RVZC30(andBB/T/TBB/WA),RVZP30(andBB/T/TBB/WA),RVC24

3

0407

TABLE OF CONTENTS

INTRODUCTION ...................................................................4

DELIVERYINSPECTION ......................................................4

PACKAGING ........................................................................4

LOCATION ............................................................................4

Figure 1: Case label information...................................... 5

INSTALLATION .....................................................................6

Leveling ........................................................................... 6

Figure 2: Leveling cases prior to joining .......................... 6

Figure 3: Typical hat channel locations............................ 7

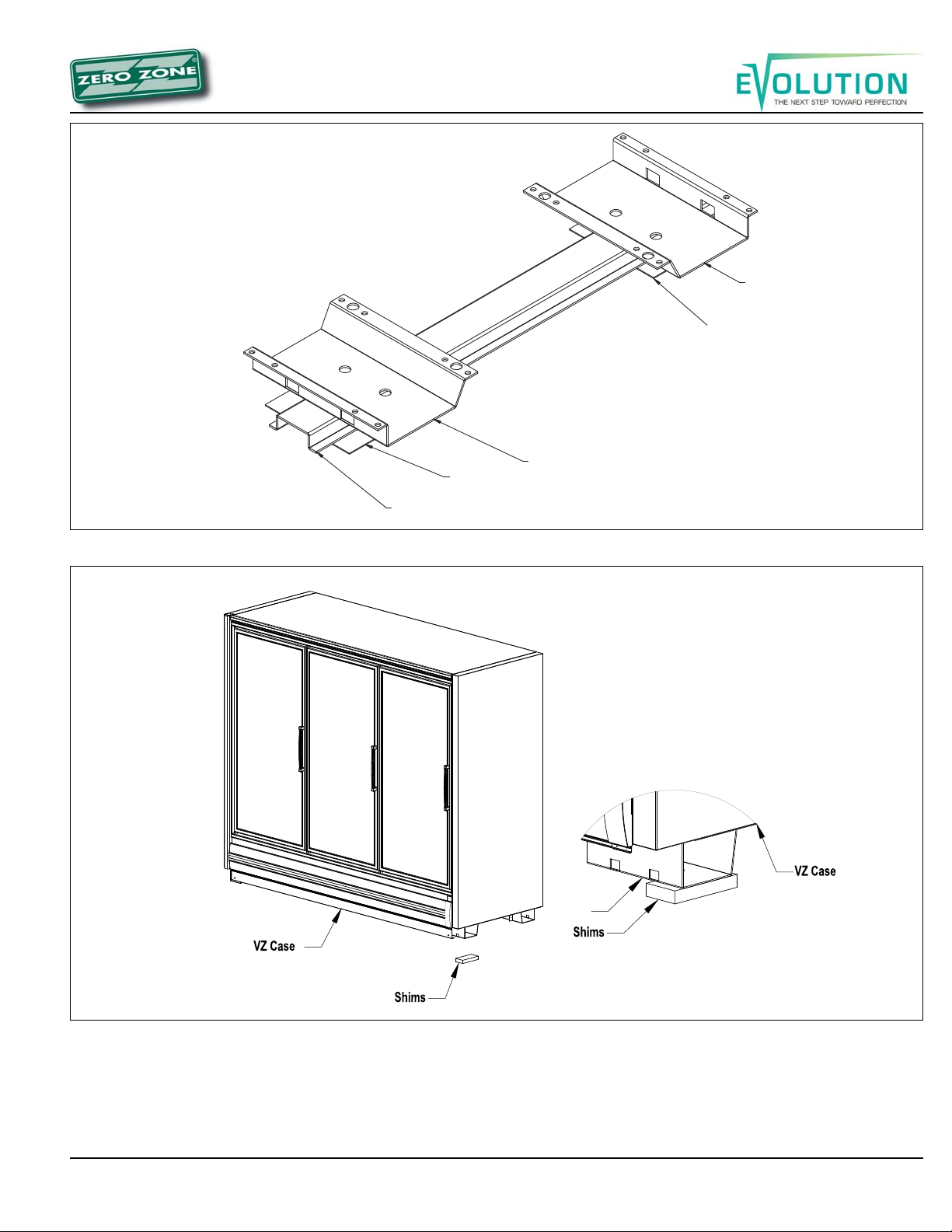

Figure 4: Shims under bases and case ........................... 7

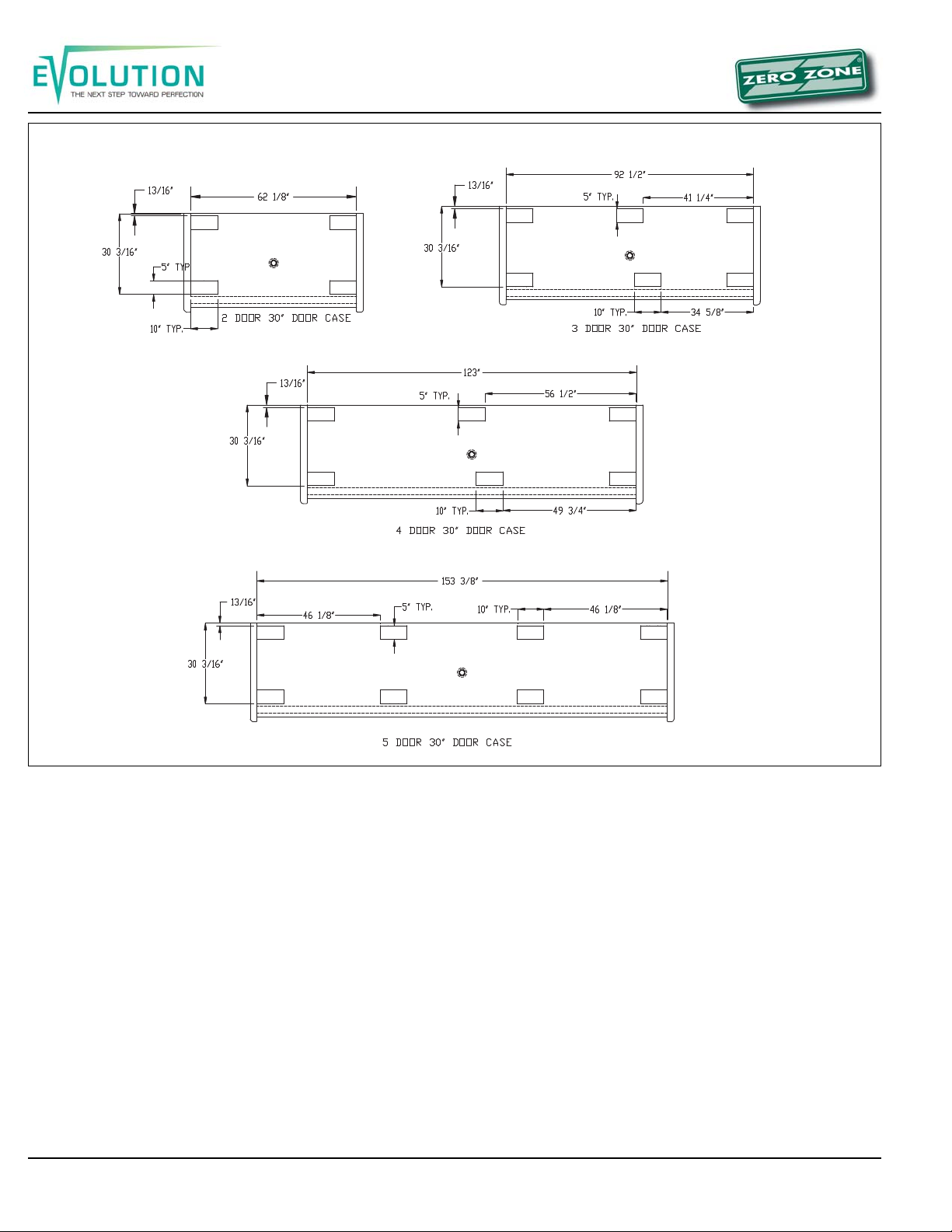

Figure 5A:All base locations ........................................... 8

Figure 5B:All base locations ........................................... 9

Figure 5C:All base locations ......................................... 10

CASEMOVEMENT ............................................................ 11

Figure6:Removingwoodplanks ................................... 12

Figure 7: Wood block inside base................................. 12

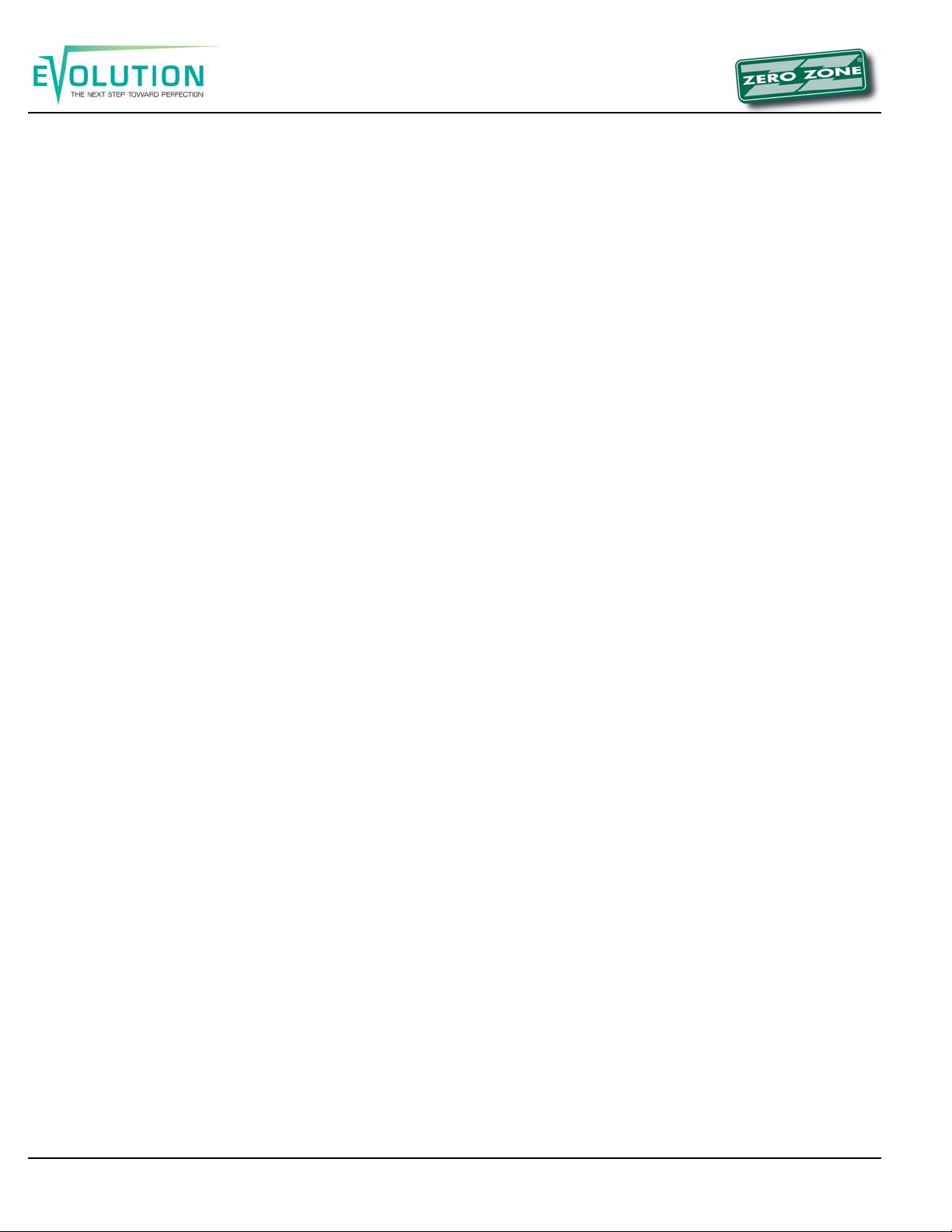

Figure8:Expandable base............................................ 12

LINEUPASSEMBLY ..........................................................13

Figure 9: Caulking cases to be joined ........................... 13

Figure 10: T-strips ......................................................... 13

Figure 11: Required sealing for

NSFapprovedinstallations .......................................... 14

DRAINLINE ........................................................................14

Figure 12: Trap support................................................. 14

BUMPERAND KICKPLATE ........................................... 15

