Operate the motor for approximately 2 hours at

the maximum desired load. Measure the surface

temperature of the motor on the casting opposite

the pipe ports. The maximum surface temperature

listed on the motor is for normal environmental

and installation conditions. For most air motors,

the maximum surface temperature should not

exceed 275ºF/135ºC. Do not continue to operate

the motor if the measured surface temperature

exceeds temperature listed on the motor. If your

measured temperature does exceed listed value,

consult with your Gast Distributor/Representative

for a recommendation.

MAINTENANCE

m WARNING

Injury Hazard

Disconnect air supply and vent all air lines.

Wear eye protection when flushing this product.

Air stream from product may contain solid or liquid materi-

al that can result in eye or skin damage.

Flush this product in a well ventilated area.

Do Not use kerosene or other combustible solvents to

flush this product.

Failure to follow these instructions can result in eye injury

or other serious injury.

It is your responsibility to regularly inspect and make

necessary repairs to this product in order to maintain proper

operation.

For Lubricated Operation

Use Gast #AD220 or a detergent SAE #10 automotive engine oil for

lubricating. Lubricating is necessary to prevent rust on all moving

parts. Excessive moisture in air line may cause rust or ice to form in

the mufer when air expands as it passes through the motor. Install

a moisture separator in the air line and an after cooler between

compressor and air receiver to help prevent moisture problems.

Manual Lubrication

Shut the air motor down and oil after every 8 hours of operation.

Add 10-20 drops of oil to the air motor intake port.

Automatic Lubrication

Adjust inline oiler to feed 1 drop of oil per minute for high speed

or continuous duty usage. Do not overfeed oil or exhaust air may

become contaminated. Check intake and exhaust lters after rst

500 hours of operation. Clean lters and determine how frequently

lters should be checked during future operation. This one

procedure will help assure the motor’s performance and service life.

Flushing

Flushing this product to remove excessive dirt, foreign particles,

moisture or oil that occurs in the operating environment will help to

maintain proper vane performance. Flush the motor if it is operating

slowly or inefciently.

Use only Gast #AH255B Flushing Solvent. DO NOT use

kerosene or ANY other combustible solvents to flush this

product.

1. Disconnect air line and mufer.

2. Add ushing solvent directly into motor. If using liquid solvent,

pour several tablespoons directly into the intake port. If using

Gast #AH255B, spray solvent for 5-10 seconds into intake

port.

