When first opening the slush machine, be very careful removing the machine from the

box. It is a heavy piece of equipment.

There is grease included for any of the moving parts in the machine. This grease

should be applied liberally to the spots where the mixer connects to the faucet, and

where it connects to the back of the machine. It should also be applied to the tube

inside the faucet assembly. There will already be grease on some of these parts, which

is the cause for any minor discoloration on the faucet or inside mechanisms.

Once the grease is applied, the machine is ready to use! It is a simple setup. Plug in the

machine, and you are ready to go!

It is important that the machine is set up in a place free of debris and clutter.

The floors should also be kept clear. Make sure hoses and wires for the machine

are all secured to avoid tripping hazards.

There are replacement gaskets included in the machine, as well as replacement parts

for the auger. These should not need to be replaced, but are included as a courtesy in

case of issues. The machine comes preassembled and pregreased.

IV. Setting Up the Machine

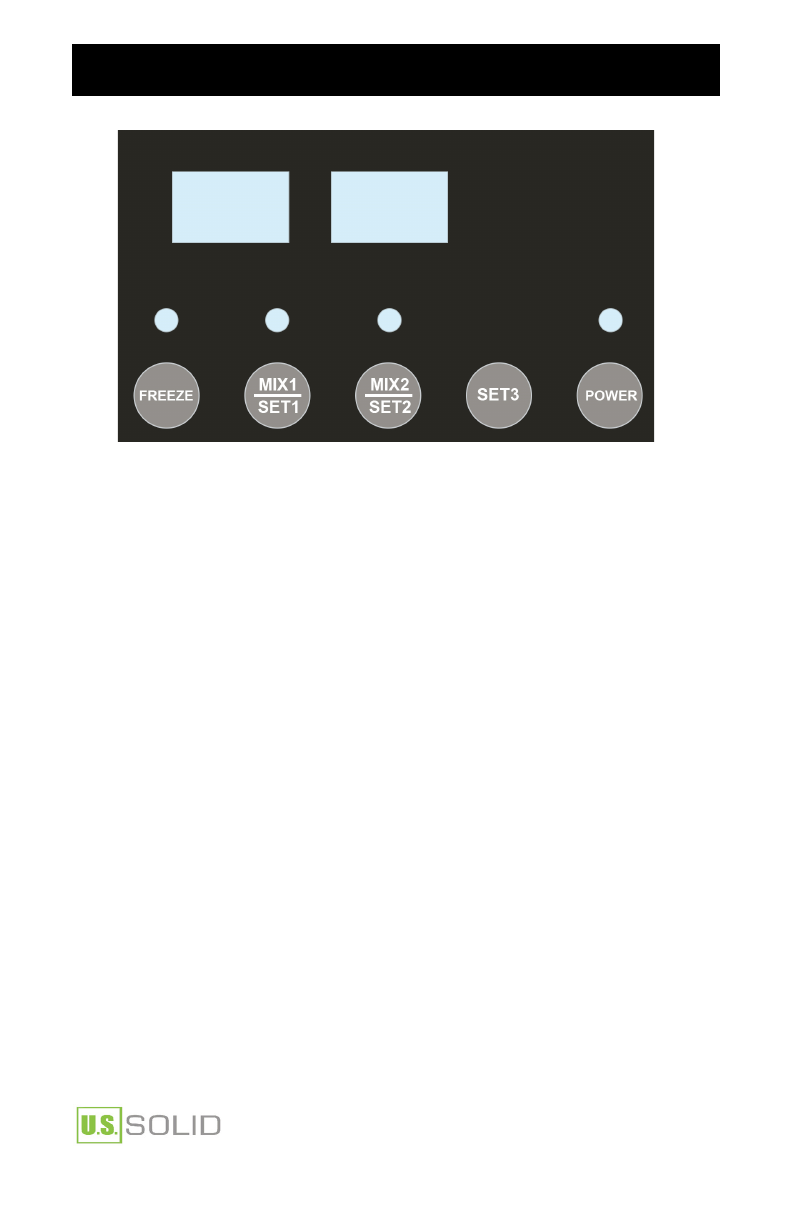

V. Operating the Machine

General Operation

The slush machine can be used with either one or both mixers in operation. The

cooling level will help determine the thickness of your slush. Be sure to monitor the

slush machine in the start-up. Always start at a lower level of freezing and work up.

If you start with the machine too cold, large blocks of ice will form and can damage

the machine.

When first operating the machine, turn on the power. If you are looking to make slush

mixtures, turn on the Freeze. There are 5 levels controlling the consistency of your

slush, which are level 0 (when there is no slush at all) to level 4 (corresponding to the

hardest slush). The recommended level is level 2 and that should be suffice for most

users. Give the machine at least an hour, and check on the consistency of the

mixture. Please be patient.

call (800) 243-5428