InstallingEndKick Plate ................................................ 15

InstallingBumper ........................................................... 15

Figure 13: Other style bumpers ..................................... 15

Figure 14: Installing bumper and kick plate.................... 16

UNDERCASERETURN AIRFLOW

ASSEMBLYINSTRUCTIONS ..............................................16

Figure 15: Bumper air flow ............................................ 16

REFRIGERATION ...............................................................17

General ......................................................................... 17

RefrigerantPiping ......................................................... 17

Figure 16: Penetration sealing....................................... 17

Figure 17A: Refrigeration line sizing - Frozen Foods .... 18

Figure 17B: Refrigeration line sizing - Ice Cream ......... 19

Figure 18: 45° elbow suction line................................... 20

TemperatureControlAdjustment .................................... 20

LeakCheck-Evacuation-Charging................................. 20

Figure19:Temperaturesettings .................................... 20

Figure20:Temperaturecontrol...................................... 20

ELECTRICAL .....................................................................21

OPTIONALELECTRICALWIRING ......................................21

SinglePointConnection ................................................ 21

MasterSatellite Connection ........................................... 21

Figure 21: Electric defrost 30” wiring ............................ 22

Figure 22: Electric defrost 24” wiring ............................ 23

Figure 23: Hot gas wiring .............................................. 24

Figure 24: Single point wiring........................................ 25

Figure25:Master satellitewiring ................................... 26

DEFROSTING ....................................................................27

General ......................................................................... 27

DefrostSettingsand Controls........................................ 27

Electric Defrost Operation ............................................. 28

GasDefrostOperation................................................... 28

LimitThermostat ............................................................ 28

Figure 26: 30” Electric .................................................. 29

Figure 27: 24” Electric .................................................. 29

Figure 28: Coil 30” Hot gas ........................................... 30

Figure 29: Coil 24” Hot gas ........................................... 30

USERINFORMATION ..................................................... 31

Cleaning........................................................................ 31

ShelfLocation ............................................................... 31

Shelves.......................................................................... 31

LoadingtheCase .......................................................... 31

LightSwitch................................................................... 31

Casethermometer ......................................................... 31

SERVICE............................................................................31

Evaporator..................................................................... 31

ExpansionValve ............................................................ 31

DefrostHeater Element ................................................. 32

HeaterElementRemoval................................................ 32

EvaporatorFans ............................................................ 32

FanRemoval ................................................................. 32

Ballasts — 1-Door, WAand WB.................................... 32

FluorescentLighting ...................................................... 32

Optional lighting ............................................................. 32