4

CONTENT

Page

INTRODUCTION ............................................................................................................................... 5

1.1. USE AND FUNCTION ................................................................................................................. 5

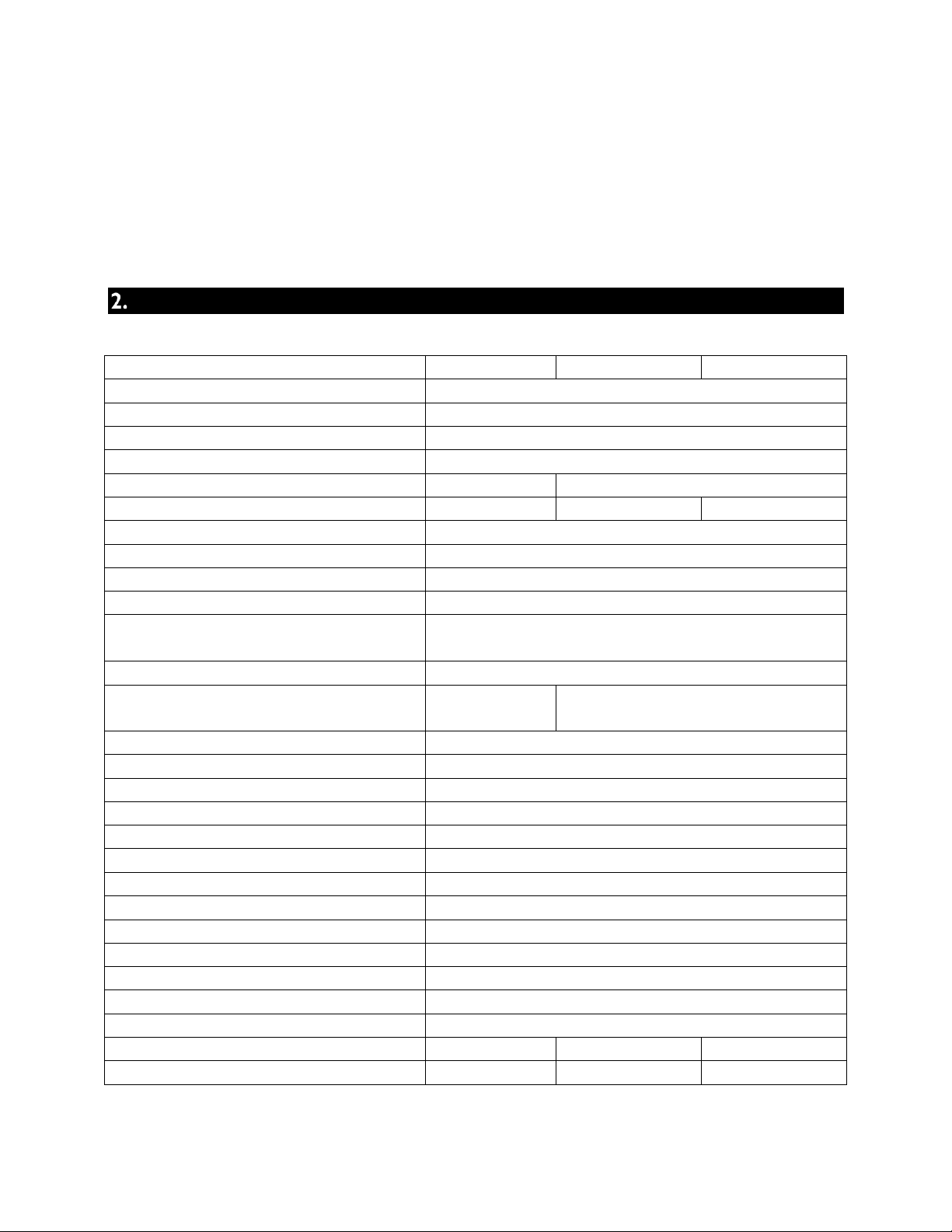

TECHNICAL SPECIFICATIONS ............................................................................................................ 6

2.1. TECHNICAL SPECIFICATIONS TABLE........................................................................................... 6

2.2. ACCESSORIES............................................................................................................................ 7

2.2.1. FACTORY FITTED ACCESSORIES ......................................................................................... 7

2.2.2. OPTIONAL ACCESSORIES ................................................................................................... 7

PRECAUTIONS AND LIMITATIONS ON USE ....................................................................................... 7

SYMBOLS AND LABELS..................................................................................................................... 8

INSTALLATION ................................................................................................................................. 9

ENVIRONMENTAL CONDITIONS ................................................................................................ 9

HANDLING AND TRANSPORTATION ........................................................................................ 10

UNPACKING............................................................................................................................ 10

MAINS SUPPLY........................................................................................................................ 10

POSITIONING.......................................................................................................................... 10

GENERAL PRESENTATION ....................................................................................................... 11

5.6.1. CHAMBER DIMENSIONS.................................................................................................. 12

CONTROL PANEL..................................................................................................................... 12

PRIOR TO OPERATION............................................................................................................. 14

OPERATING PRINCIPLES................................................................................................................. 14

PROGRAMMING..................................................................................................................... 14

6.1.1. OPERATING MODE.......................................................................................................... 14

6.1.2. SETTINGS ........................................................................................................................ 15

6.1.3. MEMORY ........................................................................................................................ 16

INTERNAL MEMORY ................................................................................................ 17

EXTERNAL MEMORY (USB STICK)............................................................................. 18

6.1.4. SMS ................................................................................................................................ 19

6.1.5. E-MAIL............................................................................................................................ 20

6.1.6. SET TEMPERATURE ......................................................................................................... 21

6.1.7. GRAPH WORKING SCREEN .............................................................................................. 21

6.1.8. TEMPERATURE ALARM RANGE........................................................................................ 21

PERIODIC MAINTENANCE AND CLEANING...................................................................................... 22

PERIODIC MAINTENANCE ....................................................................................................... 22

CLEANING............................................................................................................................... 22

DISPOSAL MANAGEMENT CONCEPT .............................................................................................. 23

TROUBLESHOOTING ...................................................................................................................... 23

ERROR CODES......................................................................................................................... 23

FUSE REPLACEMENT............................................................................................................... 24

OPTIONS ................................................................................................................................... 24

AlerText™ GSM MODULE .................................................................................................... 24

NüveWARN™ REMOTE ALARM SYSTEM ............................................................................... 25

10.2.1. MOUNTING REMOTE ALARM ...................................................................................... 25

CHART RECORDER............................................................................................................... 26

CO2BACK-UP UNIT.............................................................................................................. 26

ELECTRICAL CIRCUIT DIAGRAM.................................................................................................. 28

DF 290, DF 490 AND DF 590 ELECTRICAL CIRCUIT DIAGRAM ............................................... 28