Acqua GY-NE42RFW User manual

GY-NE42RFW & GY-NE42RFS

FROST FREE REFRIGERATOR

SERVICE MANUAL

Refrigerator

Service manual

NO FROST

Model: RS-42WL* BC-325WY

NOTE: product specificationsare subject to change.

1

Contents

Warnings and precautions for safety ............................................................................................................................ 2

Parts Description .......................................................................................................................................................... 3

Circuit diagram ............................................................................................................................................................ 4

Technical Specifications .............................................................................................................................................. 4

Cooling diagram .......................................................................................................................................................... 5

Display controls ........................................................................................................................................................... 6

Measuring sensor resistance ........................................................................................................................................ 8

Measuring Temperature fuse and heater resistance ..................................................................................................... 8

Compressor checking................................................................................................................................................... 9

Compressor Protector test .......................................................................................................................................... 10

Compressor PTC starter test ...................................................................................................................................... 10

Compulsory defrost: ................................................................................................................................................... 11

The guide for Disassembly Common parts of Refrigerator…………………………….…………………………...11

◆The instruction of replacing the main board. .......................................................................................................... 11

◆The instruction of of replacing fan motor .............................................................................................................. 12

◆The instruction of replacing temperature sensor. ................................................................................................... 13

◆The instruction of replacing evaporator temperature sensor and temperature fuse and heater. ............................. 13

◆The instruction of replacing PTC Starting relay and Overload protector. ............................................................. 15

◆The instruction of replacing Door switch. ............................................................................................................. 16

◆The instruction of replacing Display board. .......................................................................................................... 16

◆The instruction of of replacing LED Light. ........................................................................................................... 17

Installing your new appliance .................................................................................................................................... 17

Troubleshooting ......................................................................................................................................................... 18

◆ The solution for digital display code problem: .................................................................................................... 18

◆ The common problem judgement method ........................................................................................................... 19

◆ The solution for the common problem................................................................................................................. 20

■ NOTE: ............................................................................................................................................................... 23

2

Warnings and precautions for safety

Please observe the following safety precautions in order to use safely and correctly the refrigerator

and to prevent accident and danger during repair.

1. Be care of an electric shock. Disconnect power cord from wall outlet and wait for more than

three minutes before replacing PCB parts.

Shut off the power whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than five minutes after power cord was

disconnected from the wall outlet.

3. Please check if the power plug is pressed down by the refrigerator against the wall.

If the power plug was damaged, it may cause fire or electric shock.

4. If the wall outlet is over loaded, it may cause fire.

Please use its own individual electrical outlet for the refrigerator.

5. Please make sure the outlet is properly earthed, particularly in wet or damp area.

6. Use standard electrical components when replacing them.

7. Make sure the hook is correctly engaged.

Remove dust and foreign materials from the housing and connecting parts.

8. Do not fray, damage, machine, heavily bend, pull out or twist the power cord.

9. Please check the evidence of moisture intrusion in the electrical components.

Replace the parts or mask it with insulation tapes if moisture intrusion was confirmed.

10. Do not touch the icemaker with hands or tools to confirm the operation of geared motor.

11. Do not let the customers repair, disassemble and reconstruct the refrigerator for themselves.

It may cause accident, electric shock, or fire.

12. Do not store flammable materials such as ether, benzene, alcohol, chemicals, gas, or

medicine in the refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals, etc., or container with full of water

on the top of the refrigerator.

14. Do not put glass bottles with full of water into the freezer.

The contents shall freeze and break the glass bottles.

15. When you scrap the refrigerator, please disconnect the door gasket first and scrap it

3

Parts Description

6

Display controls

7

8

Measuring sensor resistance

Using a multimeter with the ohm switch to measure the resistor of sensor, normally at surrounding 25℃ the

resistor should b e ab out 2 kohm an d ev ery w ith the temperature d ecreases 1 ℃ the c orresponding resistor

value would increase about 45ohm. If the measured value is not within the normal scope, the sensor is bad

and needs to repair or change.

