Table of Contents

General Information ________________ 1

HIGHLIGHTED INFORMATION _____________ 1

GLOSSARY ____________________________ 1

IDENTIFYING NUMBER LOCATIONS ________ 1

ENGINE SERIAL NUMBER LOCATION_______ 2

SERVICING OF ENGINE AND

DRIVETRAIN COMPONENTS ______________ 2

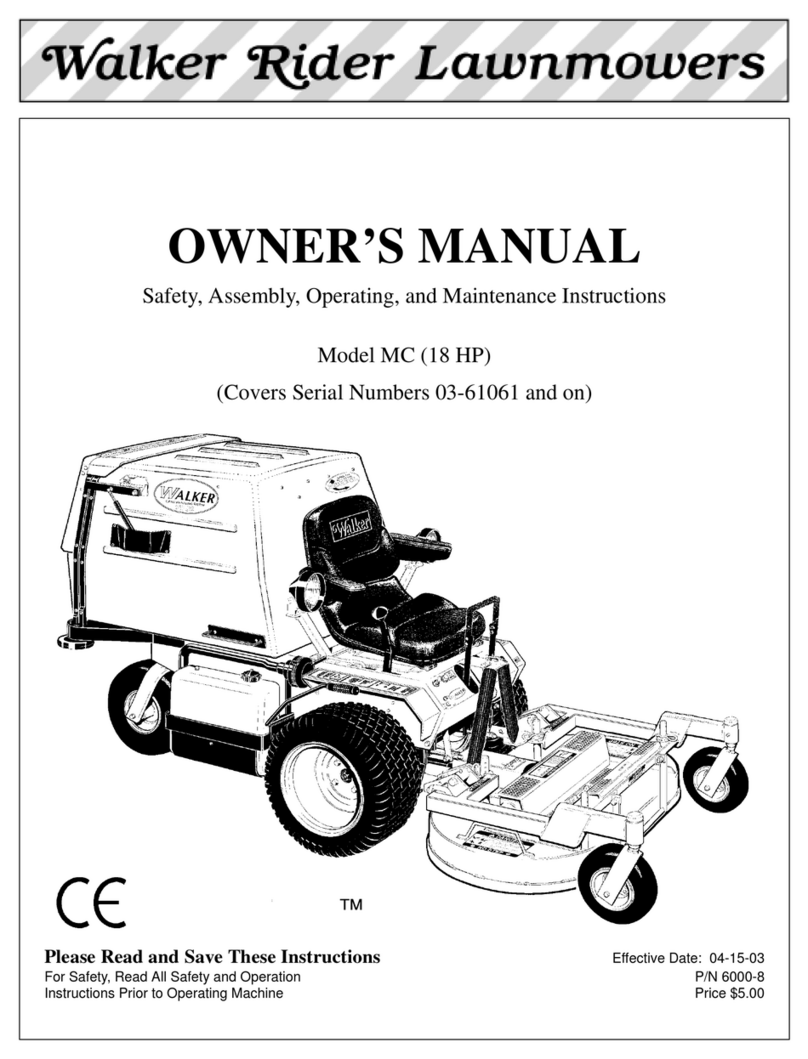

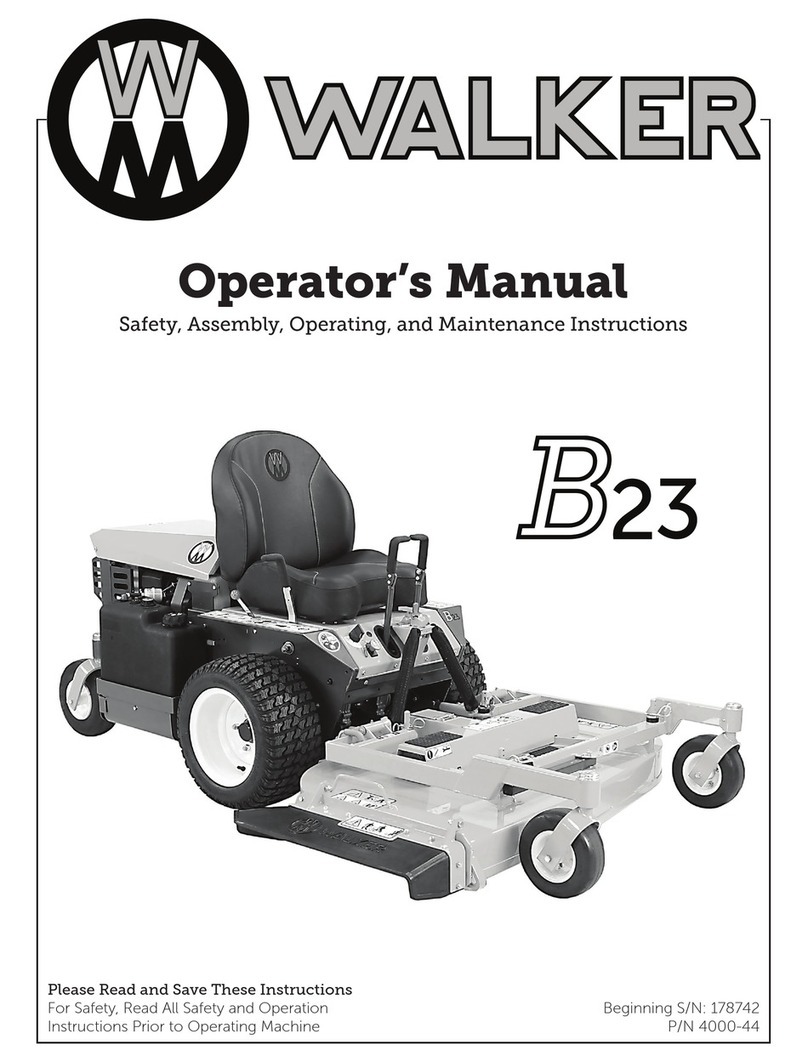

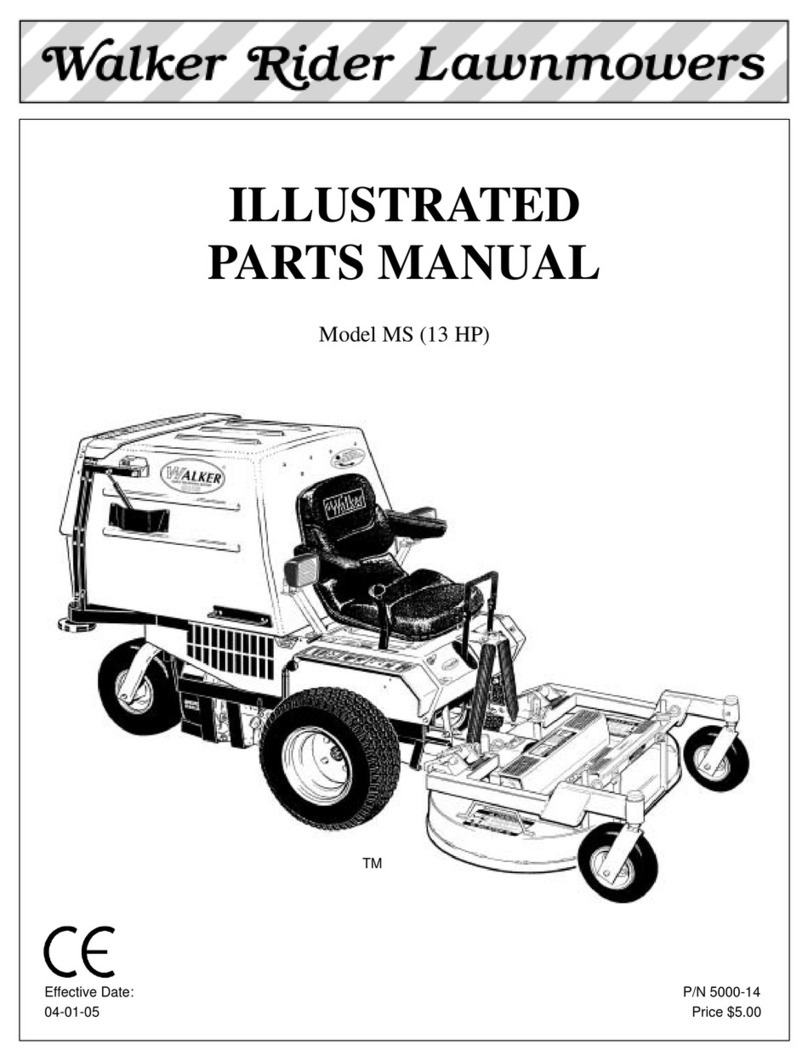

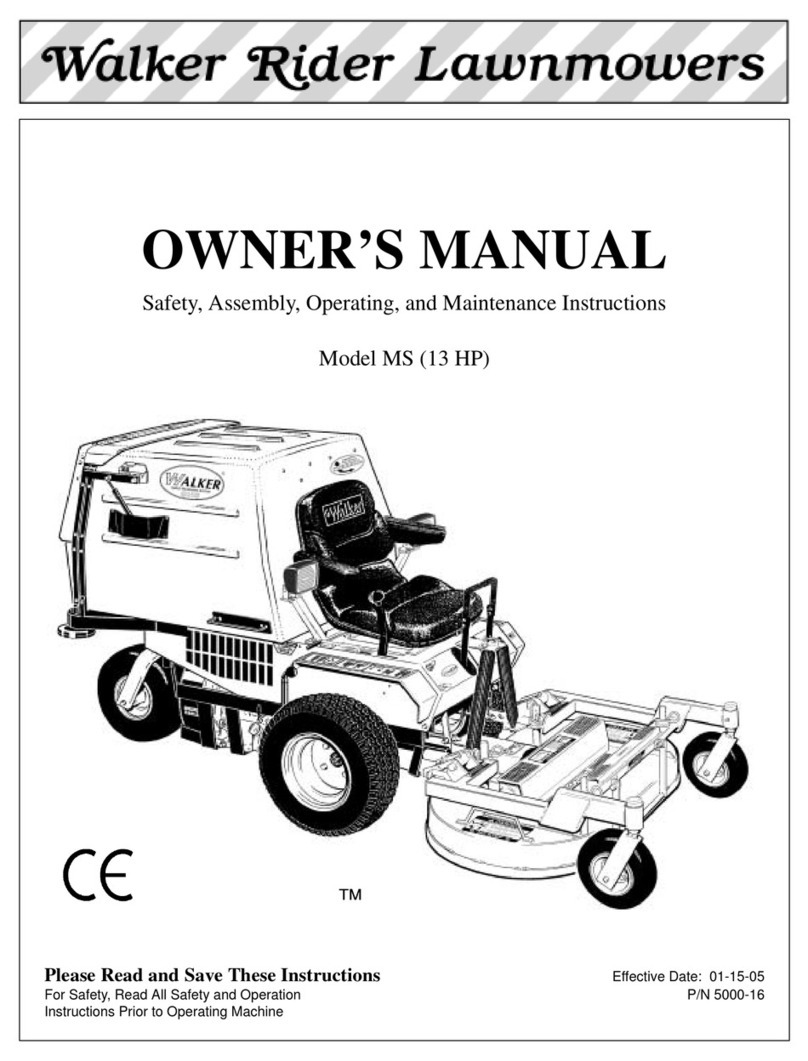

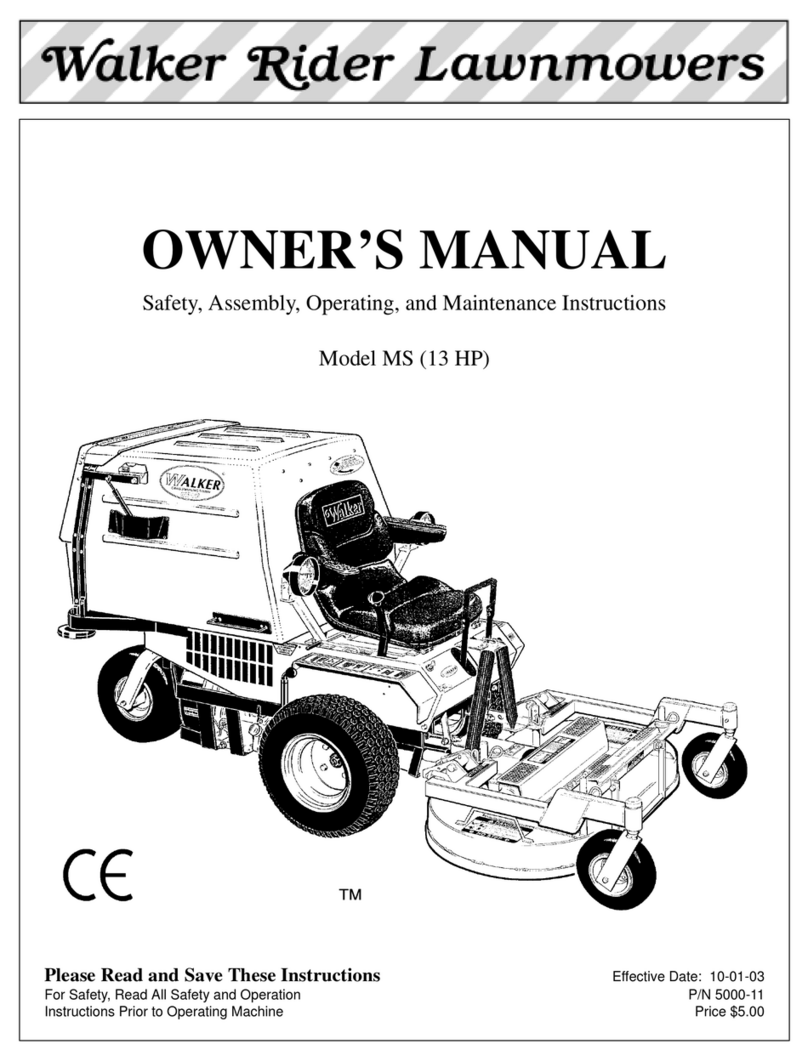

Specications________________________ 3

ENGINE________________________________ 3

ELECTRICAL SYSTEM ___________________ 3

TRANSAXLE____________________________ 3

BLADE DRIVE __________________________ 4

