Accu Cutter Company

160 Stover Drive, P O Box 1170, Carlisle, Pennsylvania 17013 800-345-0062 (Fax) 717-241-2350

“We’ve stayed in business by cutting corners!” 7

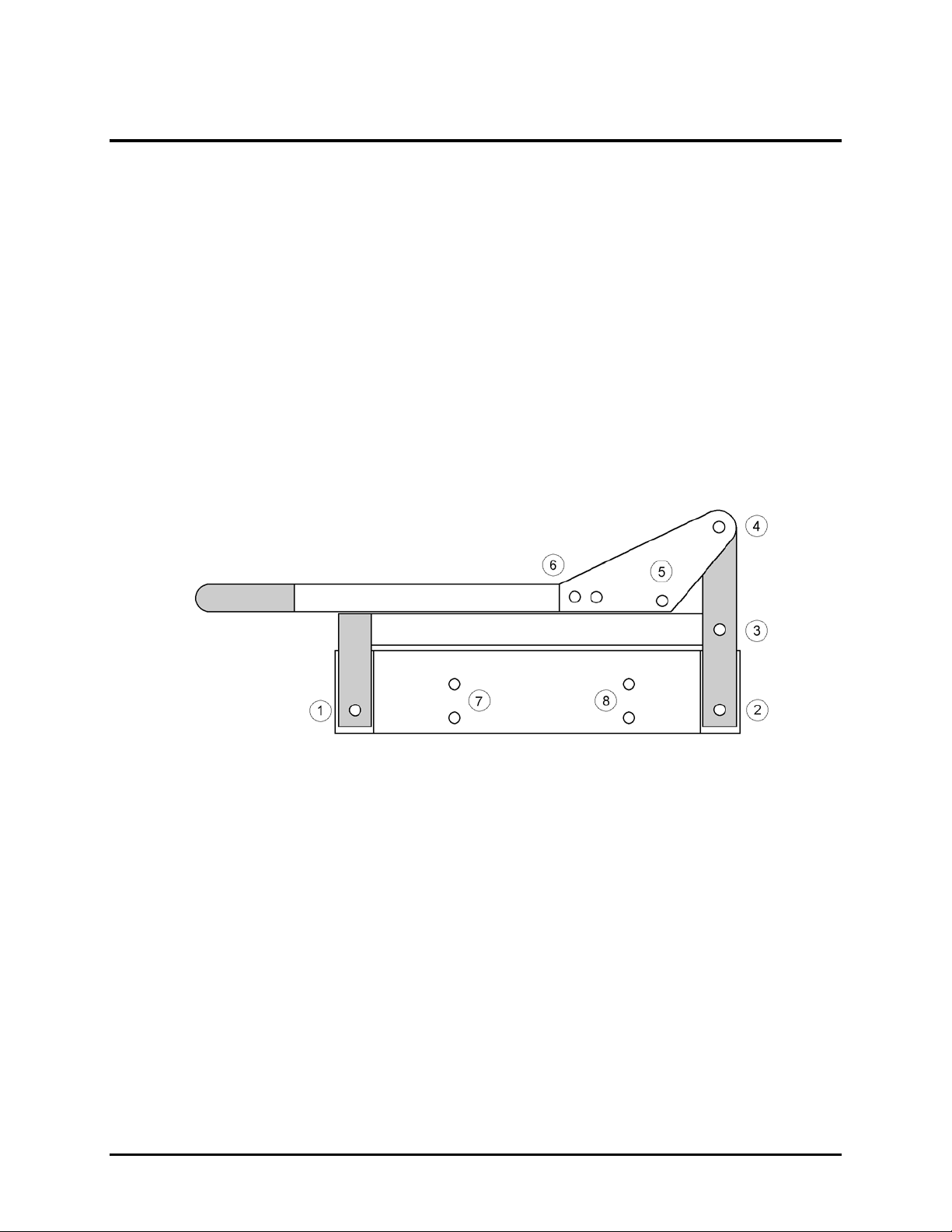

Adjusting the Blades

The following instructions are for adjusting the blades of the shear to a “zero” gap or clear-

ance. This is the preferred setting for lighter materials like .020” brass, .025” aluminum, and .060”

flexible plastic. If your application is for heavier materials within the design limits of the shear, you

may prefer a clearance set with feeler gauges. The general procedure for adjusting the blades is the

same except you would use feeler gauges in Step 7 to determine the proper location and gap for the

bottom blade and a sample of your material to test the cut of the shear.

1. Lower the operating handle so the top blade is in the closed position.

2. Remove the safety shield.

3. Using the ball hex provided with the shear, loosen the setscrews so they are no

longer touching the bottom blade.

