MF Freezer Operating manual

WCB Ice Cream 2-29

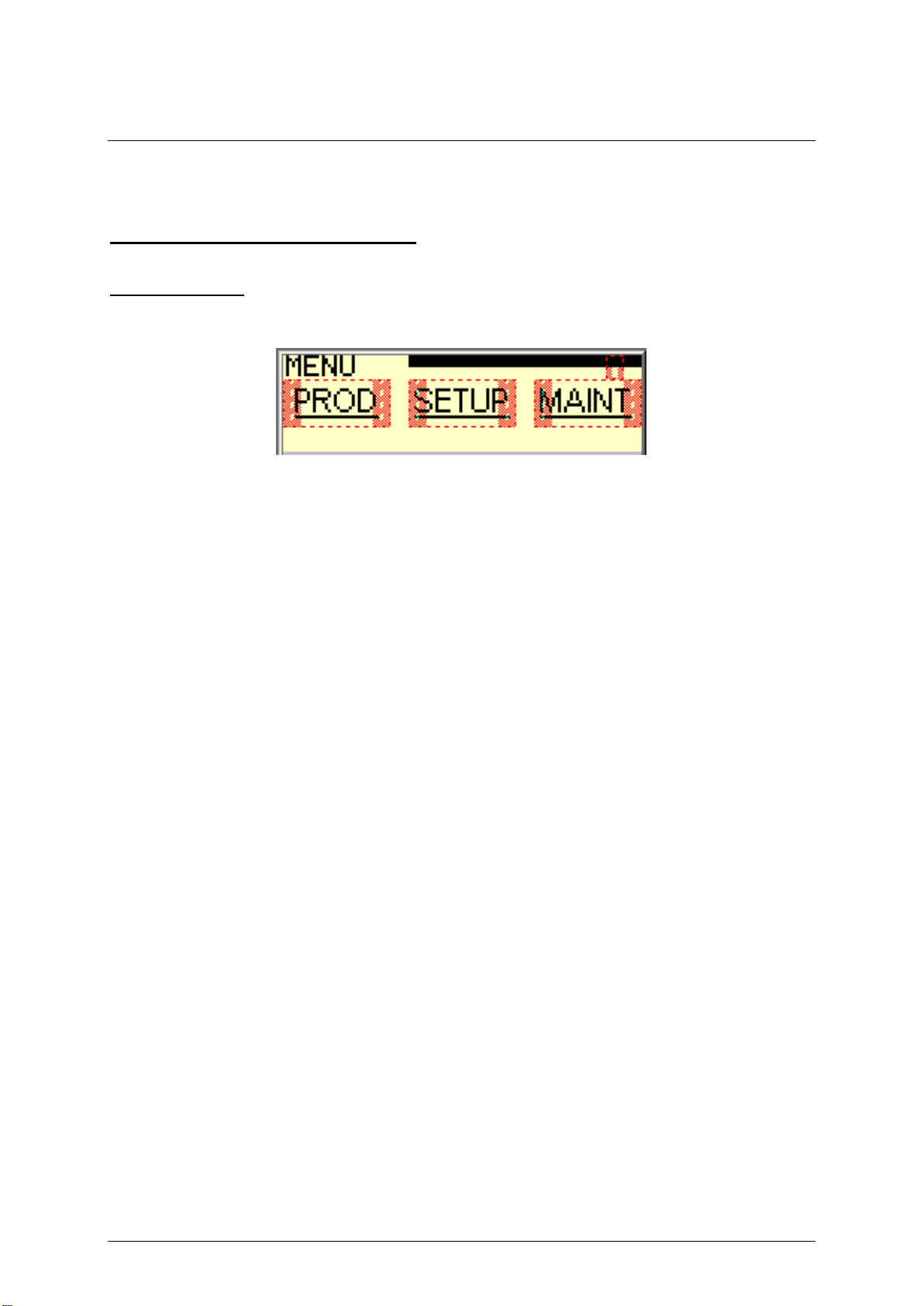

A Quick Description of the Operator Panel

For an easy reference please open the operator panel folder in the back of this manual.

K1 Key No 1: Start Pumps.

By pressing this key once the pumps will start if no error conditions exists. At the same time

the green LED L1 will light up. Pressing the key again will stop the pumps.

