Page 8 of 44 Page 9 of 44 MAN.500.REVD.06302015

Description and Principle of Operation

DESCRIPTION

The Universal Analyzers 500 Series Thermoelectric Gas Coolers condition gas sample streams to remove water vapor. The

gas sample is cooled thermoelectrically to a controlled temperature, and water vapor is condensed and removed.

The key to success is being able to condense the water from a wet gas sample with a minimal loss of the water soluble gas

fraction. The separation occurs in a classical impinger, which has a highly polished cylindrical surface, cooled to the desired

dew point temperature. The gas sample is brought to the bottom of the cylinder through an insulated tube and allowed to

rise through a narrow annular area at a relatively high Reynolds number to insure the entire sample is inuenced by the cold

surface. The condensate falls down the cold, polished surface in the form of a sheet (as opposed to droplets or the bubbling

of the gas sample through the condensate) which minimizes the surface area in contact with the gas sample.

The temperature of the cylindrical, condensation surface of the heat exchangers is maintained through intimate contact with

aluminum heat transfer blocks. The blocks are cooled with thermoelectric elements, controlled to a temperature of 5°C. The

temperature sensor is a type “K” thermocouple. The temperature controller is proportional with a band of 1°C.

The fan cooled heat sink is constructed from anodized, pure aluminum ns which transfer heat to the surrounding air. The

pure aluminum material is a far better conductor of heat than the aluminum alloys which are normally used for extruded heat

sinks. The result is an assembly with superior heat exhausting capabilities under high ambient temperature conditions.

The 500 Series Coolers have a digital display for front panel indication of the operating temperature of each of the heat

transfer blocks (switch selectable) in degrees Centigrade. Two internal jumpers at the top of the control circuit board within

the enclosure can be moved to change the indicated temperature to read out in degrees Fahrenheit.

Three LED lamps to indicate the status of the cooler. The “COOL” lamp is a green LED which indicates when the operating

temperature has fallen below the factory set temperature of 10°C. An “Over-temperature relay” is energized and closed to

the cool position when the “COOL” lamp is on. The relay board within the enclosure has dual terminal strip relay contacts for

alarm/shutdown purposes. The external gas sample pump may be interlocked with this relay to power off when temperatures

become too high (fail safe).

The “DRY” lamp is a green LED which indicates when there is no water in contact with the water carry-over sensor (provided

separately or as a system option). If no moisture sensor is used, the lamp may be turned off by installing a jumper on the

moisture sensor input terminals on the relay board. Without a moisture sensor installed, the “DRY” lamp is always lit and

doe not indicate a condition. The moisture sensor relay, which is energized in the “DRY” condition, provides contacts to an

annunciator panel and/or to turn off the sample pump in the “wet” condition.

The “TC” lamp is a red LED which indicates when there is a problem (open connection) in the temperature control

thermocouple. The “Over-temperature” relay will also transfer to the high temperature condition if the red “TC” lamp

comes on.

The WCO or WCOF, optionally available with the 500 Series Cooler Systems, is a sensor which detects the presence of

liquid water. One should be placed in each gas sample stream directly after the cooler to provide an alarm if condensate is

detected. The electronics associated with water carry-over sensors are included as a standard part of all Universal Analyzers

Thermoelectric Sample Coolers. Dual relay contact sets are provided for each moisture sensor. Relay contacts are energized

and closed to the dry position when the WCO sensor is dry and the unit is powered on.

