Contents

2Installation and maintenance instructions auroCOMPACT 0020181589_04

Contents

1 Safety.................................................................... 4

1.1 Action-related warnings ......................................... 4

1.2 Intended use.......................................................... 4

1.3 General safety information .................................... 4

1.4 Regulations (directives, laws, standards).............. 6

2 Notes on the documentation .............................. 7

2.1 Observing other applicable documents ................. 7

2.2 Storing documents................................................. 7

2.3 Validity of the instructions...................................... 7

3 Product description............................................. 7

3.1 Serial number ........................................................ 7

3.2 Information on the identification plate.................... 7

3.3 CE label ................................................................. 7

3.4 ÖVGW symbol....................................................... 7

3.5 DVGW mark........................................................... 8

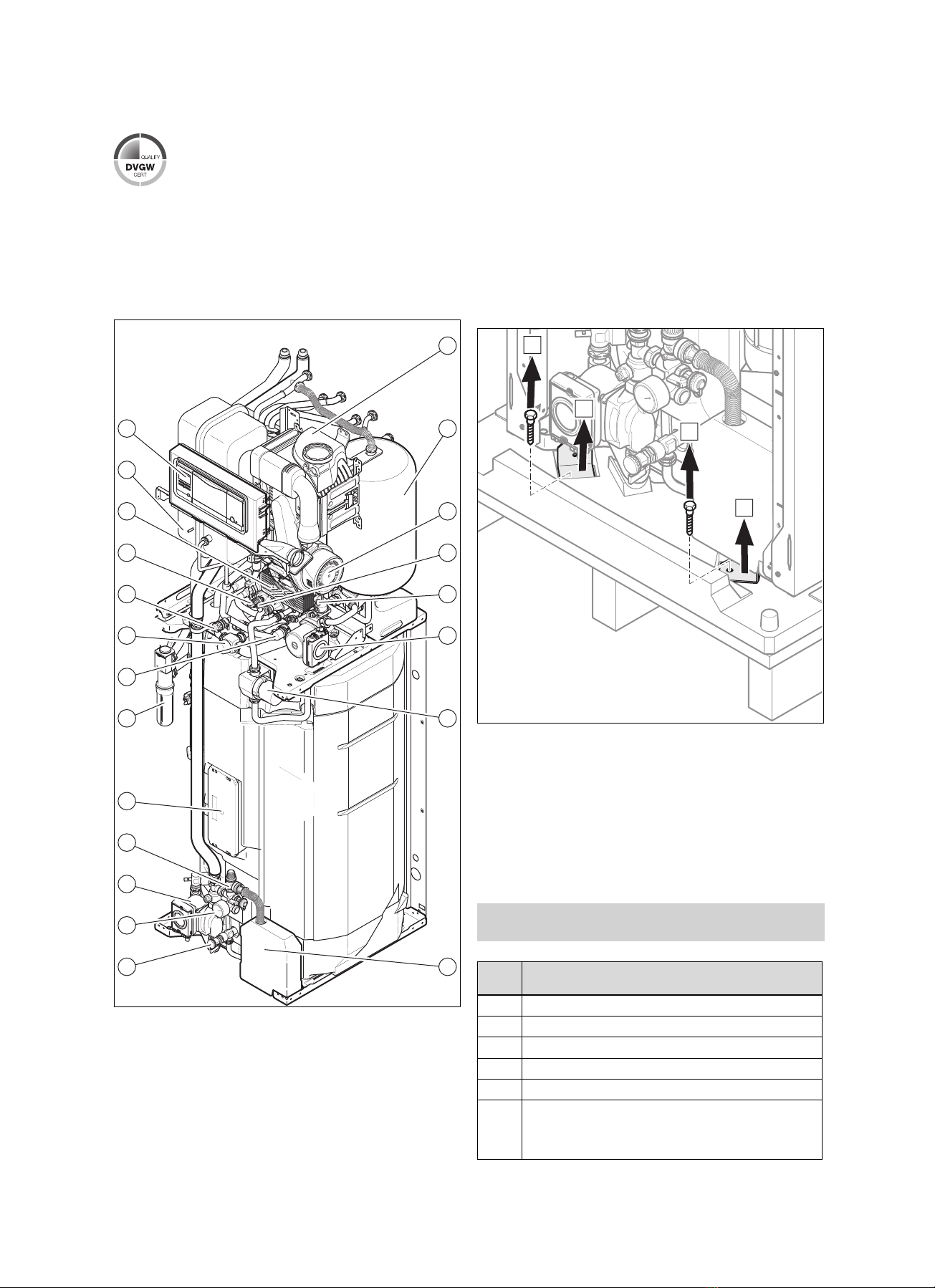

3.6 Functional elements............................................... 8

4 Set-up.................................................................... 8

4.1 Unpacking the product........................................... 8

4.2 Checking the scope of delivery.............................. 8

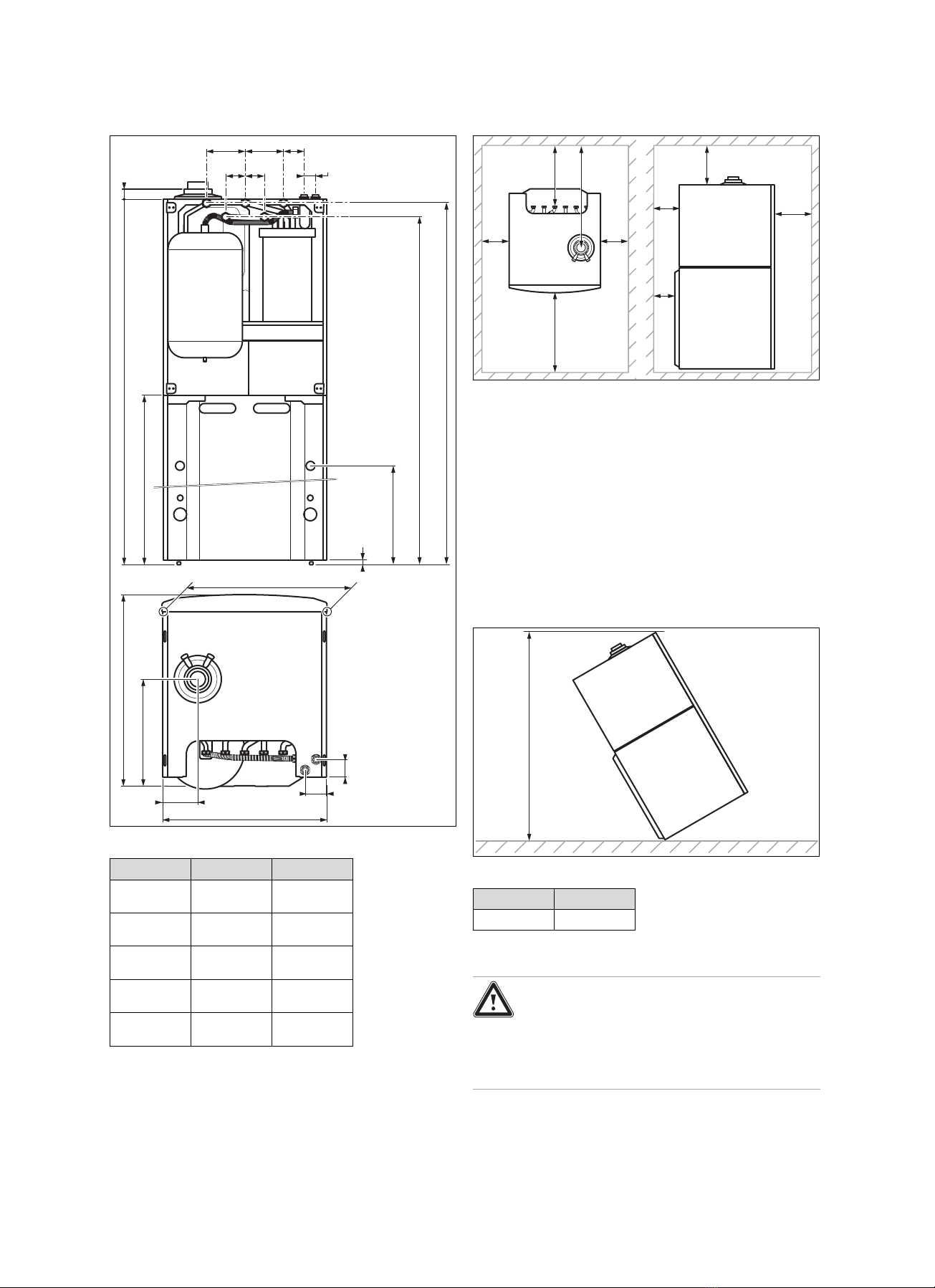

4.3 Unit dimensions ..................................................... 9

4.4 Minimum clearances.............................................. 9

4.5 Clearance from combustible components ............. 9

4.6 Unit dimensions for transport................................. 9

