Acromet WG-602 User manual

WG-602

Water Quality Analyzer

Version 5.13

March 2011

2

1 Preface

1.1 Intended Use

This manual is for qualied and trained service te chnicians who will install and service the WaterGuard

WG-602 Water Quality Analyzer. It provides instruct ions on how to install the WaterGuard system, how to

integrate it with external chemical dosing systems, as well as how to calibrate, operate, and maintain the

system.

Safety Precautions

Warning: Only properly trained and licensed electricians sho uld attempt to wire or service the electronic

components of the analyzer. There is an Electrical Shock Hazard when servicing this system. Always

verify that all electrical power source(s) are o before opening the analyzer unit or attempting to service

electronic components or wiring.

Caution: Extreme caution should be used when installing, op erating, and maintaining the WaterGuard

WG-602 Water Quality Analyzer and Controller. Only properly trained technicians are authorized to install

and maintain the analyzer. Only properly trained and licensed electricians should attempt any change to

the system’s electrical components. Only properly trained and licensed operators should attempt to make

any changes to chemical dosing levels.

Always follow local health and safety regulations when performing any service on the WaterGuard unit or

changing chemical dosing settings.

No part of this publication may be reproduced, trans mitted, trans cribed, s tored in a retrieva l s ys tem,

or trans lated into any language or any computer language, in any fo

rm or by any third party, without

the prior written permis s ion of Acromet (Aust) Pty Ltd.

Disclaimer

Acromet (Aust) Pty Ltd does not accept any responsibiltiy for any damage caused to its products by

unauthorised personnel. Use of non Acromet (Aust) Pty Ltd replacement parts will void all warranties.

3

Table of Contents

1Preface .................................................................................... 2

1.1 Intended Use ........................................................................2

1.2 Overview of Chapters ...........................................................5

2Overview.................................................................................. 5

2.1 Measurements and Features ................................................5

2.1.1 Wireless Management Package .....................................6

2.2 System Components ............................................................6

3Installation................................................................................ 7

3.1 Selecting a Location .............................................................7

3.2 Site Requirements and Installation .......................................7

3.2.1 Mechanical Installation ...................................................7

3.3 Plumbing Requirements and Installation...............................8

3.3.1 Water Supply..................................................................8

3.3.2 Drainage.........................................................................9

3.4 Electrical Requirements and Installation ...............................9

3.4.1 Connecting the Main Electrical Power Source ................9

3.4.2 Input Switches ................................................................9

4First Time Operation and Calibration...................................... 10

4.1 Installing additional Sensors and Meters.............................10

4.2 First Time Menu Setup .......................................................10

4.2.1 WaterGuard Control Panel............................................10

4.2.2 Menus...........................................................................11

4.2.3 Configuring Settings in the Operator Menu...................13

4.3 Calibration ..........................................................................13

4.3.1 Example Calibration - Chlorine .....................................13

4.3.2 Calibrating other Sensors and Meters...........................14

4.4 Technician Menu Setup ......................................................14

4.4.1 Configuring Settings in the Technician Menu................17

4.5 Calibration and Initial Operation Checklist ..........................17

5Routine Operation and Maintenance...................................... 17

5.1 Monitoring WaterGuard Alarms...........................................18

5.2 Shut-Down and Winterizing ................................................18

5.3 Troubleshooting..................................................................19

5.4 Replacing Components ......................................................19

5.4.1 Replacing Flow Switch..................................................20

5.4.2 Replacing Control Panel Module (electronics card) ......20

5.4.3 Replacing I/O Module ...................................................20

5.4.4 Module Software Update ..............................................21

4

Table of Contents

6Additional Features ................................................................ 21

