ACUVANCE XARVIX XX User manual

XARVIS XX Owner's Manual

Repair Conditions

Note that if the date and location of ESC purchase are not entered on the warranty card, you will

be charged for repairs even within the warranty term.

●If a failure occurs within three months of purchasing the ESC, write the symptoms of the problem

and operating conditions in the section below and attach this to the product. For repair, send the

ESC to the distributor where you purchased the product or directly to ACUVANCE (Technical

Service Department).

●ACUVANCE assumes no responsibility for damage or losses that occur during transportation.

Please take note of this beforehand.

●When listing the symptoms for a repair request, you can conveniently use the repair request

sheet on the ACUVANCE homepage and then send this along with the warranty card.

(Click the “repair” section located in the upper-right side of our website. Then click “repair

request sheet”, located on the left side.)

Warranty

Item

Manufacture

no.

XARVIS XX Purchase

date

Customer

Address

E-mail

Phone

number

Name

Warranty

term

3 months from purchase date

Phone no.@( )

Repair card

1. Symptoms

Write the symptoms of the problem,

giving as much detail as possible.

2. Payment for repair charges

I would like to be contacted if there is compensation

※Though it depends on the details of the repair, indicating in advance that no contact is necessary will

normally shorten the time is takes to complete the repair.

1. Parts that can be repaired.:

•Internal electronic circuitry

Damage caused by incorrect connection, inter-terminal shorting, or driving is not covered by

warranty.

2. Note that this device will not be covered under warranty if the housing has been opened.

3. ACUVANCE assumes no responsibility for damage to the receiver or servo caused by the

incorrect connection of this product.

4. Note that if the repair card (located below) or the repair sheet (on the homepage) is not properly

filled out, repair and return of the ESC may be delayed.

(M/D/Y) / /

Shopname(address,andphone.no.)

7F, Shin-Osaka Marubiru Annex 1-18-22

Higashinakajima Higashiyodogawa-ku

Osaka 533-0033 Japan.

FAX +81-6-6379-1190

www.acuvance.co.jp/english

Technical Service Dept.

330290-1

32

PRECAUTION FOR USE

WARNING

WARNING

CAUTION

DANGER

Instructions that the user must observe to prevent serious injury.

Instructions that the user must observe to prevent accidents.

Useful information for handling this product.

Before using this product, carefully read the important warnings

described in this instruction manual to understand the instructions thoroughly.

DANGER

Aboutbatteries

Topreventfumes,fire,orburns

DANGER Topreventfumes,fire,orburns

AboutcableConnections

DANGER Topreventburns

About

Toavoidaccidentsorproductfailure

Handlingprecautions

WARNING

P.4

P.6〜P.9

P.10〜P.21

INDEX

Specifications

6.0V〜8.5V

Continuous/spontaneous max current

Compatible motors

Dimensions W30.5×D35.0×H20.5mm

Weight 47. 2 g

FEATURES

Power Supply

Regulator for receiver/servo 6V/5A or 7.4V/5A output

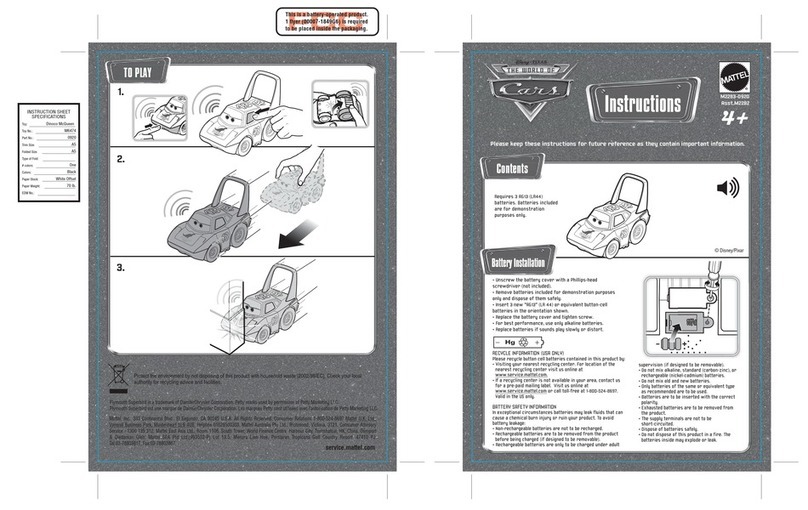

How to conHow to connect the ESC

Preparations Before Driving Tuning

the Driving Experience

Max. current of battery

Sensored motor - unrestricted (when boost turbo is disabled)

Improper use of the battery is very dangerous. The battery must be handled carefully.

