3

1 Supporting documents ............................................................................................................................................................... 5

1.1 Notices and graphics in the installation and operating instructions ...............................................................................................................................5

2 Safety notices............................................................................................................................................................................... 6

3 Proper use .................................................................................................................................................................................... 7

4 Personnel qualication................................................................................................................................................................ 7

5 Product description ..................................................................................................................................................................... 8

5.1 Possible applications...........................................................................................................................................................................................................8

5.2 Forces and torques..............................................................................................................................................................................................................8

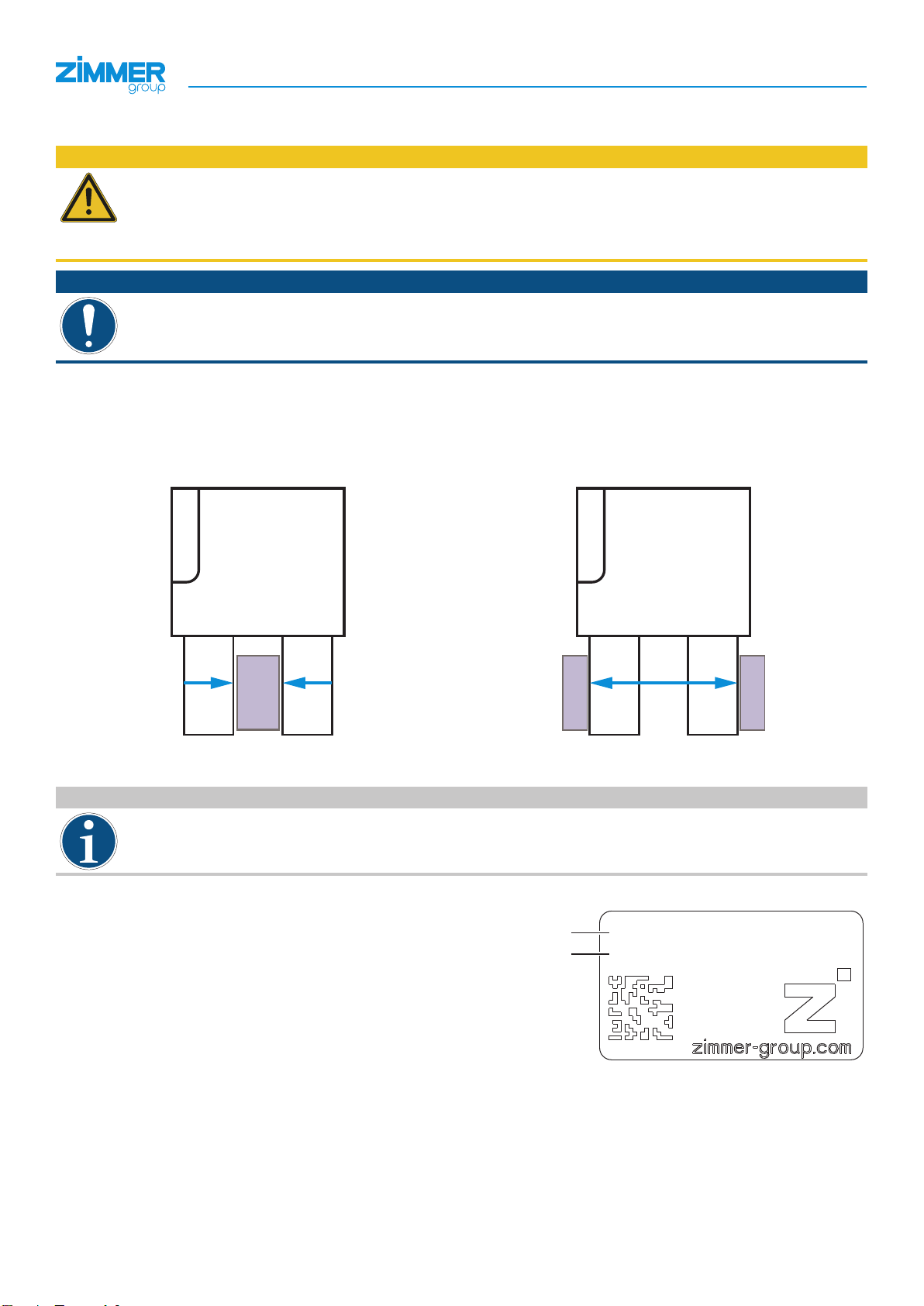

5.3 Type plate .............................................................................................................................................................................................................................8

6 Functional description ................................................................................................................................................................. 9

6.1 LED status display .............................................................................................................................................................................................................10

6.2 Control ................................................................................................................................................................................................................................10

6.3 Veried conguration examples .......................................................................................................................................................................................10

6.4 Self-locking mechanism ....................................................................................................................................................................................................10

7 Technical data ............................................................................................................................................................................ 11

7.1 Electrical specications.....................................................................................................................................................................................................11

7.2 Protection class..................................................................................................................................................................................................................11

8 Accessories/scope of delivery ................................................................................................................................................. 11

9 Transportation/storage/preservation....................................................................................................................................... 11

10 Installation .................................................................................................................................................................................. 12

10.1 Installing the product.........................................................................................................................................................................................................13

10.2 Safe shutoff for products with IO-Link..............................................................................................................................................................................14

10.3 Installing the energy supply ..............................................................................................................................................................................................15

10.4 Installing the GEP2000IL-03 power supply......................................................................................................................................................................15

10.5 Static charge ......................................................................................................................................................................................................................16

10.6 Heat dissipation .................................................................................................................................................................................................................16

10.7 Installing accessories ........................................................................................................................................................................................................16

11 Commissioning .......................................................................................................................................................................... 17

11.1 Process data .....................................................................................................................................................................................................................17

11.2 IODD Import .......................................................................................................................................................................................................................18

11.3 Handshake Data Transfer Method....................................................................................................................................................................................18

11.4 Parameters .........................................................................................................................................................................................................................19

11.4.1 ControlWord.........................................................................................................................................................................................................19

11.4.2 DeviceMode .........................................................................................................................................................................................................20

11.4.3 WorkpieceNo .......................................................................................................................................................................................................24

11.4.4 PositionTolerance ................................................................................................................................................................................................24

11.4.5 GripForce .............................................................................................................................................................................................................25

11.4.6 DriveVelocity ........................................................................................................................................................................................................25

11.4.7 BasePosition ........................................................................................................................................................................................................26

11.4.8 TeachPosition.......................................................................................................................................................................................................26

11.4.9 WorkPosition........................................................................................................................................................................................................26

11.4.10 StatusWord...........................................................................................................................................................................................................27

11.4.11 Diagnosis..............................................................................................................................................................................................................29

11.4.12 ActualPosition ......................................................................................................................................................................................................29

11.5 Minimum travel path..........................................................................................................................................................................................................30

11.6 Minimum startup path .......................................................................................................................................................................................................30

11.7 Easy Startup .......................................................................................................................................................................................................................30

11.8 Quickstart Basic Parameters ............................................................................................................................................................................................31

11.9 Starting the gripping movement.......................................................................................................................................................................................32

INSTALLATION AND OPERATING INSTRUCTIONS: LWR50L-01

DDOC01066 / d EN / 2022-05-10

Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com

Content