6.1 Cl, pH and Temperature Measurements.............................21

6.1.1 Installation ....................................................................21

6.1.2 Software Set-up............................................................22

6.1.3 Routine Maintenance....................................................23

6.1.4 Shut-down and Winterizing...........................................24

6.1.5 Replacing Sensors........................................................24

6.1.6 Troubleshooting............................................................25

6.2 Turbidity Measurements .....................................................25

6.2.1 Installation ....................................................................25

6.2.2 Relay Wiring and Use ...................................................27

6.2.3 First Time Set-up and General Operation .....................28

6.2.4 Routine Maintenance....................................................29

6.2.5 Cleaning the Turbidity Sensor.......................................29

6.2.6 Shut-down and Winterizing...........................................29

6.2.7 Replacing Components ................................................30

6.3 Conductivity Measurements................................................30

6.3.1 Installation ....................................................................30

6.3.2 First Time Set-up and General Operation .....................31

6.3.3 Routine Maintenance....................................................31

6.3.4 Cleaning the Conductivity Meter ...................................31

6.3.5 Shut-down and Winterizing...........................................31

6.3.6 Replacing Components ................................................32

6.3.7 Replacing the Conductivity Meter .................................32

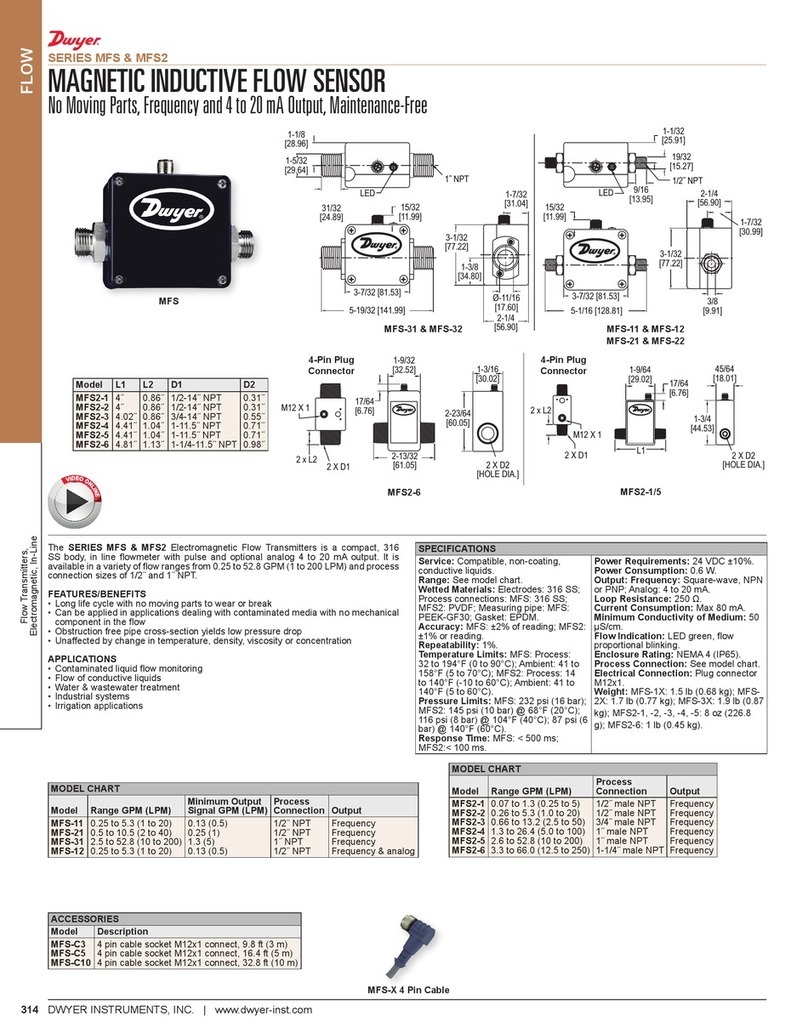

6.4 Flow Meter..........................................................................32

6.4.1 Installation ....................................................................32

6.4.2 Routine Maintenance and Troubleshooting...................33

6.5 Communication Options......................................................33

6.5.1 External 4 to 20mA Outputs..........................................33

6.5.2 Internal 4 to 20mA Output.............................................36

7Appendix A: Relays and Closed-Loop Control ....................... 38

7.1 Connecting external equipment to the Relays.....................38

7.1.1 Wiring to Dosing Systems.............................................38

7.1.2 Proportional Control Overview ......................................39

7.1.3 Setting Proportional Factor ...........................................40

7.1.4 Setting Pump Period.....................................................40

7.1.5 Step By Step Proportional Settings...............................40

8Appendix B: Technical Specifications..................................... 41

5

1.2 Overview of Chapters

This document is divided into functional sections according to the various steps involved in installing and

operating the WaterGuard system.

Section 1:

Short Overview of manual layout and general

precaution information.

Manual Overview

Section 2:

General description of how WaterGuard automatically

monitors water quality.

Analyzer Overview

Section 3:

Instructions on WaterGuard installation and how to

integrate WG analyzers with water quality systems.

Installation

Section 4:

Instructions to configure, calibrate, and operate the

WaterGuard system immediately after installation.

First Time Set up and Operation

Section 5:

Instructions on responding to alarms and

troubleshooting issues.

Routine Operation and Maintenance

Section 6:

Additional components that may be preinstalled or

upgraded in the field.

Measurement Options

Appendix A:

Description of WaterGuard’s direct control

components and operation.

Relays and Closed Loop Control

Appendix B:

Table summary of technical data for WG-602.

Technical Information

2 Overview

The WaterGuard WG-602 Water Quality Analyzer continuously monitors chemical levels in a process

water application. WaterGuard automates free chlorine, total chlorine, pH, ORP (Redox), temperature,

turbidity, conductivity and/or flow rate, administering chemicals as required, according to the results of

these tests (closed loop).

2.1 Measurements and Features

The WaterGuard unit can be configured to measures any combination of the following water quality

parameters:

•Free Chlorine – Amperometric

•Turbidity

•Conductivity

•pH and Temperature

•Flow Rate

Several communication options are also available:

•Internal 4 to 20 mA Outputs (up to 4 channels)

•External 4 to 20 mA Outputs (up to 8 channels + dry contact alarms)

•HydroSoft - Direct Connection

•Wireless Communication Package*

Optional Module – See supplemental manual for more information

6

2.1.1 Wireless Management Package

An advanced and unique WaterGuard option is the cellular communication package which provides web-

based monitoring of up to 5 analyzers. The cellular communicator accepts WaterGuard's alarms and

readings and transmits them to a web-based application server. The information is easily accessible

remotely through the Internet or mobile telephone.

Caution: Remote control of water chemistry is potentially dangerous; therefore, the WaterGuard remote

monitoring and control service is set by default to monitoring and reporting only.

2.2 System Components

WaterGuard has two primary units: the analyzing unit and the control unit. The analyzing unit performs

the actual measurements and the control units includes all electronics, the user interface and the software

that controls the measurements performed in the analyzing unit. Together, they contain the following

components:

Flow Cell - contains the sensors, including the pH, Redox (ORP), and temperature sensors.

I/O Module (Input/Output) – Power Supply to the analyzer and contains the dry-contact relays for direct

control of external dosing systems.

Control Panel Module – Calculates the measurement results and determines the required chemical

dosing to maintain an appropriate chemical balance in closed-loop systems, and provides data to external

communication devices such as 4 to 20mA Outputs or the wireless communication package.

Keyboard Panel - mounted on the cover of the control module, it functions as WaterGuard’s user

interface. The control panel displays current measurements and indicates alarms. All settings and

adjustments are performed through the control panel.

pH, Redox, Temp Module* – receives the signal from the pH, Redox, and temperature probes.

Internal 4-20 Input Module* - Contains Connections for Turbidity, Conductivity meter, and 4-20 Flow

Meter.

Internal 4 to 20 Output Module* – Provides up to 4, 4 to 20mA outputs for any measured variable.

External 4 to 20 Module* – Provides up to 8, 4 to 20mA outputs for any measured variable. Contains

dry contacts for alarms not related to measured values including: low reagents, no reagents, no flow, etc.

*Optional Module

7

3 Installation

3.1 Selecting a Location

Take extra time in selecting a location since the installation location will determine the ease of the

installation and future operation and maintenance. The location where WaterGuard is installed is

dependent on various considerations:

Convenient Access - WaterGuard should be installed where it can easily be viewed and operated.

Dry Area – WaterGuard handles electricity and includes electronic circuitry that is susceptible to short-

circuiting and/or corrosion when exposed to water or high ambient moisture levels.

Away from Chemicals - Many water treatment chemicals can be corrosive to WaterGuard’s electronic

circuitry. It is highly recommended that WaterGuard is not installed adjacent to the chemicals storage

area or the dosing systems themselves.

Minimum Distance from Supply Pipe - The water sampling line that is connected to the main pipe,

feeding the WaterGuard should be as short as possible. A long sample line from the main pipe to

WaterGuard creates an unnecessary delay between supply, measurement, analysis, and chemical

dosing.

Freezing Temperatures – The analyzer should be installed in a location that is not susceptible to

freezing temperatures. The reagents will freeze, preventing accurate readings (even when thawed) and

parts may be damaged due to expansion when ice forms.

3.2 Site Requirements and Installation

The WaterGuard assembly is wall mounted. It should be located on a wall where operators and service

technicians can easily access it for normal operation and maintenance. It is also advisable to install it

where the operators can easily view the readings and alarms. Finally, the unit weighs approximately 6 lbs.

