Table

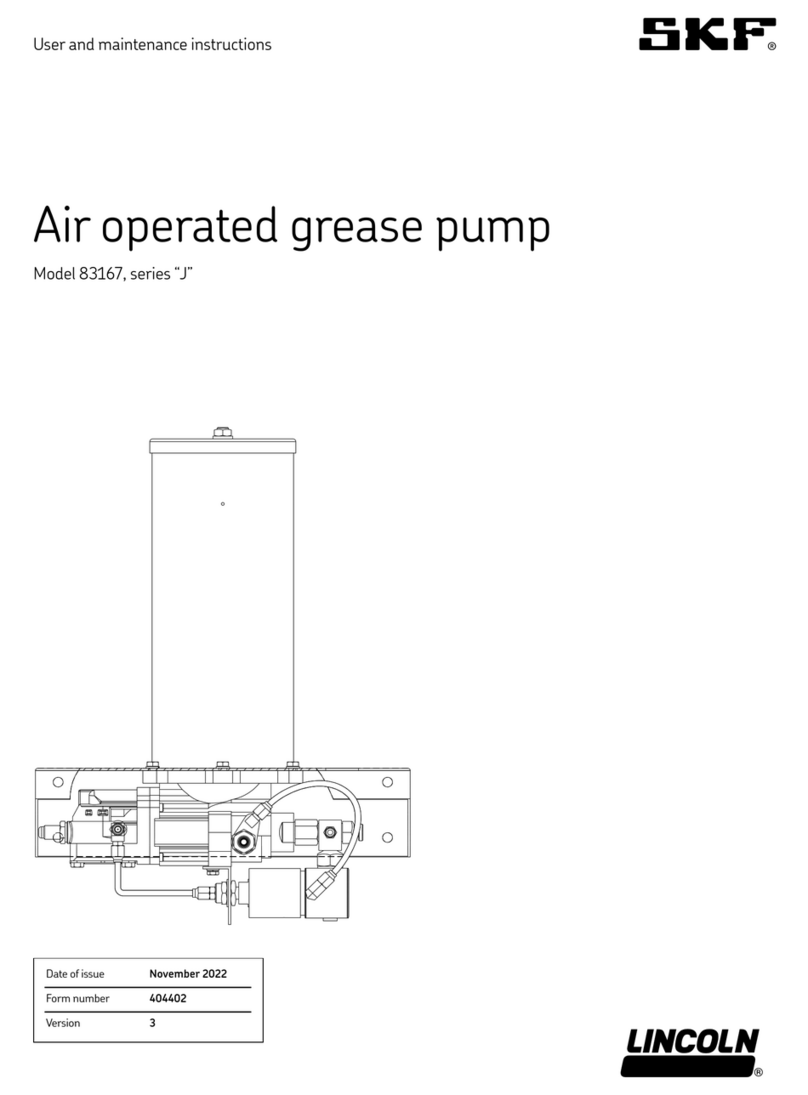

Specifications

Supply inlet hydraulic pressure Maximum psi (207 bar)

Operating working hydraulic pressure to psi (7 to 28 bar)

Maximum output pressure psi (241 bar)

Hydraulic inlet flow Up to gal/min (19 l/min)

Pump ratio with manifold :

Ambient operating temperature – to + °F (–40 to +66 °C)

Operating voltage V

Hydraulic inlet port SAE

Tank return port SAE

Maximum hydraulic fluid temperature °F (93 °C)

Container capacity lbs (27 kg)

WARNING

Do not exceed psi (207 bar)

maximum supply inlet hydraulic

pressure or psi (241 bar)

maximum outlet pressure.

Failure to comply may result in

personal injury and damage to system

components.