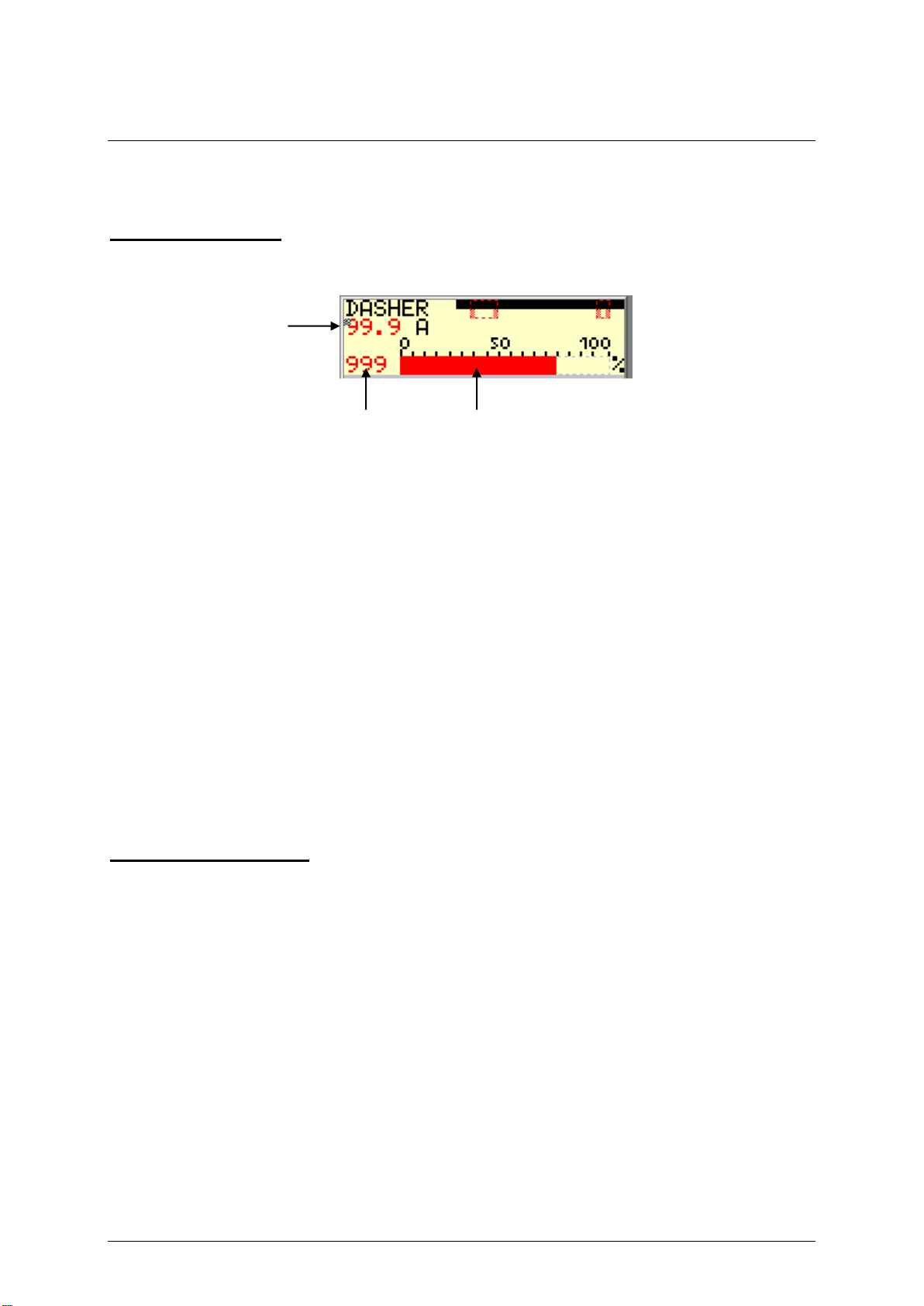

K2 Key No 2: Start Dasher.

By pressing this key once, the dasher will start if no error conditions exist. At the same time

the green LED L2 will light up. Pressing the key again will stop the dasher.

K3 Key No. 3: Start Compressor.

By pressing this key once, the compressor will start if no error conditions exist. At the same

time the green LED L3 will light up. Pressing the key again will stop the compressor.

