Acorto 2000s User manual

i,!

.{

i. .,, . ;

#:. lu ;:-- :'':;''.;I

.'

: - ,,

' ' ";" :. l'

;i#.,',i;t;.?. ',.

!ll?i{ia$*li ild ll,iliiiii!

, r;: i;, ii;i :.;. ":. . g

iti .t: it

'::!.":

rl ;

, ,'+r,

, .. ,.+;. :t ""

..". : ,

-" lH u, **t

,F''t i, *.' 'st

, "q mF" ::*

H::"il '* iil;".l'

i;:r "*:l ''

u'srssi ' ",,,;+'::

rws 'li.li

iirri E

!:1:l;;

lP. Elii, Slf.,:1r!r:ll

iFi;,i{ri{

{

Gf, rr, *;'

' : ,it '* #:.

+ i,. ,,; .,1:,i:.r'::

r. ''': ;i*:

'.;tj;r -' l.

".I,1$l

/:;il#

-!.t;:;

+,;;, r " ,

; -;l;''

- 'ii, li.-i4,":,

..,,i tri'

'F'" ri' ; j

:,, ,l ^l .'".

n:

.._=1,,, i i l$riir,

f ..:

;;,T :1;.

T:

tf':- ,.+ -:

"" . - ,' t

..'-.,= ,r-". Model 2000s/i

Espresso Machine

iloddns lecruqcal ysr000z ouoov

l-\

{r

TOOOZ/S9OOZ slopouU tenueuu yoddng tEclur;ool oyocv'80'-0062 # Ued ropro-ou

pJeM ueapeN 'ssou r{eg 'reufepl suqg

uueuDllon q6rel 'repng perg

'oleH sneJl'surelll;1111 fueg 'eur1 ;ey1

JerlloC suq3 'uosur4e6 dryg 'sre66ef r{ieg

olreN Docs

uosJapd eleued

Z0OZ lrdy :uor1pj

:sJeluM 6unnquluog

:poddng lsJruqcel

:srollp= lecrul'|oal

:reeurbu3 crqderg

roqgnype6eueyl lce[or6

uroc'ouoce'/vvr^iv\

xldJ 19rc-e9V GZV)

0660-8// (008)

o}gz-esv Gzv)

90086 VM'an^oltog

3N onue^v t)pz, Lgzl

'cu;'o;.tocy

C

1I

i

'

3020-0004

Welc;ome to Acorto!

We are very pleased to have you join our team of professionals, united in the

common pursuit of excellence on behalf of our customers.

Acorto is a leader in the design, development and manufacture of fully automated

espresso systems, serving thousands of customers throughout the world. Our goal is

to contimuously achieve the highest imaginable levels of quality, service, and

technological performance for our customers. We believe that it is the ability, talent

and spirit of people like you that will enable Acorto to reach this goal.

The basiic objectives of Acorto are:

' Deliver quality and value to our customers through leadership and excellence

in everlthing that we do.

. Provide a strong seamless network of service to all Acorto customers while,

exceeding their expectations from us.

. Build value in our employees and agents through experience, training and the

provision of opportunities for success.

. Build long term value in our Company.

. Be strong contributing members of the communities in which we conduct

business.

You are an important part of our team. We want to do our best to help you find your

work with Acorto satisfuing, rewarding and personally meaningful. The material in

this manual has been designed to be used as a training aid, reference resource and

updated library of Acorto Policies and Procedures.

It is imtrrortant that you keep your manual updated to reflect our current revisions to

ensure vve have provided you with the tools necessary to facilitate YOUR success!

z-

Director of Service and Customer Support

Acorto Inc.

