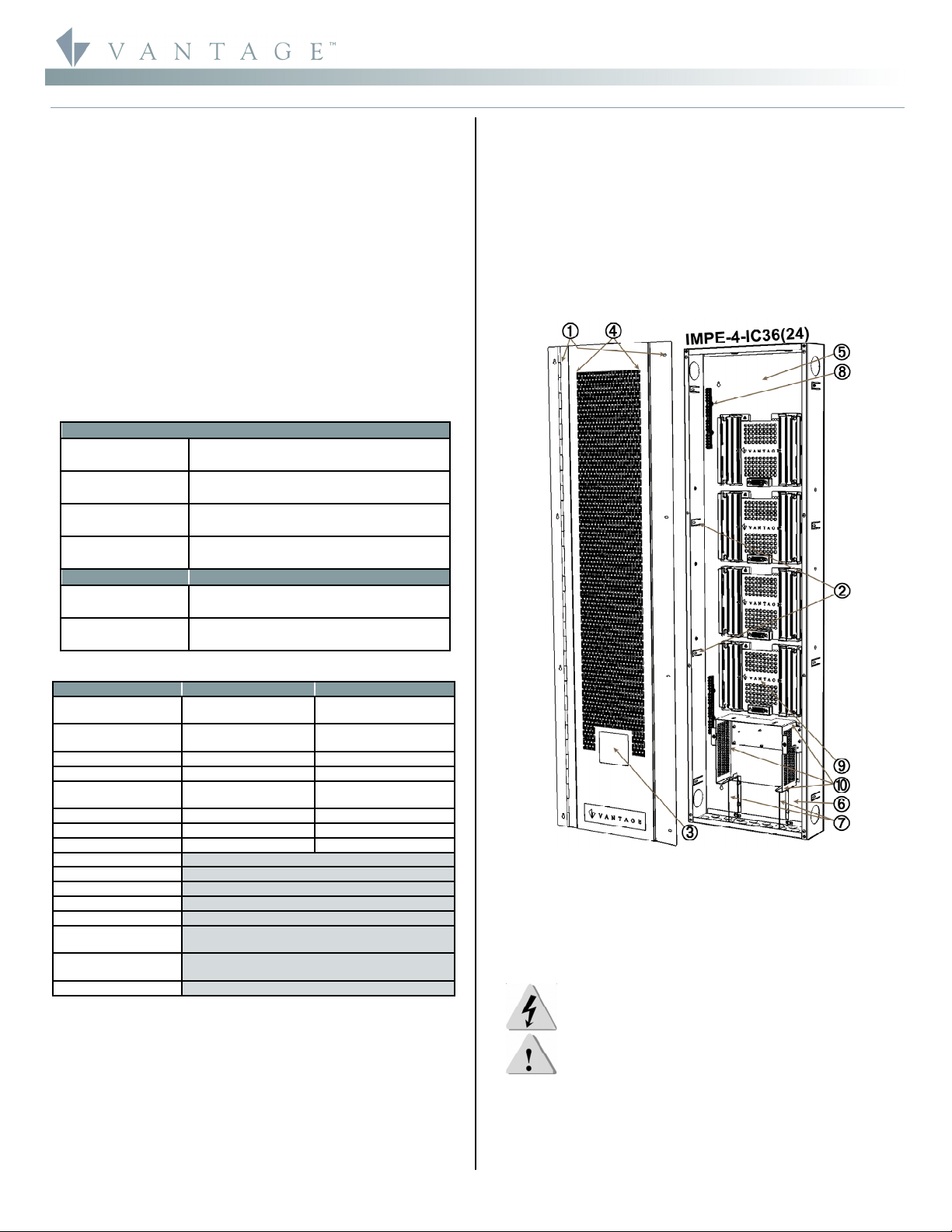

I N S T A L L A T I O N

©Vantage, 8/15/2016 / IS-0536-B InFusion Power Enclosure — MODEL: IMPE-4(2)-IC36(24) & ISPE-4(2)-IC page 2 of 6

3. National Electrical Code requires a minimum frontal

clearance of 36” for the enclosure.

4. Use eight 1 ½” screws for mounting IMPE-4 or ISPE-4.

5. Use four 1 ½” screws for IMPE-2 or ISPE-2.

6. The enclosure door has a 1/2" lip that extends past the

enclosure sides, concealing the edge of the enclosure next

to the wall. When surface mounting the enclosure leave

sufficient space between multiple enclosures to allow the

doors to be installed and swing free from each other.