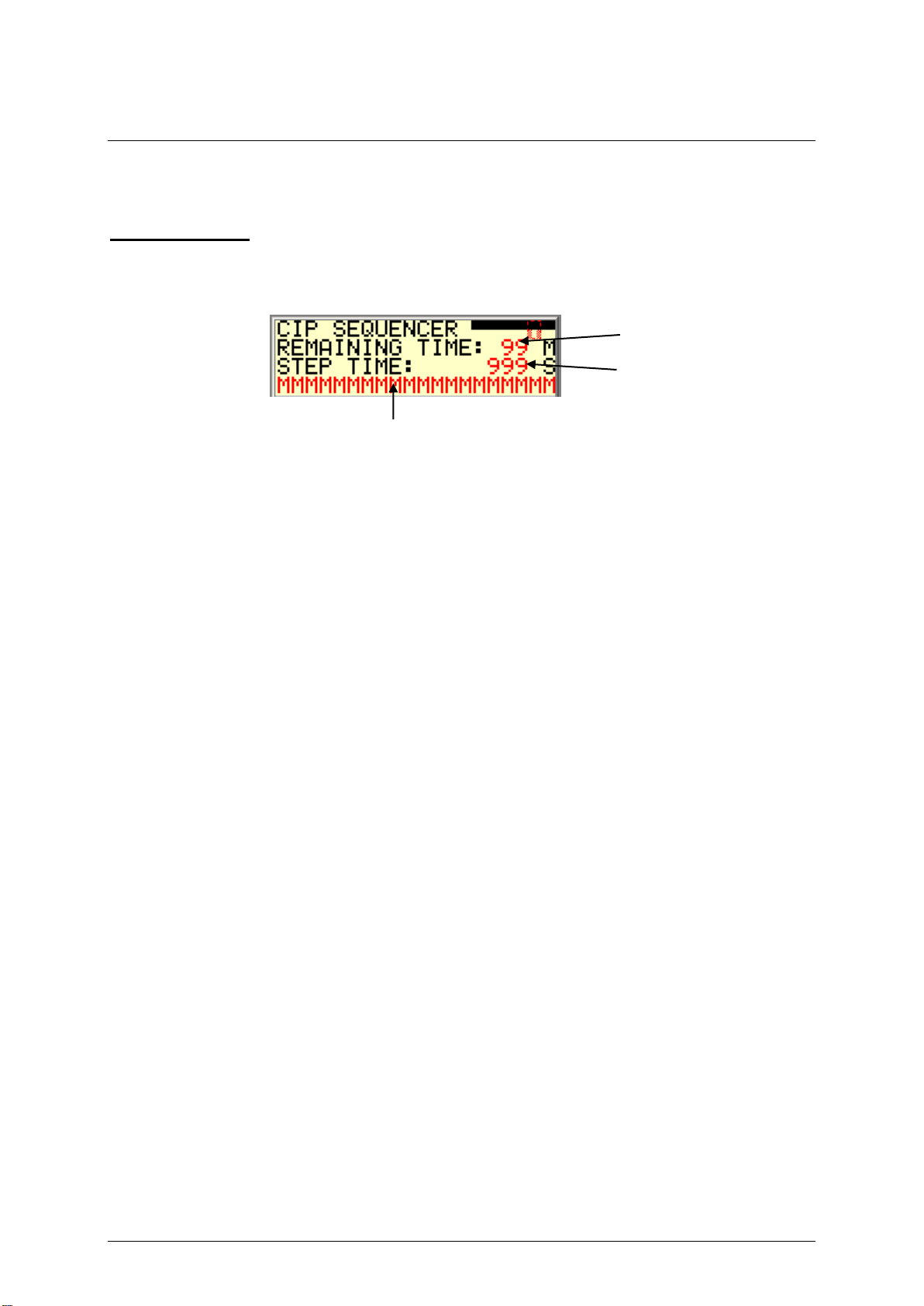

K4 Key No. 4: Start CIP.

By pressing this key once, the CIP sequence will start if no other functions are running. At the

same time the green LED L4 will light up. Pressing the key again will stop the CIP Sequence.

K5 Key No 5: Escape.

This button is used to acknowledge alarms as well as exiting the current displayed screen on

the Operator panel.

K6 Key No 6: Left arrow.

This button is used to decrement setpoints on the production screens as well as moving the

cursor in the menu and maintenance screens.

K7 Key No 7: Arrow Up.

This button is used to increment setpoints in the set Up screens as well as activating outputs

and Incrementing control values in the maintenance screens.

K8 Key No 8: Arrow Down.

This button is used to decrement setpoints in the set-up screens as well as deactivating

outputs and Decrementing control values in the maintenance screens.

K9 Key No 9: Right Arrow.

This button is used to increment setpoints on the production screens as well as moving the

cursor In the menu and maintenance screens

K10 Key No 10: Enter.

This button is used to step to the next screen in production, set up, and maintenance screens.