xFUME™ FLEX 2 Safety

EN - 5

2.2 Obligations of the operator

► Ensure that only qualified personnel are permitted to perform work on the device or system.

Authorized personnel are:

— those who are familiar with the basic regulations on occupational safety and accident prevention;

— those who have been instructed on how to handle the device;

— those who have read and understood these operating instructions;

— those who have been trained accordingly;

— those who are able to recognize possible risks because of their special training, knowledge, and

experience.

► Keep untrained persons out of the work area.

Country-specific obligations of the operator

The recirculation of filtered air can lead to health risks and is therefore prohibited in certain countries.

► Observe the local occupational health and safety regulations.

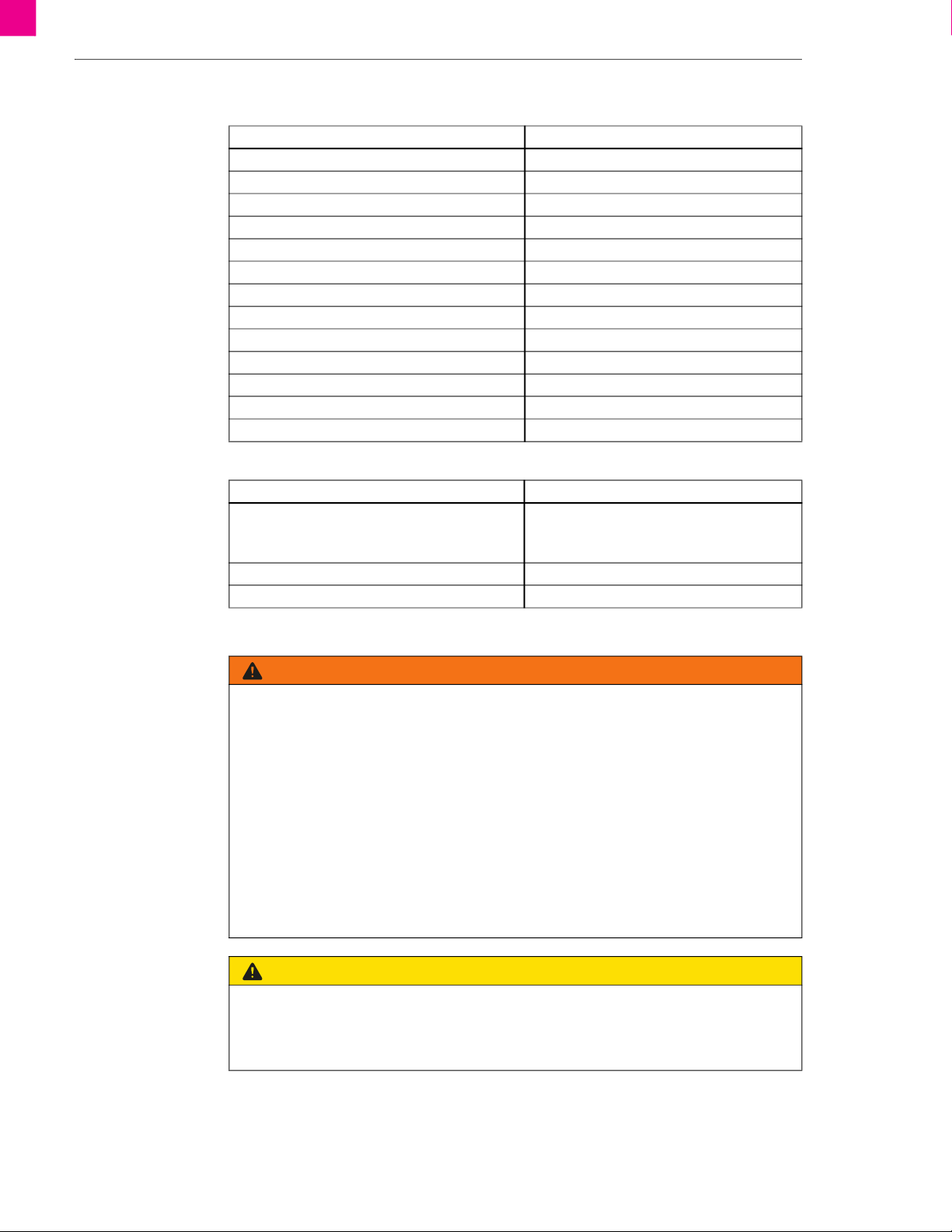

2.3 Warning and information signs

The following warning, notice and mandatory signs can be found on the product:

These markings must always be legible. They may not be covered, obscured, painted over, or removed.

2.4 Basic safety instructions

The product has been developed and manufactured in accordance with state-of-the-art technology and the

recognized safety standards and regulations. Inevitable technical residual risks to the user, third parties,

devices, or other material property are posed by the product. The manufacturer will accept no liability for

damage caused by non-observance of the documentation.

► Before using the system for the first time, please read the provided documentation carefully.

► Do not operate the product unless it is functioning properly and ensure compliance with all documents.

► Before carrying out specific work, for example, commissioning, operation, transport and maintenance,

read the documentation carefully.

► Use suitable means to protect yourself and bystanders from the hazards listed in the documentation.

► Store the documentation within easy reach of the device for reference and enclose all documents when

passing on the product.

► Consult the documentation for additional welding components.

► Information about how to handle gas cylinders can be found in the instructions provided by the gas

manufacturer and the relevant local regulations, e.g., regulations that apply to compressed air.

► Observe the local accident prevention regulations.

► Only trained specialists should commission, operate, and service the device. Qualified personnel are

persons who, based on their special training, knowledge, experience and due to their knowledge of the

relevant standards, are able to assess the tasks assigned to them and identify possible dangers.

► Keep the work area in order. Ensure good lighting of the work area.

► Switch off the power supply, gas supply, and compressed air and unplug the power plug for the entire

duration of maintenance, commissioning, and repair activities.

► For disposal, observe the local regulations, laws, provisions, standards and guidelines.

► Disconnect the mains plug before maintenance and cleaning.

► Wear a respiratory mask.