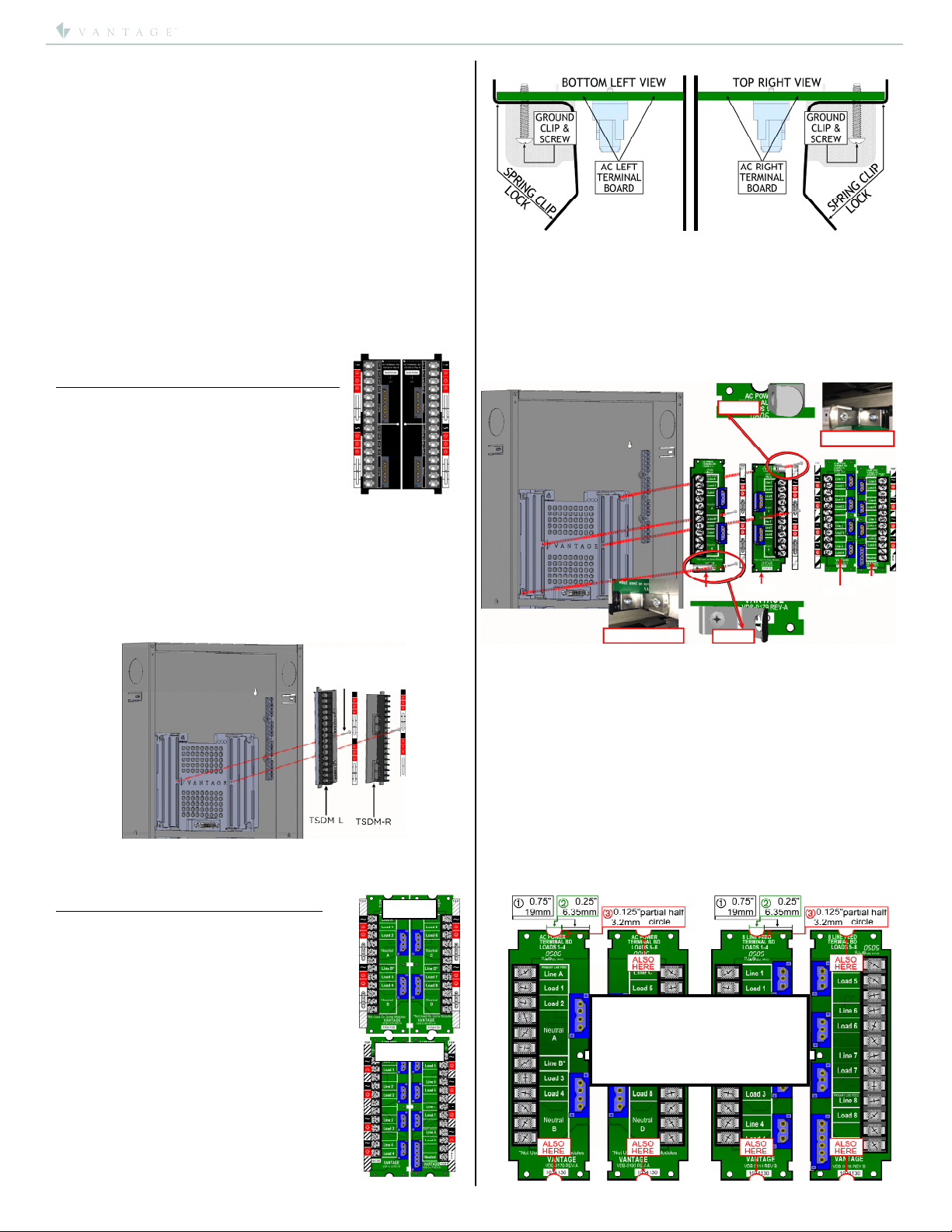

General Wiring

Enclosure conduit knockouts: Top and Bottom; 25 - 1/2"

knockouts (50 total) for wiring in the top and bottom. In the

bottom center of the enclosure, seven of the knockouts are

separated by a low voltage barrier and must only be used for

low voltage. This isolates all low voltage runs from high

voltage runs. A metal cage surrounds the Controller area of the

enclosure and is adjacent to the low voltage barrier. Left and

Right; 2 - 2” knockouts (4 total) for wiring high voltage

between enclosures through the left and right sides. Typically

these knockouts are only used in surface mount installations.

Breaker Feeds to Controllers:

Vantage recommends that the Main Controller’s power be

wired to a dedicated circuit breaker. When multiple enclosures

containing controllers are in close proximity to one another, it

is recommended to share the same breaker to all Main

Controllers; no more than nine controllers may be connected to

a 20amp breaker – allow up to 200W@120VAC per InFusion

Controller. Do not share the same breaker with controllers and

modules.