(3 kg), so, it must be mounted securely onto a stable wall. The WaterGuard unit measures 26.3” x 13.1”

(66.8 cm x 33.2 cm). The base of the complete WaterGuard assembly should be mounted at least 24” (60

cm) above the floor (preferably at eye level).

The WaterGuard unit and its mounting panel are not shipped with mounting screws or anchors. The

installer must provide screws and anchors that can hold the weight of the WaterGuard unit, mounting

panel, intake filter, and electrical outlets and junction boxes. The screws and anchors must be compatible

with the wall where it will be installed.

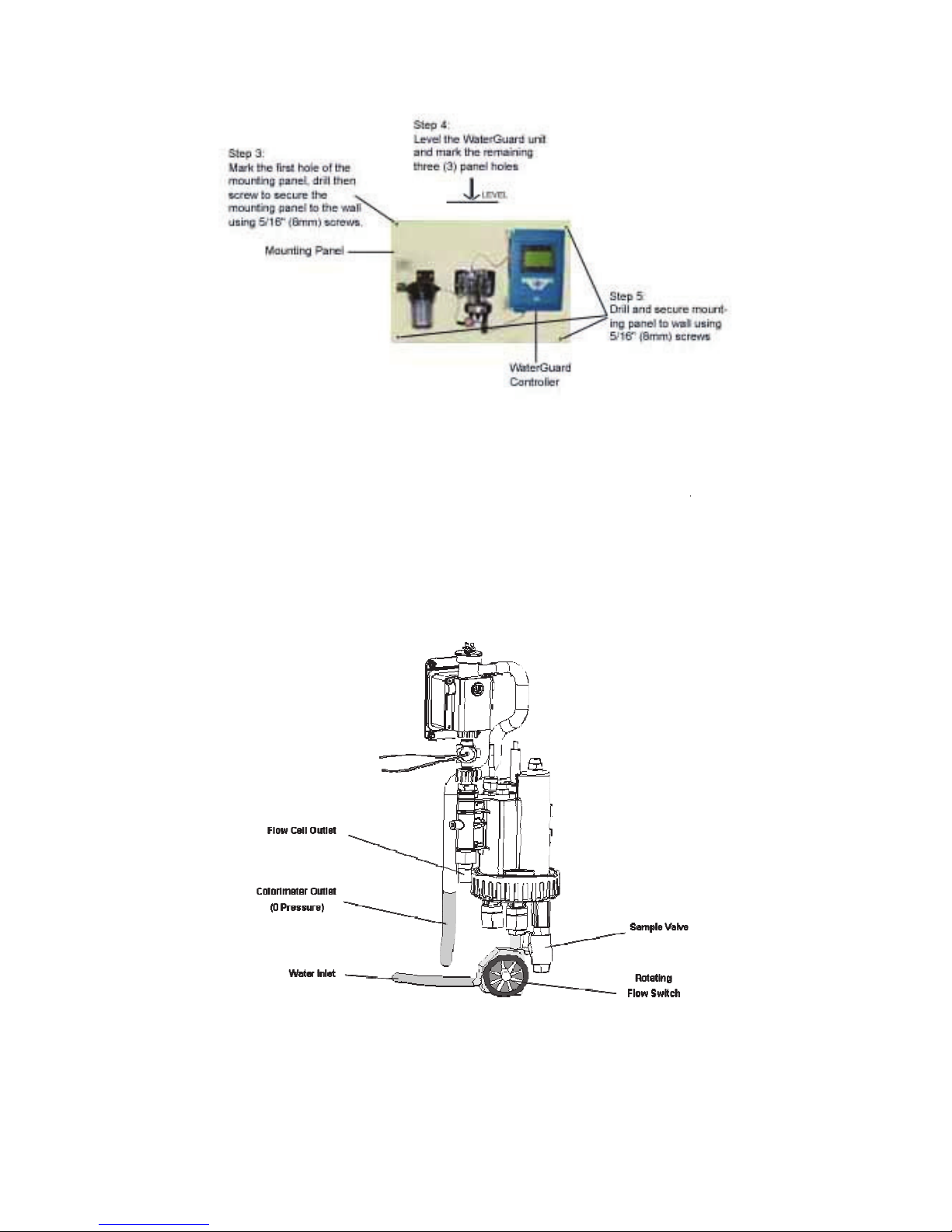

3.2.1 Mechanical Installation

1) WaterGuard is shipped pre-mounted on a mounting panel, along with a water filter. The mounting

panel includes four screw holes, one in each corner.

2) Determine the location of one hole on the WaterGuard unit or on the mounting panel.

3) Secure one corner of the WaterGuard unit or mounting panel to the wall.

4) Level the WaterGuard unit or mounting panel and mark the remaining three (3) screw holes.

5) Secure the remaining corners to the wall using 5/16” (8 mm) screws.

Figure

3.3

Plumbing Requirements and Installation

3.3.1 Water Supply

WaterGuard requires a pressurized water supply to t

from the colorimeter and a pressurized (or gravity)

installed in the main line and the pipe (or tube) f

to minimize the delay time between the water being

adjustiQJ GRVLQJ OHYHOV

VHH VHFWLRQ

should be adjusted to 7 psi (0.5 bar) using a press

Figure

2

8

Figure

1: WaterGuard 602 Mounting Panel

Plumbing Requirements and Installation

WaterGuard requires a pressurized water supply to the flow cell, a zero pressure (gravity) water retur

from the colorimeter and a pressurized (or gravity) return from

the flow cell. An isolating valve must be

installed in the main line and the pipe (or tube) from the main pipe should be as short as possible, i

to minimize the delay time between the water being sampled and WaterGuard testing the water and

VHH VHFWLRQ

3.1). The inlet pressure should not exceed 36 psi (

should be adjusted to 7 psi (0.5 bar) using a pressure regulator attached to the outlet of the pre

2

: Flow cell and Colorimeter Inlet and Outlet

he flow cell, a zero pressure (gravity) water return

the flow cell. An isolating valve must be

rom the main pipe should be as short as possible, in order

sampled and WaterGuard testing the water and

3.1). The inlet pressure should not exceed 36 psi (2.5 bar) and

ure regulator attached to the outlet of the pre

-filter.

9

3.3.2 Drainage

A pressurized, vacuum, or gravity connection is required from the outlet of the flow cell. The flow cell may

be pressurized up to 7 psi (0.5 bar) and a ¼” FNPT fitting is supplied for the flow cell drain connection.

3.4 Electrical Requirements and Installation

WaterGuard requires a 90-120 or 180-240 VAC, 50/60 Hz electrical power source on a separate 16A

circuit in the plant room’s electrical board. The main WaterGuard power supply should be connected to a

non-dependent power supply, so that the unit remains powered constantly. The active relays should be

connected to a (pump) dependent power supply (interlocked power supply) to provide an additional layer

of prevention against chemical addition and equipment operation when the main water supply is not

operating.

