4 Description and main characteristics General Instructions

ormaSET-M

IG-199-EN version 03

1 Description and main characteristics

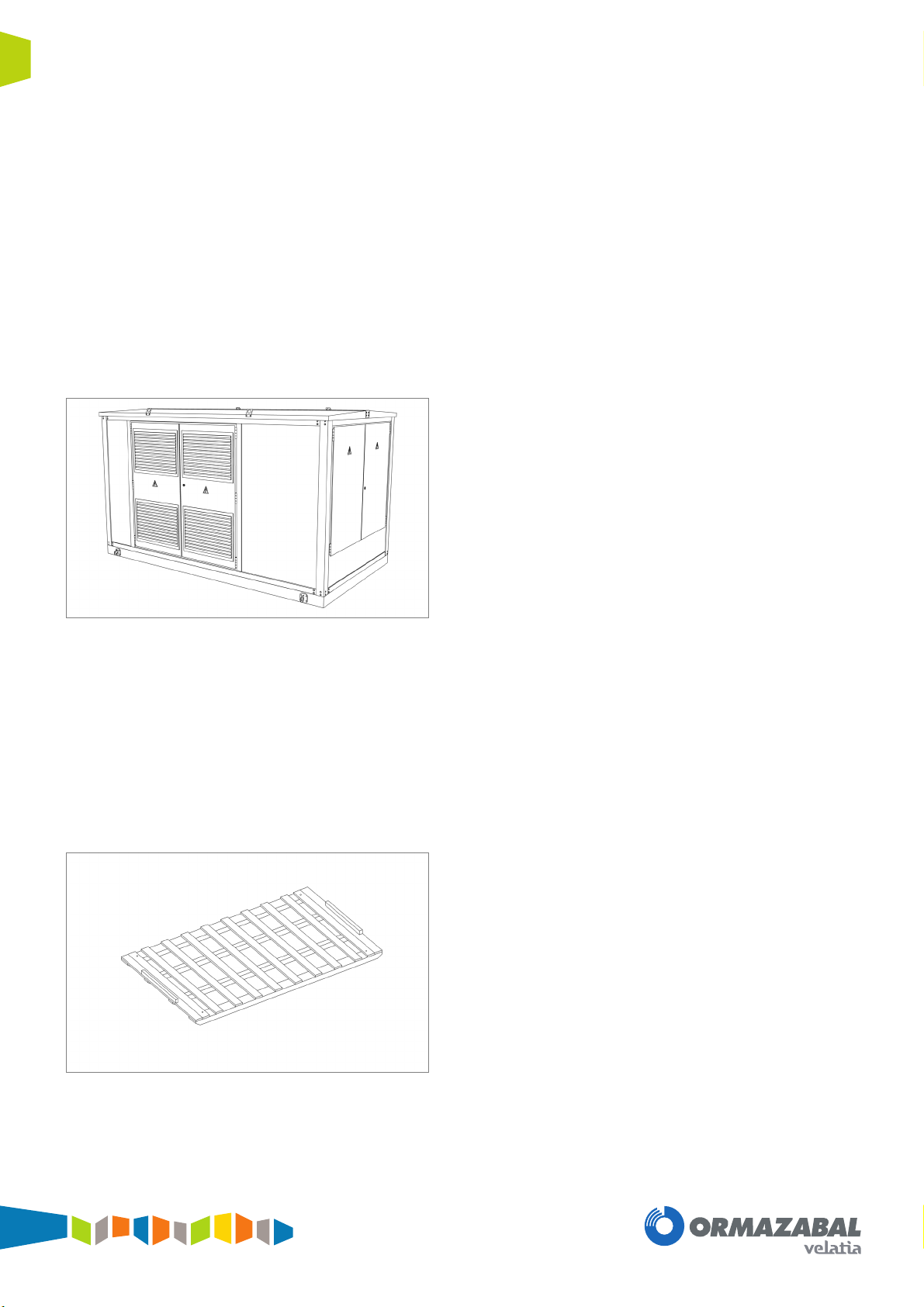

Ormazabal's ormaSET-M is a kiosk-type Metallic

Prefabricated Transformer Substation, installed on surface

and externally operated, with reduced dimensions,

standard-built, factory tested and supplied from the factory

as a unit.

ormaSET-M Transformer Substation complies with the

requirements established in standard IEC 62271-202.

ormaSET-M is designed for end-user networks with rated

voltages Urup to 36 kV and a rated power of 1000 kVA.