Vantage Station Bus Wire Specification

Vantage wire, part #VDA-0113 – 2C, 16AWG / 1.31mm2, twisted,

non-shielded, <30pF per foot. Separate a minimum of 12" /

30.5cm from other parallel communication and/or high voltage

runs.

Main Controller to Main Controller Wiring

When connecting multiple Main enclosures via the Main

Enclosure Terminal Board’s Controller Bus screw terminals,

Vantage recommends their own or an equivalent wire, (see

Vantage Station Bus Wire Specification above) be used in runs

between Main enclosures. This is a polarized connection with

two “+” and two “–” screw terminals for in and out wire runs.

The maximum wire length for all controllers connected

together on one bus should not exceed 2,000ft. using the

above wire specification.

NOTE: InFusion Systems may also use Ethernet connections

for Controller to Controller communication. Please see the

InFusion Controller instruction sheet for additional information.

Station Bus Wiring

WireLink stations connect to the Station Bus screw terminals

on the Main Enclosure Terminal Board. Use Vantage station bus

wire, (above). Maximum total station bus wire for each run =

2,000 feet with no station more than 1,000 feet from enclosure

(typically the second half of the station bus loops back to

enclosure with only one end connected). Station Bus should be

separated a minimum of 12" from other parallel communication

and/or high voltage runs.

