remove the fabric.

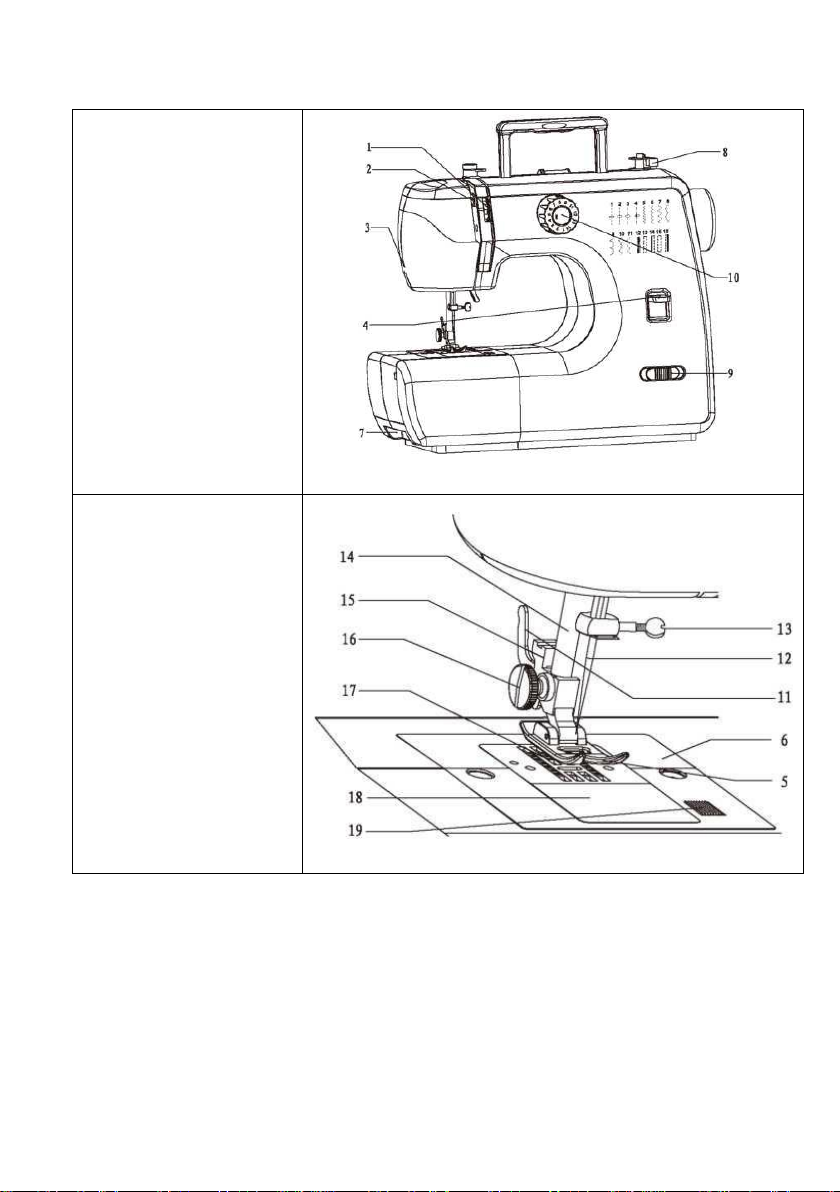

6. Needle Plate is located under the presser foot area, around the feed dogs. It

provides a flat surface for the fabric while sewing.