TIRE SIZE ______________________________ 4

TIRE PRESSURE ________________________ 4

DRIVE BELTS ___________________________ 4

SEAT __________________________________ 4

FRAME/BODY CONSTRUCTION____________ 4

DIMENSIONS (Tractor and Mower) __________ 5

DECK CHART ___________________________ 5

Component Identication ___________ 6

Safety Instructions __________________ 9

BEFORE OPERATING ____________________ 9

OPERATING ___________________________ 11

MAINTENANCE ________________________ 13

SAFETY, CONTROL,

AND INSTRUCTION DECALS _____________ 14

Assembly Instructions______________ 18

SETUP INSTRUCTIONS__________________ 18

Tire Installation (Tractor) _______________ 18

Battery Service _______________________ 18

Wet Battery Service __________________ 18

Dry Battery Service___________________ 19

Battery Charging_____________________ 19

Battery Installation ___________________ 20

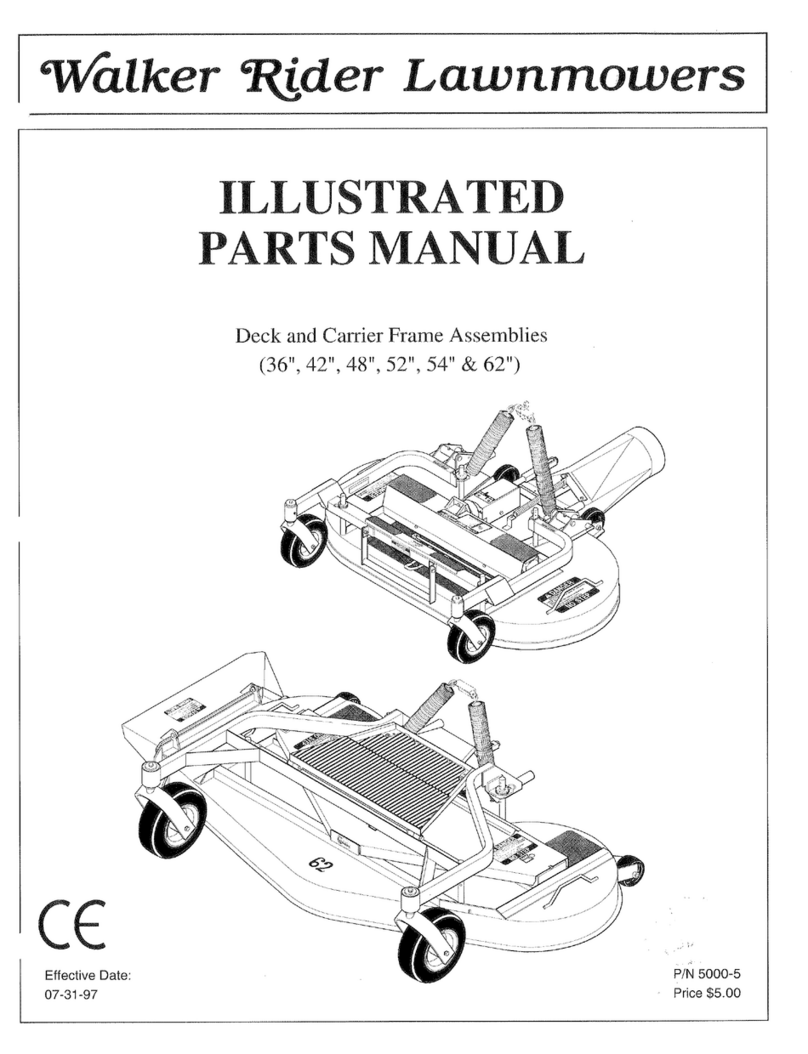

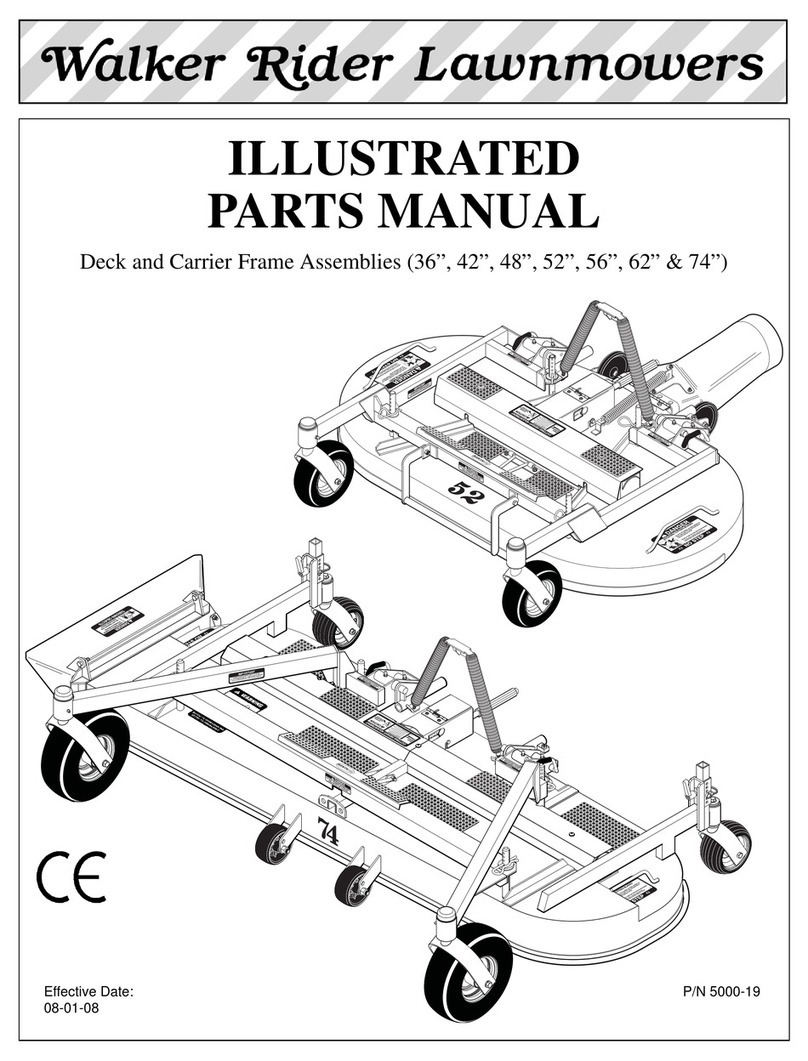

Mower Deck Assembly_________________ 20

Deck Caster Wheels Installation _________ 20

Deck Discharge Deector

Shield Installation ____________________ 20

PTO Shaft Guard Installation ___________ 21

Tilt-Up Roller Wheel Installation _________ 21

Mower Deck Installation on Tractor_______ 21

Deck Installation _____________________ 21

Deck Leveling _______________________ 23

