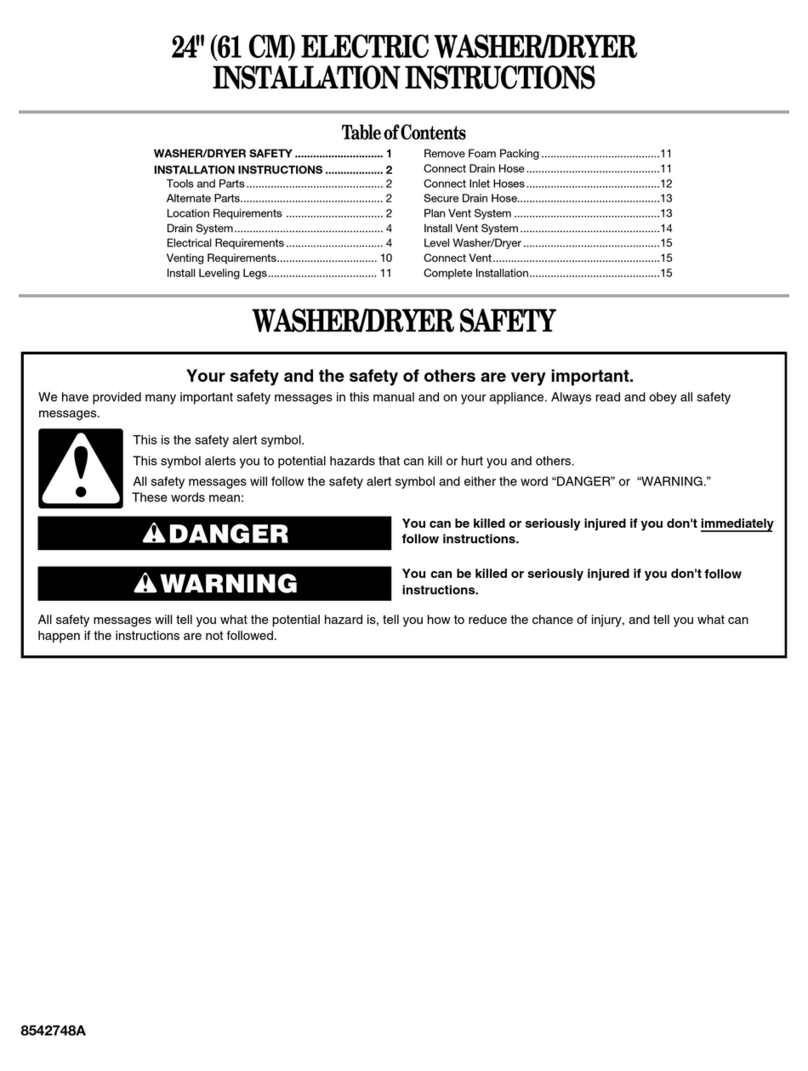

Before you start...