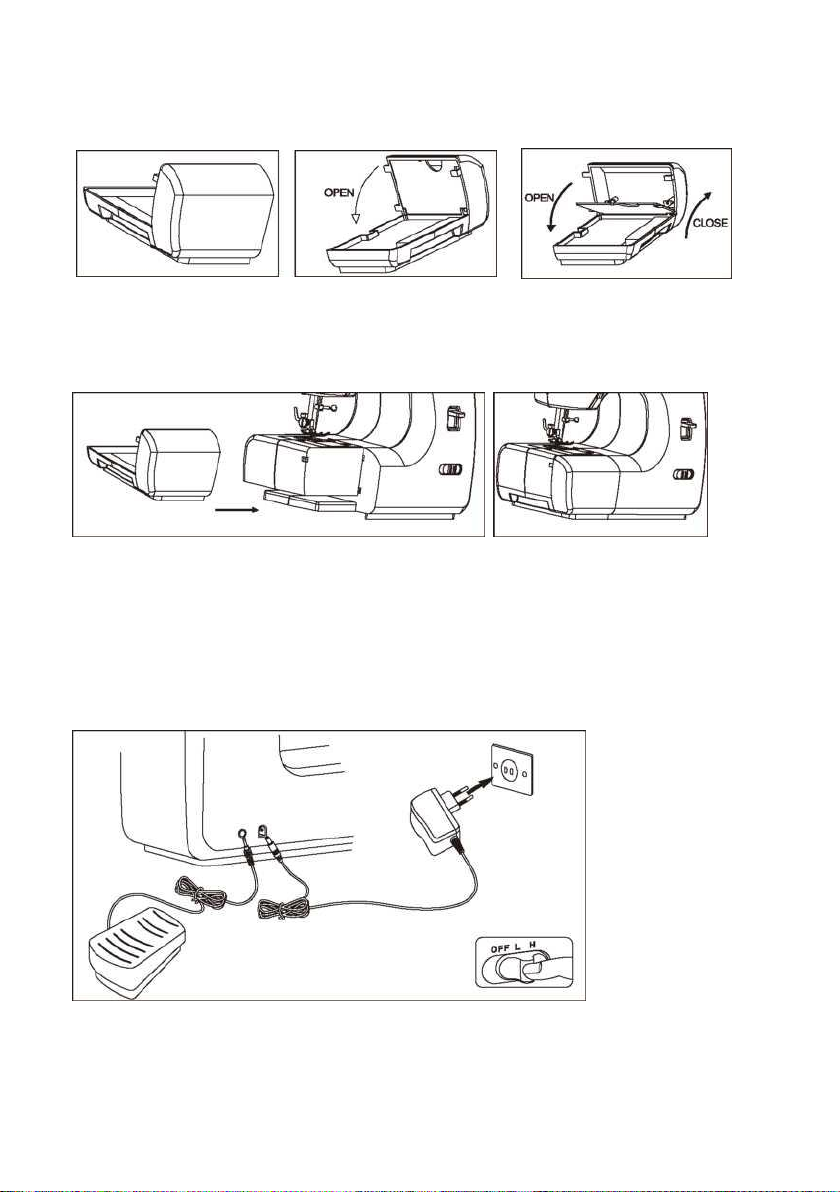

7. Removable Extension Bed provides a larger surface around the arm of the

machine to support fabric while sewing. This can be removed to access the free

arm, making it possible to sew smaller, harder-to-reach areas such as pant or

sleeve hems. There is a storage compartment for the machine's accessories,

keeping accessories within hands reach.

8. Bobbin Winding Stopper is used in the process of winding the bobbin.

9. Power On/Off & Speed Control Switch is used to turn the machine on and off.

There is an “L” setting for lower speed, and an “H” setting for higher speed.

10. Pattern Selector Dial is used to set the machine to the stitch you want to sew. It is

numbered from 1through 12, and the numbers correspond to the display near

the top of the machine. Just turn the dial to the stitch you want and sew.

11. Presser Foot Release Lever is located at the back of the presser foot holder. Use

this lever to remove the presser foot from the presser foot holder.

12. Needle is placed into the needle bar and is required in order for the machine to

sew.

13. Needle Clamp & Screw work together to hold the needle in place for sewing.

14. Presser Bar holds the presser foot and presser foot holder. It is raised and

lowered using the presser foot lifter

15. Presser Foot Holder is attached to the presser bar. It holds the presser foot in

place for sewing.

16. Presser Foot Screw is located to the left of the presser foot holder. The screw is

used to secure the presser foot holder in position on the presser bar

17. Feed Dogs move the fabric under the presser foot.

18. Bobbin Cover Plate sits over the bobbin and bobbin case. It is transparent,

making it easier to monitor the thread supply.

