Page 4 of 60 / IM 798 AE Self-Contained Unit Ventilator

Equipment Storage

If equipment is stored for any length of time before installation, it

should remain in its shipping packaging in a clean, dry, climate

controlled area. For extended storage times, rotate indoor fan motor

and outdoor fan /motor assemblies periodically to prevent flattening

of the bearing.

Lifting, Moving, and Stacking

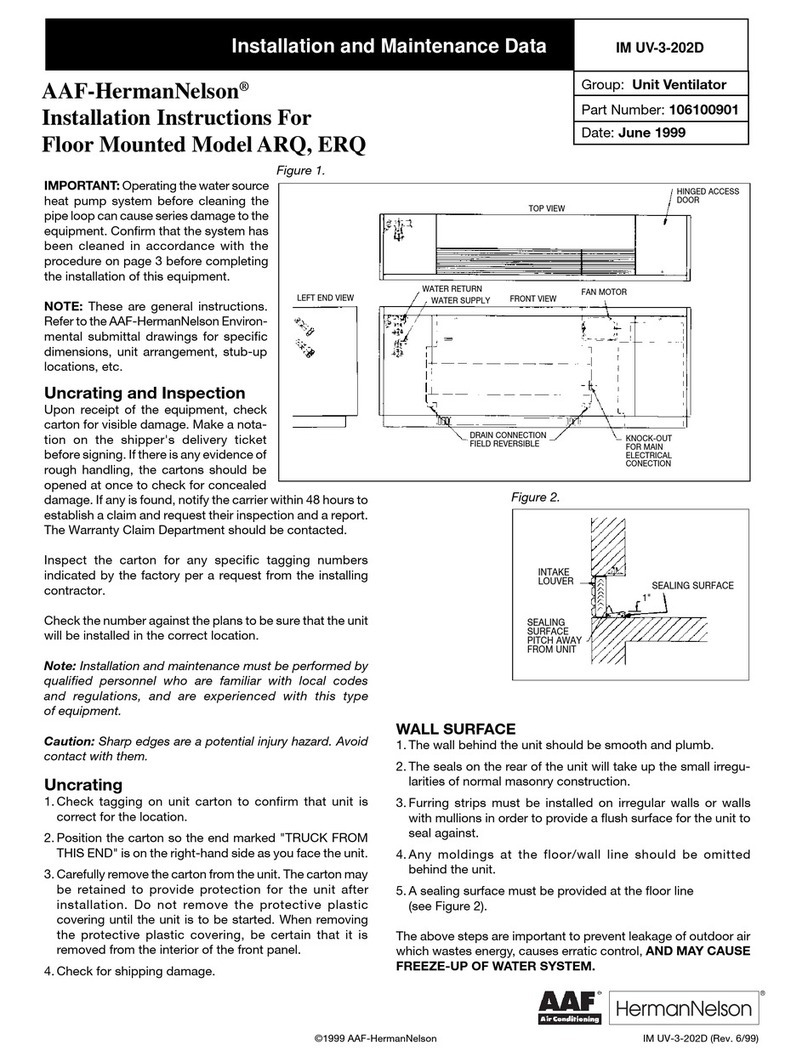

A forklift with 72" tines, or other lifting device is needed to move

these products (Figure 1).

Move the louver, wall sleeve, or unit to the location at which it is

to be installed before uncrating. Check tagging on carton to confirm

that the item is correct for the location. The carton for the unit is

imprinted with the AAF®-HermanNelson®trademark which is the

"front" or room side of the unit. The end of the unit carton marked

"TruckFromThisEnd"shouldbeontheright-handsidewhenfacing

the front of the carton.

Forklift-type vehicles may be used to unload and move the

cartons. When using a forklift, it is important that the products

remain banded to its skid and be lifted only from the end designated

on the carton (Figure 5). Move only one unit at a time. Do not drop

unit.

Use 72" length forklift tines. Short tines will damage the unit

bottom. Improper handling can damage internal components

CAUTION

!

4’

6’

Figure 1 – Forklift Lifting Requirements

Important Information

Made in the U.S.A., pride and workmanship go into every AAF®-

HermanNelson®Model AE self-contained unit ventilator to provide

our customers with quality products. Products should be installed

and serviced only by qualified installers and service technicians

familiar with and in compliance with state, local and national codes

and regulations, and experienced with this type of equipment. This

installation manual is designed to help with the installation and

start-up.

Transportation Damage

Items supplied by McQuay may include louvers, wall sleeve,

Model AE unit and accessories. Each item has been carefully

inspected and securely packed in a McQuay-approved carton at the

factory. In addition, each Model AE unit has been operated at the

factory to verify proper performance. The carrier checked the items

when the shipment was loaded and assumed responsibility for

damage or loss upon acceptance of the shipment.

The purchaser is responsible for filing the necessary claims with

the carrier. Check each carton upon arrival for external damage or

shortages. Note any damage or shortage and any damage on all

copies of the freight bill. If damage or shortages are found, the

consignee should:

1) Note any visible damage to the shipment or container on all

copies of the delivery receipt and have it signed by the carrier’s

agent. Failure to adequately describe such external evidence of

a loss or damage may result in the carrier refusing to honor a

claim.

2) Notifycarrierpromptlywithawrittenrequestforaninspection.

3) In case of concealed loss or damage, or damage and/or loss that

does not become apparent until the product has been unpacked,

notify the carrier as soon as possible, preferably within five (5)

days and no later than 15 days.

4) File the claim within the six (6) month statute of limitations of

the carrier with the following supporting documents:

a) Original Bill of Lading, certified copy, or indemnity bond.

b) Original paid freight bill or indemnity in lieu thereof.

c) Original invoice, or a certified copy thereof, showing trade and

other discounts or reductions.

d) Copy of the inspection report issued by carrier’s representative

at the time damage is reported to the carrier.

Thecarrierisresponsibleformakingpromptinspectionofdamage

and for providing a thorough investigation of each claim. McQuay

will not accept claims for transportation damage.

To help avoid concealed damage:

1) Lay the louvers on their side for shipping, handling and storage.

Do not stack louver more than 10 high (Figure 2).

2) Do not stack wall sleeves more than 2 high (Figure 3).

3) Model AE unit ventilators must be shipped, handled and stored

right-side up. Do not stack units more than two (2) high

(Figure 4).

Receiving, Handling, and Storage

NOTICE

McQuaylouvers,wallsleeves,ModelAEunitsandaccessories

arecarefullypackedandthoroughlyinspected before leaving

thefactory. The carrierassumedresponsibility fordamage or

loss upon acceptance of the shipment. Claims for loss or

damagesustainedintransitmustbemadeuponthecarrieras

follows:

VISIBLE LOSS OR DAMAGE

Anyexternalevidenceoflossordamagemustbenotedonthe

freight bill or carrier’s receipt and signed by the carrier’s

agent.Failuretoadequatelydescribesuch external evidence

ofloss ordamage mayresult inthecarrier’s refusingto honor

a damage claim. The form required to file a claim will be

supplied by the carrier.

CONCEALED LOSS OR DAMAGE

Forconcealedloss ordamage(damageand/orlossthatdoes

not become apparent until the product has been unpacked),

make a written request for inspection by the carrier’s agent

within fifteen (15) days of the delivery date. File a claim with

the carrier since such damage is the carrier’s responsibility.