3.4.1 Connecting the Main Electrical Power Source

The Main Power Supply may be connected to either 90-120 or 180-240VAC 50/60Hz. Switching between

voltages is accomplished by changing two (2) jumpers located above the main power connection, to the

left of the transformer. For 90-120VAC, a 1amp fuse should be use; for 180-240VAC, a 0.5amp fuse

should be used. These changes must be completed prior to wiring.

Caution: Before making a connection to a power source, confirm that both jumpers are located on the

correct voltage and that the appropriate fuse is in place.

6) Verify that the power switch or circuit breaker to the non-dependent power source is off.

7) Connect the line (live) wire to the I/O board connector marked Line.

8) Connect the neutral wire to the I/O board connector marked Neutral.

9) Connect the earth wire to the I/O Module connector marked Ground.

10) Continue with the other electrical connections.

11) Turn on electrical power only after all electrical connections have been completed.

For information on wiring and using the relays as dry contact or for control, see Appendix A.

3.4.2 Input Switches

Flow input switch terminal blocks on the I/O module allow for three input switches to be connected to the

system as additional layers of security against accidental chemical additions when there is no flow. If a

connection is expected but not detected at each input, the analyzer/controller will indicate an alarm and

will close all relays (and open the alarm relay). Therefore, if a safety switch (flow, level, etc.) will not be

installed, a fixed connection (jumper wire) is required to allow the controller to operate.

Two flow switches and one flow meter may be connected:

•Flow Switch (internal): Flow switch connected to flow cell of analyzer. Supports both 2 and 3 wire

flow switches.

oIf a 2 wire switch is used, it should be connected to the “In” and “Gnd” connections. If a 3

wire switch is used, the “VCC” connection will also be used.

oIf a rotating flow switch is used, the J25 jumper should be in place; if a float-type or other

on/off flow switch is used, the J25 jumper should be removed (to be used with the open

cell analyzer models).

•External Flow Switch: Connection for external 2-wire flow switch. If an external switch is not

connected, a jumper must be installed for the analyzer to operate properly.

10

•Flow Meter: Connection for 2 or 3 wire flow Meter. The analyzer will not look for the flow meter

connection unless the option is turned ON in technician menu; therefore, no jumper is required if

a meter is not installed.

Caution: Electrical connections in this section are ONLY recommendations. All electrical

connections should comply with National Electrical code (NEC) and all local regulations.

First Time Operation and Calibration

3.5 Installing additional Sensors and Meters

Install all additional sensors and meters and connect to the WG-602 main system, following the

supplemental manuals for each sensor or meter.

3.6 First Time Menu Setup

This section describes how to configure the settings (set points, alarms, and calibrations) through the

WaterGuard control panel.

Caution: WaterGuard's control board unit should not be opened except for initial installation and

troubleshooting and should only be opened by a trained and approved technician.

3.6.1 WaterGuard Control Panel

The WaterGuard control panel is a simple, intuitive interface for monitoring and controlling water quality

with the following components:

When an alarm is issued, the bottom row of the LCD displays the alarm.

Pressing the up and down arrows together will display the Langelier index for approximately five (5)

seconds, and then returns to the previous display mode.

3.6.2 Menus

WaterGuard has two menu levels: Operator and Technician. The Operator menu includes settings that

may be controlled by on-site operators. The Technician menu includes settings and calibrations that

should be restricted to specially trained WaterGuard maintenance technicians. Each menu has a

separate password. The technician level password may be used whenever a password is required,

however the operator password will only be accepted in the operator menu.

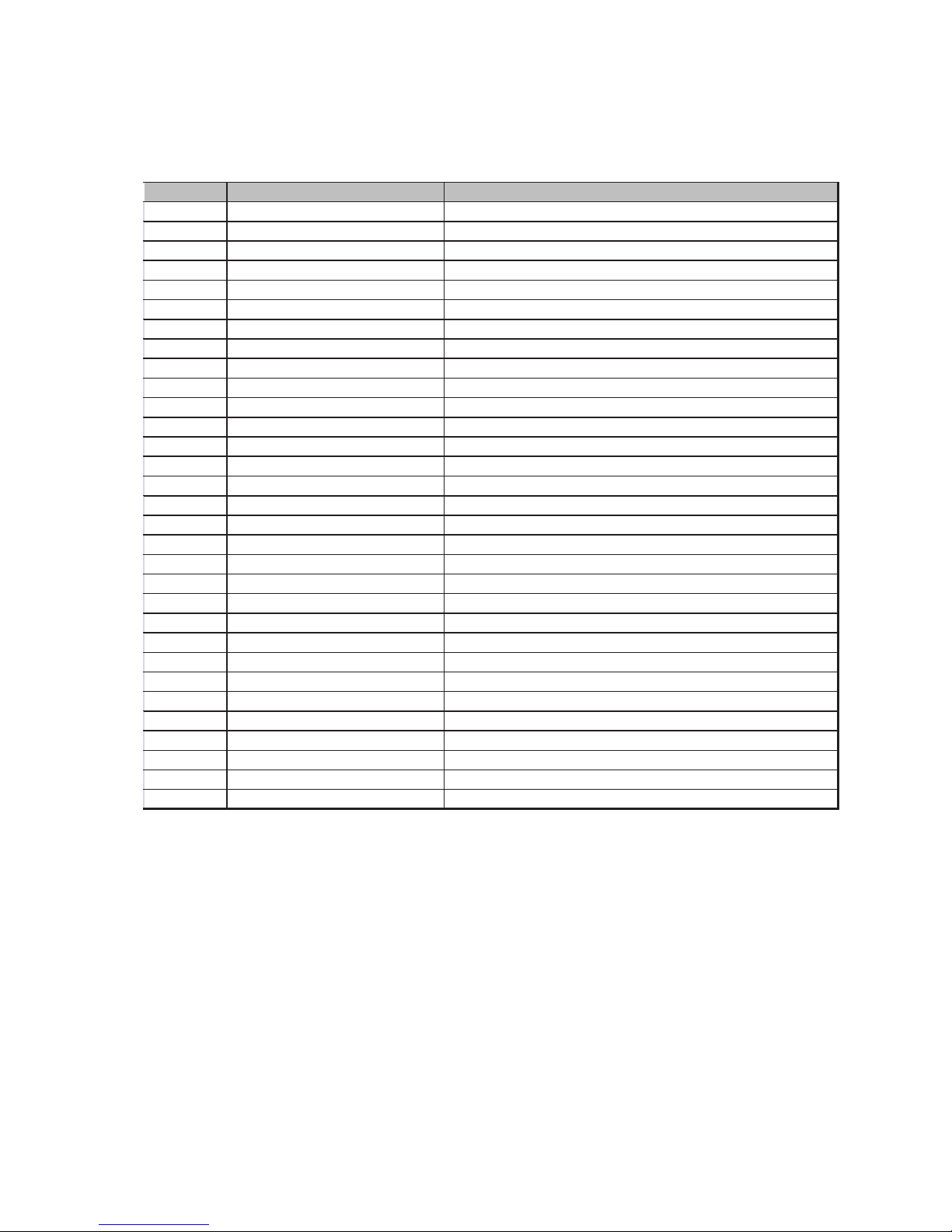

Table 1 displays the operator menu functions and their description and Table 2 displays the menu

functions with the minimum and maximum values for each.

