aci A/LCD-R-4-20MA Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 4.0

I0000195

2.75"

(69.85 mm) 1.12"

(28.55 mm)

4.50"

(114.30 mm)

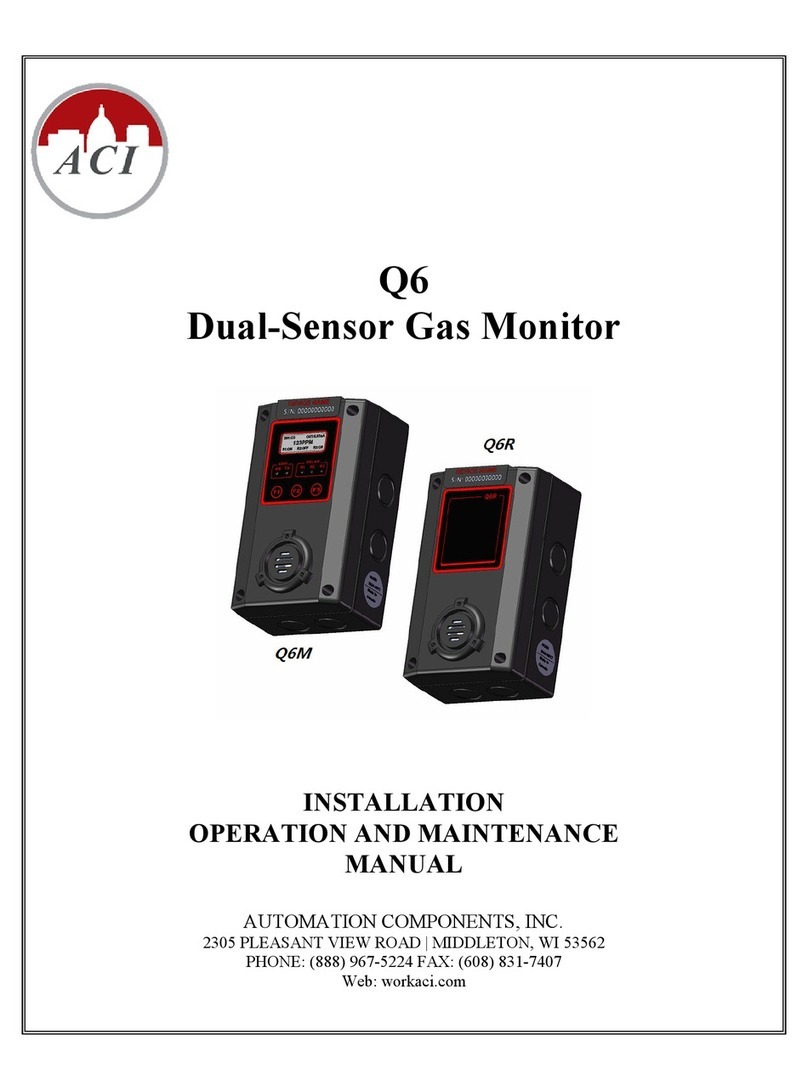

ROOM, VERSION 1

[R]

FRONT

BOTTOM

RIGHT

FIGURE 1: ROOM DIMENSIONS

ROOM SERIES

Installation & Operation Instructions

A/LCD-R-4-20MA

Phone: 1-888-967-5224

Website: workaci.com

PRECAUTIONS

• DO NOT RUN THE WIRING IN ANY CONDUIT

WITH LINE VOLTAGE (24/120/230 VAC).

GENERAL INFORMATION

The A/LCD-R-4-20MA is a low power, high accuracy, 3.5

digit LCD display. The A/LCD-R-4-20MA may be used

with any 4 to 20 mA loop powered Temperature,

Relative Humidity, Current, and Dierential or Gage

Pressure transmitter. The display is factory calibrated

for a preset range. A great solution for remote

monitoring of any 4-20 mA loop powered device.

MOUNTING INSTRUCTIONS

Separate the cover from the base. The ACI/LCD is

shipped as a two-piece unit. The LCD Module must be

unplugged from the 10 pin connector before the base

of the sensor may be mounted. Attach the base directly

to the wall or to a standard 2” x 4” junction box using

the (2) #6-32 x 1”screws provided.

Take care when mounting. Check local code for

mounting height requirements. Typical mounting

heights are 48-60” (1.2-1.5 m) o the ground and at

least 1.5’ (0.5 m) from the adjacent wall. The sensor

should be mounted in an area where air circulation is

well mixed and not blocked by obstructions - see

FIGURE 2 (p. 2).

Note: If mounting an LCD-RS(with setpoint), you must

mount to standard 2” x 4” junction box. It cannot be

surface mounted. The set point PCB is located on back

of enclosure (see Figure 3 p.2).

Refer to the wiring instructions (p. 2) to make

necessary connections.

LCD Installation

The LCD Module should then be gently inserted into

the 10 pin connector. Tighten the cover down, using

the (2) 1/16” Allen screws located in the bottom of the

housing. Take care to make sure the LCD module lines

up with the enclosure LCD window. The LCD module

can be bent if adjustments are needed. A

1/16” Hex driver is needed to secure the cover to the

base.

