Table A: Specific Gravity and Maximum Viscosity ................................................................................1

Figure 1.1 Leak Detector and Manifold Dimension ..............................................................................2

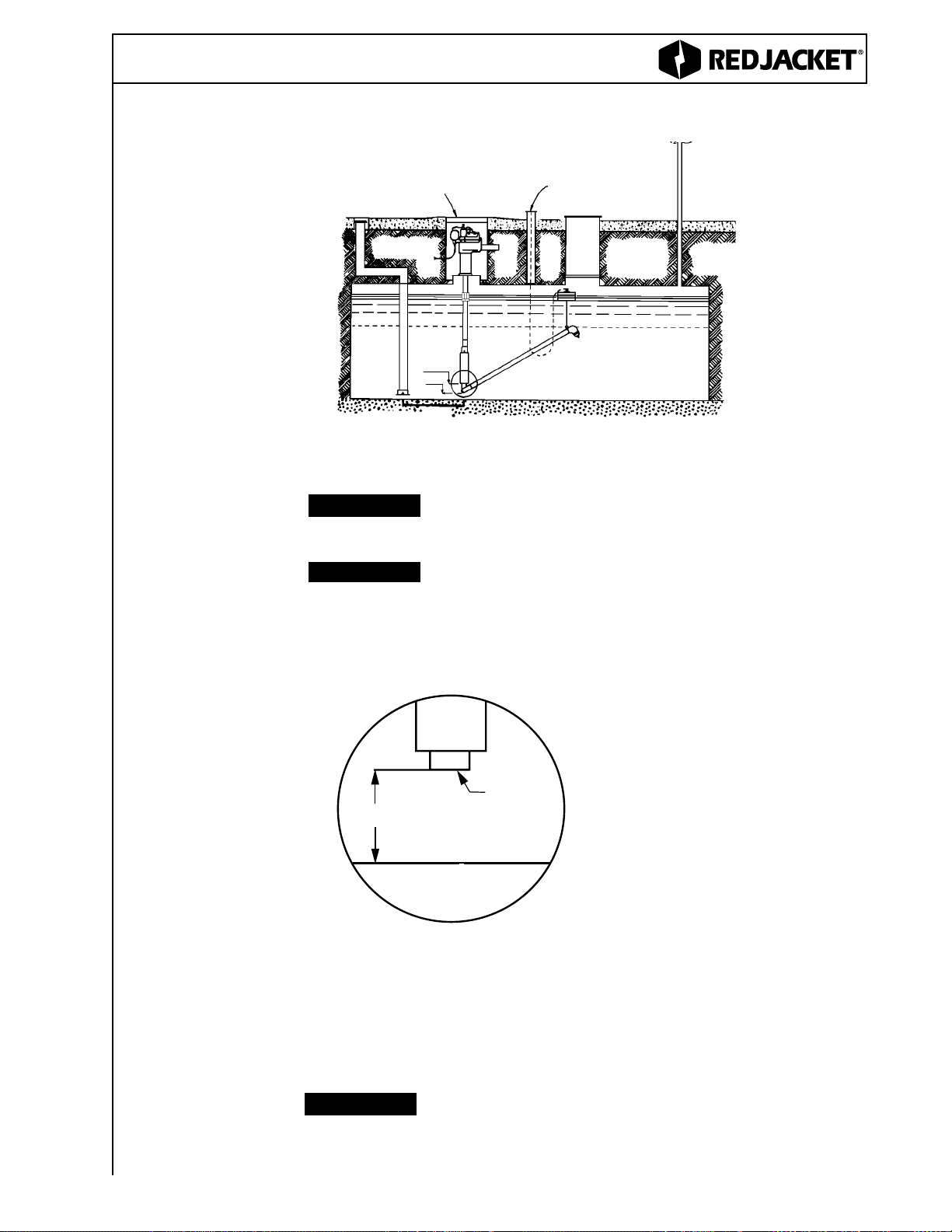

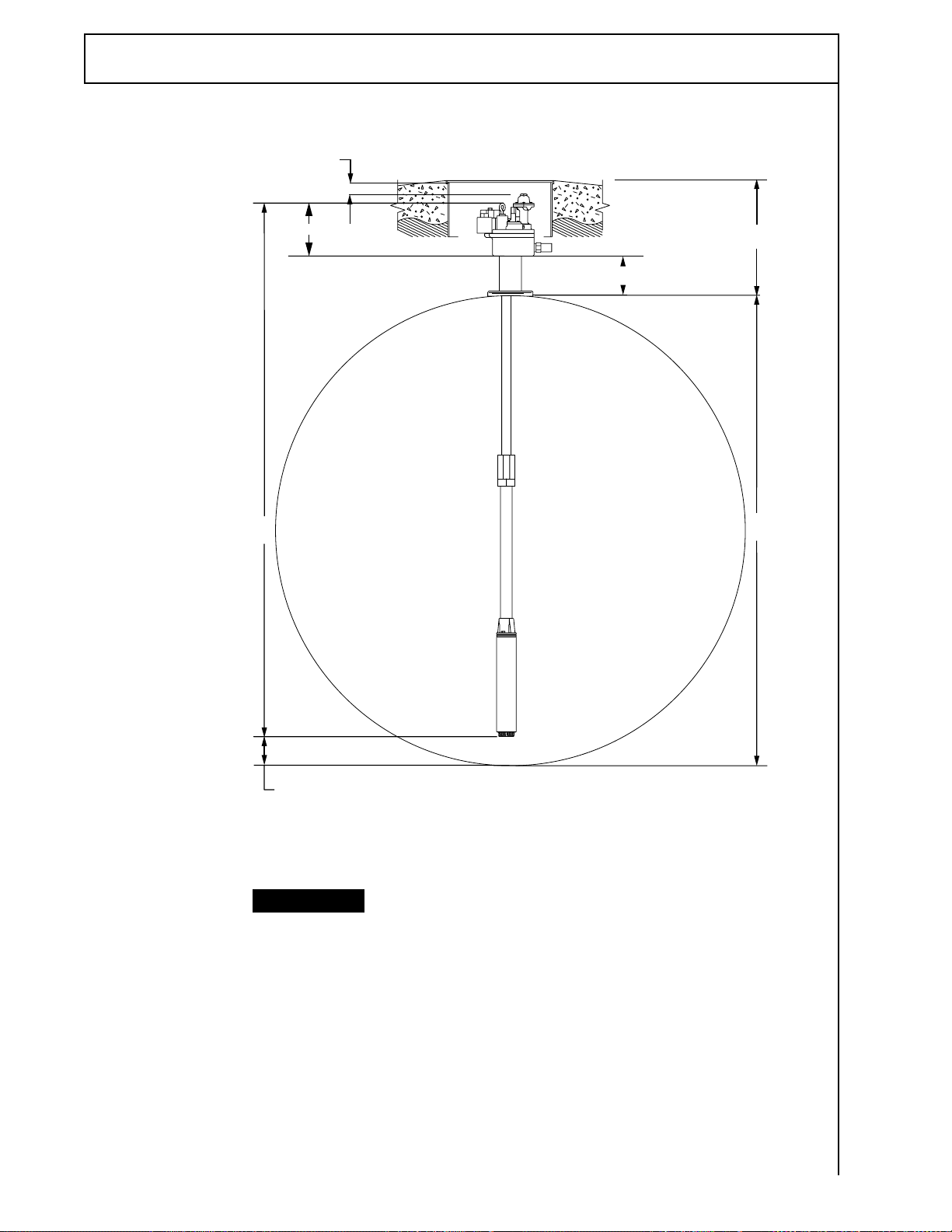

Figure 1.2 Floating Suction Installation ................................................................................................3

Figure 1.3 Floating Suction Adapter......................................................................................................3

Figure 1.4 Measuring the Tank..............................................................................................................4

Table B: Pump Selection ......................................................................................................................5

Table C: Distance from Eye Bolt to Inlet ..............................................................................................6

Table D: Weights and Lengths..............................................................................................................7

Table E: Attaching the UMP ..................................................................................................................9

Figure 2.1 Attaching the UMP............................................................................................................10

Figure 2.2 Aligning the Gasket............................................................................................................10

Figure 2.3 Measuring the Tank............................................................................................................11

Figure 2.4 Loosen the Fittings ............................................................................................................11

Figure 2.5 Adjusting the Pump............................................................................................................12

Figure 2.6 Wiring Schematic ..............................................................................................................13

Figure 2.7 Conduit Box Wiring............................................................................................................13

Figure 2.8 230 VAC Remote Control Box with 110 VAC Coil ............................................................14

Figure 2.9 Suggested Wiring Diagram without Control Box ..............................................................14

Figure 2.10 230 VAC Remote Control Box with 110 VAC Coil and Capacitor....................................15

Figure 2.11 230 VAC Remote Control Box with 230 VAC Coil ..........................................................15

Figure 2.12 Tandem Pumps................................................................................................................16

Figure 2.13 Suggested Wiring for Tandem Pumps ............................................................................16

Figure 2.14 Functional Element ..........................................................................................................18

Table F: Approximate Operating Pressures ........................................................................................19

Figure 3.1 Closing the Check Valve....................................................................................................20

Figure 3.2 Line Test Port ....................................................................................................................20

Figure 4.1 Packer................................................................................................................................21

Figure 4.2 Removing the UMP............................................................................................................22

Figure 4.3 Replacing the Gasket ........................................................................................................22

Figure 4.4 Packer with Functional Element ........................................................................................23

Figure 4.5 Functional Element ............................................................................................................23

Figure 4.6 Loosen the Fittings ............................................................................................................25

Figure 4.7 Adjusting the Pump............................................................................................................25

Figure 4.8 Wiring Schematic ..............................................................................................................26

TABLE OF FIGURES & TABLES

ii