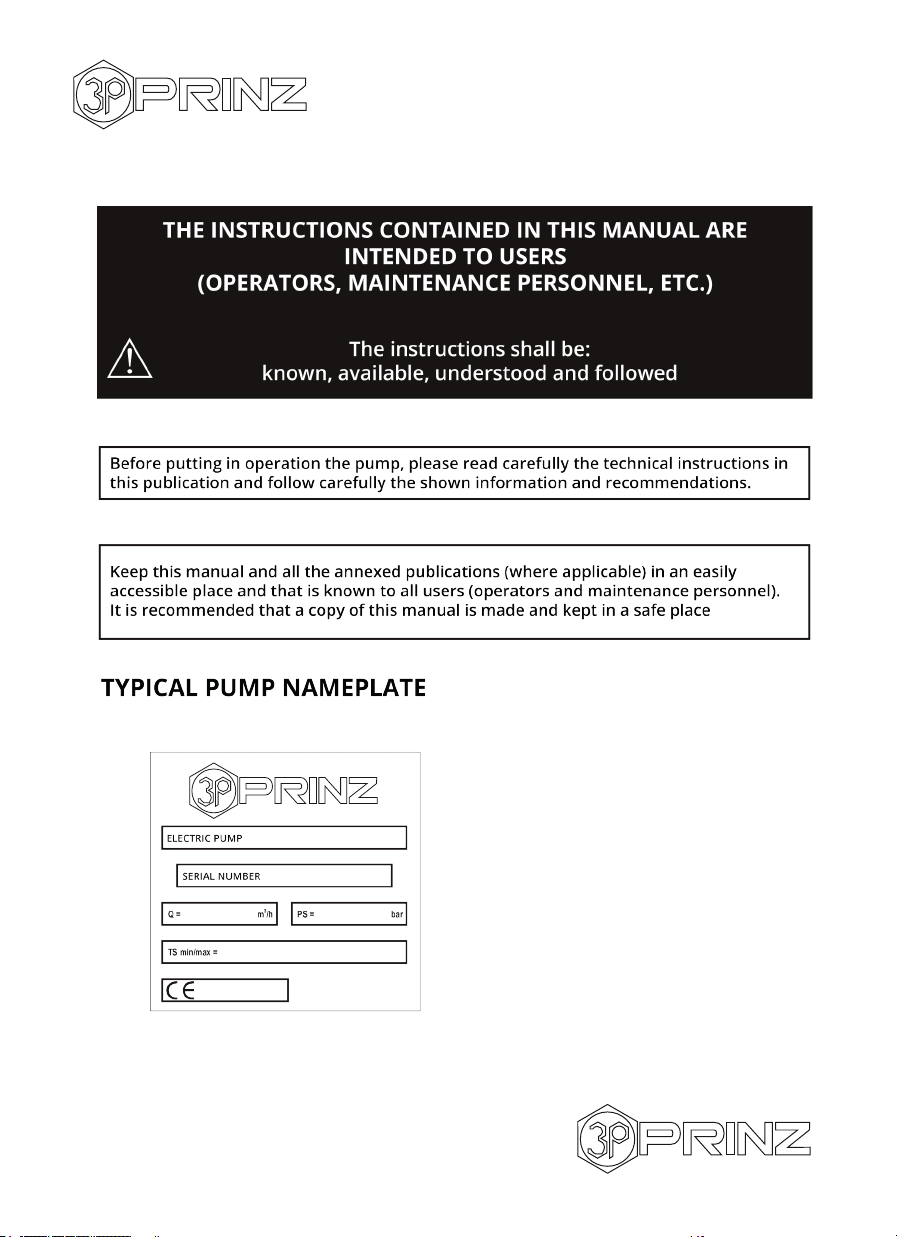

PUMP IDENTIFICATION

- Model: _______________________________

- Serial Number: _______________________________

- Date of Manufacturing: _______________________________

- Electric Motor Power / Polarity: _______________________________

- Voltage / Phase / Frequency: _______________________________

DIRECTIVE 2006/42/CE; 2006/95/CE; 2004/108/CE (MACCHINE)

- Applicable Standards: UNI EN ISO 12100 :2010;

UNI EN ISO 13732-1:2009

UNI EN 809:2009;

UNI EN 953:2009

3P Prinz S.r.l. hereby declares, under its sole responsibility, that the above-mentioned electric pump is in

conformity with the provisions of the Machinery Directive (Directive 2006/42/CE).

