CONTENTS OF TECHNICAL SPECIFICATION

1. SAFETY INSTRUCTIONS.....................................................................................................3

1.1 Definition....................................................................................................................................3

1.2 General safety provision.............................................................................................................3

1.3 Safety warning............................................................................................................................4

1.4 Warning ......................................................................................................................................5

1.5 Guarantee....................................................................................................................................6

2. TECHNICAL PARAMETERS...............................................................................................7

2.1 Technical parameters..................................................................................................................7

3. DESCRIPTION.........................................................................................................................9

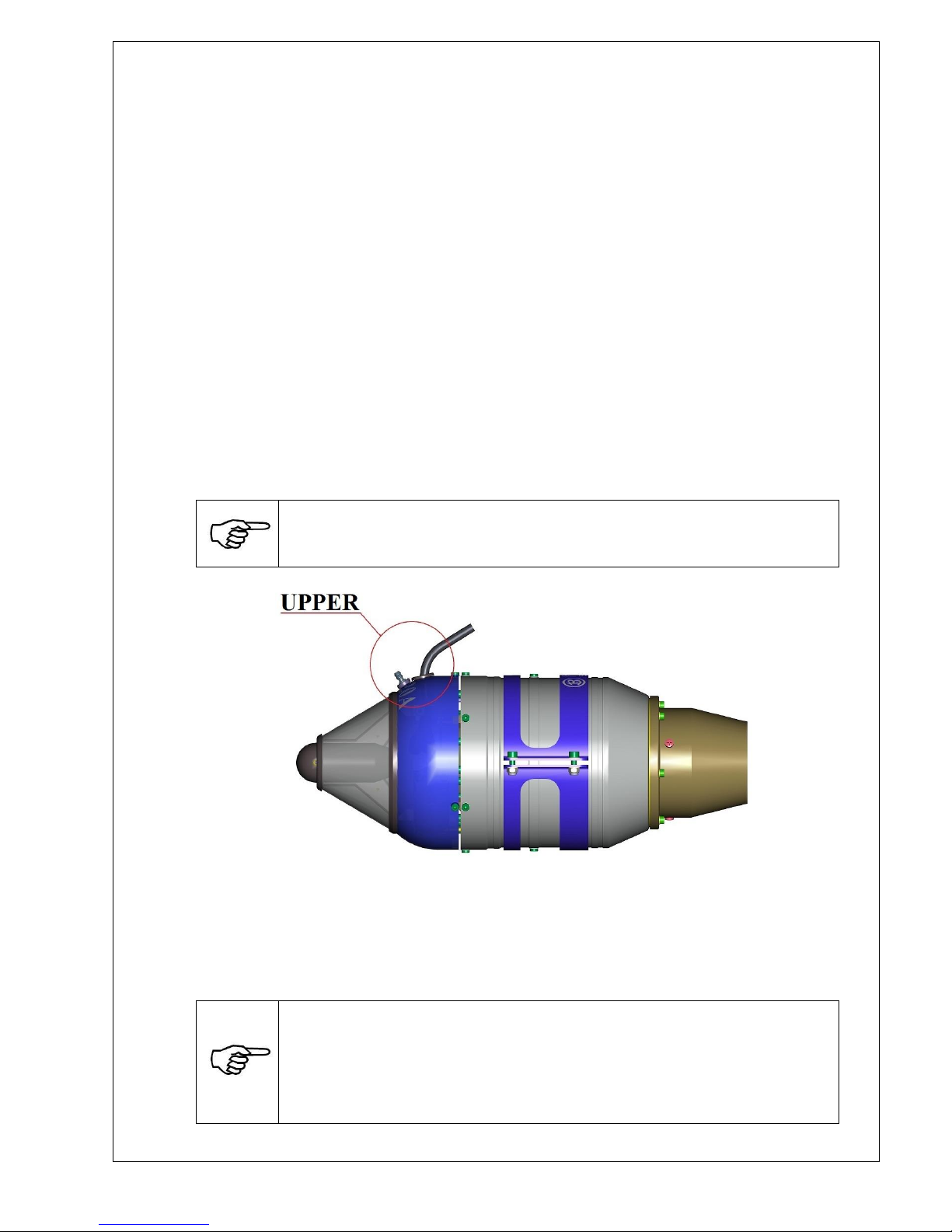

3.1 Description of engine..................................................................................................................9

3.2 Wiring of harness........................................................................................................................9

3.3 Connect of fuel supply................................................................................................................9

3.4 Starting instructions..................................................................................................................10

3.5 Connection scheme...................................................................................................................11

3.6 Recommended accessories .......................................................................................................13

4. EDT STATUS DISPLAY (ENGINE DATA TERMINAL) ................................................14

Menu A –Control Unit Modes ..........................................................................................................15

Menu B - Data....................................................................................................................................15

5. MAINTENANCE OF ENGINE ............................................................................................28

5.1 Check-up of rotating parts ........................................................................................................28

5.2 State of fuel filter pollution.......................................................................................................28

5.3 Stocking instructions.................................................................................................................28

6. CONTENT OF ENGINE IS PACKAGE..............................................................................28

7. EXHAUST PIPE FOR THE TJ20A TURBOJET ENGINE ..............................................29

8. TURBOJET ENGINE TJ20A DIMENSIONAL DRAWING............................................30