Incorrect wiring or short-circuiting of wiring may cause re or fumes. Before

connecting or disconnecting the battery to or from the speed controller (ESC), be

sure to turn offthe power switch of the ESC. When the battery is not in use,

disconnect it from the ESC or charger, and store it in a suitable location free of any

loose wires or screws.

Incorrect wiring may cause re or fumes that can damage both the ESC and

battery beyond repair.

The surface of the body can be extremely hot after heavy load driving. Please

handle the unit carefully after operation to avoid risk of burn.

Do not modify the ESC in any way. Use it only for its intended purpose. Keep the

ESC away from ames or seat. Avoid splashing any liquid, such as water, on the

ESC.

Thank you for choosing XARVIS XX. This product is a high-performance speed

controller for drivers seeking the top end. Please read this instruction manual

carefully before using this product, and use it correctly and safely. Please keep it

carefully after reading.

Please check our website and official Twitter for details on the features and the

latest information. (@ACUVANCE_JAPAN)

This new ESC is equipped with a high-performance MOSFET of the industry's

highest peak

(currently when this product was released / according to our research).

As a result, output performance such as torque and efficiency has been greatly

improved.

XARVIS's unique “bridge type FAN floating structure” is further evolved to

greatly increase the ventilation capacity.

Equipped with two ACUVANCE cooling fan terminals (including FLEDGE fan)

Equipped with capacitor mounting terminal

Equipped with reverse battery protection circuit (see page 22)

BEC voltage switching (6.0V / 7.4V) function (see page 20)

Supports bidirectional communication with TAO II, Ne-St, FUTABA S.BUS

system compatible transmitters, etc.

※This product needs to be updated to use the S.BUS system (see ACUVANCE

website).

