| Pg 4

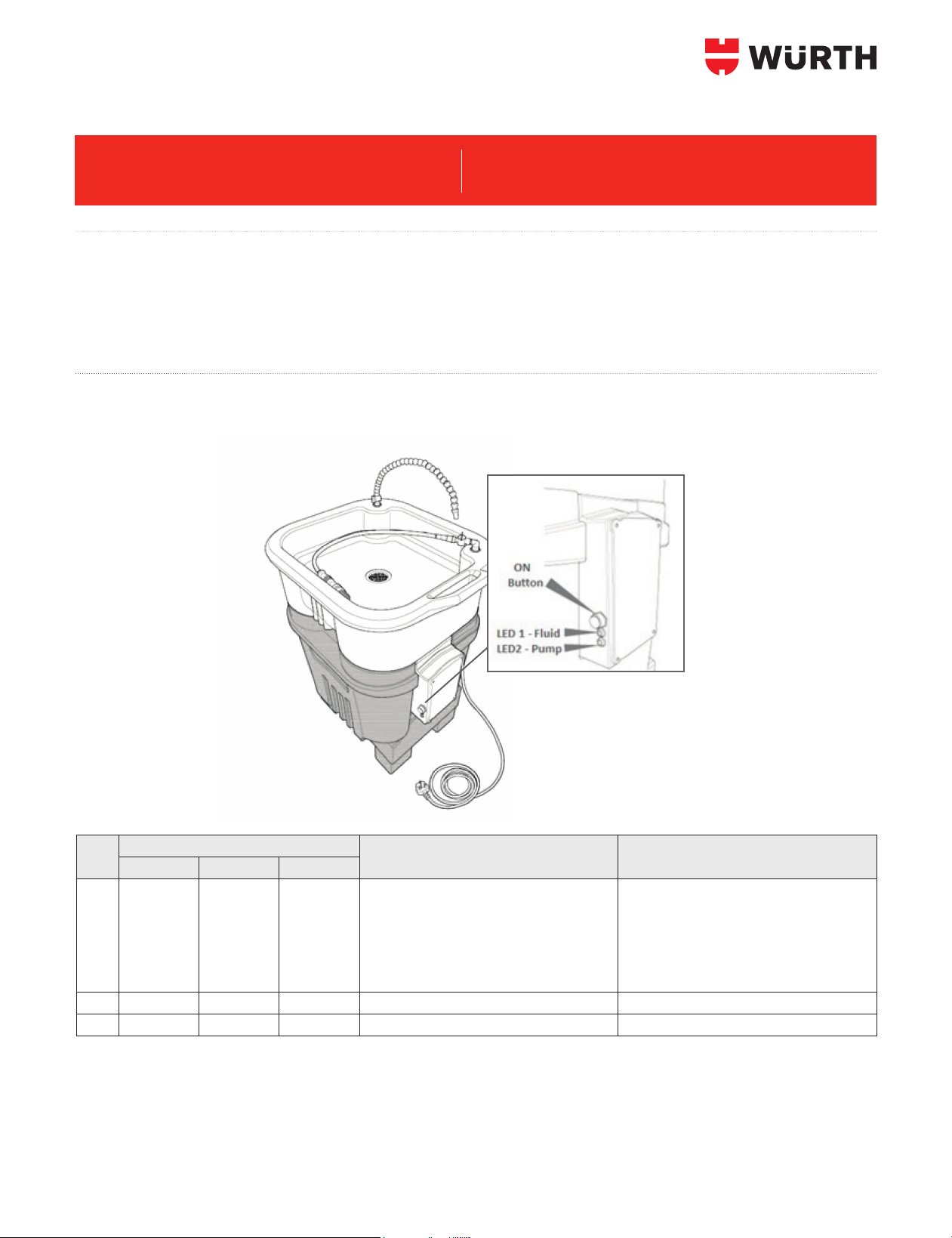

6. SETTING UP

After removing packaging, check the unit for transport damage. If any defect is detected do not connect the machine to the mains.

Report damage to vendor.

Situate the Biomatic Parts Washer on at stable ground. The oor must be even to ensure safe operation.

Press the wheel brakes on the rear of the machine.

Remove the black sink tray.

Unpack the lter mat and place it white side up on top of the lter support grid.

Replace the black sink tray on top.

Pour 60 litres of Biomatic Fluid slowly into the sink.

Do not overll.

WARNING – Adding any other cleaning solution or liquids such as solvents, disinfectants and alkaline cleaners can deactivate

the microbes and the bioremediation of grease and oil will be aected resulting in the Biomatic Parts Washer not working properly.

Plug into the correct mains supply. To avoid damage, the machine must be plugged into the power source stated on the machine

control box label. Switch on electrical supply.

The Biomatic Parts Washer will begin to heat up the cleaning solution to its optimal

working temperature of 42°C. (This will take approx. 4 hours)

7. OPERATION

Cleaning is a manual operation using the o-thru brush in the Biomatic Parts Washer sink top.

Wear appropriate PPE such as safety goggles and protective gloves.

Place the dirty parts in the sink tray (maximum weights must not be exceeded – see 3. PROPER USE).

Press the metal on/o button to turn the pump on. Wet the sink, nozzle and brushes prior to cleaning to prevent grease and dirt

sticking to the surfaces. The pump will run for 5 minutes and then automatically switch o.

Open the tap of the desired tool – you can use both the nozzle and the o-thru brush at the same time for maximum cleaning if desired.

Note: Any parts susceptible to corrosion should not be left in sink after cleaning.

As with all parts washers excess grease and oil should be disposed of prior to washing.

DO NOT USE THE Biomatic Parts Washer AS A WASTE DUMP

Do not turn the Biomatic Parts Washer o unless it is for safety reasons, moving or servicing. The

optimum temperature for the activity of the microbes and therefore breakdown of oil and grease is between

37°C and 42°C, therefore the biomatic parts washer must always be left switched on.

BIOMATIC 2.0 MOBILE WASHER

Operating Manual