19. Bobbin Cover Release Button is located to the right of the bobbin cover plate.

Press it to the right to release the cover when replacing the bobbin.

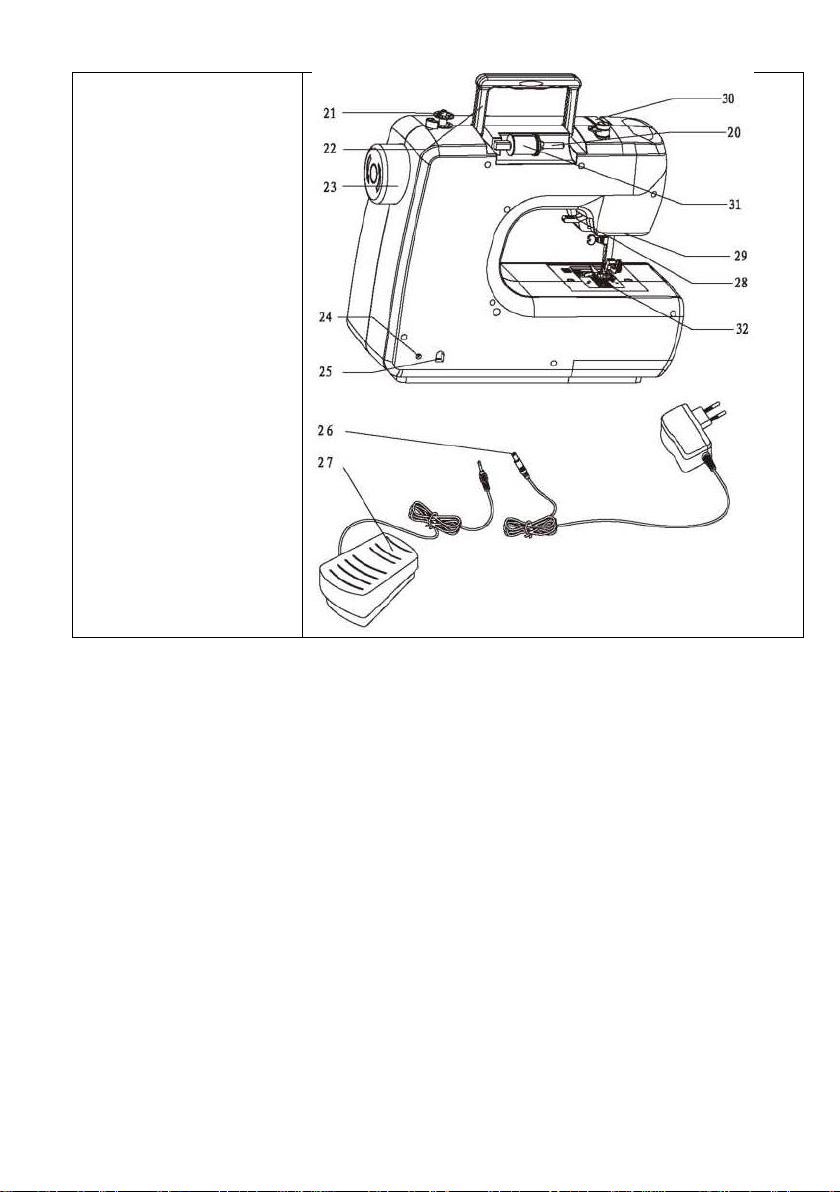

20. Spool Pin holds the thread spool. The spool pin holder fits onto the spool pin to

allow thread to unwind without tug or drag. The spool pin can be used in either

of two ways (horizontally or vertically), depending on the size of the thread

spool being used.

21. Bobbin Winder is used for smoothly and evenly winding thread onto the bobbin.

22. Carry Handle is built-in, making it easy and convenient for transporting the

machine.

23. Hand Wheel controls the movement of the take-up lever and the needle.

Always turn the hand wheel toward you.

24. Foot Controller Input is located at the back of the machine. The foot controller

cord must be plugged into this input before starting to sew.

25. Power Cord Socket at the back of the machine is where the power cord is

inserted in order to provide power to the machine.