INSTALLATION INSTRUCTIONS INSTALLATION INSTRUCTIONS

This appliance can be used with Natural Gas and LP Gas. It is shipped

from the factory adjusted for use with Natural Gas. Propane

conversion kits can be purchased separately.

The maximum inlet gas supply pressure incoming to the gas appli-

ance pressure regulator is 20’’ water column (5 kPa). The minimum

gas supply pressure for checking the regulator setting shall be at

least 1“ w.c. (249 Pa) above the inlet specified manifold pressure to

the appliance (thisoperating pressure is

4” w.c. (1.00 kPa) for Natural Gas and 10” w.c. (2.75 kPa) for LP Gas).

ATTENTION

A manual valve shall be installed in an accessible location in the gas

line external to the appliance for the purpose of turning on or shut- ting

off gas to the appliance.

WARNING

Do not use aerosol sprays in the vicinity of this appliance while it is in

operation

INSERTING THECOOKTOP

After having removed the various loose parts from the internal and

external packing, make sure that the cooktop is not damaged and is

suitable for the specific gas usage. The gas type label is on the un-

derside of the cooktop base.

In case of doubt, do not use the appliance and contact skilled

personnel.

Keep all the packaging parts (polystyrene foam, cardboard, staples,

etc.) away from children. Consider the critical dimensions of the ap-

pliance, before making an opening in the top surface of the

countertop. (relative measurements as per Page 18-19, Fig. 1, 2).

ATTACHING THE COOKTOP

To prevent liquids from leaking accidentally into the underlying

storage space, the appliance is equipped with a special gasket.

To apply this gasket, carefully follow the instructions in Fig. 3. Lay out

the protective sealing strips along the edges of the opening in the

countertop and carefully overlap the strip end. (See Fig. 3). Insert the

cooktop into the countertop opening. With a screwdriver assemble

the brackets A to the cooktop bottom by means of the screws B.

(See Fig. 4). Slide the hooks into position and secure them with the

screws.Trim the part of the sealing strips which extend beyond the

hotplate base.

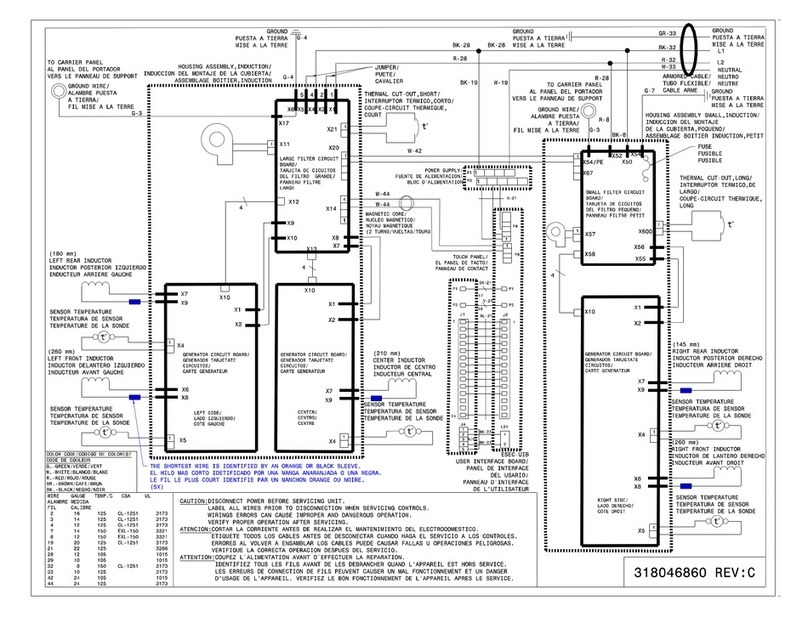

GAS CONNECTION

Before connecting the appliance to the gas supply, first remove the

plastic plug on which is press- fitted into the gas inlet union; to

remove, just pull it off.

1. Check the ‘gas type’ sticker attached to the cooktop. Details of the

injector sizes used are recorded on the data plate located on the

base of the appliance.

2. This appliance shall be installed in accordance with installation re-

quirements of the local gas authority of the appropriate

installation code.

3. Before installing the cooktop consider the location of the gas supply

and routing the gas line.(Referfig.6)

4. For LPGmodels: the gas supply is connected to the regulator which

issupplied loose. The inlet connection has a 1/2” B.S.P.male thread. IT

ISESSENTIALTHATTHEELBOW ON THEAPPLIANCEBEHELDFIRMLY

WITH A SPANNERWHEN CONNECTING THESUPPLY.DO NOT OVER

TIGHTEN. The regulated pressure For LPG is 10” w.c. (See Fig. 5).

6 7