WIRING INSTRUCTIONS

Do not apply power to the (+) Input terminal

or you may damage the LCD Display.

Open the cover of the enclosure. ACI

recommends 16 to 26 AWG twisted pair wires or

shielded cable for all transmitters. Refer to

FIGURE 4 (p. 3) and TABLE 1 (p. 2) for wiring

connections. The number of wires needed

depends on the application. All wiring must

comply with all local and National Electric Codes.

ACI/LCD-4 to 20 mA will drop a maximum of 7

VDC, therefore:

Vs-V1>7VDC

Where: Vs = Source Voltage

V1 = Voltage Requirement of

Transmitter (Load)

7V = Maximum Voltage Drop of

ACI/LCD-4 to 20 mA

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 4.0

I0000195

COVER

FIGURE 2: MOUNTING

#6-32 x 1”

MOUNTING SCREWS

LCD MODULE

Must be unplugged before

the sensor is mounted

BACKPLATE

OPTIONAL INSULATING

GASKET

CIRCUIT BOARD

FIGURE 3: SETPOINT PCB MOUNTED

ON BACKPLATE

0.63"

(16 mm)

TABLE 1: PCB CONNECTIONS

TERMINAL BLOCKS

+

-

+ SET (located on back

PCB)

-SET (located on back

PCB)

O/R

O/R

CONNECTIONS

(+) 4 to 20 mA current loop input (Input to Display from Transmitter or Controller)

Note: If Set Point, this wire will be factory installed.

(-) 4 to 20 mA LCD current loop output to controller analog input

+24VDC Supply Voltage

(-) 4 to 20 mA set point current loop output to controller analog input

Note: This wire will be factory installed into the (-) Terminal Block

Override signal to controller analog input (N/O Dry Contact Closure)

Override signal common to controller analog input (N/O Dry Contact Closure)

Backplate

Setpoint

PCB

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 4.0

I0000195

FIGURE 4: LAYOUT FIGURE 5: SETPOINT PCB

FIGURE 6: WIRING ACI’S GP PRESSURE SENSOR

GP Sensor

Automation Panel

Power Supply

+13 to 30 VDC

Note: The example below shows ACI’s GP Pressure sensor wired to the A/LCD-R-4-20MA.

WARRANTY

The ACI Room Series temperature sensors are covered by ACI’s Five (5)Year Limited Warranty, which is located in

the front of ACI’S SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

PRODUCT SPECIFICATIONS

TROUBLESHOOTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 4.0

I0000195

2 Wire, 4-20 mA current loop

+7 VDC for LCD Display

+/- 0.5% of span

3 ½ Digit LCD (-199.9 to 199.9) | F (Fahrenheit), C (Centigrade) or No Descriptor

Dry Contact “N/O” Contact | Minimum: 10 uA @ 1 VDC; Maximum: 50 mA @ 24 VDC

0.1 Ohms maximum | 100,000 Cycles

+/- 10% | 4-20 mA: 4 mA (Far Left) | 20 mA Far Right (DA- Direct Acting (Default)

20 mA (Far Left / 4 mA Far Right (RA- Reverse Acting (Optional)

+24 VDC +/-10%

35 to 131ºF (1.5 to 55ºC)

-40 to 160ºF (-40 to 71ºC)

5 to 95% non-condensing

Screw Terminal Blocks | 16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

SENSOR NON-SPECIFIC INFORMATION

Input:

Maximum Voltage Drop:

Display Accuracy:

LCD Resolution | Descriptors:

Override Contact Type | Contact

Ratings:

Override Contact Resistance | Life

Expectancy:

Set Point Accuracy:

Setpoint Supply Voltage: (4 to 20 mA

Only):

Operating Temperature Range:

Storage Temperature Range:

Operating Relative Humidity Range:

Connections | Wire Size:

Terminal Block Torque Rating:

PROBLEM

Display Not Working

SOLUTION(S)

•Wires not connected correctly, no signal from transmitter or

common ground. Also make sure the display is plugged in correctly

after mounting.

TEMPERATURE DISPLAY ADJUSTMENTS

The Temperature Display may be adjusted by adjusting the ZERO Potentiometer as shown on the above

diagram. Adjust zero pot until the LCD Display reading matches your sensor if necessary. Do not adjust the

SPAN pot.

SETPOINT CONTROL

Adjust slider at bottom of housing for set point control. Slide to right to increase set point temperature.

Slide to left to decrease temperature control. Units can be setup from factory for Direct Acting (resistance

increases when adjusted to right), or Reverse Acting (resistance decreases when adjusted to right).

OVERRIDE ADJUSTMENTS

Override will be set to Dry Contact.

Other aci Monitor manuals

Popular Monitor manuals by other brands

ViewSonic

ViewSonic GS773 user guide

ViewSonic

ViewSonic VX1962wm - 19" LCD Monitor Service manual

Iiyama

Iiyama ProLite T1531SR specification

NEC

NEC LCD1990SX - MultiSync - 19" LCD Monitor user manual

Austin Hughes Electronics

Austin Hughes Electronics CyberView RP-1020QD brochure

Philips

Philips 170P5EG/00 Service manual