2

tar

Ray Rosrs

Acorto 2000s/i Technical Support ill

uoddns le3luqseMsroooz ouoev nt

v000-020e

3020-0004

Table of Contents

Section I Espresso Overview .....................1-l

Wat is espresso? ......................1-2

Basic'Espresso Beverages .........1-3

Espretsso Terminologt ...............1-5

Section 2 Overview ..................2-l

Mode'|2000i Overview Diagram.... ..............2-2

The Artodel2000s/i....... ..............2-3

The Oomponents............ ............2-3

Section 3 User Information, Keypad Navigation and Software......................3-1

Model 2000s Touch Pad............ ...................3-2

Model 2000i Touch Pad............ ...................3-4

Machine Operation.., .................3-6

Sofl-ware..... .............3-7

Software Quick Reference Table ................3-l I

Upgroding Sofnvare ................3-16

Section 4 Installation

Sectio n 5 EIectrical................. .............5-1

4-l

Acorto 2000s/i Technical Support V

3020-0004

Electrical Components .............. J_g

Transformer Diagroms ........... 5_I I

LED's on DC Power Supply &oard............. ................. S_12

Fuses ......... ........... S_I5

Jumper Plug Connector Detail. .................5_16

Heater Element Wiring Diagrams .............5_21

Section 6 Water System ..........6_1

l[/'ater Quality....... ..................... 6_4

Preventing Water Related problems.......... .....................6_5

Woter Supply . . ........... .............6_s

pump......... .............6_6

Water Tank........... .........6-7

Flowmeter - ............. 6-9

valves....---.. ............6-9

Quick Release Fitting Directions......... ...... 6_I I

Section 7 Steam System ..........7-l

Steam Level Sensor Board and Sight Tube. ....................7_2

Steam Tank........... .....................7_3

Va1ves......... ............7_4

Section 8 Milk Sysrtem....... ...... g_l

Milk Valve Assembly... ..............8_2

understanding the Relationship Between steam Temperature and Milk

Temperature ........... B_j

Section 9 Refrigeration Unit.... ..................9_l

Refrigeration Unit Overview Diagram.... .... g_2

Refer Module Assembly ............. g_3

Fans .......... ............. g_4

Alt Milk Yqlve .......... ................. g_4

Weigh Tray............ .................... g_5

Section 10 The Brew Group...........

Brew Group Overview ............10_2

Hall Effect Sensors on the Pistons. ............ I0_3

Piston Movement.. ................... I0_4

VI Acorto 2000s/i Technical Support

3020-000A

Group Initialization................. ...................10-5

Meas,uring Coffee Powder Dose........... ...... j0-5

Motot s ..................10-6

Pistons ..................10-7

Coffee Piston O-Ring Replacement.... ........10-g

Piston Removal Procedures ..10-10

Gear Box Removal and Installation............... .............10-10

Section 11 Grinders................. .................11-1

Grinalers..... ...........1 I -2

Removing Grinder...... .............11-4

Disas,sembling Grinder ............11-4

Settin.g Grinder Adjustment to "Ze/o".... ....1 1-5

Section 12 Calibration............ ..................12-1

Espre,sso Extraction.. ...............12-2

Five Steps to Calibrating Espresso 9hot........... ............12-3

Step l: Verifu Factory Settings...... .............12-4

Step 2': Use Fresh Espresso Roast Coffee 8eans......... ..12-4

Before you start Step 3, afew things you should lmow ....................12-5

Step 3: Adjust the Coffee Grind Texture....... .................12-6

Step 4: Ask Customer to Approve Extraction................. ..................12-7