11

Table 1: Operator Menu Functions and Descriptions

0(18 1$0( '(6&5,37,21

6KRFN&O

7XUQ&O

6KRFN2Q2II

0HQX5HOD\V 0DQXDODF LYD LRQRI5HOD\V

&O

6H SRLQ &RQ UROV&O

5HOD\2Q2IIRU3URSRU LRQDO

&O

6KRFN6H SRLQ 6H SRLQ IRU&O6KRFN

&O

6H SRLQ &RQ UROV&O

5HOD\2Q2II2QO\

&O

&DOLEUD HG7R

6KRZVPRV UHFHQ FDOLEUD LRQDQG

VHQVRUYDOXH

D FDOLEUD LRQ RDLGLQ URXEOHVKRR LQJ

&O

6HQVRU:DV

&O

/RZ$ODUP $ODUPZKHQ&O

EHORZ KLVYDOXH

&O

+LJK$ODUP $ODUPZKHQ&O

DERYH KLVYDOXH

S+6H SRLQ &RQ UROVS+5HOD\ 2Q2IIRU3URSRU LRQDO

S+&DOLEUD HG7R 6KRZVPRV UHFHQ FDOLEUD LRQ RDLGLQ URXEOHVKRR LQJ

S+6HQVRU:DV

6KRZVVHQVRUYDOXHD FDOLEUD LRQ RDLGLQ

URXEOHVKRR LQJ

S+/RZ$ODUP $ODUPZKHQS+EHORZ KLVYDOXH

S++LJK$ODUP $ODUPZKHQS+DERYH KLVYDOXH

7HPS6H SRLQ &RQ UROV7HPSHUD XUH5HOD\

7HPS&DOLEUD HG7R 6KRZVPRV UHFHQ FDOLEUD LRQDQG

VHQVRUYDOXHD FDOLEUD LRQ RDLGLQ URXEOHVKRR LQJ

7HPS6HQVRU:DV

7HPS/RZ$ODUP $ODUPZKHQ HPSEHORZ KLVYDOXH

7HPS+LJK$ODUP $ODUPZKHQ7HPSDERYH KLVYDOXH

7XUELGL \6H SRLQ &RQ UROV7XUELGL \5HOD\RS LRQDOPRGXOH

178/&DOLEUD HG7R 6KRZVPRV UHFHQ 178ORZFDOLEUD LRQDQG

VHQVRUYDOXHD FDOLEUD LRQ RDLGLQ URXEOHVKRR LQJ

6HQVRU9DOXH:DV

178+&DOLEUD HG7R 6KRZVPRV UHFHQ 178KLJKFDOLEUD LRQDQG

VHQVRUYDOXHD FDOLEUD LRQ RDLGLQ URXEOHVKRR LQJ

6HQVRU9DOXH:DV

7XUE+LJK$ODUP

$ODUPZKHQ7XUELGL \DERYH KLVYDOXHRS LRQDO

PRGXOH

&RQGXF LYL \

&DOLEUD HG7R 6KRZVPRV UHFHQ &RQGXF LYL \FDOLEUD LRQDQG

VHQVRUYDOXHD FDOLEUD LRQ

6HQVRU9DOXH:DV

$ODUP'HOD\ 7LPHGHOD\EHIRUH$ODUP5HOD\FORVHV

)ORZ/RZ/LPL /RZIORZOLPL IRUH[ HUQDOIORZPH HU

)ORZ.)DF RU .)DF RUIRUH[ HUQDOIORZPH HU

7R DO$ONDOLQL \ 0DQXDOO\HQ HUHGIRU/DQJHOLHU,QGH[

7R DO+DUGQHVV 0DQXDOO\HQ HUHGIRU/DQJHOLHU,QGH[

7'6 0DQXDOO\HQ HUHGIRU/DQJHOLHU,QGH[

/DQJXDJH $OORZVFKRLFHRIODQJXDJH

6\V HP5HVH 5HV DU VFRQ UROOHUVDIHU KDQ XUQLQJRIIDQGRQ

12

Table 2: Operator Menu and Variable Limits

0(18

1$0(

0,1,080

9$/8(

0$;,080

9$/8(

'()$8/7

81,76

6KRFN&O

2)) 21 2)) ȸ

0HQX5HOD\V

2))

21

2))

ȸ

&O

6H 3RLQ 330

&O

6KRFN6H 3RLQ 330

&O

6H 3RLQ 330

&O

&DOLEUD HG7R

1$

330

&O

6HQVRU:DV 1$ 330

&O

/RZ$ODUP 330

&O

+LJK$ODUP 330

S+6H 3RLQ

ȸ

S+&DOLEUD HG7R

1$

ȸ

S+6HQVRU:DV

1$

ȸ

S+/RZ$ODUP

ȸ

S++LJK$ODUP

ȸ

7HPS6H 3RLQ

ͼ

&

ͼ

&RU

ͼ

)

7HPS&DOLEUD HG7R

1$

ͼ

&RU

ͼ

)

7HPS6HQVRU:DV

1$

ͼ

&RU

ͼ

)

7HPS/RZ$ODUP

ͼ

&

ͼ

&RU

ͼ

)

7HPS+LJK$ODUP

ͼ

&

ͼ

&RU

ͼ

)

7XUELGL \6H SRLQ

178

178/&DOLEUD HG7R

1$

178

6HQVRU9DOXH:DV

1$

178

178+&DOLEUD HG7R

1$

178

6HQVRU9DOXH:DV

1$

178

7XUE+LJK$ODUP

178

&RQGXF LYL \

&DOLEUD HG7R

1$ 86

6HQVRU9DOXH:DV

1$

P

KURU

*30

$ODUP'HOD\

0LQX HV

)ORZ/RZ/LPL

RU

2))

P

KURU

*30

)ORZ.)DF RU

ȸ

7R DO$ONDOLQL \

330

7R DO+DUGQHVV

330

7'6

330

/DQJXDJH

(QJOLVK

ȸ

6\V HP5HVH

1$

1$

1$

ȸ

/DQJXDJH6HOHF LRQ

13

3.6.3 Configuring Settings in the Operator Menu

Each of the parameters in the operator menu is configured in the same way. The following procedure

describes how to configure a typical setting:

12) Locate the desired parameter in the menu:

a) Press Menu until the desired parameter name appears in the LCD display.