Equipped with a new program control circuit to secure additional setting items

for only XARVIS XX

FEATURES

4 5

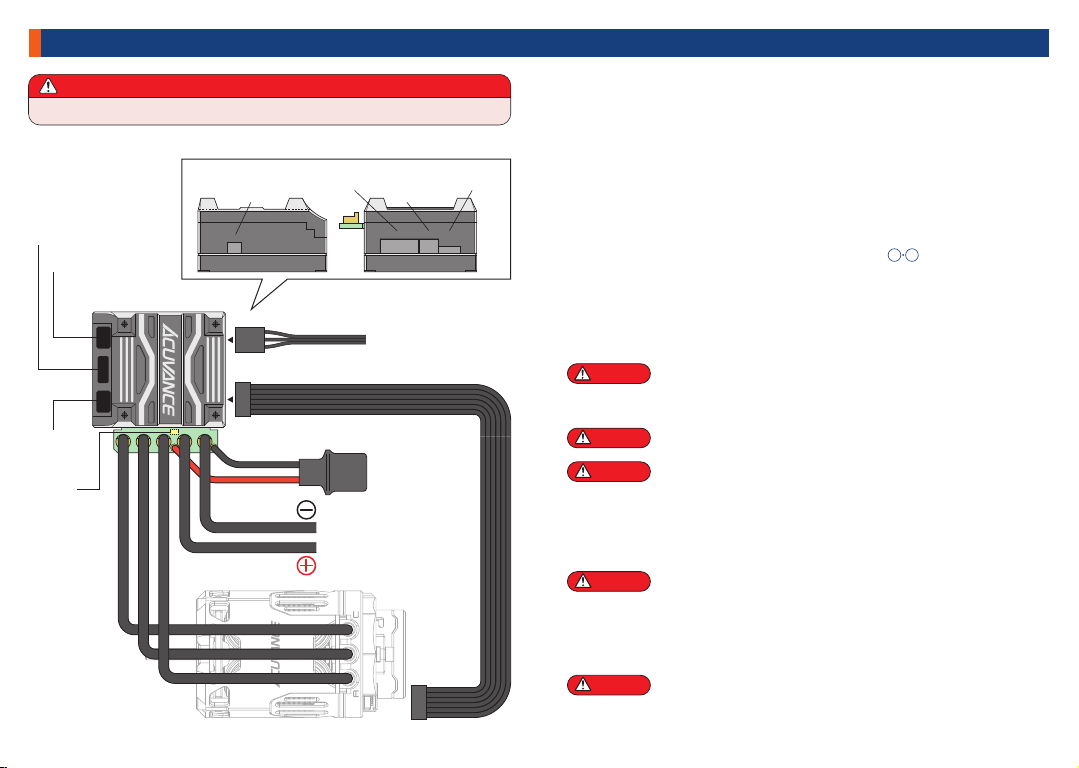

PART NAMES AND WIRING

Be careful not to reverse the battery poles. Doing so can cause the ESC to fail.

If the sensor cable is not connected, has not been properly inserted, has been

disconnected, or is loosely connected, all the LEDs will blink (highspeed

blinking). While in this state, all operations will not be received. If this occurs,

check the connection for the sensor cable or replace the cable.

When inserting the connector, pay attention to the way in which it being inserted.

If inserted backwards, the device will not operate.

Be sure to match the cables to the symbols A, B, and C on the ESC. Failure to

follow this precaution can result in loss of control over the motor speed, or

subject the ESC and motor to large currents. Unlike brushless motors without a

sensor, swapping these cables does not change the rotating direction of the

motor. If necessary, change the direction of rotation at the ESC※.

※To switch the direction of rotation, it is essential to have the rotation direction

change function in the ESC. This machine has this function (P.16)

When replacing the motor cable, use a soldering iron with a broad tip and high

output rating (as high as 60 W) and work swiftly. A soldering on with the low

output rating will not melt enough of the solder resulting in a poor soldering

connection which can cause cables to loosen under vibration or loose

connections. Also, subjecting the internal parts to excessive heat over prolonged

periods (10 seconds or more) can damage them. (Be careful not to shortcircuit

the terminals with solder)

Be sure to use screws with a length of 8 mm or less to secure the motor to the

motor mount. If the screw is too long, it may interfere with parts inside the motor,

resulting in malfunctions such as short circuit.

WARNING

WARNING

WARNING

WARNING

WARNING

• POWER BUTTON

• LINK TERMINAL

• SET BUTTON

• COOLING FAN CONNECTION TERMINAL

It is the button to turn the unit ON or OFF.

It is used for setting change in the XARVIS XX main unit. It is also used to switch

between "ESC mode" setting of the main unit, and "Link mode" setting with TAO

II.

ACUVANCE optional cooling fan or fan connection terminal with our motor.

It doesn't matter if you use either terminal ①or ②.

Since it is designed exclusively for ACUVANCE cooling fan, other manufacturers'

cooling fans cannot be used.

(If you use a fan of a different brand, the fan may be damaged.)

Terminal for communication with TAO II, Ne-St. Air-Link Adapter (OP-15065),

S.BUS Adapter (OP-15067), etc. are also connect here.

DANGER To prevent fumes, re, or burns

1 2

RX

FANSENSOR -+S

Please connect as

shown below

Sensor cable

Battery cables

Motor Cable C

Motor Cable A

Motor Cable B

XARVIS XX body

Sensored Brushless Motor

RX Cable

POWER button

SET button

[Behind]

Reverse

connection

alert LED

( s e e P. 2 2 )

The throttle channel(CH2)

