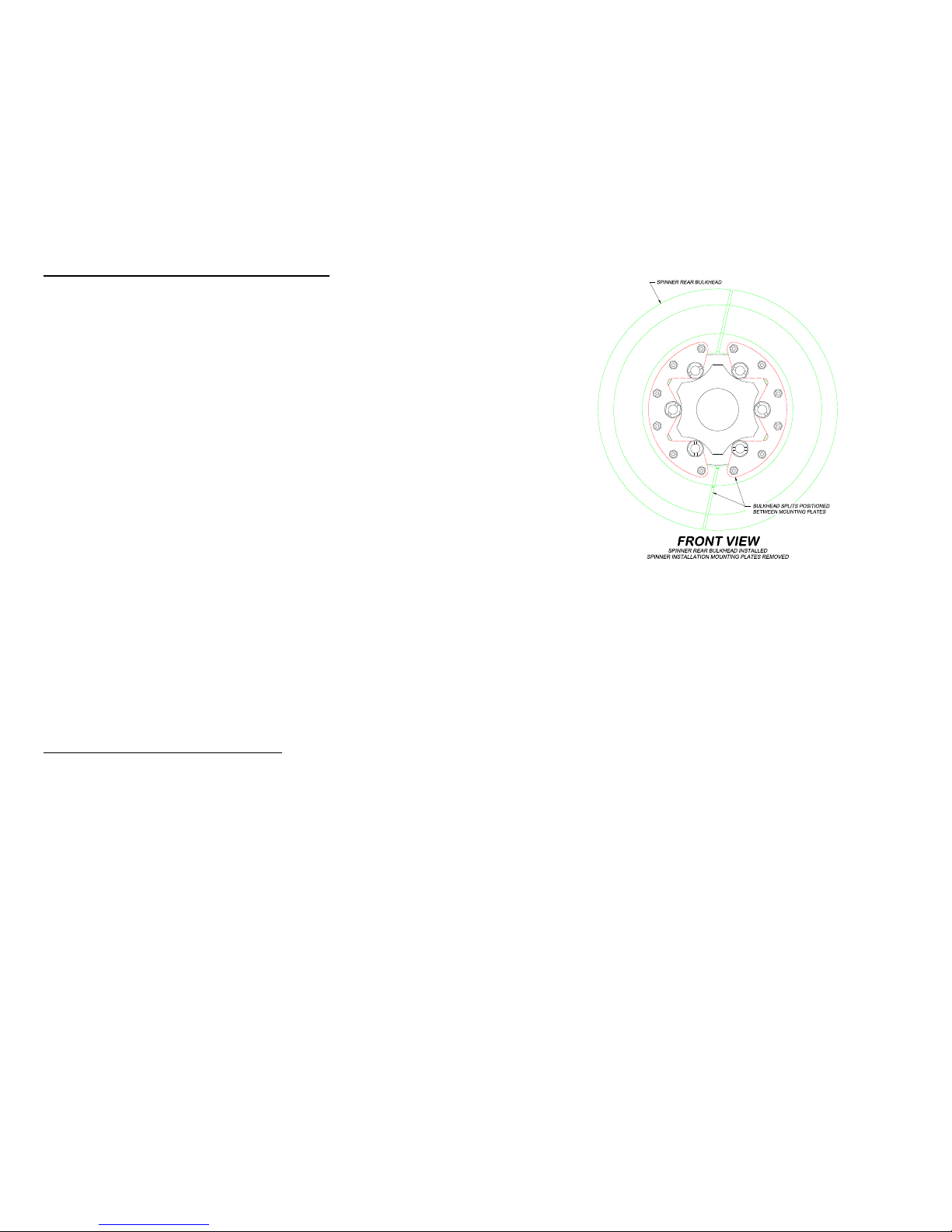

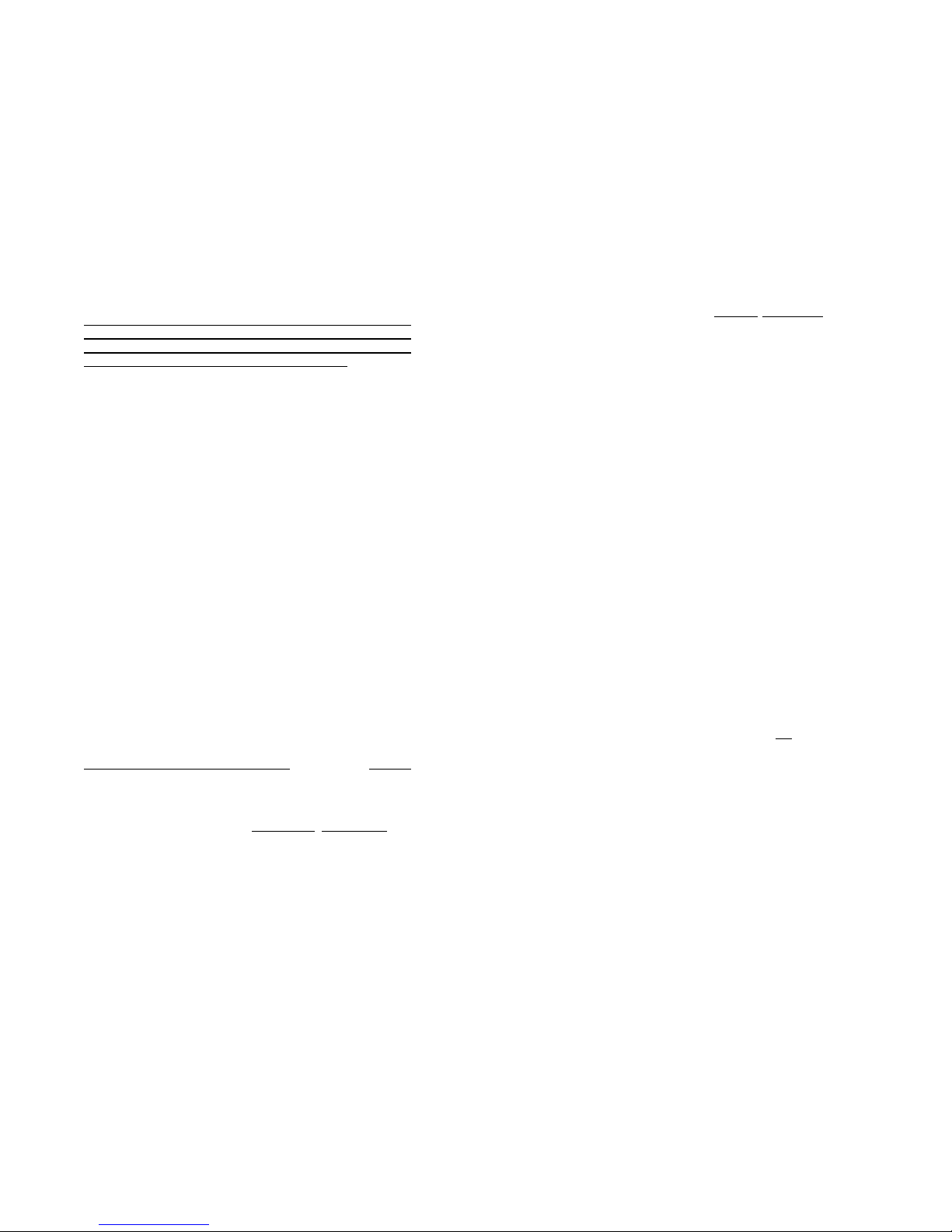

5.2 First Time Operation

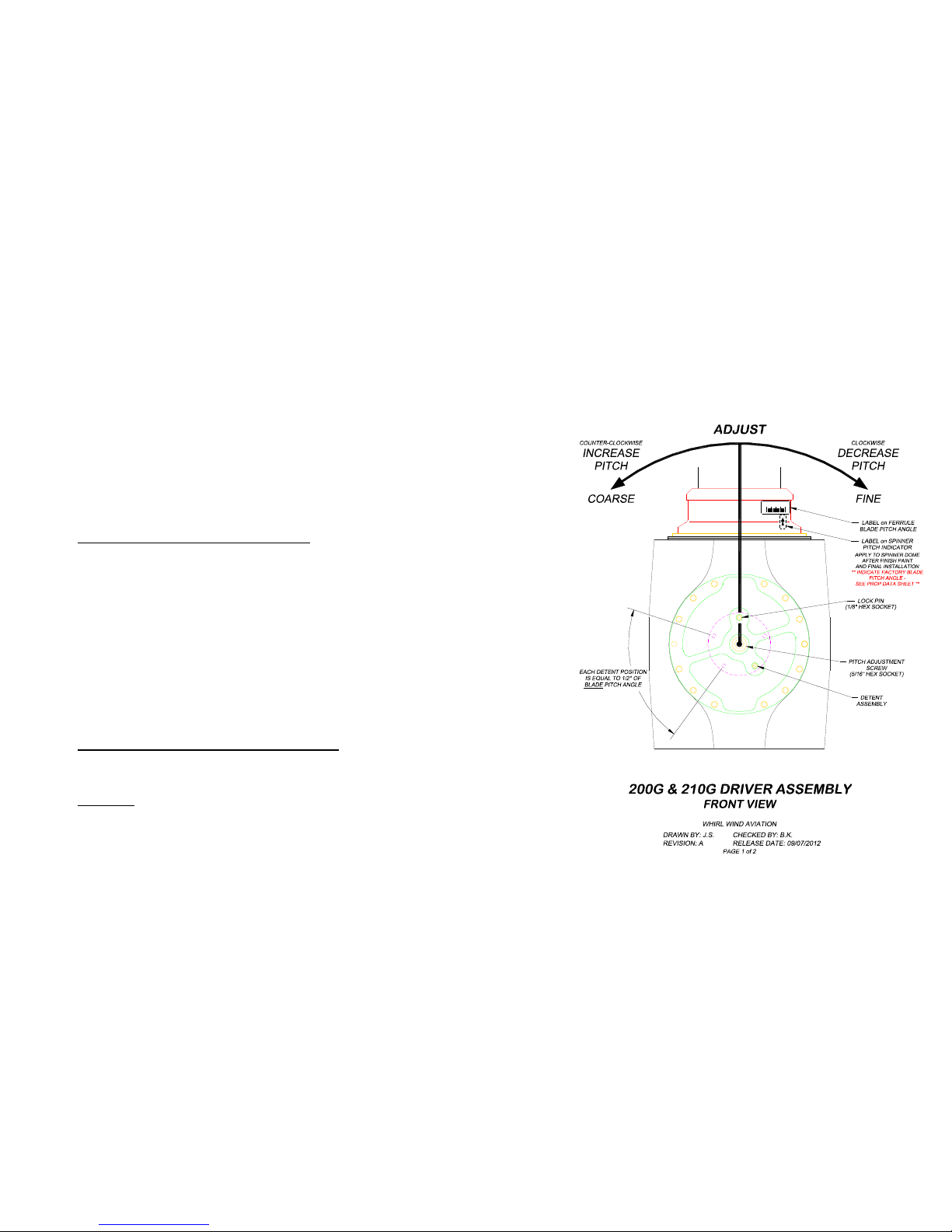

Do not change the pitch adjustment screw until the

propeller is installed on the airplane and the pitch scale

and indicator are installed on the blade ferrule and the

spinner dome (see Figures 5-2 and 5-3 below).

Per Figure 5-2, place the pitch indicator arrow label on the

spinner dome indicating the factory low pitch setting.

* Refer to the original propeller data sheet for initial factory

low pitch setting.

5.3 First Run-Up

The primary objective of the first run-up series is to

establish baseline values for engine RPM at full power

(maximum throttle with various blade pitch angles.

CAUTION! As stated above, many airplane and propeller

manufacturers do not recommend high power run-ups due to

the possibility of debris damage. If a high engine speeds are

required be sure to perform the run up on a clean surface

and you are in a safe, unobstructed area.

Follow your airplane’s manual and perform an engine run-up

using the factory set low pitch setting.

The RPM restrictions from the engine and propeller

manufacturers must be strictly observed.

The initial factory set low pitch setting (refer to original

propeller data sheet) may be too fine for your engine and