4.7 Transporting the unit.............................................. 9

4.8 Unit installation site.............................................. 11

4.9 Setting up the unit horizontally ............................ 11

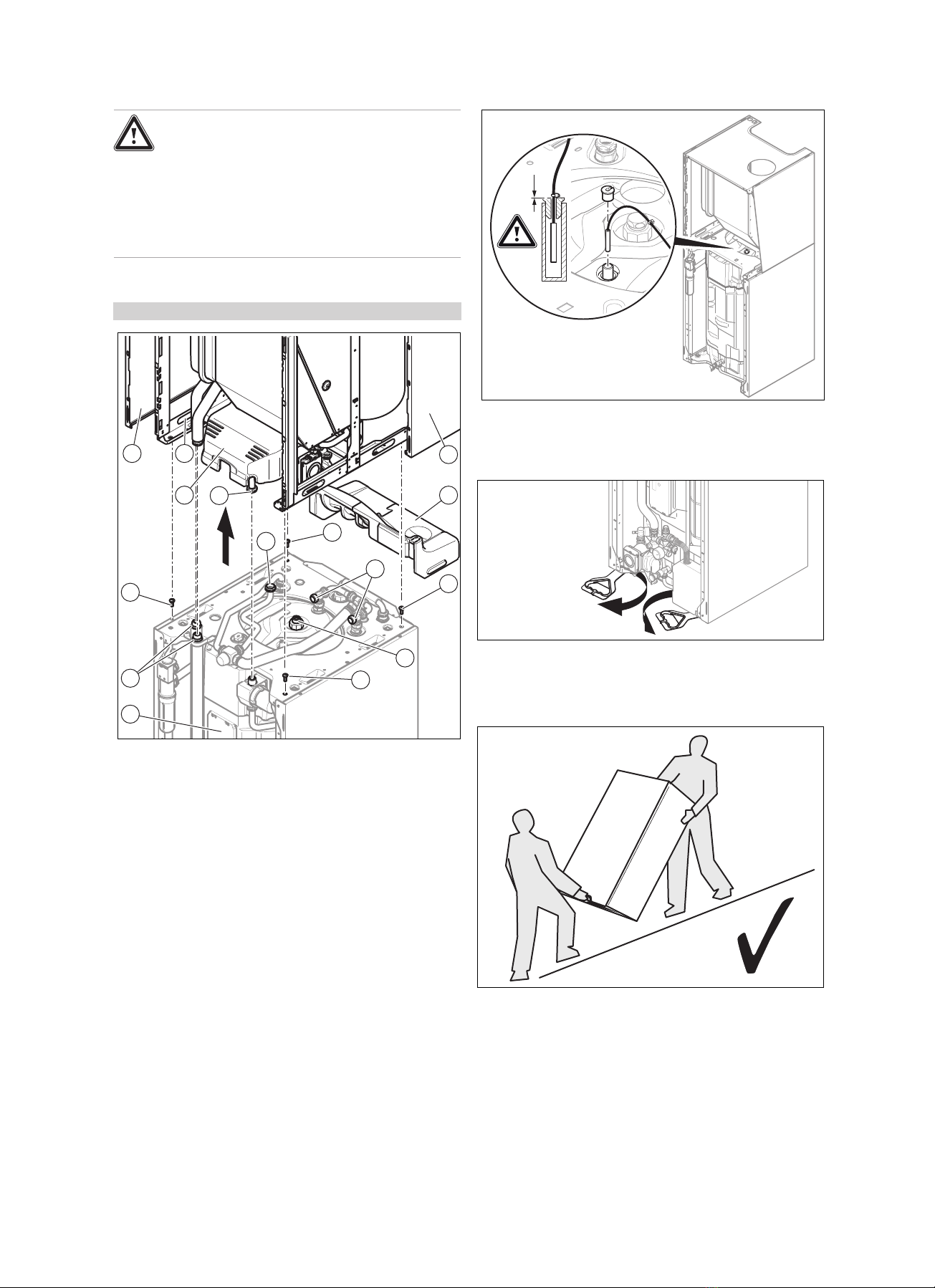

4.10 Removing/installing the front casing.................... 11

4.11 Installing/removing the side casing...................... 11

4.12 Moving the electronics box into the lower or

upper position ...................................................... 11

4.13 Removing/installing the vacuum chamber's

front wall .............................................................. 12

5 Installation.......................................................... 12

5.1 Information on liquid gas operation ..................... 12

5.2 Checking the gas meter....................................... 13

5.3 Gas and water connections ................................. 13

5.4 Connecting the condensate drain pipework ........ 13

5.5 Solar connection.................................................. 14

5.6 Air/flue system ..................................................... 15

5.7 Electrical installation ............................................ 16

6 Operation............................................................ 19

6.1 Operating concept of the product ........................ 19

6.2 Live Monitor (status codes) ................................. 19

6.3 Test programmes................................................. 19

7 Start-up............................................................... 19

7.1 Auxiliary service equipment................................. 19

7.2 Checking the factory setting ................................ 20

7.3 Filling the condensate siphon .............................. 20

7.4 Filling the solar system ........................................ 21