Mark an X across the letter or

number as you complete each

step. phillips screwdriver

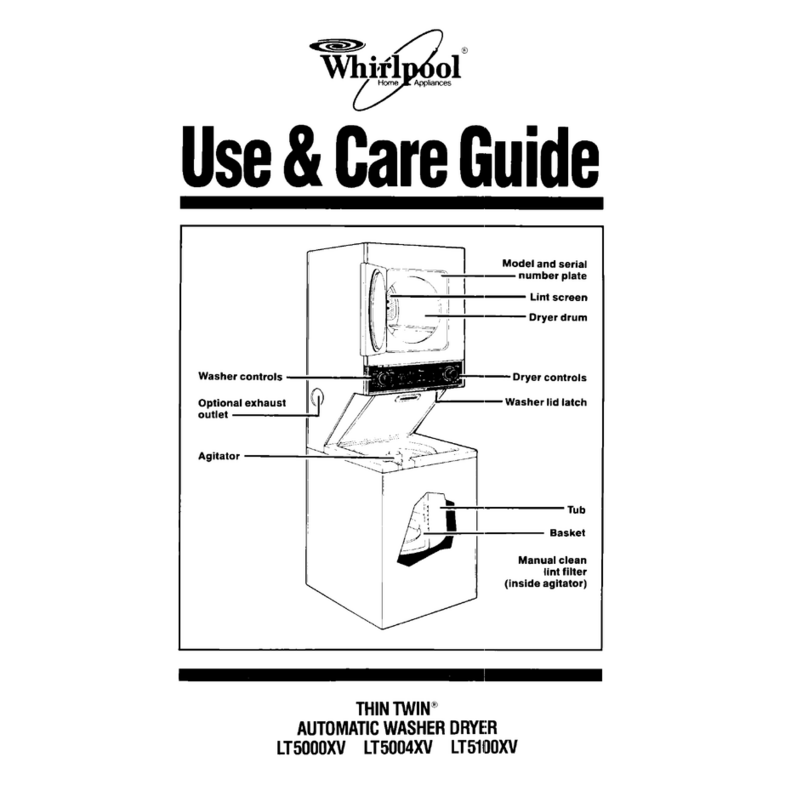

You need these looIs to install your

Whirlpool washer/dryer. Get them

together in one place to keep

washeridryer...pro-&r

installation isyour responsibility

Make sure you have everything

necessary for proper installation.

You’ll need

Tomeet code tequlremenb:

some codes keep from or limit

installation of clothes dryers in

garages. closets. mobile homes

and sleeping quarters. (Check

with your local building inspector)

Important: observe all governlng

codes and ordinances.

Location

Size: Must be large enough to fully

open dryer door. For recessed or

closet inrjtallationssee Panel Ffor

spacing. for product dimensions

see back page of these

instructions.

Support: The floor must be able

to support the appliance weight

of 375 pounds.

Level Floor: Maximum floor slope

under washer/dryer1 inch.

Protectlon from the weather:

Proper operaflcn of dryer cycles

requires temperatures above 45°F.

As some water remains In the

washer do not store or operate the

washer below 32’F. For storage

below 32°F see Laundry Guide for

“Wtnterizing:’

Moblle Homes: Washer/dryer

must be secured to the mobile

home using Mobile Home

Installation Kit 693900.

CAIJIION:

l

It isthe personal responsibility

Ofthe customer to ensure that

gasoline. paint.thinners and

other flammable materials are

not used or stored near the

washer/dryer. Fumes from these

materials could result in fire or

explosion

l

Never install the washer/dryer

up against draperies or curtains

and be sure to keep any and all

Items from falling or collecting

behind the washer/dryer.

l

Replace all access or sewice

panels before operating

washer/dryer.

Electrical

requirements

Electrical ground Is required on

this appliance.

1. A three-wtre single phase

1201240 volt 60 HzAC only

electrical supply (orthree-wire

1201208 volt if specified on

nameplate) is required on a

separate 30 ampere circuit,

fused on both sides of the line

(time-delay fuse or circuit

breaker isrecommended]. Do

not have a fuse in the neutral

or ground circuit.

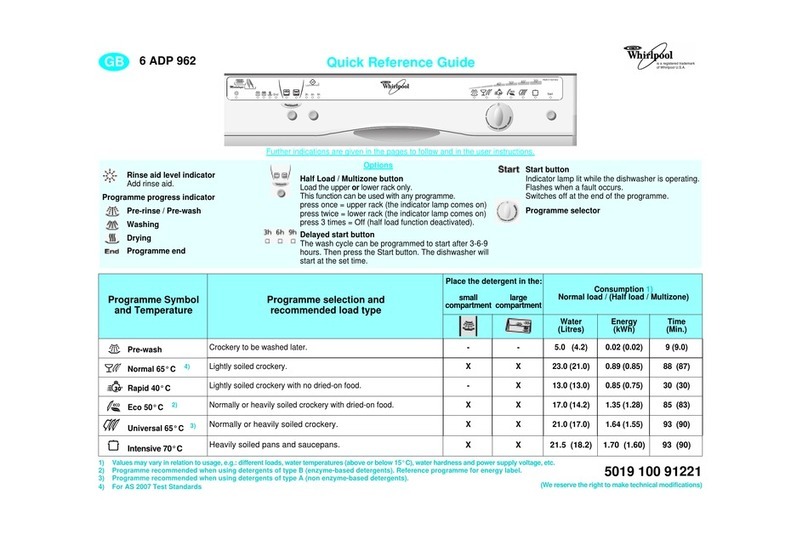

PANEL A

2. Thiswasher, dryer ISequrpped

with a 30 amp rated flexible

type power supply cord [pigtall).

Where local codes permit. it

See Figure 1. (IO-3OR)

3-wire receptacle

3. IFTHEPOWER FIgureI

MUST BECONNECTED WITH

10GAUGE COPPER WIRE ONLY

Aluminum wire musf not be

used at the washer/dryer

appliance terminal block, to

avord potentially unsatisfactory

connections. See Panel F.

Alternate Electrical

Connection. for detailed

instructions.