Ormazabal's ormaSET-M Transformer Substation is made

up of the following main components:

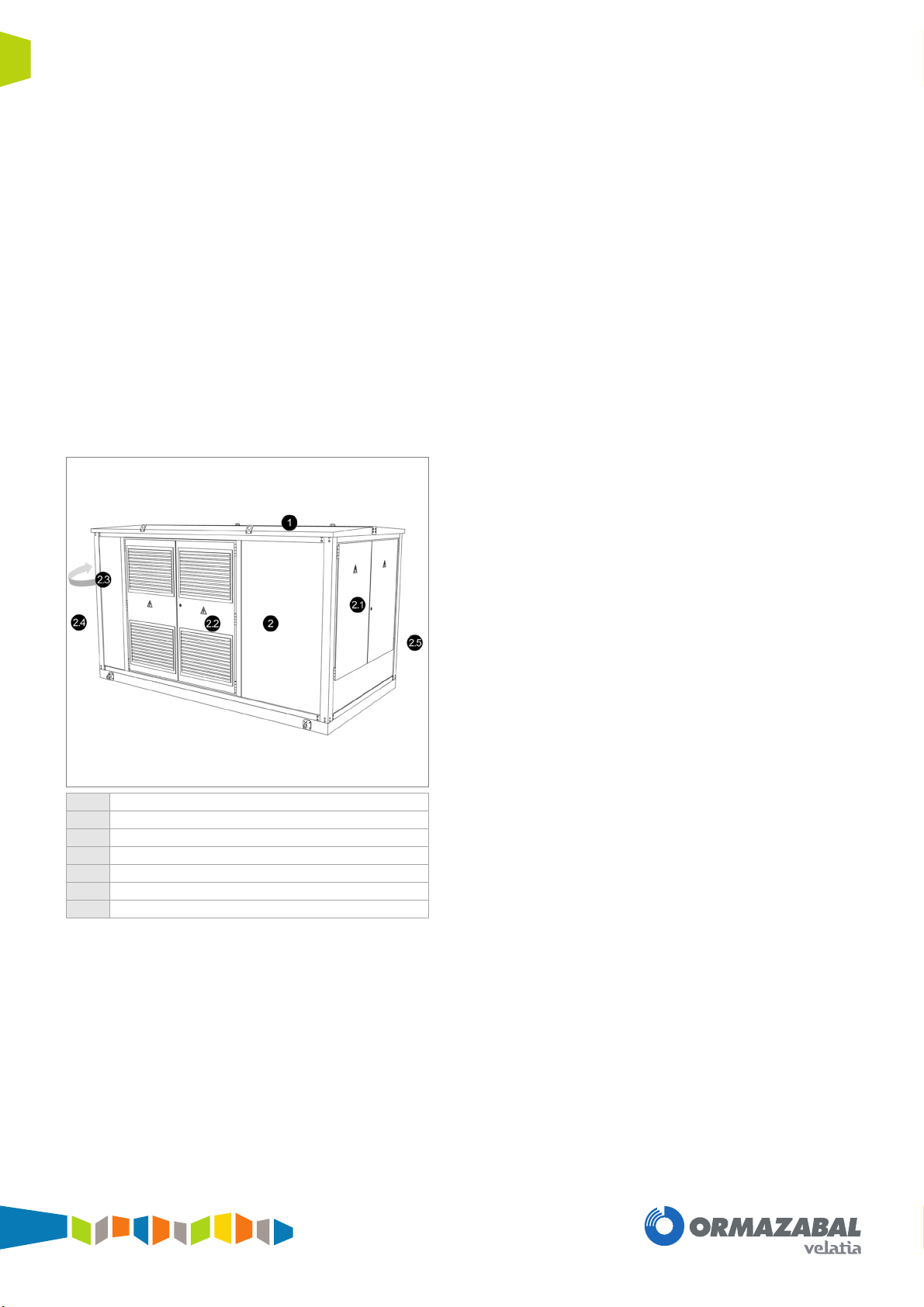

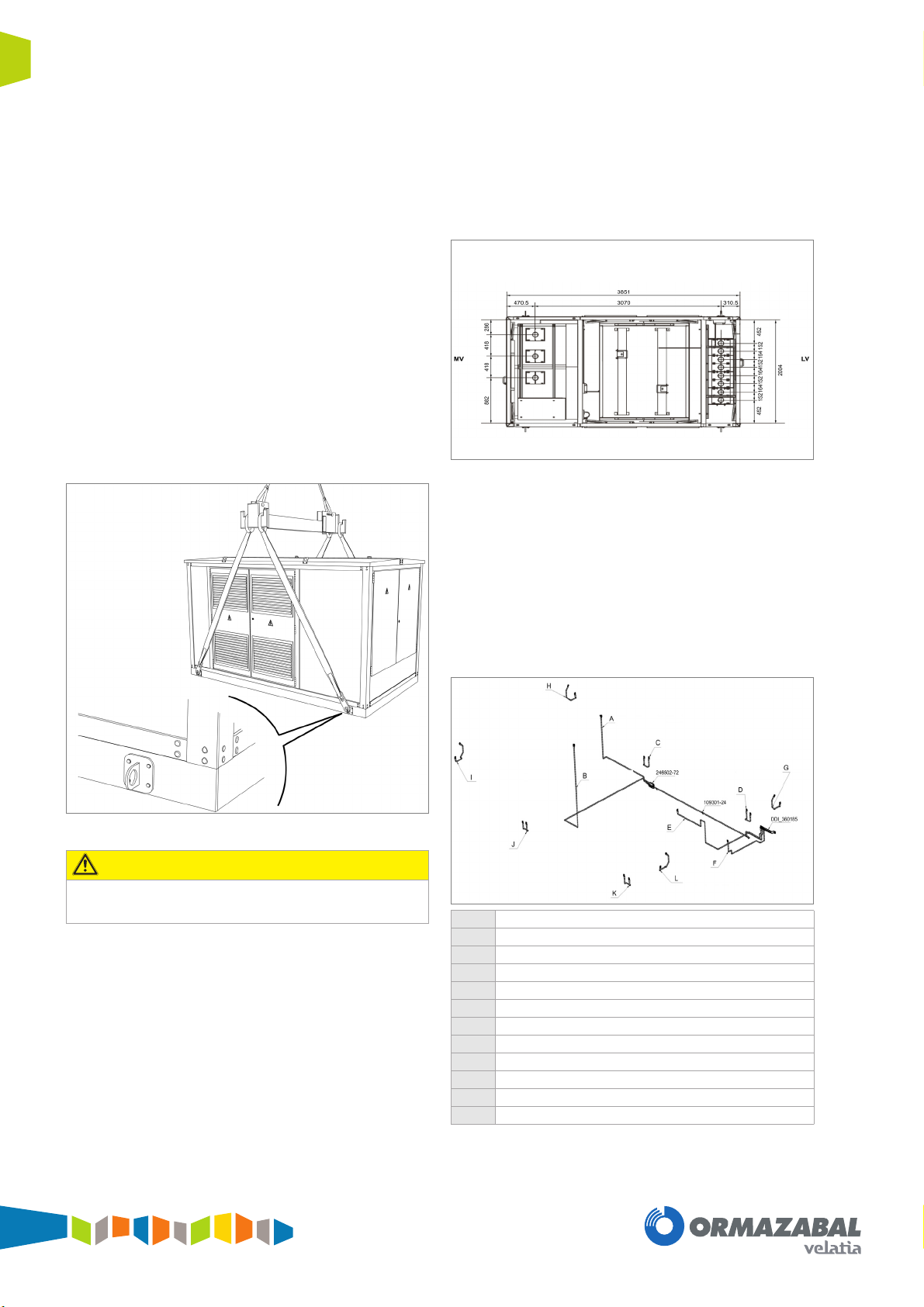

Fig. 1.1: Main Components of ormaSET-M

It is characterised by the incorporation of medium voltage

(MV) equipment for public distribution networks up to

36 kV. It has independent accesses for the medium voltage

switchgear compartment, for the transformer compartment

and for the low voltage switchboard compartment.

Made up of:

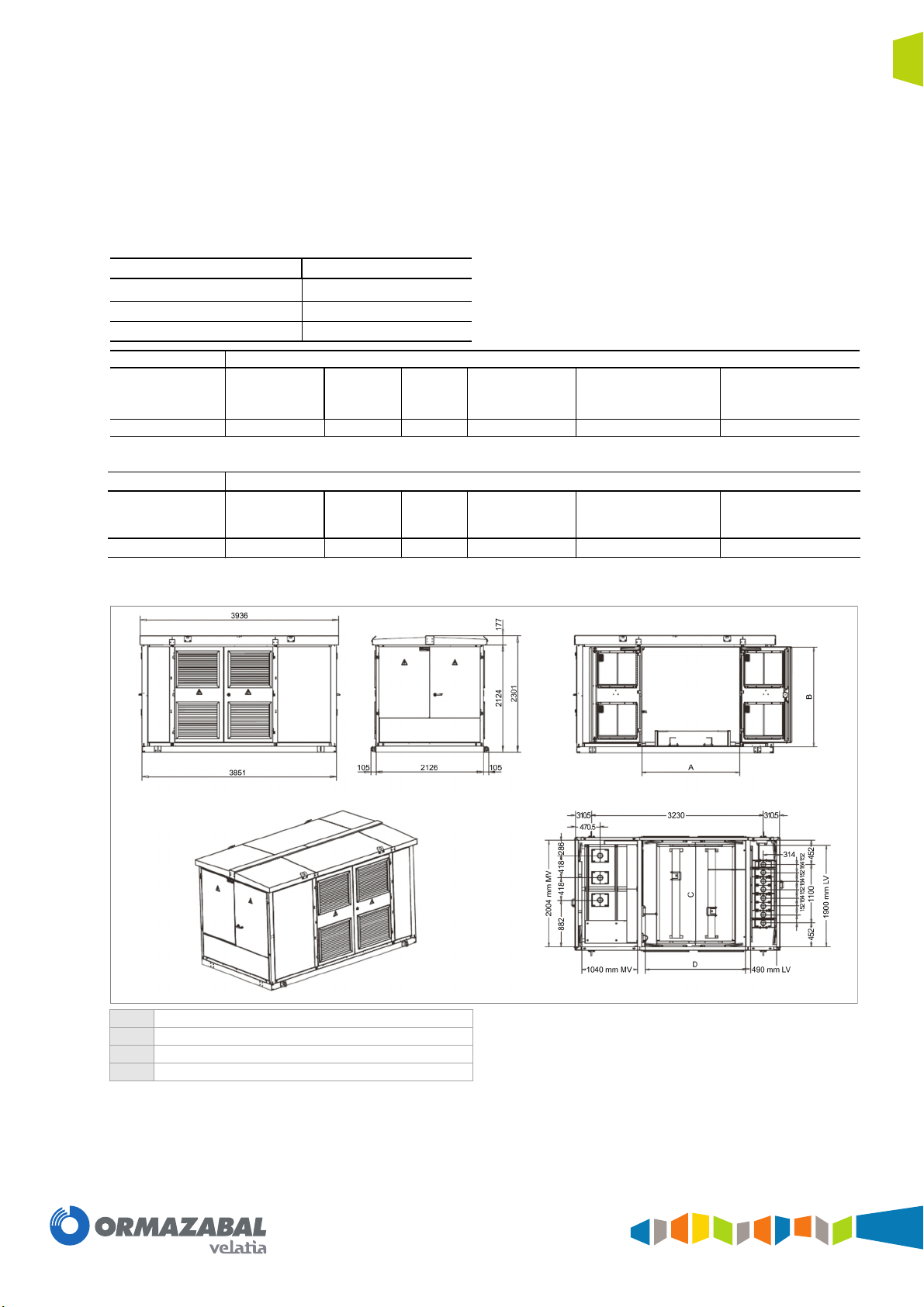

►Metal prefabricated enclosure.

►Removable roof dimensions 4046 x 2275 mm.

►Access doors to the electrical switchgear:

□Double access doors and dimensions of

997 x 1400 mm in the medium voltage area and

low voltage board area. Folding doors at 90º and

180° on the outside wall, hinged, with a two fixing

point and a fastening rod to hold them open

preventing untimely closures.

□Snow panel below medium voltage and low

voltage doors, dimensions 1997 x 486 mm.

□Access doors to the Transformer: Two accesses

to the transformer, one on either side, made up of

double doors of 963 x 1890 mm, folding at 90º

and 180° on the outside wall, hinged, with a two

fixing point and a fastening rod to hold them open

preventing untimely closures.

►Air intake and exhaust grille for natural ventilation,

fitted with a grille of 6 x 6 mm.

►Optionally, a closing system for the medium voltage

input cables in the lower part of the enclosure. Up to

3 input cables for 3 x 1 x 240 mm2XLPE 18/

30 kV H16. Maximum single core cable diameter

90 mm.

►Optionally, a closing system for the low voltage

input cables in the lower part of the enclosure. Up to

8 input cables for 4 x 1 x 240 mm2XZ1 0.6/1 kV.

Maximum single core cable diameter 90 mm.