from the receiver

Capacitor

RX TerminalSensor Cooling

FAN②

Rear LayoutSide Layout

LINK terminal

- + S

FAN

Cooling

FAN①

6 7

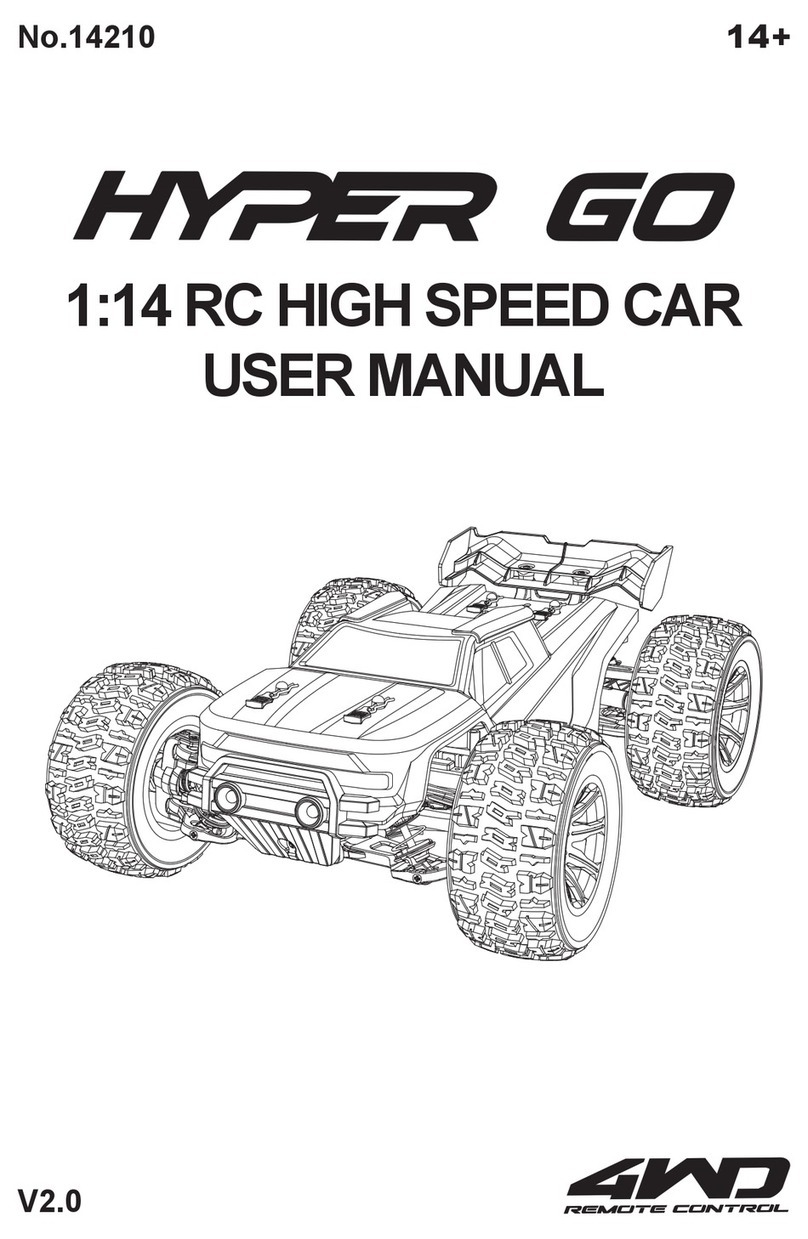

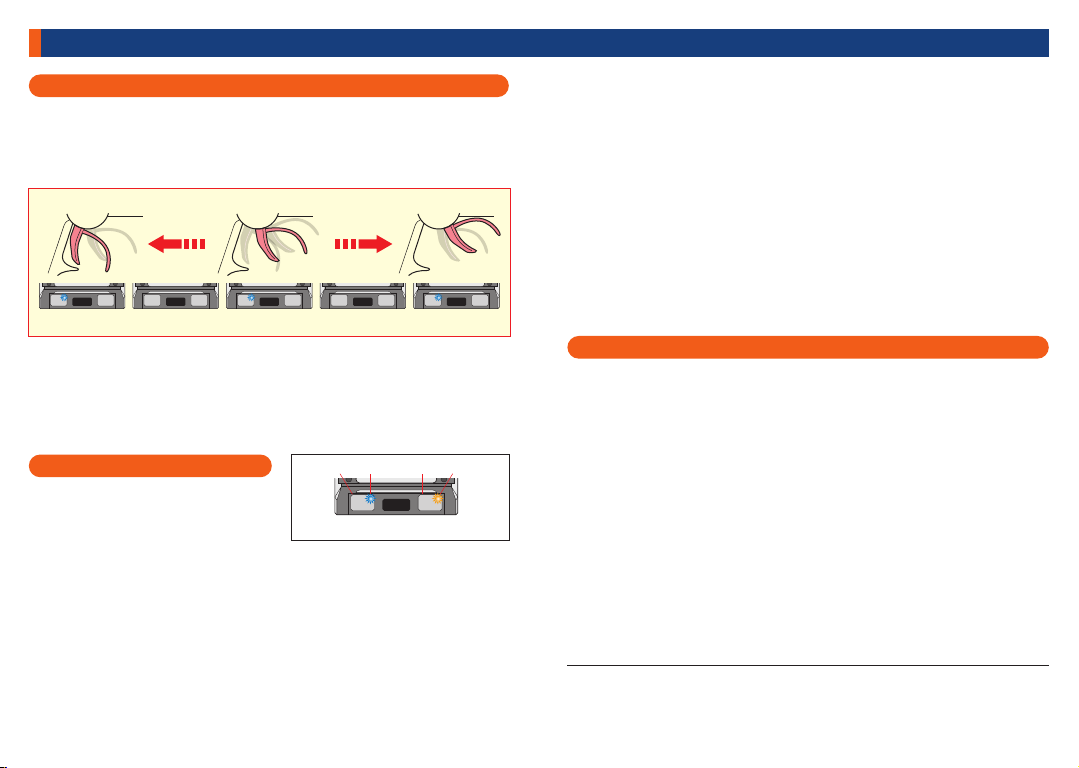

PREPARATIONS BEFORE DRIVING

While the blue LED is blinking, set the throttle

on the transmitter to the maximum forward

position and press the set button on the ESC

once. The red LED will start blinking.

※If the red LED does not blink after pressing the

set button with the throttle at the maximum forward

position, set the throttle to the maximum reverse

(brake) position and then press the set button

once.

While the red LED is blinking, set the throttle

on the transmitter to the maximum reverse

position of Step 4, and press the set button on

the ESC once. All LEDs will blink three times.

4

5

Important

Caution

If you performed the procedure described by the ※under Step 4 above, <<Setting

the high point>>, switch the throttle channel on the transmitter between normal and

reverse after completing the initial setting for all transmitter positions.

The throttle position for the transmitter may become misaligned due to changes or

deterioration over time.If the LED lights are ashing while the ESC is in standby

mode, readjust the initial settings for the transmitter.

When using for the first time, the neutral position of ESC with the transmitter you

have will not match. If you try driving before the initial setting is completed, the

motor may start rotating at the same time as the switch is turned on. Since it is

very dangerous, be sure to perform the following "initial setting of the radio

throttle position" when turning on the power for the first time.

(The motor will not rotate during initial setting.)

Initial setting of radio throttle position

How to Calibrate

Supports SANWA super response <SSR> mode