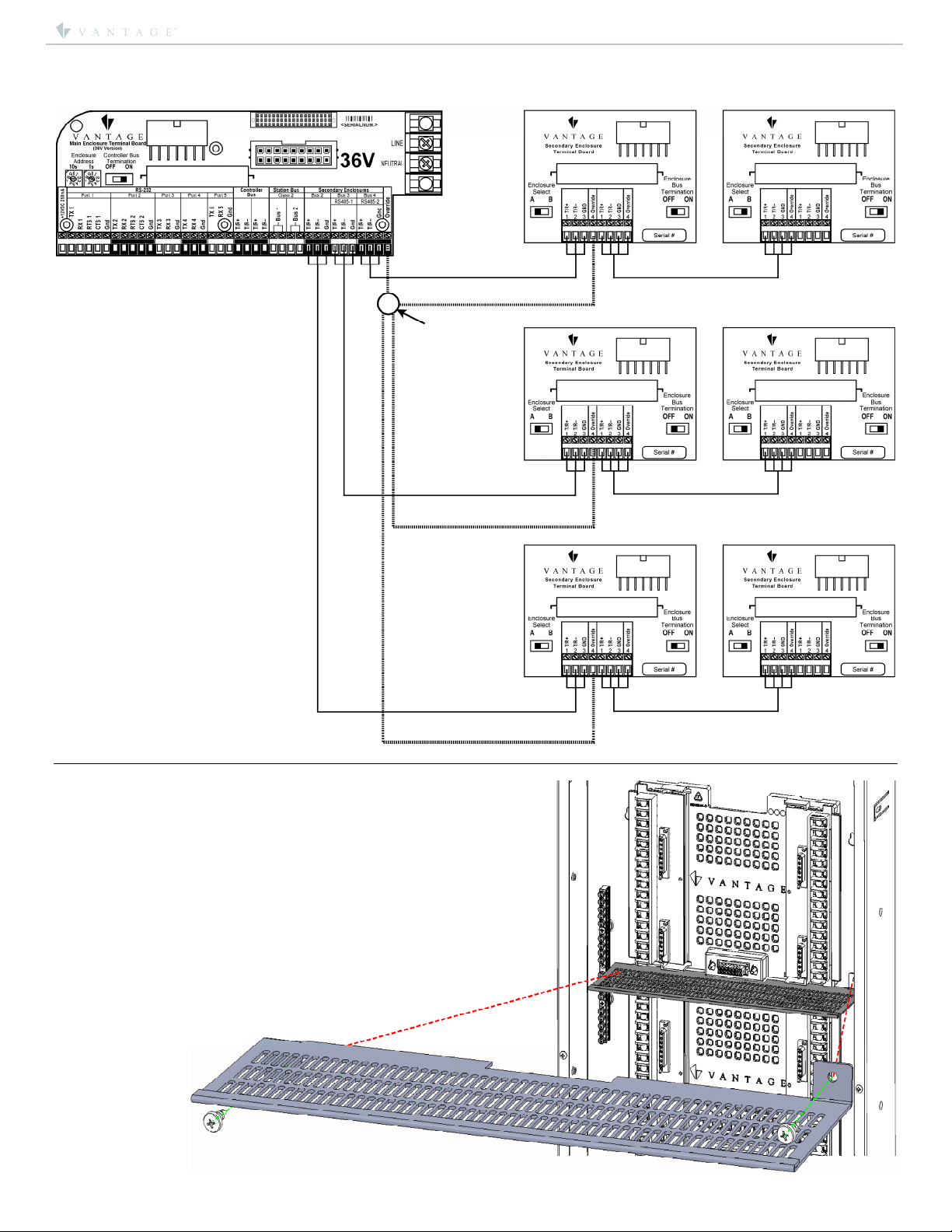

Main & Secondary Enclosure to Secondary Enclosure Wiring

Connecting a Main enclosure to a Secondary enclosure or

Secondary enclosure A to Secondary enclosure B, requires

16/18-gauge 4-conductor twisted, non-shielded wire. Three of

the wires are always used to connect a Main enclosure to a

Secondary enclosure and chained secondary enclosures. This is

a polarized connection with “+”, “–” and “Gnd” screw terminals

for communication. The 4th wire is for Manual Override and is

optional. Each Secondary enclosure bus can support two

Secondary enclosures for a maximum of six Secondary

enclosures (see InFusion wiring below) per Main enclosure.

Maximum wiring distance from Main enclosure to Secondary

enclosure is 200ft including an A/B Secondary system (e.g.,

100ft from Main enclosure to Secondary enclosure A and an

additional 100ft from Secondary enclosure A to Secondary

enclosure B).

Main Terminal Board Terminator

If only one or two Main enclosures are used, the Controller Bus

Termination switch must be ON. This switch is located on the

Enclosure Terminal Board. If more than two Main enclosures

are used ONLY the first and last Enclosure Terminal Boards on

each controller bus should have the Network Termination

switch set to ON. Example: In a five Main enclosure system,

Main Controllers 1 and 5 may not be the first and last

Controllers. The daisy-chain “wiring” order could be 2-1-3-5-4.

In this example, Main enclosures 2 and 4 are the first and last

Controllers, so only these two would have the Network

Termination switch ON, the other three must be set to OFF.

RS-232 (Ports 1-5) for Main Enclosures

The Main Enclosure Terminal Board has five RS-232 ports. Use

these ports to connect any device that uses RS-232

communication. Only connect one RS-232 device at a time to

an RS-232 port. If additional RS-232 ports are needed, Vantage

also manufactures an RS-232 Station or, some products like

the IRX II, have built-in RS-232 ports.

Vantage typically uses RX, TX and GND for communication but

does have RTS and CTS for some applications on RS-232 Ports

1 and 2. RS-232 Ports 3-5 only have TX, RX and GND., however,

all five ports can use software flow control. The default

communication protocol may be changed through Design

Center software.

Communication protocol parameter settings:

Standard baud rates 1200 – 115.2K

7-8 Data Bits

Even, Odd, Forced or No Parity

200ft. maximum wiring distance

Default protocol for RS-232 communication is:

Baud: 19200

Parity: None

Total bits: 8

Stop bits: 1

RS-485 Connections

The Main Enclosure Terminal Board has two RS-485 ports.

These ports are connected to the same screw terminals used

for Secondary enclosure ports 3 and 4. The ports may not be

used for Secondary enclosure support and RS-485 support

simultaneously. However, if Secondary enclosure bus ports 3

and/or 4 are free they may be used as RS-485 communication

ports. The RS-485 ports are half-duplex, meaning that each

port can transmit and receive but not at the same time.

Maximum wiring distance for RS-485 ports is 200ft.

Possible Ground Loop Issues

All RS-232/RS-485 connections between third party

equipment and RS-232/RS-485 connections on the Main

Enclosure Terminal Board may produce a ground loop. Most

often, the connected RS-232/RS-485 device is not using the

same power source or is far away from the Vantage enclosure

resulting in a possible ground loop that may produce a data

noise condition. If this condition is suspected, Vantage

recommends a third party RS-232/RS-485 Opto (optical)

Isolation Module. Opto Isolation provides a communications

link and is an important consideration if a system uses different

power sources, has noisy signals or must operate at different

ground potentials.

Auxiliary Power

The enclosure, Main Enclosure Terminal Board has a 12VDC

auxiliary power connection. The 12VDC connection is typically

used for one RFE1000 RadioLink Enabler or one RFLC-V232

Enabler. Total power is limited to 250ma. NOTE: Do not