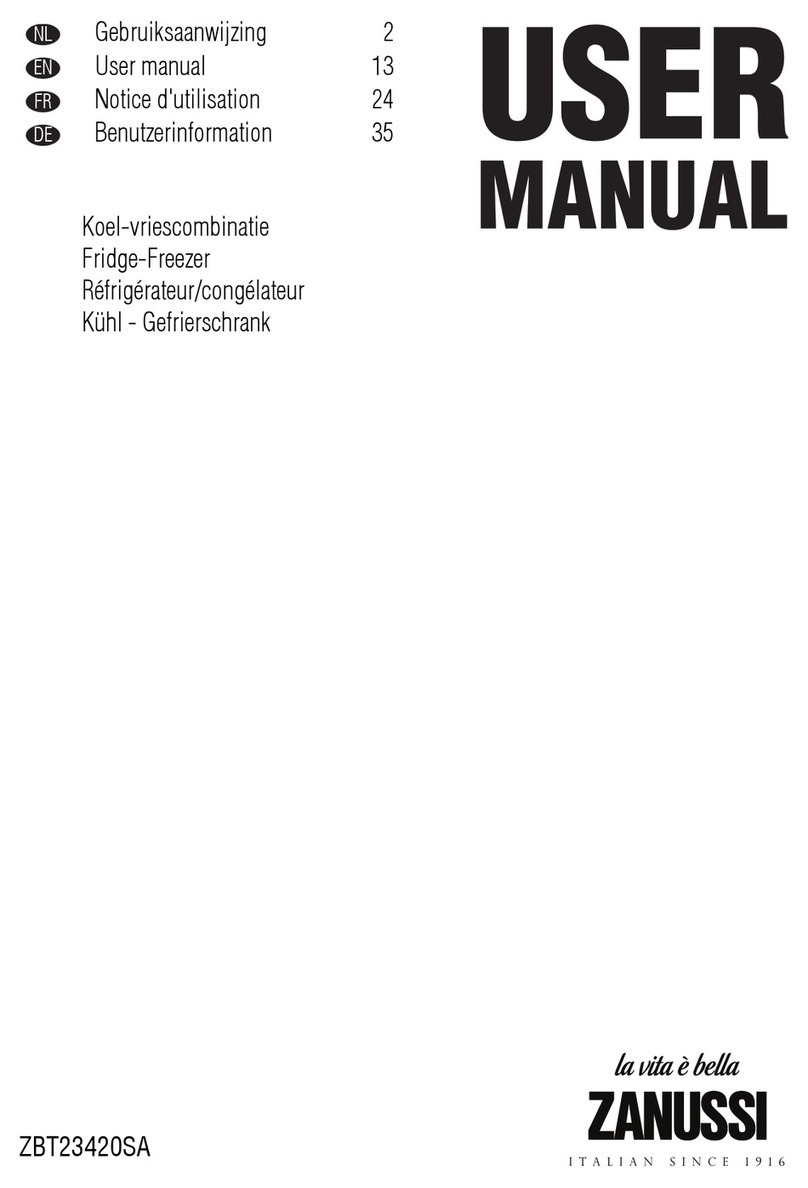

Measuring Temperature fuse and heater resistance

Measuring Temperature fuse and heater resistance,About 426Ω then it is OK.