Immediately after purchasing or immediately after replacing the transmitter, it is

necessary to store the neutral point, forward MAX point and reverse (brake) MAX

point of the transmitter in the ESC. Follow the procedure below.

Before setting, please set all settings (EPA = endpoint adjustment, maximum

braking amount, etc) for the throttle of the transmitter to a neutral position (zero

value). If the settings are different, the ESC may not detect the throttle input and

calibration will not be performed successfully.

When performing the initial setting, be sure that the sensor cable is connected to

the motor and ESC. If the sensor cable is not connected, has not been properly

inserted, has been disconnected, or is loosely connected, all the LEDs will

blink(high-speed blinking). Check the connection for the sensor cable or replace

the cable as all operations will not be received while it is in this state. Also, in

assition to when performing the initial settings, the sensor cable should always be

connected when the vehicle is being driven.

The three motor cables (A, B, C) may be left disconnected but be careful to not

have the cable connectors touch each other as they will short.

If performing the initial settings with the motor cables connected, secure the motor

in a motor mount or other device, and remove the pinion gear to keep the car from

moving unexpectedly.

Be sure the ESC power is turned off,and make sure the ESC is properly

connected to the battery, motor (only the Sensor cable needs to be connected),

and receiver. Then turn the transmitter power on.

If you press and hold the POWER button

for 2 to 3 seconds while the power is OFF,

the LED green blinks 3 times at the same

time, the LED green starts blinking and the

initial setting mode is entered. Then

release the POWER button.