4. Loosen the four button head bolts holding the bottom blade. A standard 5/32” hex

head wrench is required. If the top of the bottom blade is level with the blade car-

rier and worktable, go to Step 5. If it is not, remove the button head bolts and

place shims under the entire blade to raise it until it is level. Align the holes and

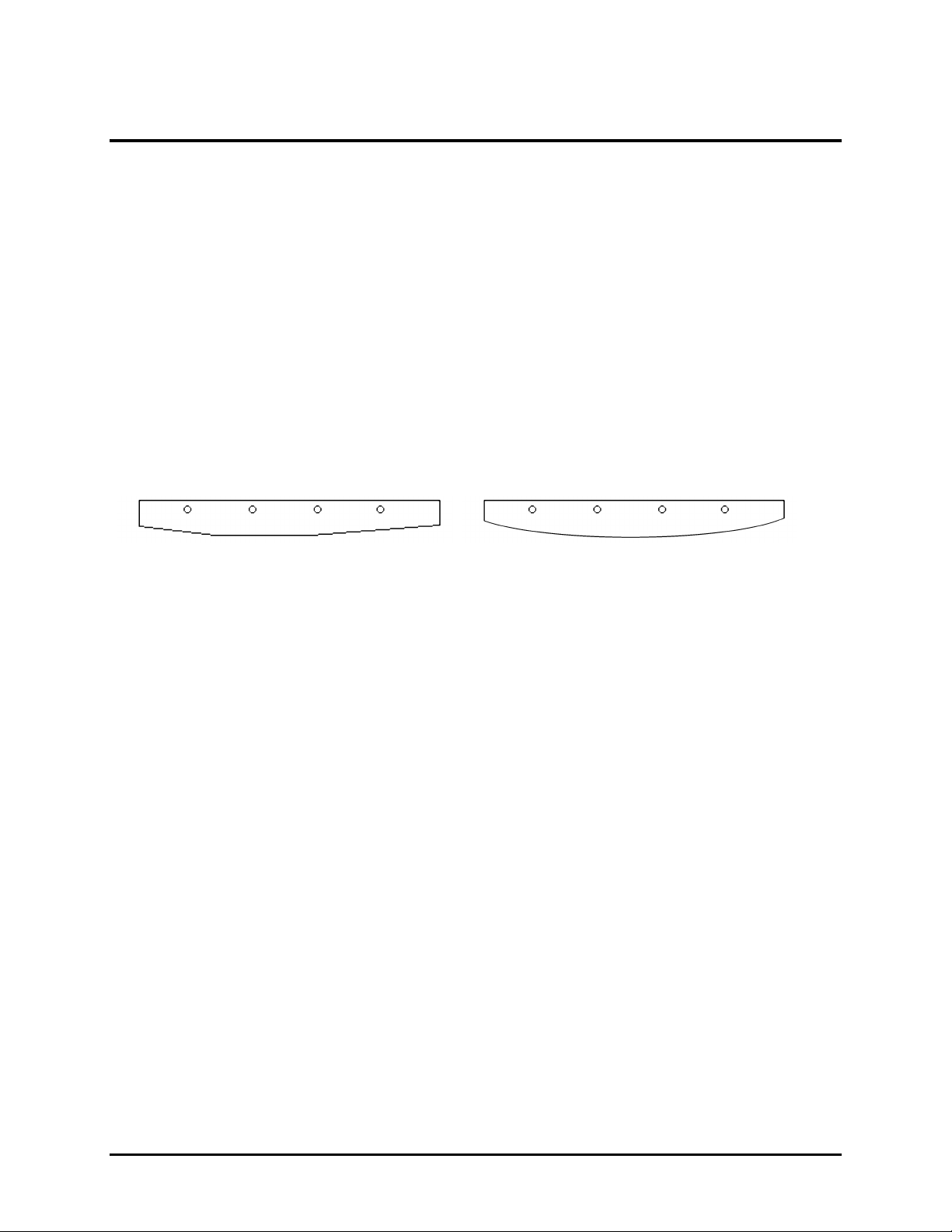

insert but do not tighten the button head bolts. Note the orientation of the be-

veled edge of the blade in Figure 4 above. A leather glove is recommended for

holding the blade while installing it.

5. Using your fingers, push the bottom blade against the top blade and lightly tigh-

ten the four button head bolts.

6. Make a test cut with a piece of paper. CAUTION: When you are making your

test cut, if you hear an unusual or grinding noise or you feel unusual or excessive

resistance or stiffness, stop immediately. Moving the handle further could cause

serious damage to the blades. Before moving the handle further, back off or loo-

sen the bottom blade and start the adjusting process over.

a) If the shear cuts the paper completely, tighten the four button head bolts,

and tighten the setscrews against the bottom blade.

b) If the shear does not cut the paper completely, try loosing the button head

bolts in the problem area and retighten while applying additional pres-

sure. If this is unsuccessful, use the setscrews as need to apply the pres-

sure needed. Do not over tighten the setscrews. Once the shear cuts the

paper completely, tighten the four button head bolts, and tighten the set-

screws against the bottom blade.

7. If the top guide was removed or loosened, reinstall or tighten it. See the instruc-

tions for squaring the top guide.

8. Replace the safety shield.

* * * * *