9

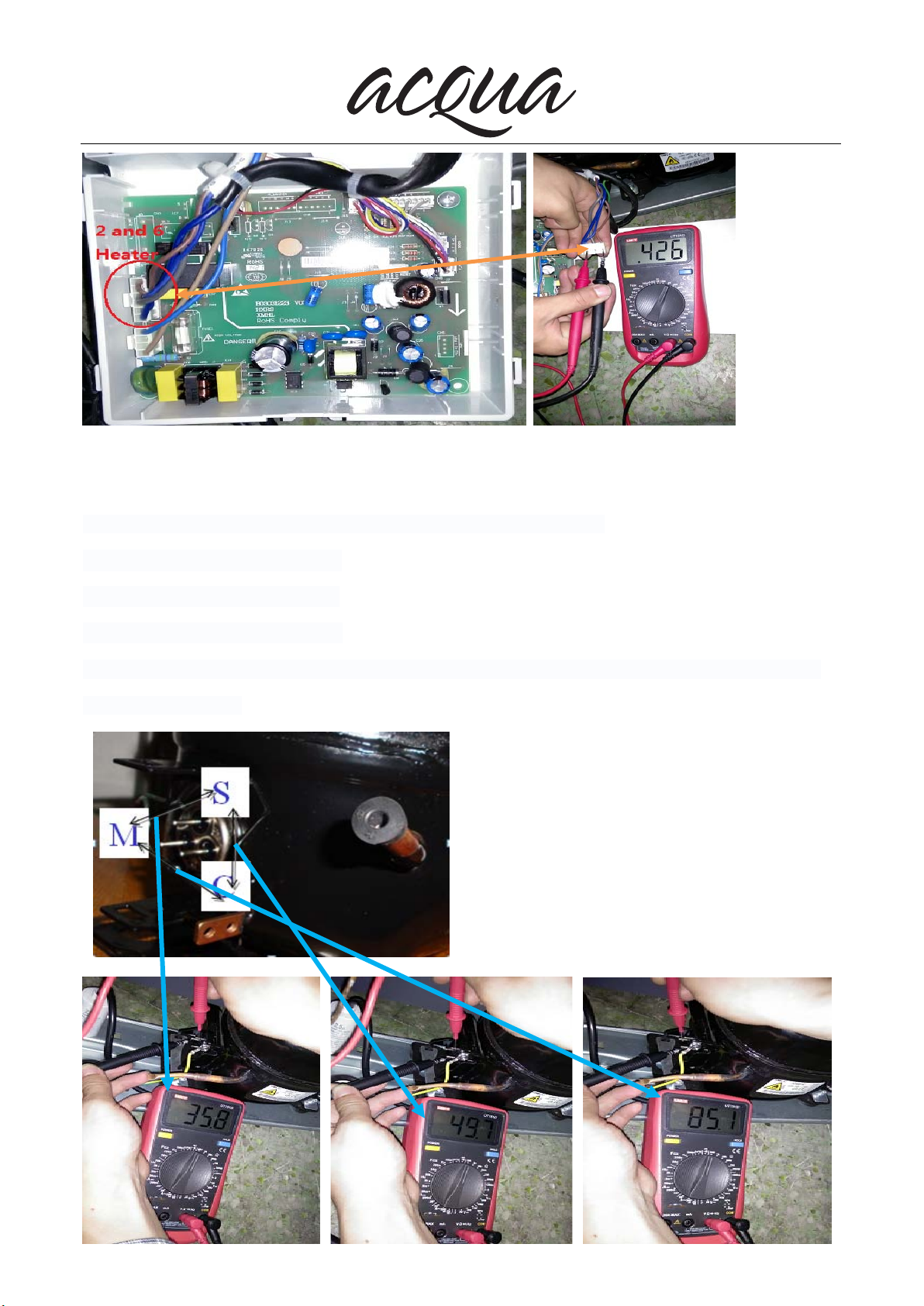

Compressor checking

Use a multi-meter to test the resistance between C & S, M&S and M&C :

Normal range of M&S :About 36Ω

Normal range of C&S : About 50Ω

Normal range of M&C : About 85Ω

If the test result is not in this range then it means the inner coil has some problem and the compressor

can not work properly.

10

Compressor Protector test

Use a multi-meter to test the resistance between the two end as the pic show :

If there show0 0Ωor almost 0Ωthen it is OK.

If there is no response then it is broken.

Compressor PTC starter test

Use a multi-meter to test the resistance between the two end as the pic show :

If there show the number is between About 15Ωthen it is OK.

If there show 000 or no response then it is broken.

11

Compulsory defrost:

Connecting power within 1 minute, refrigerater or freezer door open situation, press Fridge and super

cool 3 seconds, enter the compulsory defrosting process:

——--After entering the compulsory defrosting, we can run the defrosting same as the normal automatic

defrosting process.

——Under compulsory defrosting process, displaying b area displays from 99 to 00.

After exiting the entire compulsory defrosting process, it reverts to normal operation and display.

