3

INTRODUCTION:

Always inspect the components before and after use for identifying any

damage. Do not use the damaged part until it is repaired or replaced if

damage is observed.

Verify sterility prior to use. Do not use if not sterilized.

The hub and blade should be securely fixed to the main unit.

Test and check the saw movement and sharpness of the blade prior to use.

The battery should not be sterilized at high temperature and/or high pressure.

Do not leave the battery in the saw for an extended period of time. Remove

the battery immediately if there is something wrong with the power during

surgery.

Explosion hazard if batteries are exposed to flames. Properly dispose of used

batteries.

Stop using this device immediately if the main unit gets hot or makes an

abnormal sound. Contact your distributor and return the saw for repair.

Optimum speed is 16000r/min. Damage to the bone can occur if the speed is

too high, and cutting time will increase if speed is too low.

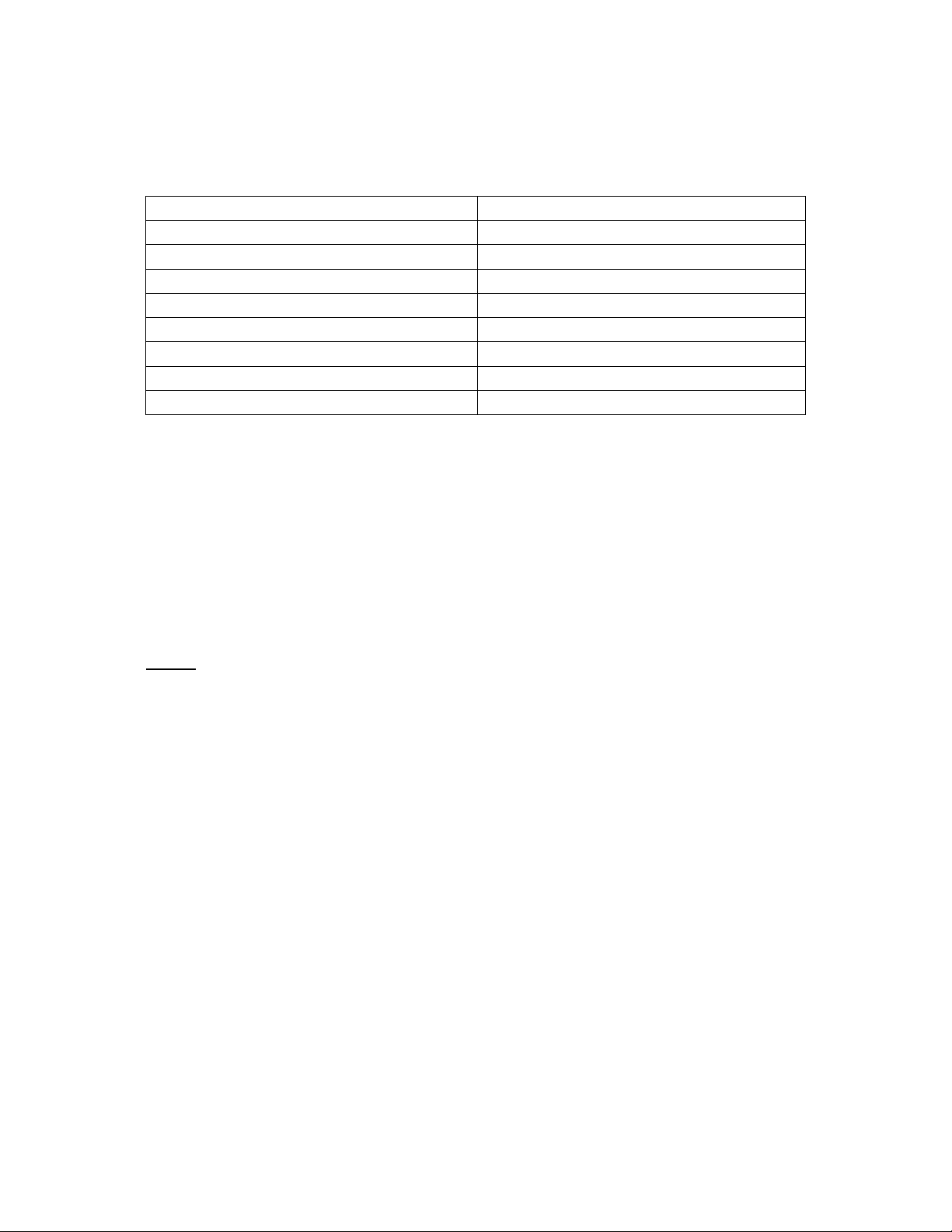

PRODUCT CONFIGURATION:

This device is composed of the main unit, battery, and battery charger.

Fig.1 Structure of main unit

1. Rotating head 2. Power switch 3. End cover 4. Knob switch