13) Press OK. Enter Password 100 appears in the LCD display.

14) Enter the Operator password (or technician password; both are accepted)

15) Press the up arrow or down arrow until the password number is reached.

Note: Holding Menu why pressing up or down will advance the first digit. Holding up or down for an

extended period of time will proceed through the numbers more quickly.

The factory-set operator password is 123. The operator password can only be changed by entering

the current operator or technician password (see Technician Menu Setup).

16) Press Enter to accept the password. The parameter name and current setting appear in the LCD

display.

17) Press Enter, again. The LCD display shows the parameter and the current setting.

18) Enter the new parameter setting:

a) Press the up arrow or down arrow until the desired value is reached.

b) The second row of the menu display, below the value that is being changed, shows the current

value.

19) Press Enter to save the new setting or Esc to abort without saving the new setting.

To change the settings of additional parameters, press Menu until the desired parameter appears in the

LCD display and repeat steps 6-8 above to set the new parameter.

Note: The Menu button displays the next parameter in the list, so that the operator can check every

parameter in the menu. There is no scroll-back option. To view or change a previous parameter in the

menu, you must exit the menu by pressing Esc, and start the above procedure from the beginning.

3.7 Calibration

Parameters must be calibrated with measurements taken with external testing devices. Always use digital

calibration devices, not the less accurate visual test kits. Alternatively, standard solutions may be used.

Make sure the standard solution is not expired or contaminated prior to using. Follow the procedures

below EXACTLY as instructed.

ALWAYS take water for calibration from the sampling valve, NOT from the process line directly. The

analyzer should always be calibrated with water from the same source.

Following calibration directions for each sensor as indicated in the sensor manual; however chlorine is

listed below as an example.

3.7.1 Example Calibration - Chlorine

20) Open the water sampling valve.

21) Fill the sampling container.

22) Test the water sample for chlorine using a digital photometer.

23) Press Menu until “Cl Calibrated to” appears in the LCD display.

14

The top line will display “Cl Calibrated to” and a number. The number displayed is the last value

someone entered for the calibration. The bottom line will display “Cl Sensor was” and a number. This

number is the sensor reading without any calibration at the time of the last calibration. If there is a large

discrepancy between these two numbers, the sensor was calibrated improperly or there is a problem with

the analyzer. The value displayed normally on the main screen and the value the analyzer uses to

determine dosing rates is the calibrated value.

24) Press OK.

25) Enter the password. Press the up arrow or down arrow until the password is reached.

26) Press OK.

27) Press OK again.

The display will now show “Calibrate Cl to” on the top line and “Sensor Reading” on the bottom line. The

“Sensor Reading” is the current reading of the sensor with no calibration. The “Calibrate Cl to” value is

the new value which you want to set.

28) Press the up arrow or down arrow until the value is the same as the value given by the digital

photometer.

29) Press OK to save the new calibration or Esc to abort without saving.

30) Press Esc to return to the main display.

3.7.2 Calibrating other Sensors and Meters

Calibration of other sensors and meters is similar to the chlorine calibration and requires the use of a

reliable external testing device or standard solution. See the supplemental manuals for each sensor or

meter for specific information on calibration.

3.8 Technician Menu Setup

The Technician menu includes advanced parameter settings that are accessible separately from the

Operator menu. Anyone can view the settings, but only someone with technician password can change.

This has been done to allow only those who are qualified to change the advanced analyzer settings.

These are also settings that should not require frequent changes after the initial installation and set-up.

15

Table 3: Technician Menu Functions and Descriptions

0(18

1$0(

'(6&5,37,21

&O

3)DF RU

3URSRU LRQDO)DF RUIRU&O

5HOD\

&O

3XPS3HULRG

3XPSF\FOH2Q2II LPHIRU&O

5HOD\

&O

3XPS)UHTXHQF\

&O

SXPSPD[SXOVHVPLQIRU2Q2II

&O

$YHUDJLQJ

'LVSOD\VDQDYHUDJHRI KHODV &O

UHDGLQJV

&O

6HQVRU7\SH

6HOHF ZKLFK&O

6HQVRULVFRQQHF HG

S+S)DF RU

3URSRU LRQDO)DF RUIRUS+5HOD\

S+3XPS3HULRG

3XPSF\FOH2Q2II LPHIRUS+5HOD\

S+3XPS)UHT

S+SXPSPD[LPXPSXOVHVPLQIRU2Q2II

SK%DODQFH7\SH

7RVHOHF LIDFLGRUEDVHLVEHLQJDGGHG R

)ORZ6HQVRU

:LOO XUQGLVSOD\RI)ORZUD HRQRII2QO\XVH

)ORZ5D H

&KRRVHEH ZHHQPH ULFDQG(QJOLVKXQL V

&HOVLXV)DUK

&KRRVHEH ZHHQPH ULFDQG(QJOLVK

7HPS+\V HUHVLV

9DOXHLQGHJUHHVEHORZVH SRLQ ZKLFKZLOO

7XUELGL \

7XUQV7XUELGL \PRGXOH212))RS LRQDO

178:LSHU,Q HUYDO

,Q HUYDOIRU7XUELGL \PRGXOH:LSHU RFOHDQ

0LQX HV

&XUUHQ LPHIRUGD DORJJHU

+RXU

&XUUHQ LPHIRUGD DORJJHU

'D\

&XUUHQ LPHIRUGD DORJJHU

0RQ K

&XUUHQ LPHIRUGD DORJJHU

<HDU

&XUUHQ LPHIRUGD DORJJHU

5HFRUGLQJ,Q HUYDO

7LPHLQ HUYDOEH ZHHQUHDGLQJVV RUHGRQ KH

9LHZ)UHH&O

'LVSOD\VPHDVXUHPHQ YDOXHRQ/&'

9LHZS+

'LVSOD\VPHDVXUHPHQ YDOXHRQ/&'

9LHZ&RQGXF LYL \

'LVSOD\VPHDVXUHPHQ YDOXHRQ/&'