The guide for Disassembly Common parts of Refrigerator

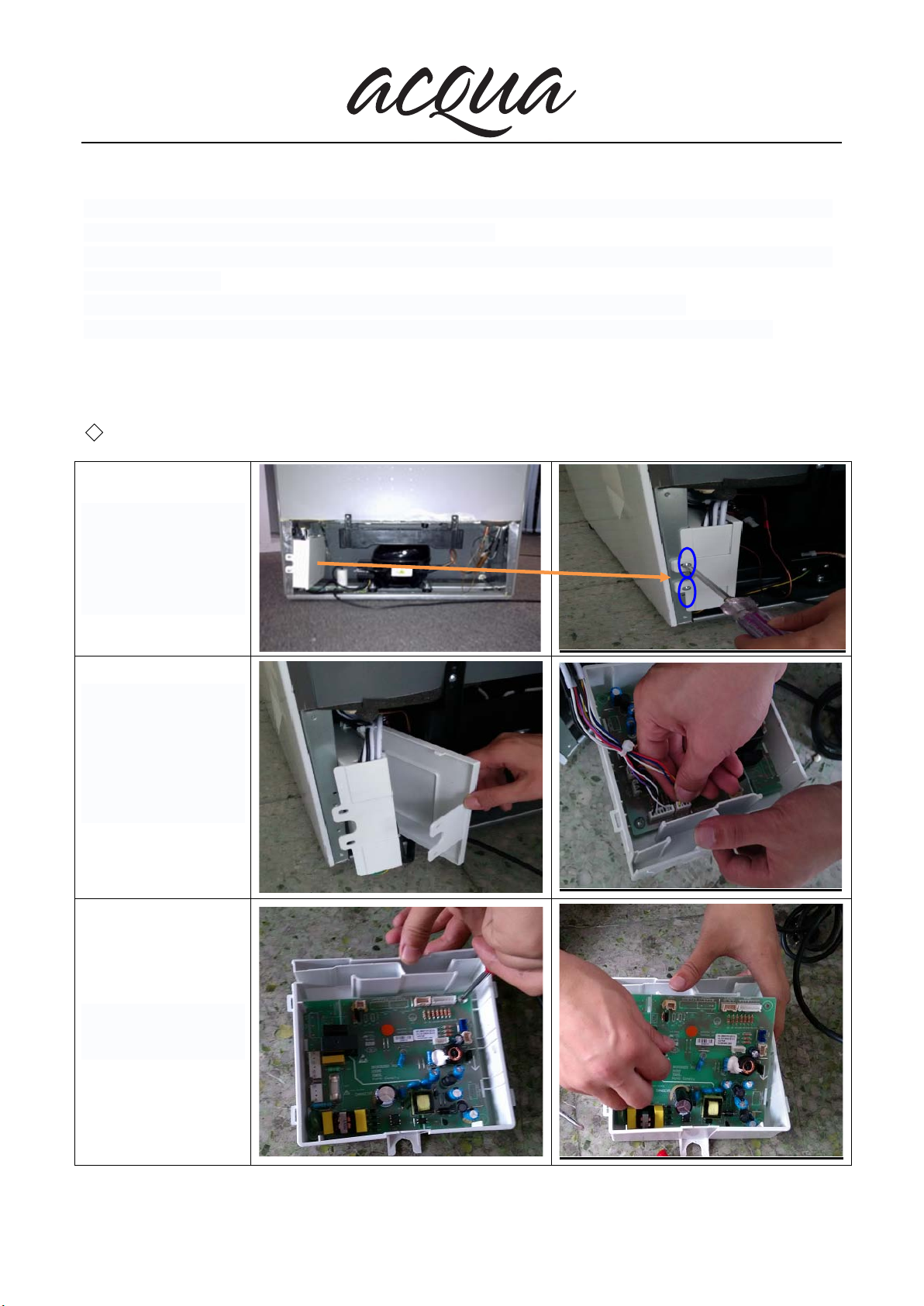

◆The instruction of replacing the main board.

1. The location of the

electrical main board.

2. Unscrew electrical

box ( 2screws ).

3. Remove the

electrical box.

4. Open the electrical

appliances lifted the

lid.

5. Unplug the

electrical wires.

6. Remove the main

board screw

12

7. Take out the main

board.