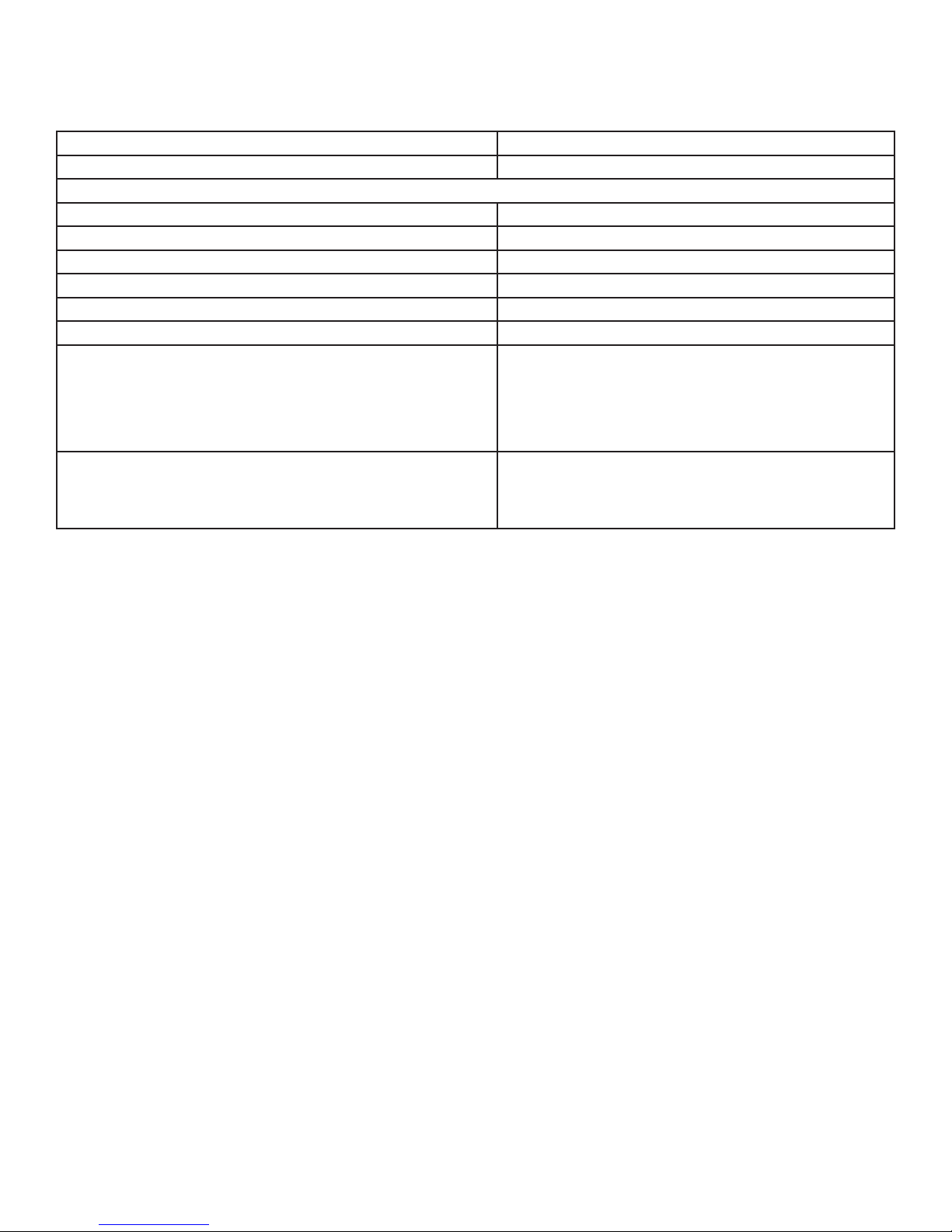

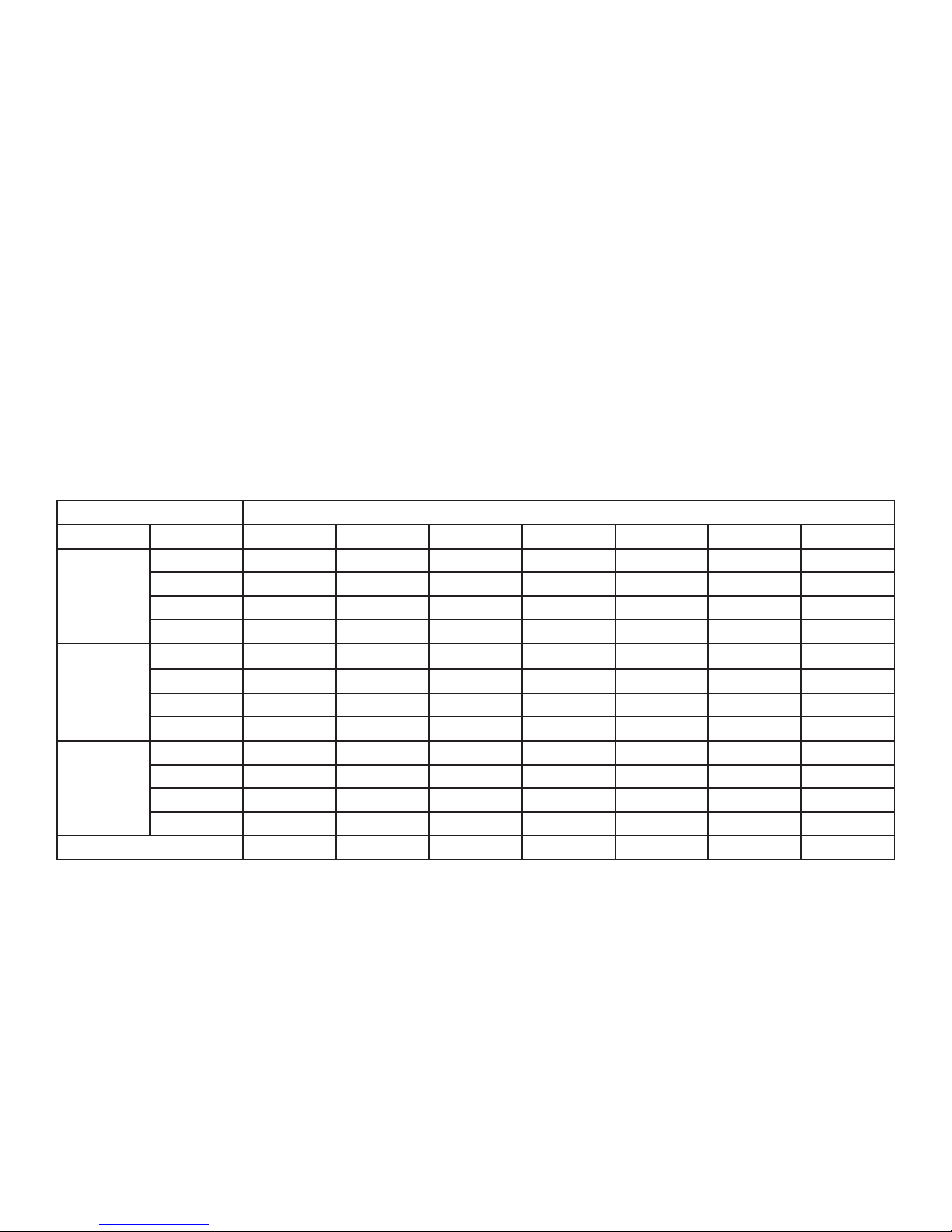

LED INDICATOR CHART

LED Color Status Condition Relay Status

COOL Green On Operating properly, temperature below 10°C Over Temperature: Energized, towards COLD

Off Temperature too high or unit is OFF Over Temperature: De-Energized, towards HOT

DRY Green On WCO sensor connected and sample is dry Moisture Sensor: Energized, towards DRY

Off Moisture detected or jumper installed Moisture Sensor: De-Energized, towards WET

TC Red On Temperature control TC has BAD quality Over temperature: De-Energized, towards HOT

Off Temperature control TC has OK quality Does not affect relays