3. Rotate the shaft by hand in both directions for a few minutes.

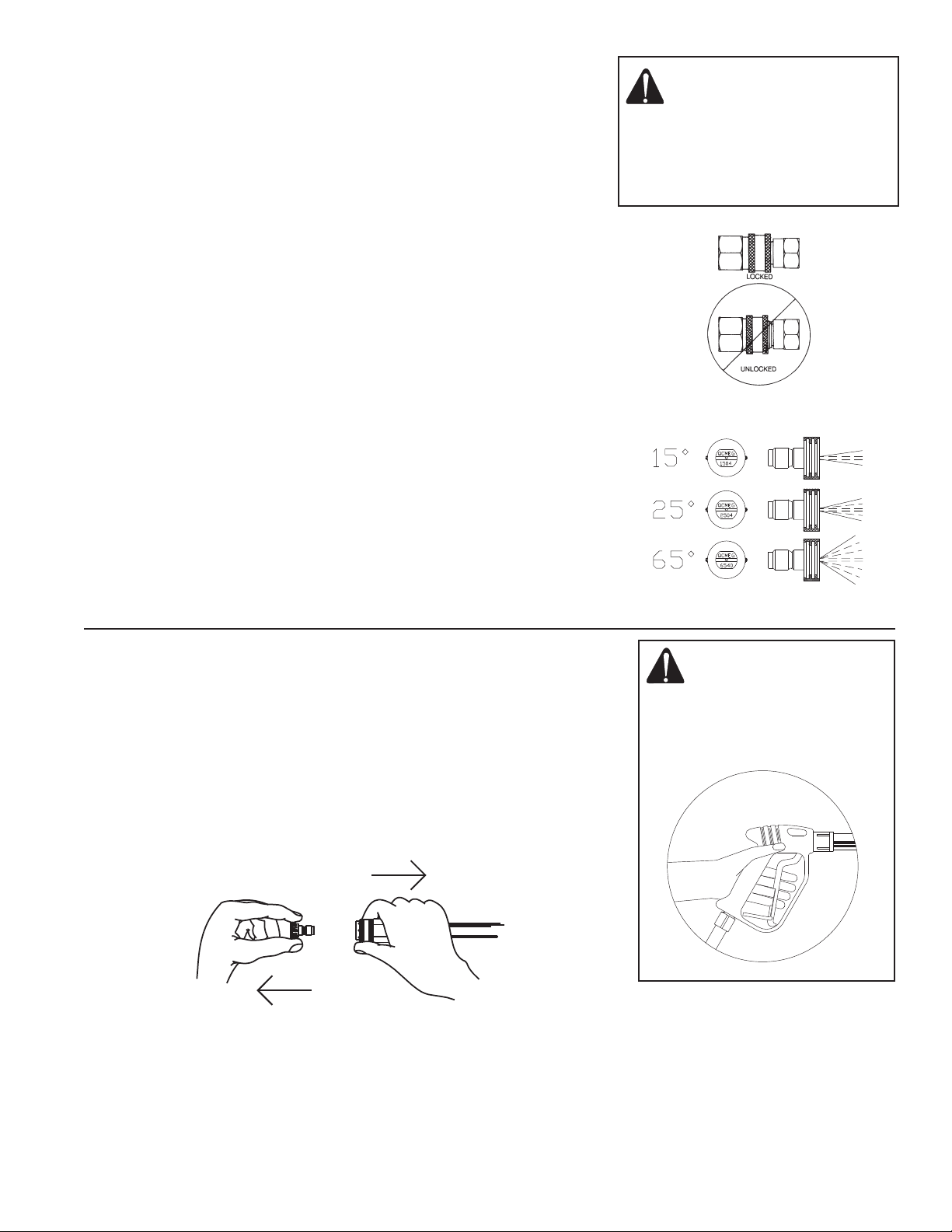

4. You must wear eye protection for this step. Cover exhaust with

a cloth and reconnect the air line.

5. Restart the motor at a low pressure of approximately 10 psi/

0.7 bar until there is no trace of solvent in the exhaust air.

6. Listen for changes in the sound of the motor. If motor sounds

smooth, you are nished. If motor does not sound like it is

running smoothly, installing a service kit will be required (See

“Service Kit Installation”).

Check that all external accessories such as relief valves or

gauges are attached and are not damaged before operating

product.

Cleaning the sound absorber.

1. Remove the sound absorber (for non-lubricated operation,

inspect mufer every 90 days. To avoid excessive clogging of

mufer element, change frequently).

2. Clean the felt lter.

3. You must wear eye protection for this step. For lubricated

operation, add 3-4 drops of oil.

4. Check the air compressor.

5. Listen for changes in the sound of the motor. If motor sounds

smooth, you are nished. If motor does not sound like it running

smoothly, installing a service kit will be required (See “Service

Kit Installation”).

Shutdown.

It is your responsibility to follow proper shutdown procedures

to prevent product damage.

1. Turn off air intake supply.

2. Disconnect air supply and vent all air lines.

3. Disconnect air lines.

4. Remove air motor from connecting machinery.

5. Remove the mufer.

6. Wear eye protection. Keep away from air

stream. Use clean, dry air to remove condensation from the

inlet port of the motor.

7. For lubricated operation, add a small amount of oil into the

intake port. Rotate shaft by hand several times to distribute oil.

8. Plug or cap each port.

9. Coat output shaft with oil or grease.

10. Store motor in a dry environment.

Disposal (Please note current regulations) Parts of the

air motor or air powered gear motor, shafts, cast iron

or aluminum castings, gear wheels as well as rolling

contact bearings may be recycled as scrap metal.

Revision 11/3/2021

6