CARBURETOR FLOAT BOWL DRAIN

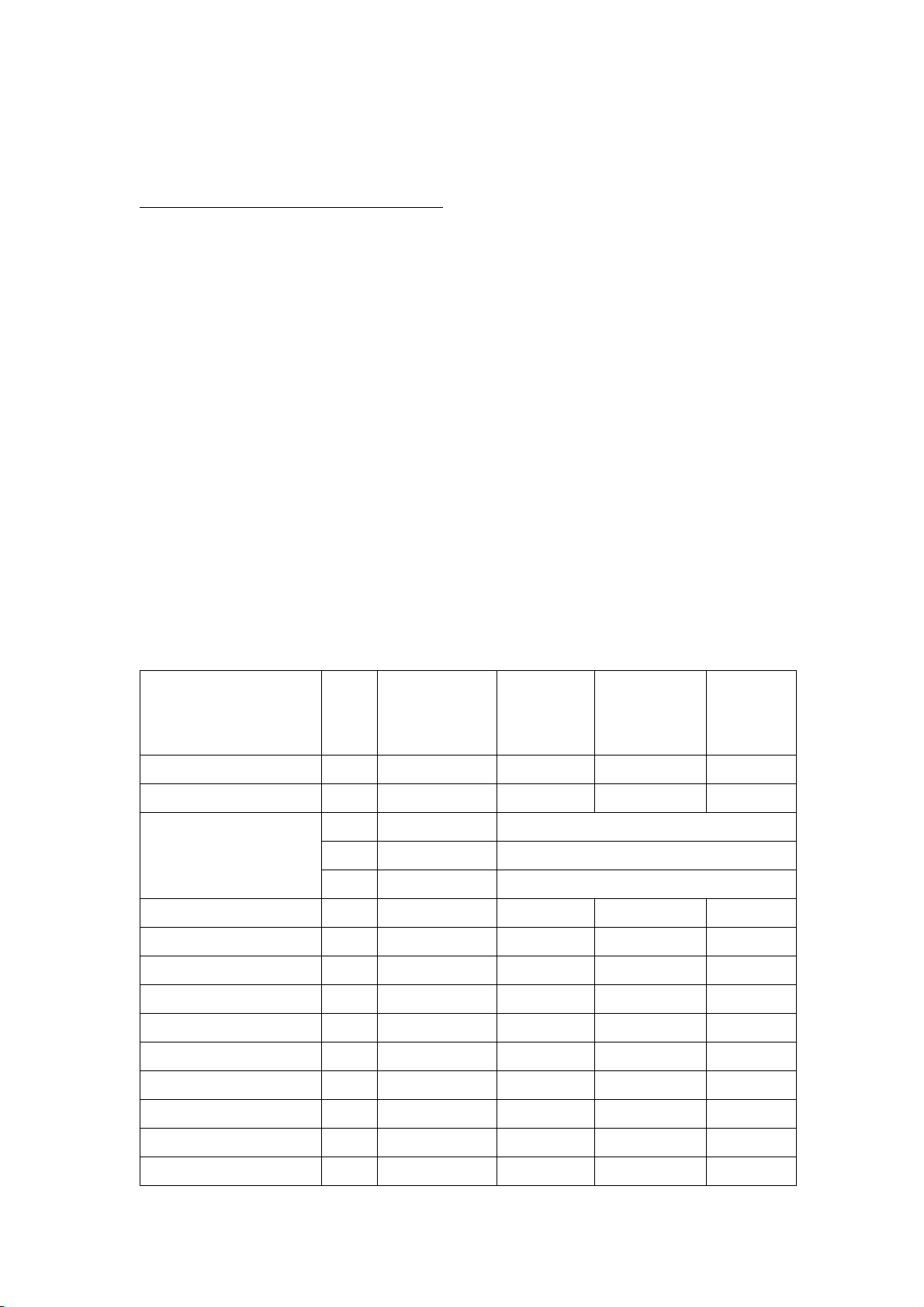

Periodically, the float bowl should be drained to remove condensation.

To drain the float bowl, use the following procedure.

1. Attach a hose to the float bowl

drain and direct it into a container.

2. Loosen the drain screw and allow

the gasoline and condensation to

flow out.

3. Tighten the drain screw securely

and remove the hose.