7.5 Switching on the product ..................................... 22

7.6 Running the installation assistants ...................... 22

7.7 Restarting the installation assistants ................... 23

7.8 Calling up appliance config. and diagnostics

menu.................................................................... 23

7.9 Performing a gas family check ............................ 23

7.10 Using check programmes.................................... 24

7.11 Checking and treating the heating water/filling

and supplementary water .................................... 25

7.12 Reading off the filling pressure ............................ 26

7.13 Preventing low water pressure ............................ 26

7.14 Filling and purging the heating installation .......... 26

7.15 Filling and purging the hot water system ............. 26

7.16 Checking and adjusting the gas settings............. 27

7.17 Checking leak-tightness ...................................... 28

8 Adapting the unit to the heating

installation.......................................................... 28

8.1 Calling up diagnostics codes ............................... 28

8.2 Setting the maximum heating output ................... 29

8.3 Setting the pump overrun and pump operating

mode.................................................................... 29

8.4 Setting the maximum flow temperature ............... 29

8.5 Setting the return flow temperature control ......... 29

8.6 Burner anti-cycling time ....................................... 29

8.7 Setting the maintenance interval ......................... 29

8.8 Setting the pump output....................................... 30

8.9 Setting the domestic hot water temperature........ 32

8.10 Descaling the water ............................................. 32