Step 5: Coffie Powder Dose and Water Volume are adjustable per customer

request....... ...........12-7

Settinig Milk and Water Timings...... ...........12-9

Espre,sso Extraction & Temperature Parameters .......12-11

Section 13 C1eaning................ ..................13-1

Importance of Cleaning ...........13-2

Daily Maintenance of Acorto Espresso Machine...,. .....13-2

Acorto Cleaning Products .... ...13-2

Cleaning Timers ...13-2

Milk Cleaning Timer-24 Hour/150 Drink ..13-3

Brew ,Group Cleaning Timer-24 Hour.......... ................13-3

Resetting Timers ........ ..............13-3

Auto-t?.inse ............13-3

Cleaning the Milk System,............ ....,,...,.,..13-4

Acorto 2000s/i Technical Support vtl

3020-000A

Cleaning the Brew Group........ .................. I3_s

Cleaning the Milk System- Machines with Cleaning Timers ........... I3_6

Cleaning the Brew Group- Mochines with Cleaning Timers........ ...I3_7

Section 14 Removal of Machi

Removal Procedures ...... -........ I4_2

Preparationfor Shipping ........ I4_3

lTater Filtration System........ ..I4_3

Packagingfor Shipment. .........14_3

Section 15 Preventative Maintenance....... ................15-1

Preventative Maintenance............... .......... I5_2

PM Kit Parts List (part Number 5000-010) .... ................. I5_2

Instructions ..........I5_2

Completion of Preventative Maintenance Check1is1.................. ...... I5_3

Part I: Statistical Information...... .............I5_3

Part 2: Water Quality and Treatment System.. ............. I5_5

Part 3: Plumbing .................... t5_5

Part 4: Brew Group ................I5-Z

Part 5: Grinders..... .................I5_g

Part 6: Elecnical... 15_10

Part 7: Cleaning and Machine Appearance............... IS_10

Part 8: Milk Valve Assembly..'.. .............. Is_t I

Part 9: Refrigerator................. ................15_ll

Part l0: Calibration ............. i5_12

Part lI: Reset PMCounter........... ........... tS_13

PMCheck1ist.................. .......15_14

Section 16 Acorto lProcedures ................. l6-f

Acorto Service Call Process................. ..... 16-2

Complete Call Protoco|............... ..............16-3

Acorto Service Code Procedure.........,.. ..... i6-s

Parts Return Po1icy......... ........ 16-6

Section 17 Customer Service & Training ................. l7-l

Training the Customer................. .............. IZ-2

Acorto, Value-Added Service....... .............. l7-5

vltl Acorto 2000s/i Technical Support

3020-0004

/1

,. 1Section I 8 Troubleshooting.... ................... 18-1

Troultleshooting Display Messages... .........1g_2

Trouhleshooting Machine Failure.... .......... jg_7

Troubleshooting Trees... ..........1g_g

Section 19 Parts List & Diagrams.. .........19_l

Recommended Tools List... ......1g_2