$GGUHVV

&RQ UROOHU,'XVHGZL KH[ HUQDO

6RI ZDUH9HUVLRQ

&XUUHQ VRI ZDUHYHUVLRQ

0D[)ORZ5DQJH

0D[LPXP)ORZ5D HIORZD $RI

$2X SX 6H LQJV

&RQILJXUHVRX SX VIRULQ HUQDO$

2Q$ODUP*R7R

$RX SX GXULQJDQDODUPFRQGL LRQ

2SHUD RU3DVVZRUG

&KDQJHRSHUD RUSDVVZRUG

7HFKQLFDO3DVVZRUG

&KDQJH HFQLFKDOSDVVZRUG

16

Table 4: Technician Menu and Variable Limits

0(18

1$0(

0,1,0809$/8(

0$;,080

9$/8(

'()$8/7

81,76

&O

3)DF RU ȸ

&O

3XPS3HULRG 0LQX HV

&O

3XPS

)UHTXHQF\

212))

SXPS

0D[LPXP

SXOVHVPLQ

&O

$YHUDJLQJ 2)) 21 21 ȸ

&O

6HQVRU7\SH ȸ

S+S)DF RU

ȸ

S+3XPS3HULRG

0LQX HV

S+3XPS)UHT

212))

0D[LPXP

SK%DODQFH7\SH

$FLG

%DVH

$FLG

ȸ

)ORZ6HQVRU

2))

21

2))

ȸ

)ORZ5D H

P

KU

*30

P

KU

ȸ

&HOVLXV)DUK

ͼ

&

ͼ

)

ͼ

&

ȸ

7HPS+\V HUHVLV

ͼ

&RU

ͼ

)

7XUELGL \

2))

21

2))

ȸ

178:LSHU,Q HUYDO

0LQX HV

0LQX HV

1$

0LQX HV

+RXU

1$

+RXUV

'D\

1$

'D\V

0RQ K

1$

0RQ KV

<HDU

1$

<HDUV

5HFRUGLQJ,Q HUYDO

0LQX HV

9LHZ)UHH&O

2)) 21 21 ȸ

9LHZS+

2))

21

21

ȸ

9LHZ&RQGXF LYL \

2))

21

21

ȸ

$GGUHVV

ȸ

6RI ZDUH9HUVLRQ

1$

1$

1$

ȸ

0D[)ORZ5DQJH

P

KU

RU*30

$2X SX

6H LQJV

1$ 1$ 1$ ȸ

2Q$ODUP*R7R

1$

2SHUD RU

3DVVZRUG

ȸ

7HFKQLFDO

3DVVZRUG ȸ

17

3.8.1 Configuring Settings in the Technician Menu

Navigation within in the Technician Menu is identical to the operator menu.

1) To enter the Technician menu, press Menu to enter the operator menu and then the up arrow and

down arrow together simultaneously until the menu display changes.

2) Locate the desired parameter in the menu:

a) Press Menu until the desired parameter name appears in the LCD display.

b) Press OK. Enter Password 100 appears in the LCD display.

3) Enter the Technician menu password:

a) Press the up arrow or down arrow until the password number is reached.

b) Press OK. The parameter name and current setting appear in the LCD display.

Note: Technician menu password is different from the Operator menu password. The default

Technician menu password is 456 and if lost, can only be reset by replacing the chipset.

4) Continue changing the parameter setting, as described in the Operator menu.

3.9 Calibration and Initial Operation Checklist

Before leaving the site, perform the procedure in this section and record the requested values.

Calibrate the following WaterGuard parameters and enter the information into the table below. If pH is

reading slightly low, do not calibrate as it will continue to increase for the first 24-48 hours.

4 Routine Operation and Maintenance

Once installed by a qualified technician, WaterGuard can begin monitoring and controlling water quality.

WaterGuard is specifically designed for easy operation; however some periodic maintenance is still

required.

•Basic Operation: involves setting the desired parameters and monitoring the system for alarms.

When operating normally, WaterGuard demands very little operator involvement.

•Calibration: Sensor sensitivity and accuracy can degrade or drift over time. For this reason,

WaterGuard settings must be periodically recalibrated and compared with measurements from

other measuring devices, such as electronic photometers, pH sensors, and thermometers or

compared to standard solutions like pH buffers.

18

•Shut-down and Winterizing: If the analyzer will not be operating for an extended period of time

or in areas where temperatures drop below freezing, all water must be removed from the analyzer

to prevent components from breaking and the probes must be removed and stored in a warm

area and kept wet at all times.

•Troubleshooting: Occasionally problems will occur with the analyzer readings or chemical

dosing. These problems are most often simple to correct. The troubleshooting section provides

an outline to follow to help correct the problems easily.

4.1 Monitoring WaterGuard Alarms

WaterGuard issues alarms when it detects chemical levels that are above or below the allowed range.

Every alarm is automatically displayed in the LCD status display and logged in the data logger. Most

deviations in chemical levels, however, are automatically corrected. Thus, the internal alarms do not

immediately activate an external alarm. A delay mechanism prevents false alarms from minor deviations

that were automatically corrected. The external alarm is only activated after an internal alarm has been

continuously active for a certain period of time, as defined by the operator.

The Alarm Delay command in the Operator menu sets the number of seconds WaterGuard waits before

closing Relay 5, the relay that operates the external alarm. Only one alarm is shown on the screen at a

time based on importance and the order in which it should be fixed. For example, if the pH is high and

the ORP is low, only the pH alarm will be indicated since lowering the pH will likely also correct the low