8.11 Handing the product over to the end user ........... 32

8.12 Setting the hot water thermostatic mixer ............. 33

9 Inspection and maintenance ............................ 33

9.1 Checking the product for leak-tightness .............. 33

9.2 Observing inspection and maintenance

intervals ............................................................... 33

9.3 Procuring spare parts .......................................... 34

9.4 Using the function menu...................................... 34

9.5 Carrying out electronics self-tests ....................... 34

9.6 Removing the compact thermal module.............. 34

9.7 Cleaning the heat exchanger............................... 35

9.8 Checking the burner ............................................ 35

9.9 Cleaning the condensate siphon ......................... 36

9.10 Installing the compact thermal module ................ 36

9.11 Draining ............................................................... 36

9.12 Checking the pre-charge pressure of the

expansion vessel ................................................. 37

9.13 Checking the magnesium protection anode ........ 37

9.14 Cleaning the domestic hot water cylinder............ 37

9.15 Cleaning the heating filter.................................... 38

9.16 Inspection and maintenance................................ 38

9.17 Installation position of the safety cut-out ............. 38

10 Troubleshooting ................................................ 38

10.1 Contacting your service partner........................... 38

10.2 Calling up service messages............................... 38

10.3 Reading off the fault codes.................................. 39

10.4 Querying the fault memory .................................. 39

10.5 Resetting the fault memory.................................. 39