Reconnmended Van 5tock.......... ..................1g_3

Parts List and Diogramr................. ...........1g-s

Section 20 Index ................20-r

Sectio n 2 1 Servic'e Bulletins.... .......21-r

r\

il

Acorto 2000s/i Technical Support IX

{}

Sec;tion 2 Overview

I

t

I

Machine Overview Diagram

The Model 2000s/i

Major Components

Section 2: Overview 3o2o-oo2A

Model 2000i Overview Diagram

Bean Hoppers Hot Water

Tank

"{$_**^_**__

*ffiM

Whter Pump

r Refrigeration Unit

i, Gold Milk Storage

!1

UJ

z

o-

F

z

o

t

ll-

o

o

o

(\l

Drink Dispensing

2-2 Acorto 2000s/i Technical SuPPort

2030-oo2A

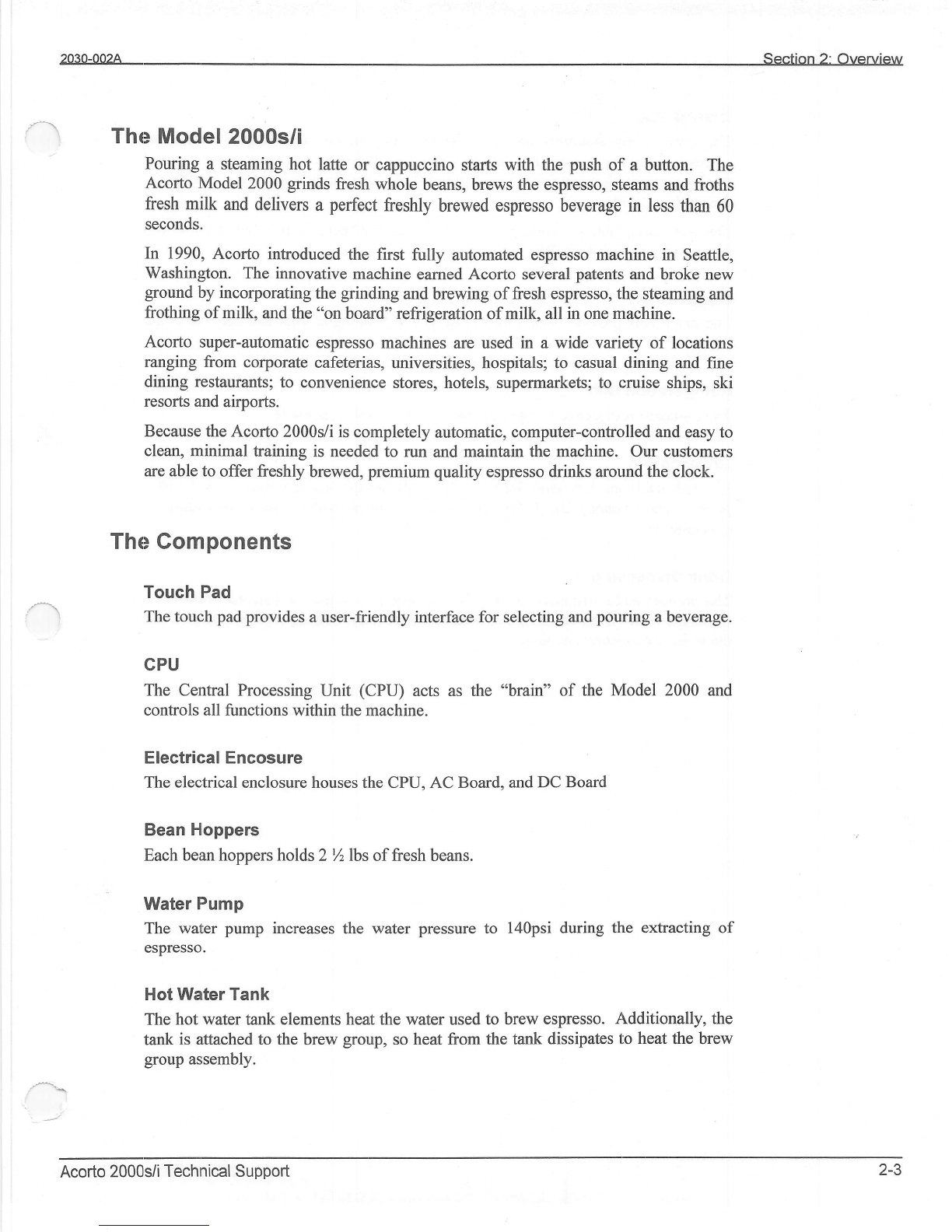

\ The Model 2000s/i

Pouring a steaming hot latte or cappuccino starts with the push of a button. The

Acorto lModel 2000 grinds fresh whole beans, brews the espresso, steams and froths

fresh miilk and delivers a perfect freshly brewed espresso beverage in less than 60

seconds,,

ln 1990, Acorto introduced the first fully automated espresso machine in Seattle,

Washintr5ton. The innovative machine earned Acorto several patents and broke new

ground by incorporating the grinding and brewing of fresh espresso, the steaming and

frothing of milk, and the 'oon board" refrigeration of milk, all in one machine.

Acorto super-automatic espresso machines are used in a wide variety of locations

ranging from corporate cafeterias, universities, hospitals; to casual dining and fine

dining restaurants; to convenience stores, hotels, supermarkets; to cruise ships, ski

resorts and airports.

Because the Acorto 2000s/i is completely automatic, computer-controlled and easy to

clean, mLinimal training is needed to run and maintain the machine. Our customers

are able to offer freshly brewed, premium quality espresso drinks around the clock.

The Gomponents

Touch Pad

z-1 The touoh pad provides a user-friendly interface for selecting and pouring a beverage.

CPU

The Central Processing Unit (CPU) acts as the "brain" of the Model 2000 and

controls all functions within the machine.

Electrical Encosure

The elec;trical enclosure houses the CPU, AC Board, and DC Board

Bean Hoppers

Each bean hoppers holds 2 % lbs offresh beans.

Water ltump

The waller pump increases the water pressure to 140psi during the extracting of

espresso.

Hot Warter Tank

The hot water tank elements heat the water used to brew espresso. Additionally, the

tank is aLttached to the brew group, so heat from the tank dissipates to heat the brew

group assembly.

Acorto 2000s/i Technical Support 2-3

Section 2: Overview 3o2o-oo2A

Brew Group

The brew group assembly precisely brews espresso, cup after cup. After fresh

espresso beans are groundinto the biew chamber, hot water is forced into th,e top of '\-"

the brew group, through the espresso grounds, and out the bottom of the chaLrnber to

the product outlet.