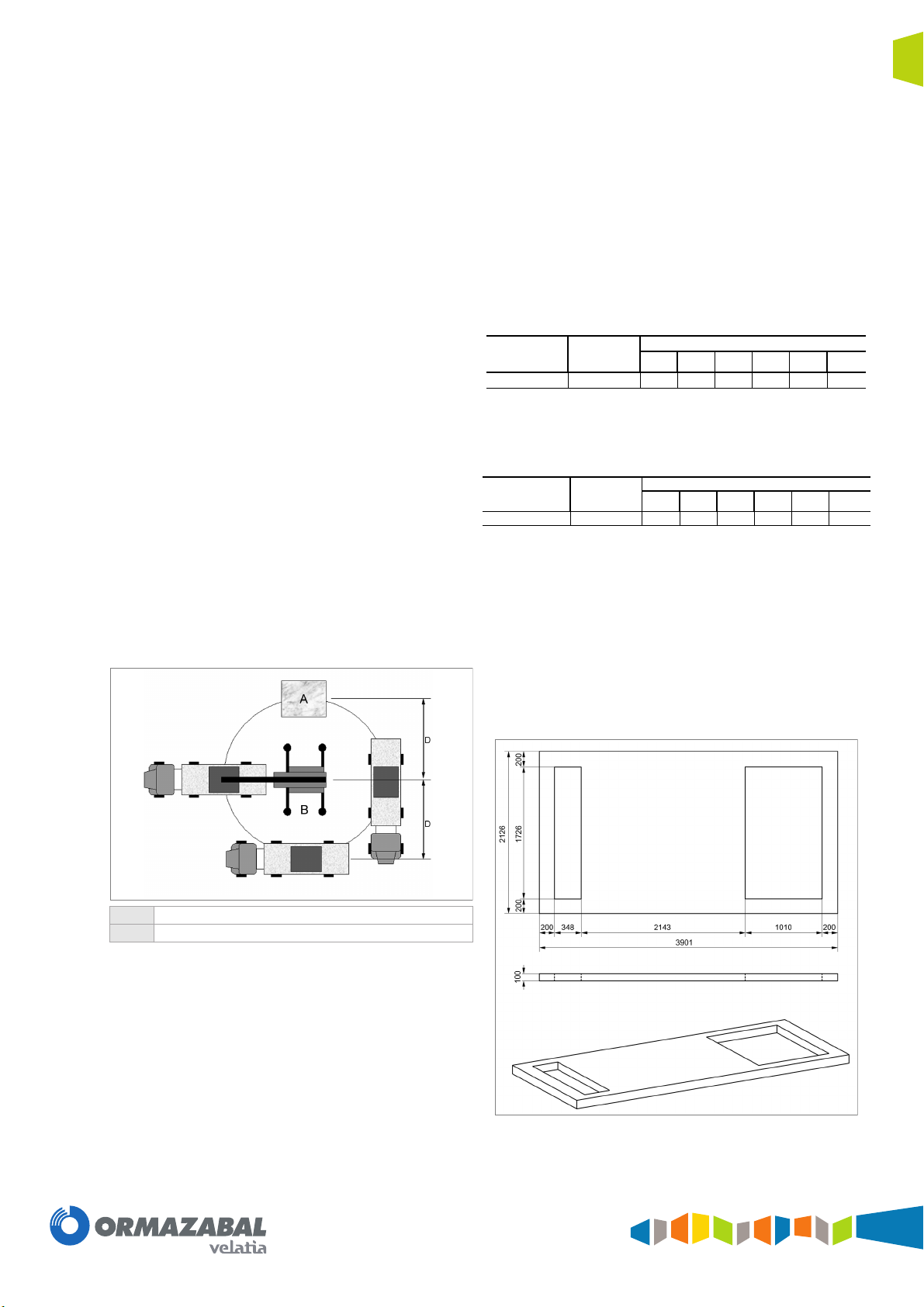

►Base frame manufactured with laminated profiles

UPE 140

►Optionally, an oil collection pit made of galvanised

sheet metal, with a capacity of 600 litres.

►Optionally protective earth disconnection box and

service earth disconnection box can be supplied,

located in the low voltage compartment on the left

and right of the low voltage switchgear.

►Earth circuit, copper conductor cross section

50 mm2.

►Document holder for general instructions relating to

the transformer substation.

►Lighting in the medium voltage, low voltage and

transformer compartments supplied.

►Optionally, emergency lighting of 50 Lm 1h NM,

IP42, IK04 1 x 6W, class II, 230 V 50/60 Hz.

According to standard IEC 60598-2-22.

►Physical separation between the medium voltage

compartment, power transformer and low voltage

compartment.

1Roof of prefabricated substation

2Enclosure of prefabricated substation

2.1 Medium voltage switchgear door

2.2 Power distribution transformer door

2.3 Low voltage switchboard door

2.4 Medium voltage cable inter-connection

2.5 Low voltage cable inter-connection