SEAT LOCK

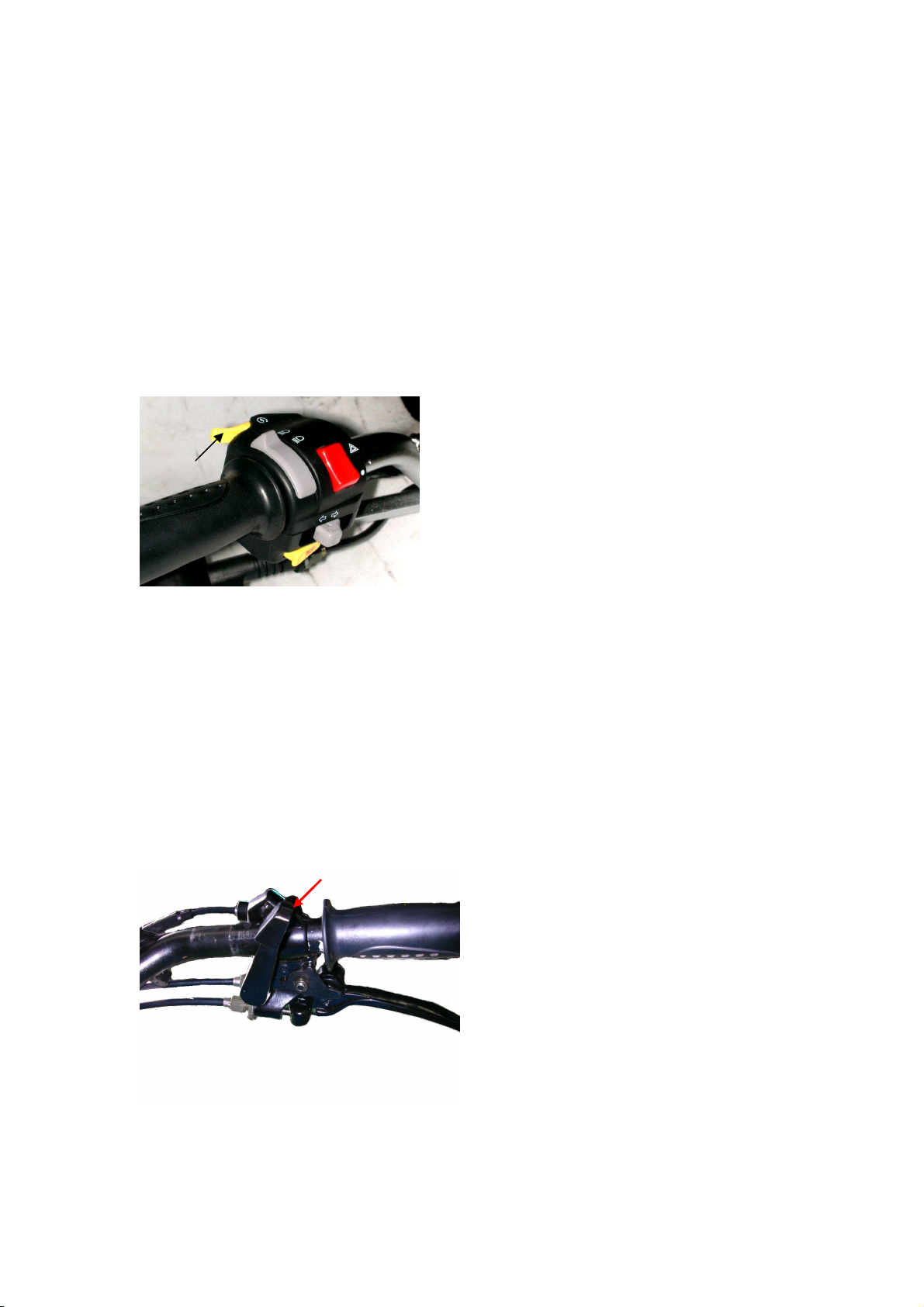

1. To remove the seat, pull the seat lock knob out (located at the).Raise

the rear end of the seat and slide it rearward.

3. To lock the seat into position, slide the front of the seat into the seat

retainers and push down firmly on back of seat. The seat should

automatically lock into position.

Warning: Make sure the seat is secure before mounting the ATV.

Severe personal injury may result if the seat is not properly secured.

SAFETY FLAG/BRACKET

A bracket is provided for mounting a flag at the rear at the rear of the ATV.

The flag should be displayed to make the ATV more visible.

TRANSPORTINGATV

When transporting the ATV, we recommends that the ATV be in its

normal operating position (on all four wheels) and the following

procedure be used.