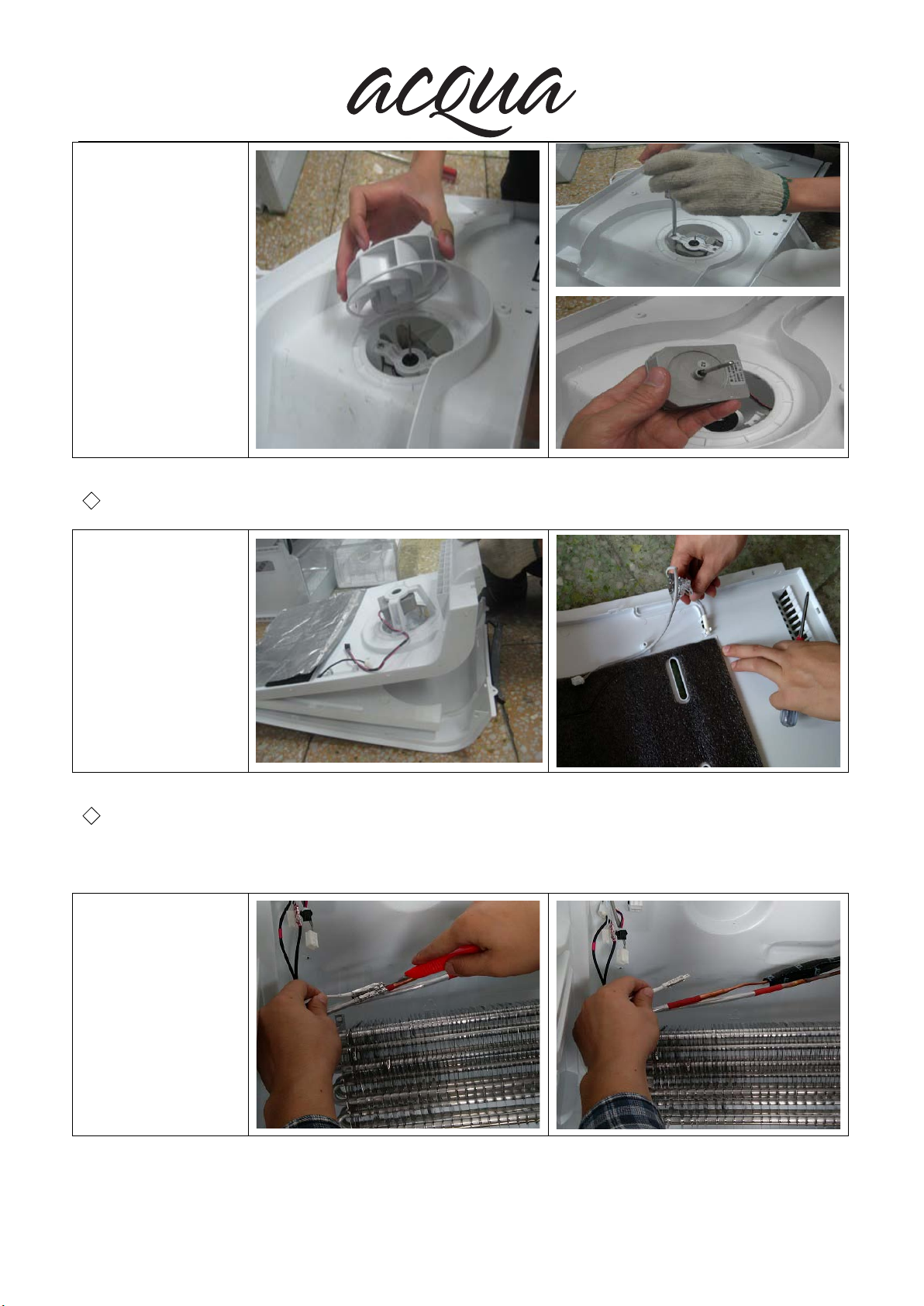

◆The instruction of of replacing fan motor

1.Remove the

refrigerator

compartment

Accessories

2. Remove the air

duct cover screws

3.Remove the air duct

Board

4.Open air duct Board

11

Compulsory defrost:

Connecting power within 1 minute, refrigerater or freezer door open situation, press Fridge and super

cool 3 seconds, enter the compulsory defrosting process:

——--After entering the compulsory defrosting, we can run the defrosting same as the normal automatic

defrosting process.

——Under compulsory defrosting process, displaying b area displays from 99 to 00.

After exiting the entire compulsory defrosting process, it reverts to normal operation and display.

The guide for Disassembly Common parts of Refrigerator

◆The instruction of replacing the main board.

1. The location of the

electrical main board.

2. Unscrew electrical

box ( 2screws ).

3. Remove the

electrical box.

4. Open the electrical

appliances lifted the

lid.

5. Unplug the

electrical wires.

6. Remove the main

board screw

13

5.Unscrew the fan

motor screws

6.Take out fan motor

◆The instruction of replacing temperature sensor.

Open air duct Board

And take out sensor

◆The instruction of replacing evaporator temperature sensor and

temperature fuse and heater.

1.Take out the defrost

sensor.

14

2.Take out the

temperature fuse.

3. Remove

evaporator fixing

screws.

4. Take out the

evaporator.