4. When removing the power

SUDDlvcord loiataill. the

appliance may be connected

directly to the fused disconnect

[or circuit breaker] box through

flexible armcxed (x ncn-metallic

sheathed 10gauge copper

cable. It Isthe oersonal

responsibility and obligation of

the customer to contact a

qualified installer to assure

that Me electrical installation

isadequate and is in

conformance with the Nationa!

Electrical Code and local

codes and ordinances.

Allow slack in the line between

the wall and the appliance

so that it can be moved if

servicing is ever necessary. A

U.L.recognized strain relief must

be provided at each end of the

power supply cable (af the

appliance and at the junction

box). Wire sizes (10gauge

COPPER WIRE ONLY] and

connection must conform with

the rafing of the appliance

(30 amperes). DO NOT USEAN

EXTENSION CORD.

5. CAUTION - For mobile home

installation the J-wire power

Supply cord must be removed

and the appliance wiring must

be revised; the appliance

frame must not be connected

to the neutml termrnal. but must

be connected to the ground

cord (see Punel F,Alternate

ElectrIcal Connection, for

detailed instructions].

Figure 2 (14.30RJ : : ”

I-wire receptacle

iT‘

rvPkOl30AllIDmcep)1acle ;> ,“Y I

., :

“Y:“se*,elocolcode,

Pmnllnem,. typewpp,y j, :

cord,PIOIdl,.

If a four-wire receptacle of

NEMA type14-30R [see Figure 2)

isavailable, a matching power

supply cord (pigtail) must be

used. Thiscord contains four No. 10

gauge copper conducton with

spade or ring terminals on the

washer/dryer end and terminating

in a NEMA tYpe 14.30P plug

on supply end. The Fourth

(grounding) conductor must be

identified by a green cover and

the neutral conductor by a white

cover Cord should be lope SRDor

SRDT.with a U.L.recognized strain

relief. and be at leost 3 feet and

na more than 6 feet long. The four

wire power supply cord and strain

relief are not provided with the

washer/dryer

Exhaust requirements

Four Inch Metal Exhaust Duct is

required. (Do not use 3 inch

exhaust duct.] Metal flexible duct

may be used Non-metallic

flexible duct isnot recommended

For Safely:

l

Do not exhaust dryer into a

chimney. furnace cold air duct,

attic or crawl pace. or any

other duct used for ventina.

Accumulated lint could s

become a fire hazard OT

moisture could cause damage

l

The exhaust system should be

cleaned periodically. at least

every 2 years.

l

Flexible duct should never be

installed concealed in walls,

ceiling or floor. Use Duct Tape

to seal all joints.

Ewhaurtlng the

dryer outslde is

recommended If

you cannot exhaust

Whirlpool dealer.

Exhousllng the dryer lhtiugh

the side isavailable with use

of Side Exhaust Kit LCK4600. Follow

the installation instructions with Me

kit for proper exhaust installation.

For Moblle Home Exhaust

Requlremenh see Panel F,

Alternate Exhaust Methods. for

The Exhaust Duct should end

with an exhaust hood to prevent

exhausted air returning i%o dryer.

The outlet of the hood must be

at leasi 12Inches from the grwnd

or anylhing else that may be in

the path of the exhaust.

A 2K Inch outlet Exhaust Hood

should be used with short systems

only. Thisoutlet creates greater

backward pressure than other

hood types.

Exhaust Hoods with magnetic

latches should not be used

The Maxlmum Lenglh of the

exhaust system depends upon the

tYpe of duct used, number of

elbows and type of exhaust hood.

The maximum length for both rigid

and flexible duct isshown in chart.

Exhaust Systems longer than

specified will:

l

Shorten the life of the dryer.

l

Reduce the performance. such

as cause longer drying times

and increase the use of energy.

l

Accumulate lint.

Water -

*uPPIY

and

drain

requtfenl

Hot&d Cold water faucets

within 4 feet of back of the

washer/dryer and enough

pressure [5-100 PSI]are required.

Water Healer should be set to

deliver 13o’F or above water to

the washer foebest results.

ToDrain the Whirlpool washer, you

need either a 20 gallon laundry

capacib of

17gallons per fnInu%

The top of the tub or the tm of the

standpipe cannot be low& than

28 inches or higher than 48 inches

from the bottom of the

washer Use a floor dmin

only II a siphon break

[air valve to equalize

pressure] is installed.

[A siphon break. Part No.

285320 isovoilable from

WhIrlpool authorized

parts distributor)

Slandpl