The brew group automatically pushes the used coffee oopuck" out of the chamber and

discards it into the Dress Bin.

Steam Tank

The steam tank provides steam for the automatic frothing of milk and optional steam

wand.

Refrigeration Unit

The on-board refrigeration unit holds two 1-gallon milk containers.

Grounds Bin

Located inside the left hand door, the Grounds bin catches the used ground coffee

pucks. The Grounds Bin holds approximately 40-50 coffee pucks, depenLding on

beverage size.

Drink Dispensing

The product outlet dispenses freshly brewed espresso while the patented milk valve

froths the milk. Both steaming hot milk and freshly brewed espresso are poured into

the waiting cup simultaneously.

24 Acorto 2000s/i Technical Support

Software

The 2000s/i user interface contains drink statistics, programming

diagnostic service information. The 2000s/i is programmable

customer's specific drink requirements.

Software Sitructure

The software is devised of a "Main Menu - Sub Menu" Category system' The Main

Menu is c,cmposed of 11 Categories: Cumulative Statistics, Daily Statistics,

Automatic Sltart, Check Temps, Temperature Seffings' Coffee Powder Dose' Coffee

Powder l,re, Water Volume, Milk Timings, Miscellaneous, and Test Routines.

Navigatingl

To navigate through the menu system, use the "unmarked" buttons near the display'

Accessing Gumulative Drink Statistics

To accesis the Cumulative Drink Count, press the OVAL MENU BUTTON 1 time'

The disprlay will change from "select Drink" to "Cum Statistics: Cum Total," and the

total nulnber of drinks poured will be displayed. After a few seconds, the display

will automatically return to "select Drilk." The "Cumulative Drink Total" is only

reset thnoug;h the installation of a new CPU or Software.

Stats In & Stats Out

Acorto requires that you record the Cumulative Drink Statistics at the start and

end of eraih service calt. This information is required to close the service call'

access and

to meet the

rfi

EI

2000s Touch Pad Menu Navigation

MENU tlcRoLL UP -]--|A L€ INCREASEVALUE

V <--- DEcREAsE vALuE

MENU scRoLL oowr.r ..-.14 I

MENLrAccEss -4+ C)

z

e8

=6

3=

Oz

o:)

v.z

o- lrJ

E

IVIENU SCROLL UP ARROW Scroll up Menu and Sub-Menu Categories

IVIENU SCROLL DOWN

/\RROW Scroll Down in Menu and Sub-Menu Categories

IVIENU ACCESS'OVAL

13UTTON" Press 1 times for Cumulative Drink Statistics

Press 3 times to access Main Menu

INCREASE VALUE ARROW lncrease value in Sub-Menu Category

I]ECREASE VALUE ARROW Decrease value in Sub-Menu Category

Acorto 2000s/i Technicial Support 3-7

Section 3: User Information ?ntn-nnaa

Accessing the Main Menu

To access the Main Menu, press the ovAL MENU BUTTON 3 times, slowly. you \--l

should hear a tone after each press. The display will change from "select Drink'to

"Select Category."

Scrolling in the Menu

The Main Menu is composed of i 1 Categories. To scroll through the Main Menu,

press the SCROLL UP ARROW orthe SGROLL DOWN ARROW.

MENU SCROLL UP

MENU SCROLL DOWN

MENU ACCESS

a [*------l a

Vlselectcateso"lV

\

The Main Menu Category

appear in the center of

the screen.

In the Sub lMenu, the

Main Gategory moves to

the top line and the Sub

Menu appears on the

center line.

The value appear on the

lower line.

Accessing a Sub Menu

To access a sub Menu, with the desired category appearing in the display, press the

ovAL MENU BUTTON to enter the category. The Main Menu category onill -oro" \

to the top line of the display and the Sub Menu Category will appear in the middle of ,._r/

the display. The value will appear on the lower line of the display.

A ffi MainMenuGategory

l. I i;;lfi-v-;:,:,1""'

O

Exiting the Menu System

To exit a Sub Menu, press the OVAL MENU BUTTON.

To exit the Main Menu category, press any green srART button on the machine.