DIRECTIVE 94/9/CE (ATEX)

- Applicable Standards: UNI EN 1127-1:2011, UNI EN 13463-1:2009,

UNI EN 13463-5:2011, UNI EN 13463-8:2004

- Technical Dossier: MCA 01.01

- Marking: II 2 G c k TX

3P Prinz S.r.l. hereby declares, under its sole responsibility, that the above-mentioned electric pump satises

the Directive for equipment and protective systems intended for use in potentially explosive atmospheres as

per 94/9/CE (ATEX) (D.P.R. 23/03/98 no. 126) applicable to it.

The above-mentioned electric pump has undergone a risk evaluation as per Machinery Directive and ATEX,

including an ignition risk evaluation in accordance with Standards UNI EN 13463-1, EN 13463-5 and EN

13463-8.

Lucca: / / Silvia Marianetti

Legal Representative

CAP.1 PREFACE ................................................................................................................................6

1.1 Introduction ........................................................................................................................................ 6

1.2 Warranty ............................................................................................................................................... 8

CAP.2 CARRIAGE, PACKAGING AND HANDLING ............................................................................ 9

2.1 Carriage and packaging ..................................................................................................................... 9

2.2 Handling .............................................................................................................................................. 10

CAP.3 INSTALLATION ................................................................................................................. 11

3.1 General installation regulations .................................................................................................. 11

CAP.4 SAFETY ........................................................................................................................... 13

4.1 General safety regulations .............................................................................................................13

4.2 Information on the risks that cannot be eliminated by the measures taken by the

designer......................................................................................................................................................14

CAP.5 NOISE LEVEL.......................................................................................................................... 15

5.1 Noise Level.......................................................................................................................................... 15

CAP.6 DESCRIPTION OF THE PUMPS ............................................................................................. 16

6.1 Volumetric pumps “M” Series (mono-body).................................................................................... 16

6.2 Working principle of the hollow disk pump...................................................................................... 17

CAP.7 USAGE OF THE PUMP ............................................................................................................ 18

7.1 Operating instructions for 3P “M” Series pumps ............................................................................. 19

CAP.8 MAINTENANCE ................................................................................................................ 20

8.1 General Rules ................................................................................................................................. 20

8.2 Maintenance of 3P “M” Series pumps....................................................................................... 20

CAP.9 ACCESSORIES ..................................................................................................................... 21

9.1 Filter.................................................................................................................................................... 21

9.2 Heating covers ................................................................................................................................... 21

9.3 Pressure relief valve ........................................................................................................................ 22

CAP.10 TROUBLESHOOTING ........................................................................................................ 23

10.1 Causes of malfunction ................................................................................................................. 23

10.1.1 Lack of suction ............................................................................................................................ 23

10.1.2 Insucient ow ............................................................................................................................. 23

10.1.3 Zero ow rate ................................................................................................................................. 24

10.1.4 Excessivepowerabsorption..........................................................................................................24

10.1.5 Noise and vibrations ..................................................................................................................... 25

CAP.11 DECOMMISSIONING ......................................................................................................... 26

11.1 Pump Decommissioning ...................................................................................................... 26

CAP.12 SPARE PARTS ...................................................................................................................... 27

12.1 Spare Parts for “M” Series (mono-body) pumps .........................................................................27

12.1.1 Exploded view for “M” Series pumps (double radial seal) ...........................................................27

12.1.2 Exploded view for “M” Series pumps (internal mechanical seal) ...............................................28

12.1.3 Exploded view for “M” Series pumps (external mechanical seal) ............................................29

12.1.4 Exploded view for “M” Series pumps (packing type seal) ...........................................................30

TABLE OF CONTENTS

®

Vat. N° 06390230487

Phone. +39 0583 491183 - Fax +39 0583 954659

5