the guide bar by hand easily without binding.

PROPER CHAIN TENSION

If the chain is too loose, it could come off the bar, or it will allow the drive

sprocket to spin without turning the chain, which can chew up the chain drive

links. If the chain is too tight, a lot of the saw’s power goes into turning the

chain rather than into the cut. In extreme over-tightened cases, the saw may not

be able to turn the chain at all. In addition, damage can occur to the bar nose

and premature stretch may occur.

HOW TO CHECK

Before cutting, check for proper tension by pulling the chain around the bar

by hand. If you cannot easily pull by hand, the chain is too tight and needs to

be loosened.

WHEN TO TENSION

All chains have a tendency to stretch when used. Diamond chains stretch

more than wood cutting chains because of the abrasive materials they are

cutting. When a chain stretches to a point where the drive links are hanging

approximately 1/2 in- 3/4 in (12 - 18 mm)below the bar, it’s time to tension

the chain.

HOW TO TENSION

To tension the chain, first loosen the side cover nuts, then while holding the nose of

the bar up, use a screw driver to turn the tensioning screw clockwise until the chain

drive links hanging below the bar are just beginning to enter the bar groove. Continue

to hold up on the nose of the bar and firmly tighten the side cover nuts, (20 ft-lbs,

27 Nm). And remember, it’s the side cover nuts that hold the bar in position.

HOW TO PREVENT CHAIN TENSIONER BREAKAGE

Do not attempt to adjust the tensioner without first loosening the side cover nuts. Do

not use the saw without making sure the side cover nuts are tight. If the side cover nuts

are not tight, the bar can slip backwards during cutting and break the tensioner pin.

correct chain tension

chain chain

too loose too tight

Air Saws • Gas Saws • Pipe Saws • Concrete Saws • Hydraulic Saws

Diamond Blades • Abrasive Blades • Diamond Wire • Electroplated Blades

Quality Saws, Blades, and Services

1 866 987 7297

Visit our website at www.ussaws.com

3317 W. Warner Avenue 11 High Street 8004B E Broadway Ave

Santa Ana, CA 92704 Sufeld, CT 06078 Tampa, FL 33619

Local 714 434 7297 Local 860 668 2402 Local 813 621 8015

Fax 714 434 7299 Fax 860 668 2404 Fax 813 621 7125

01312013

IMPORTANT

A properly tensioned chain will optimize cutting performance. The tensioning rule of thumb for

a concrete cutting chain saw is that a properly tensioned diamond chain must not be bowstring

tight and can be pulled freely around the guide bar by hand easily without binding.

PROPER CHAIN TENSION

If the chain is too loose, it could come off the bar, or it will allow the drive

sprocket to spin without turning the chain, which can chew up the chain drive

links. If the chain is too tight, a lot of the saw’s power goes into turning the

chain rather than into the cut. In extreme over-tightened cases, the saw may not

be able to turn the chain at all. In addition, damage can occur to the bar nose

and premature stretch may occur.

HOW TO CHECK

Before cutting, check for proper tension by pulling the chain around the bar

by hand. If you cannot easily pull by hand, the chain is too tight and needs to

be loosened.

WHEN TO TENSION

All chains have a tendency to stretch when used. Diamond chains stretch

more than wood cutting chains because of the abrasive materials they are

cutting. When a chain stretches to a point where the drive links are hanging

approximately 1/2 in- 3/4 in (12 - 18 mm)below the bar, it’s time to tension

the chain.

HOW TO TENSION

To tension the chain, first loosen the side cover nuts, then while holding the nose of

the bar up, use a screw driver to turn the tensioning screw clockwise until the chain

drive links hanging below the bar are just beginning to enter the bar groove. Continue

to hold up on the nose of the bar and firmly tighten the side cover nuts, (20 ft-lbs,

27 Nm). And remember, it’s the side cover nuts that hold the bar in position.

HOW TO PREVENT CHAIN TENSIONER BREAKAGE

Do not attempt to adjust the tensioner without first loosening the side cover nuts. Do

not use the saw without making sure the side cover nuts are tight. If the side cover nuts

are not tight, the bar can slip backwards during cutting and break the tensioner pin.

correct chain tension

chain chain

too loose too tight

Air Saws • Gas Saws • Pipe Saws • Concrete Saws • Hydraulic Saws

Diamond Blades • Abrasive Blades • Diamond Wire • Electroplated Blades

Quality Saws, Blades, and Services

1 866 987 7297

Visit our website at www.ussaws.com

3317 W. Warner Avenue 11 High Street 8004B E Broadway Ave

Santa Ana, CA 92704 Sufeld, CT 06078 Tampa, FL 33619

Local 714 434 7297 Local 860 668 2402 Local 813 621 8015

Fax 714 434 7299 Fax 860 668 2404 Fax 813 621 7125

01312013

IMPORTANT

A properly tensioned chain will optimize cutting performance. The tensioning rule of thumb for

a concrete cutting chain saw is that a properly tensioned diamond chain must not be bowstring

tight and can be pulled freely around the guide bar by hand easily without binding.