Usage

Description

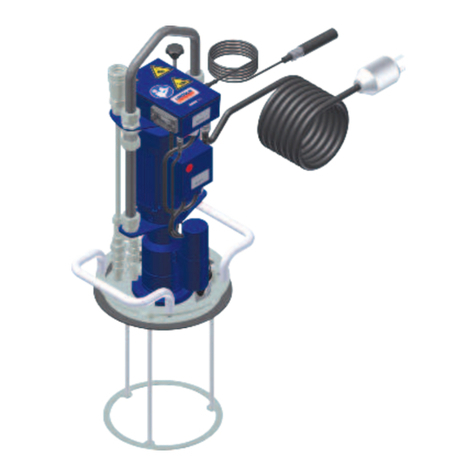

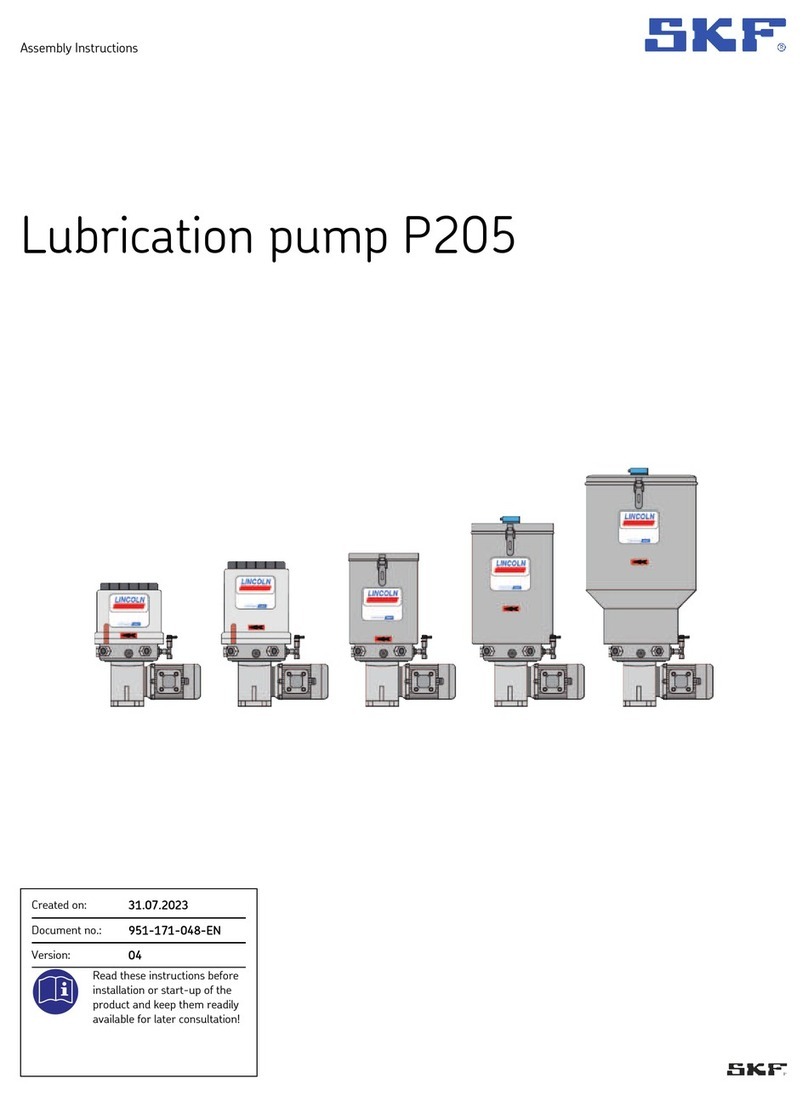

Models , MSO and are

pumping units designed to operate a Centro-

Matic lubrication system. Units includes a

vent valve to relieve line pressure to recharge

injectors. FlowMasterII rotary driven hydraulic

pump includes pressure reducing valve, flow

control valve and solenoid operated

( V ) “on” and “off” valve.

FlowMasterII pump is fully automatic

when used with system controller and

pressure switch. FlowMasterII pump is

double acting, dispensing lubricant on both

“up” and “down” strokes. Unit is designed to

be used with SL-V, SL-, SL-, SL- and

SL- series injectors or a combination of

these injectors.

Model includes follower plate and

mechanical low level indicator.

Model MSO includes follower plate,

mechanical low level indicator, and a

mechanical shut off.

Model has no follower plate and no

low level indicator.

Appropriate use

• Pump on unit is exclusively designed to

pump and dispense lubricants using

hydraulic power only.

• Do not exceed maximum specification

ratings.

• Any other use not in accordance with

instructions will result in loss of claims for

warranty and liability.

Operation with

mechanical shut-off

When attached, a mechanical shut-off

system integrates with bucket pumps to

prevent grease from overfilling during refill

process. System is designed for bucket

pumps with capacity of , , and

lbs (27, 41, 54 and 181 kg). Refer to

for maintenance and operating

instructions if present.

Operation with

system controller

Operation with lube system controller is

recommended. System control must be

capable of operating hydraulic solenoid

valve, supplied with pump, and have

pressure detection or other means to

determine when lube event is complete.

Pump and vent valve operation are

controlled automatically by single solenoid

valve supplied on pump manifold.

System controller determines when lube

event starts and stops. Time is used to start

lube event, and pressure signals to controller

that lube event is complete.

In typical lube event, when system

controller times out, lube cycle is initiated.

Solenoid energizes to deliver hydraulic

pressure to pump and vent valve.

Pump begins dispensing lubricant through

injectors to bearings.

When all bearings have received lubricant,

pressure rises in system to actuate pressure

switch. As pressure switch actuates,

controller resets, de-energizing solenoid

valve, cutting hydraulic oil pressure to pump

and vent valve. Pump stops, pressure vents

and pressure switch de-actuates.

Controller begins timing toward next lube

event.