Measuring Deck Levelness ____________ 23

Deck Leveling Procedure _____________ 24

PREOPERATING CHECKLIST_____________ 25

Operating Instructions _____________ 28

CONTROL IDENTIFICATION,

LOCATION, AND FUNCTION _____________ 28

Ignition Switch _______________________ 28

Engine Throttle _______________________ 29

Body Latch __________________________ 29

Forward Speed Control (FSC) ___________ 29

Steering Levers_______________________ 29

Blade Clutch (PTO)____________________ 29

Parking Brake ________________________ 30

Oil Pressure Warning Light/Horn ________ 31

Engine Service Light __________________ 31

Over Temperature Warning Light/Horn____ 31

Transaxle Lockout Arms _______________ 32

Circuit Breaker _______________________ 32

Hourmeter ___________________________ 32

Roll-Over Protection

System (ROPS, Optional)_______________ 33

Suspension Seat______________________ 34

STARTING THE ENGINE _________________ 37

ADJUSTING GROUND

SPEED AND STEERING__________________ 37

ENGAGING THE BLADE DRIVE ___________ 39

STOPPING THE MACHINE _______________ 40

FUEL TANK SELECTOR VALVE ___________ 41

ADJUSTABLE FOOT RESTS ______________ 41

ADJUSTING CUTTING HEIGHT____________ 41

Transport Position ____________________ 42

TRANSAXLE LOCKOUT _________________ 42

RECOMMENDATIONS FOR MOWING ______ 42

RECOMMENDATIONS FOR TILT-UP DECK

OPERATION/TRANSPORT _______________ 44