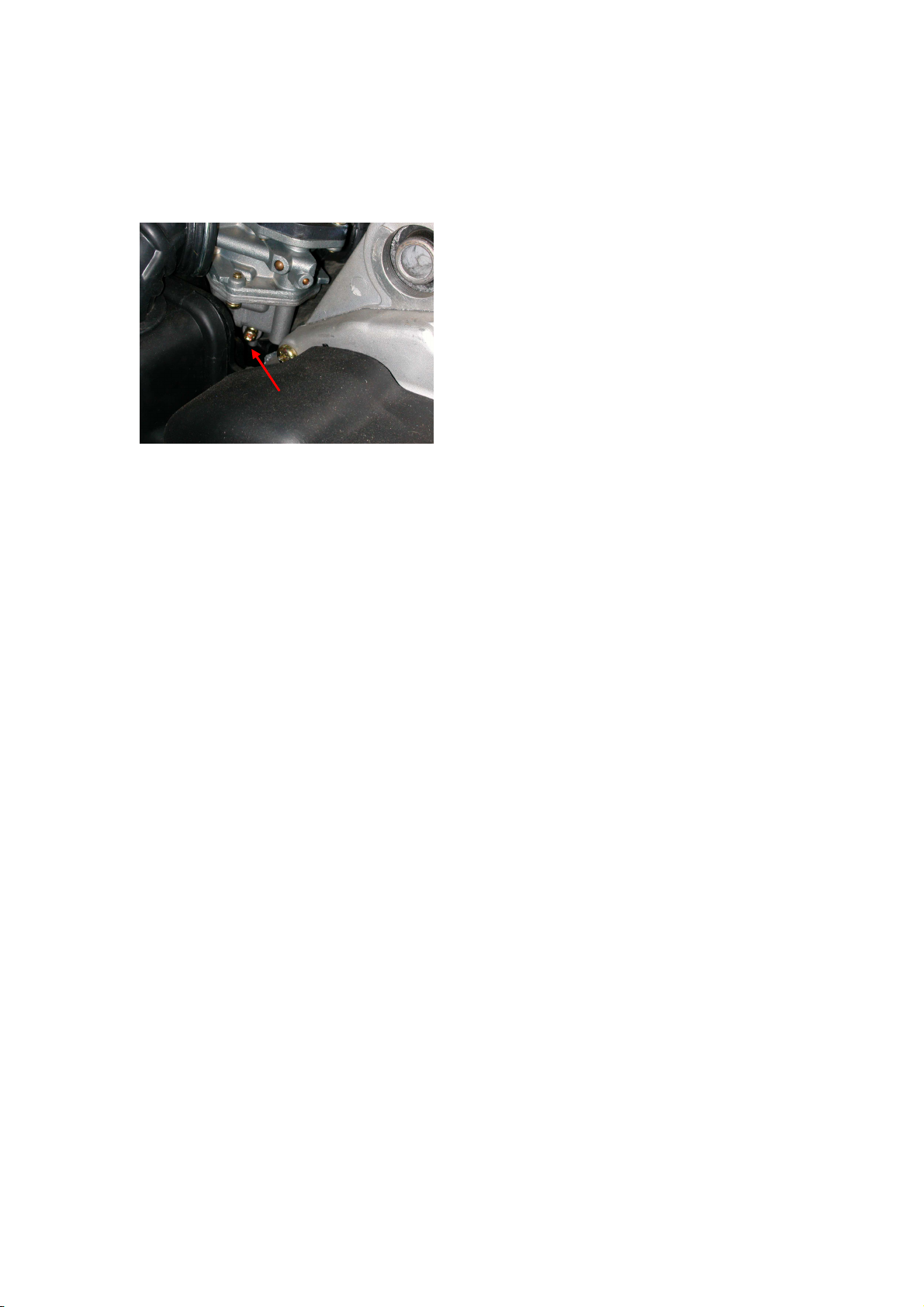

1. Engage the brake lever locks.

2. Turn the fuel valve OFF.

3. Secure the ATV with load rated hold-down straps.

NOTE: Suitable hold-down straps are suggested. Ordinary rope is not

recommended because it can stretch under load.

Caution: If using additional hold down straps in any other areas, care

must be taken not to damage the ATV.

Caution: When transporting theATV, make sure the brake lever lock is

engaged and the ATV is properly secured.

DRAIN