PROPER CHAIN TENSION

If the chain is too loose, it could come off the bar, or it will allow the drive

sprocket to spin without turning the chain, which can chew up the chain drive

links. If the chain is too tight, a lot of the saw’s power goes into turning the

chain rather than into the cut. In extreme over-tightened cases, the saw may not

be able to turn the chain at all. In addition, damage can occur to the bar nose

and premature stretch may occur.

HOW TO CHECK

Before cutting, check for proper tension by pulling the chain around the bar

by hand. If you cannot easily pull by hand, the chain is too tight and needs to

be loosened.

WHEN TO TENSION

All chains have a tendency to stretch when used. Diamond chains stretch

more than wood cutting chains because of the abrasive materials they are

cutting. When a chain stretches to a point where the drive links are hanging

approximately 1/2 in- 3/4 in (12 - 18 mm)below the bar, it’s time to tension

the chain.

HOW TO TENSION

To tension the chain, first loosen the side cover nuts, then while holding the nose of

the bar up, use a screw driver to turn the tensioning screw clockwise until the chain

drive links hanging below the bar are just beginning to enter the bar groove. Continue

to hold up on the nose of the bar and firmly tighten the side cover nuts, (20 ft-lbs,

27 Nm). And remember, it’s the side cover nuts that hold the bar in position.

HOW TO PREVENT CHAIN TENSIONER BREAKAGE

Do not attempt to adjust the tensioner without first loosening the side cover nuts. Do

not use the saw without making sure the side cover nuts are tight. If the side cover nuts

are not tight, the bar can slip backwards during cutting and break the tensioner pin.

correct chain tension

chain chain

too loose too tight

Air Saws • Gas Saws • Pipe Saws • Concrete Saws • Hydraulic Saws

Diamond Blades • Abrasive Blades • Diamond Wire • Electroplated Blades

Quality Saws, Blades, and Services

1 866 987 7297

Visit our website at www.ussaws.com

3317 W. Warner Avenue 11 High Street 8004B E Broadway Ave

Santa Ana, CA 92704 Sufeld, CT 06078 Tampa, FL 33619

Local 714 434 7297 Local 860 668 2402 Local 813 621 8015

Fax 714 434 7299 Fax 860 668 2404 Fax 813 621 7125

01312013

IMPORTANT

A properly tensioned chain will optimize cutting performance. The tensioning rule of thumb for

a concrete cutting chain saw is that a properly tensioned diamond chain must not be bowstring

tight and can be pulled freely around the guide bar by hand easily without binding.

PROPER CHAIN TENSION

If the chain is too loose, it could come off the bar, or it will allow the drive

sprocket to spin without turning the chain, which can chew up the chain drive

links. If the chain is too tight, a lot of the saw’s power goes into turning the

chain rather than into the cut. In extreme over-tightened cases, the saw may not

be able to turn the chain at all. In addition, damage can occur to the bar nose

and premature stretch may occur.

HOW TO CHECK

Before cutting, check for proper tension by pulling the chain around the bar

by hand. If you cannot easily pull by hand, the chain is too tight and needs to

be loosened.

WHEN TO TENSION

All chains have a tendency to stretch when used. Diamond chains stretch

more than wood cutting chains because of the abrasive materials they are

cutting. When a chain stretches to a point where the drive links are hanging

approximately 1/2 in- 3/4 in (12 - 18 mm)below the bar, it’s time to tension

the chain.

HOW TO TENSION

To tension the chain, first loosen the side cover nuts, then while holding the nose of

the bar up, use a screw driver to turn the tensioning screw clockwise until the chain

drive links hanging below the bar are just beginning to enter the bar groove. Continue

to hold up on the nose of the bar and firmly tighten the side cover nuts, (20 ft-lbs,

27 Nm). And remember, it’s the side cover nuts that hold the bar in position.

HOW TO PREVENT CHAIN TENSIONER BREAKAGE

Do not attempt to adjust the tensioner without first loosening the side cover nuts. Do

not use the saw without making sure the side cover nuts are tight. If the side cover nuts

are not tight, the bar can slip backwards during cutting and break the tensioner pin.

correct chain tension

chain chain

too loose too tight