5.Use a screwdriver

or pliers to pry open

the receiving tank

retaining tabs

6.Take out the water

drain.

15

7.Use pliers to pry

open the heater fixed

buckle.

8. with a craft knife to

cut the Heater cable

fixing bolt.

9.Take out the heater.

◆The instruction of replacing PTC Starting relay and Overload protector.

1. The locat ion of the

PTC Starting relay and

Overload protector.

2. Disconnect the

connecting wire of the

PTC Starting relay and

Overload protector.

16

◆The instruction of replacing Door switch.

Using a screwdriver to

pry the upper cover

plate.

Take out the

magnetron switch.

◆The instruction of replacing Display board.

1. in the display panel

Paste tape( Prevent

scratching shell).

17

2. With a craft knife to

pry open the display

board buckle .

3.Unplug the display

board wires and Take

out display board.

◆The instruction of of replacing LED Light.

1. The locat ion of the

LED Light.

2. Unplug the electrical

wires and remove the

screws fixing the LED

Light board.

Installing your new appliance

18

Troubleshooting

◆The solution for digital display code problem:

1 The digital display window

show “E1”

1. The Refrigerator chamber

Tem. Sensor is open circuit or

short circuit.

2. The Refrigerator chamber

Tem. Sensor is bad.

3. The control PCB is bad.

1. Using a Multimeter with the ohm

switch to measure the resistor of

sensor or checking the connecting is

well or not.

2. Change the sensor

3. Change the control PCB

19

2 The digital display window

show “E2”

1. The Evaporator Defrost

Sensor is open circuit or short

circuit.

2. The Evaporator Defrost

Sensor is bad.

3. The control PCB is bad.

1. Using a Multimeter with the ohm

switch to measure the resistor of

sensor or checking the connecting is

well or not.

2. Change the sensor

3. Change the control PCB

3 The digital display window

show “EC”

1. The receive communication

fault between the main

electrical PCB and the display

PCB.

2. The control PCB is bad.

3. The display PCB is bad.

1. Check the wire terminal is well or

not between the main electrical PCB

and display PCB.

2. Change the main electrical PCB.

3. Change the display PCB.

4 The freezer digital display

window show “EF”

1.The Fan motor is open circuit

or short circuit.

2. The Fan motor is bad.

3. The control PCB is bad.

1. Using a Multimeter with the ohm

switch to measure the resistor of Fan

motor or checking the connecting is

well or not.

2. Change the Fan motor

3. Change the control PCB

The testing method of sensor:

Using the multimeter with the ohm switch to measure the resistor of sensor, normally at surrounding 25℃the

resistor should be about 2kohm and every with the temperature decreases 1℃the corresponding resistor value

would increase about 45ohm.If the measured value is not within the normal scope, the sensor is bad and needs

to repair or change.

◆The common problem judgement method

Problem Cause

Refrigerator can’t start

1.1 Is the power cord connecting well?

1.2 Is the power voltage too low?

1.3 Is the sensor irrational setting?

1.4 Is the ambient temperature too low?

1.5 Is the circuit on power?

1.6 Is there some default in compressor

1.7 Is the refrigeration system blocked by ice or dirty, please stop the unit and restart

after 10 minutes to see if the compressor can start.

Weak cooling effects

2.1 Is there any heat source around the refrigerator?

2.2 Is there enough space around the refrigerator for rejection of heat?

2.3 Is the setting of the temperature appropriate?

2.4 Is there too much food or overheating food in it?

2.5 Does there open the door frequently?

2.6 Is the door completely closed?

2.7 Does the gasket destroyed or distort?

2.8 Does the gas leak?

The unit can not stop

running

3.1 Is there any heat source around the refrigerator?

3.2 Is there enough space around the refrigerator for rejection of heat?

Other manuals for GY-NE42RFW

1

This manual suits for next models

1

Table of contents

Other Acqua Refrigerator manuals

Acqua

Acqua GY-NE350RF User manual

Acqua

Acqua GY-NE242RF User manual

Acqua

Acqua GY-NE255FR User manual

Acqua

Acqua GY-NE350RF/01 User manual

Acqua

Acqua GY-NE42RFS User manual

Acqua

Acqua GY-NE325RFW User manual

Acqua

Acqua GY-NE42RFW User manual

Acqua

Acqua GY-NE250RF User manual

Acqua

Acqua GY-NE272TM User manual

Acqua

Acqua GY-NE250RF User manual