3-8 Acorto 2000si/i Technical Support

,n?n-on?a Section 3: User lnformation

EXAMPILE

Viewing tlhe "Last Milk Clean" date and time

1. Press the MENu ovAL BUTTott 3 times (press slowly, you will hear a

"beep" after each press.) "select Category" will appear in the

display

2. Press the scRot-l- DowN ARRow 3 times. "Milk Timings" will appear in

the display

3, Press the meruu ovAL BUTTott. "Milk Timings Latte" will appear in the

display

4. Pness SCR9LL DOWN ARRow f time. "Last Milk Glean" will appear in the

display

Modifying a Value

To change a Sub Menu valueo access the desired Sub Menu Category, and press the

fNCREASE VALUE or DECREASE VALUE button. The value is automatically

stored.

A

VCoffee Powder

Single Caf

o

A€ INCREASEVALUE

V <t- DE.REASE 'ALUE

/-\,

Use the arrows to the

right of the display to

increase or decrease a

value.

EXAMP'LE

Increasing "single Espresso Goffee Powder Dose"

1. Press the naeuu OVAL BUTTott 3 times (press slowly, you will hear a

,,beep" after each press.) ,,select category" will appear in the display

2. Press the SCnOU- DOWN ARROW until "Coffee Powder Dose" appears in

the display

3. Press the uetu oVAL BUTTott. "single Gaf'will appear in the display

4, Press the trucneasE VALUE ARROW to increase the amount of coffee

ground into the brew chamber

Acorto 2000s/i Technical SuPPort 3-9

Section 3: User fnformation 3020-0034

Main Menu Categories

1. Gumulative Total

2. Gumulative Statistics

3. Daily Statistics

4. Automatic Start

5. Check Temps

6. Temperature Settings

7. Goffee Powder Dose

8. Coffee Powder Pre

9. Water Volume

10. Milk Timings

11. Miscellaneous

{2. Test Routines

Displays the total number of drinks poured from

machine. This number is reset onlv when a new CPU or

software is installed

Displays the total number of drinks by drink type

Displays daily drink statistics by drink type. lltatistics

are reset when a brew group/shutdown clean is mn.

The machine is programmed to automatically siart each

morning. Machine can be programmed to start 7 days a

week or Monday - Friday. Automatic Start also

contains the settings for internal clock.

Displays water, steam and refrigerator temperatures

Change steam, water and refrigerator settings

Change amount of coffee ground into the brew chamber.

Coffee is displayed in Grams.

Change coffee pre-treatment setting. The Pre-treatment

settings include the pre-infusion of water into the cofflee

grounds, additional packing of coffee grounds iand wait

time before extraction begins.

Change water volume for espresso extraction, arnericano

and hot water button.

Change Milk Timings for all drinks, milk buttons and set

Cap Boost Delay. Display last milk clean. Czrp Boost

Delay increases the number of seconds steamecl milk is

poured before foamed milk is poured when making a

cappuccino.

Display current software version, load defaults, adjust

auto rinse time, and reset PM counter.

Used for service diagnostic testing, each component of

the machine can be run independently.

Factory Default Seftings

The machine is programmed with specific Factory Default Settings.

Sub-Menu Categories have both minimum and maximum values, and an adjustable

interval value. The following table displays all factory default settings, min and max

values and adjustable intervals. The Statistics and Check Temp categories etre "read

only" and the value is displayed but is not ad.justable.