could lead to an engine over speed. Advance the throttle

slowly to be sure that an over speed does not occur!

If the engine can not reach 2,250 to 2,300 RPM at full

throttle the factory setting is too coarse. DECREASE the

blade pitch angle by ½° increments following the propeller

pitch changing instructions below. For each ½° decrease of

blade pitch angle repeat the run up to full throttle until the

correct pitch setting is found that maintains 2,250 to 2,300

RPM at full power.

5-3

If the engine wants to exceed 2,250 to 2,300 RPM at full

throttle the factory setting is too fine. INCREASE the blade pitch

angle by ½° increments following the propeller pitch changing

instructions below. For each ½° increase of blade pitch angle

repeat the run up to full throttle until the correct pitch setting is

found that maintains 2,250 to 2,300 RPM at full power.

Note: The procedure above is recommended to establish

baseline settings of blade pitch and resultant engine speeds

(RPM) at full power. 2,250 RPM is only an example – a

conservative RPM for safety and prevention of engine over

speed. The most appropriate baseline settings will vary for each

application. As this procedure is completed record the static

RPM in the table on page 5-2 for future reference.

5.4 Inspection After First Run-Up

1. Inspect the propeller system blades and spinner for any

nicks, cracks, or chips.

2. Inspect each aluminum blade ferrule and blade intersection

(located at the root end of blade where the silicone sealant is

visible) for movement and/or signs of chafing. There should

be no movement between the aluminum ferrule and the

blade. Notify Whirl Wind Aviation immediately if movement

is detected.

3. Gently shake each propeller blade to feel for blade

movement in the hub. Blade shake movement is allowed up

to 1/8 inch measured from the tip. Radial play of up to 2

degrees is acceptable. If the check shows values above

these tolerances contact Whirl Wind Aviation immediately.

Movement is only allowed between the aluminum blade

ferrule and the propeller hub – and not as described in point

#2 above.

4. Inspect the nickel leading edge erosion shield. The nickel

erosion shield should not be loose or have any cracks. Small

paint cracks parallel to and along the edge of the shield

where the nickel and paint meet are acceptable.

5. Check the spinner dome and the aft and forward bulkheads

for cracks of any kind or looseness.

Your Whirl Wind Propeller System has been statically balanced

at the factory. However, it is recommended to have the

engine/propeller dynamically balanced before the first flight.

5-4