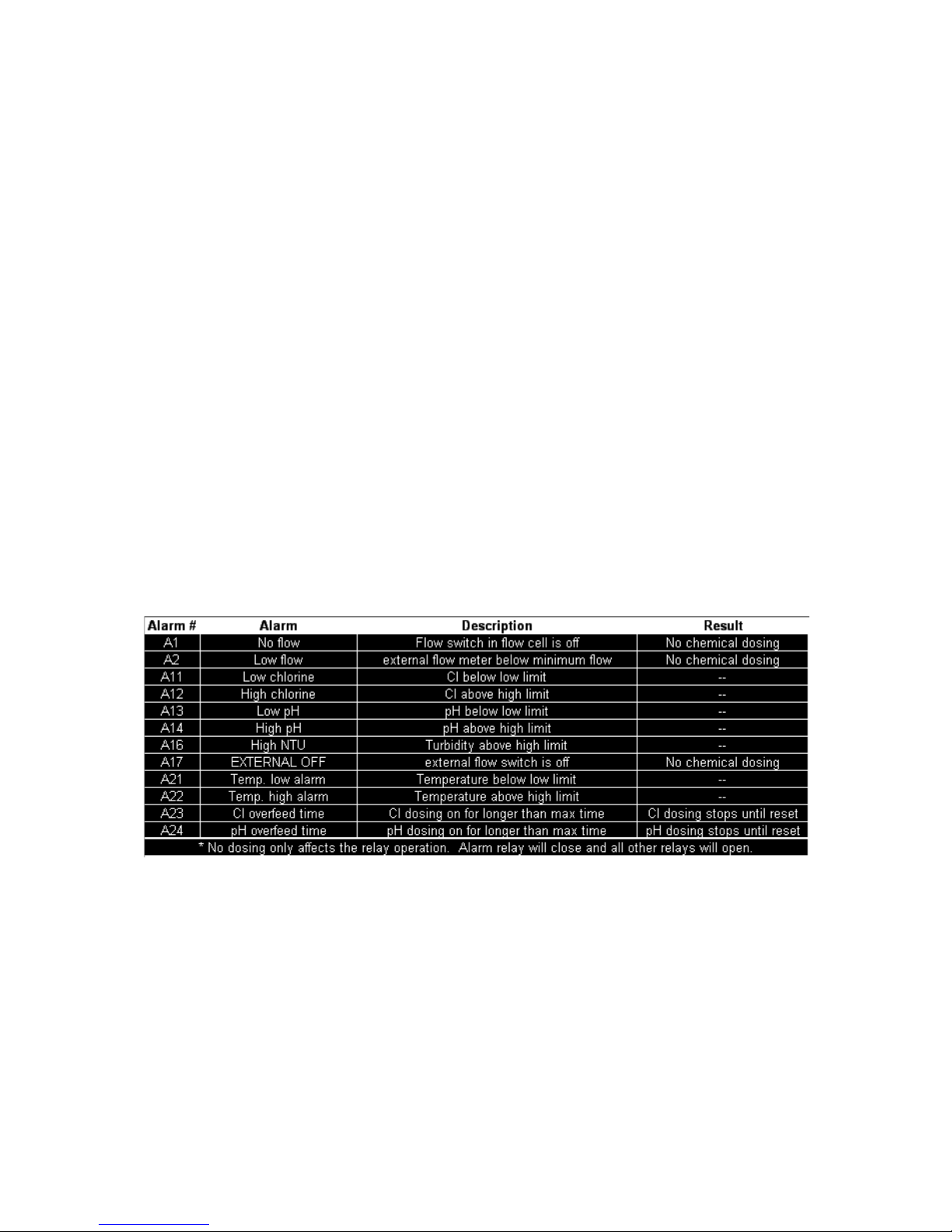

ORP. All of the alarms are presented in Table 5 along with a description and resulting action of the

analyzer/controller.

Table 5: Alarm Description and Result

4.2 Shut-Down and Winterizing

The WaterGuard analyzer is designed to keep the probes submerged even if there is no flow to the

analyzer. However, if the analyzer is going to be offline for an extended period of time and/or exposed to

freezing temperatures, it must be winterized to prevent damage to the analyzer and the probes.

1) Store all probes following directions in the supplemental manuals for each sensor.

2) Drain the flow cell completely by opening the sampling valve on the bottom. Leave the valve in the

open position to allow air to completely dry the cell.

3) Check the security of the analyzer doors to ensure a weatherproof seal.

19

4.3 Troubleshooting

The following procedures instruct how to locate, evaluate, and fix a problem when WaterGuard issues an

alarm or indicates suspect chemical levels.

4.4 Replacing Components

The following procedures describe how to replace certain WaterGuard components.

Caution: The following procedures should only be performed by properly qualified and trained

WaterGuard analyzer technicians.

Warning: Disconnect all power supplies to the WaterGuard analyzer before opening the control unit door.

Replacing any parts of WaterGuard without the expressed written authorization of Chemical Injection

Technologies, Inc., or the qualified representative who supplied the product may void the warranty.

Chemical Injection Technologies, Inc., takes no responsibility, written or implied, for installation or

maintenance of WaterGuard that is not performed by a properly trained and certified WaterGuard

technician.

4.4.1

Replacing Flow Switch

1)

Turn off the inlet and outlet water to the flow cel

2)

Open the doors of both the analyzing

3)

Locate the flow switch attached to the flow cell.

4)

Disconnect the flow switch wires from the I/O modul

5)

Remove the inlet connection to the old flow switch.

6)

Remove the flow switch from the flow cell.

7) Pull the flow switch wires

gently to completely remove from the analyzer

8)

Insert the new flow switch on the flow cell

9)

Insert the inlet connection on the flow switch

10)

Route the flow switch wires back to the connection

input switch terminal block.

11)

Close the analyzer doors and turn on the water and

4.4.2

Replacing Control Panel Module (electronics card)

Disconnect the power supply to the unit before open

1)

Disconnect the flat cable plug fr

2)

Unscrew the four (4) mounting screws.

3)

Put in the new card and tighten the 4 mounting scre

4)

Connect the flat cable plug to the card.

Figure 3:

Replacing all types of electronic modules (cards)

4.4.3 Replacing I/O

Module

Disconnect the power supply to the unit before open

1)

Disconnect the flat cable plug from the card.

2)

Unscrew the four (4) mounting screws.

3)

Put in the new card and tighten the 4 mounting scre

4)

Connect the flat cable plug to the

20

Replacing Flow Switch

Turn off the inlet and outlet water to the flow cell and the power to the analyzer.

Open the doors of both the analyzing

module and the control module.

Locate the flow switch attached to the flow cell.

Disconnect the flow switch wires from the I/O module.

Remove the inlet connection to the old flow switch.

Remove the flow switch from the flow cell.

gently to completely remove from the analyzer

Insert the new flow switch on the flow cell

Insert the inlet connection on the flow switch

Route the flow switch wires back to the connection on the I/O module and connect the wires to the

Close the analyzer doors and turn on the water and power and ensure proper operation.

Replacing Control Panel Module (electronics card)

Disconnect the power supply to the unit before opening the control unit.

Disconnect the flat cable plug fr

om the card.

Unscrew the four (4) mounting screws.

Put in the new card and tighten the 4 mounting screws.

Connect the flat cable plug to the card.

Replacing all types of electronic modules (cards)

Module

Disconnect the power supply to the unit before opening the control unit.

Disconnect the flat cable plug from the card.

Unscrew the four (4) mounting screws.

Put in the new card and tighten the 4 mounting screws.

Connect the flat cable plug to the

card.

on the I/O module and connect the wires to the

power and ensure proper operation.

Table of contents

Popular Measuring Instrument manuals by other brands

Valeport

Valeport fastCTD operating manual

Dwyer Instruments

Dwyer Instruments MFS2-3 Installation and operating instructions

Circutor

Circutor CEM-C12 instruction manual

Zoom

Zoom H4N quick start guide

NUCLEONIX SYSTEMS PRIVATE LIMITED

NUCLEONIX SYSTEMS PRIVATE LIMITED GR612 instruction manual

FRC

FRC DFA400 instruction manual