3-1 0Acorto 2000rVi Technical Support

2030-003A Section 3: User lnformation

Software Quick Reference Table

CUM TOITAL DISPLAY TOTAL DRINK COUNT STATISTIC

- PRESS OVAL MENU BUTTON 2 TIMES -

CUM STATISTICS

Curn Total DISPLAY CUMULATIVE STATISTICS

BY DRINK

Latte

DblTall Latte

Cappuccino

DblCappuccino

Esrrresso

Am,ericano

Steamed Milk

Foarmed Milk

DAILY S|TATISTICS

Curn Total DISPLAY DAILY STATISTICS

BY DRINK

DAILY STATISTICS ARE RESET WHEN A

BREW GROUP/SHUTDOWN CLEAN IS RUN

Latte

DblTall Latte

Capouccino

DblCappuccino

Esrrresso

Americano

Steamed Milk

Foermed Milk

AUTOMATIC START 3:A|| Adiustabre By

Auto Start OFF M-F ONLY, M-F/SAT/SUN, OFF

Start Time-Hours 61

DEFAULT SETTING

FORAUTO START

TIME lS 6:30AM

Start Time-Minutes 30 5

Clock Set-Hours current

I

I

+

1

Clock Set-Minutes

Clock Set-Dav

Clock Set-Month

Clock Set-Year

Darrlioht Savinos Time ON/OFF

CHEGK TEMPS

Ste,am Temp DISPLAY CURRENT STEAM TEMPERATURE

Warter Temp DISPLAY CURRENT WATER TEMPEMTURE

Relfriqeratoi Temp DISPLAY CURRENT REFER TEMPEMTURE

TEMP SiETTING ('F) Default

Settins Min *"* oo,Hf;o'"

Steram 244 235 250 1

Steram Hi (atarm) 252 245 255

Steram Lo (alarm) 232 230 240

BrelwWater 198 185 205

Brelw Water Hi (alarm) 21}sl2O5i 180 210

Brew Water Lo (atarm) 175 160 180

Refrioerator 36 33 42

Refer Temp Hi (atarm) 40 40 60

Refer Temp Lo (alarm) 32 30 35

Acorto 2000s/i Technical SuPPort 3-1 1

coFFEE PowDER DosE (s) 3:ff1!t Min M"* Adj!tr-

Sinsle Caf I523 0.5

Double Caf 14

Triple Caf (2000s onlY) 19

Sinqle Decaf I

Double Decaf 14

Triple Decaf (2000s onlY) 19

Grind AdiArrows OFF NiA N/A ot:F/oN

coFFEE pwDR PRE (#) 3:H[ Min ru"' AdjEfT

Sinqle Caf 5071

Double Caf 2

Triole Caf (2000s only) 0

Sinqle Decaf 5

Double Decaf 2

Triole Decaf (2000s onlv) 0

WATERVoLUME 3:ffH[ Min Max oo''Hfl'"

Sinqle 45 mL 30 150 5mL

Double 75 mL 30 150 5mL

Triple (2000s only) 95 mL 30 150 5mL

Americano 220 mL 150 400 5mL

TallAmericano 360m1 150 400 5mL

HotWater B seconds 560 'l sec

M|LK flMINGS (sec) 3:ftll Min Max oo't"fo"

Latte 1B 1(s) 4(i) 50 0.5

Dbl Latte 17 150 0.5

Sinqle Tall Latte (2oooionly) 38 150 0.5

DblTall Latte 37 150 0.5

Tpl Tall Latte (2ooos only) 36 150 0.5

Cappuccino 14 150 0.5

Dbl Caoo 13 150 0.5

Tall Caop (2oooionlv) 22 150 0.5

Dbl Tall Capp (2oooionly) 21 150 0.5

Tpl CapP (2ooos only) 12 150 0.5

Caoou Boost Delav 7020 1

Tall Capp Boost Dly lzoooi

onlv) 12 020 1

Capo Coffee Delav On On/Off

Steamed Milk 16 4 50 0.5

Foamed Milk 74 50 0.5

Tall Steamed Milk (2oooionly) 25 450 0.5

Tall Foamed Milk (zoooiontv) 13 450 0.5

Last Milk Clean DISPLAY DATE & TIME OF LAST MILK CLEAN

7,i :.'

,tl -V ':

,,;2

3'.*

1-t ;

-:'u

0sl

,l

!{a

t.]

x

?

0

3-12 Acorto 2000s/i Technical SuPPort

This manual suits for next models

1

Table of contents

Popular Coffee Maker manuals by other brands

Gaggia Milano

Gaggia Milano CADORNA PRESTIGE operating instructions

Bialetti

Bialetti diva Instructions for use

Acopino

Acopino ravenna user manual

Bialetti

Bialetti 89837 instruction manual

Cuisinart

Cuisinart Thermal Coffee Center SS-20 Series Instruction booklet

Coffee Queen

Coffee Queen CQube Series Programming manual