While the LED blinks green, set the transmitter

throttle to the neutral position and press the

POWER button briefly. After that, the blue LED

will blink.

1

2

3

Preparations

Preparations

Preparations

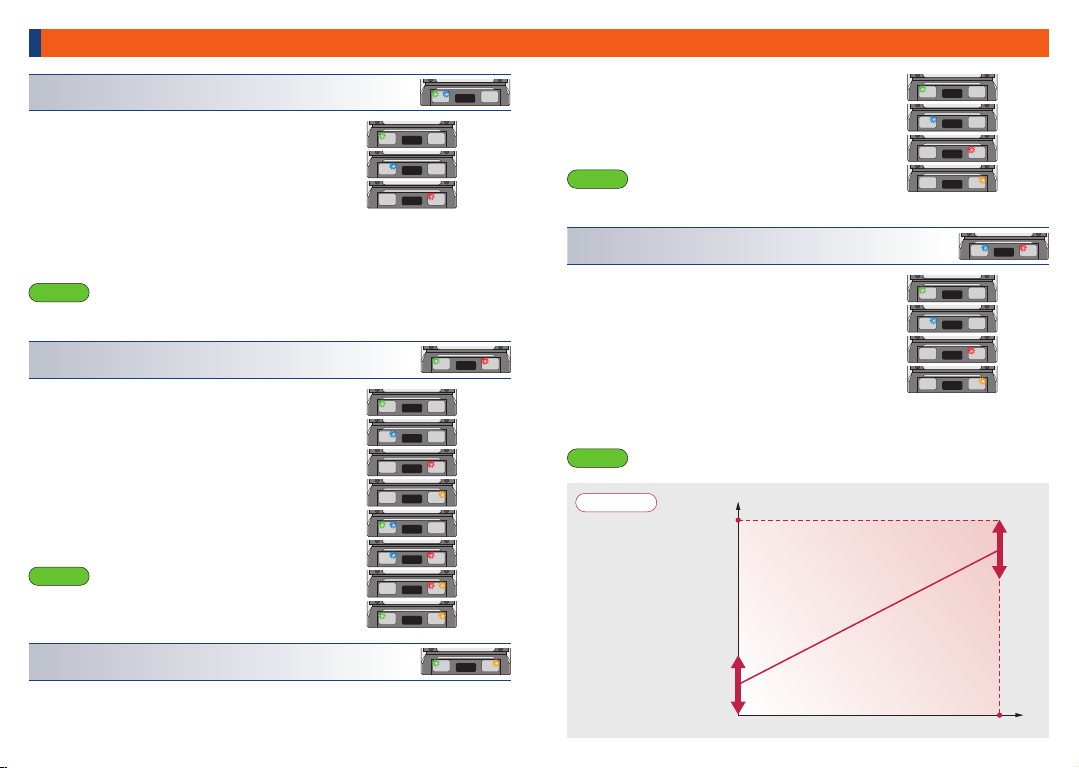

LED Green · Orange

Blink for 3 seconds

at the same time

LED blinking

Press and hold the POWER button

for 2 to 3 seconds

Green

blinking

LED

changes to

Blue

blinking

LED

Press POWER button

Blue

blinking

LED

changes to

Red

blinking

LED

Press POWER button

Neutral position

Max.forwardposition

Red

blinking

LED

changes to

All LEDs

Blink three

Times

Press POWER button

Max.reverseposition

This completes the initial settings for the transmitter

positions. The ESC automatically changes to the

standby mode (p. 8).

<<Before making calibration>>

<<Calibration mode>>

<<Setting of the neutral point>>

<<Setting of the high point>>

<<Before making calibration>>

*“SSR mode” is an original system from Sanwa Denshi Co. Ltd.

Powering OFF

Press and hold the POWER button for 2 seconds to

turn off the power.

8 9

PREPARATIONS BEFORE DRIVING

Checking standby mode

At the time of shipment, the standby

mode is as shown in the figure on the

right. Each LED has the following

meaning.

[Important] Safety feature for driving in reverse

On radio controlled cars, the same throttle controls are used for braking and

driving in reverse. This can cause car to move backward when the intention is to

apply the brakes. Suddenly trying to reverse the motor while it is rotating forward

can place severe stree to the gears, motor, and ESC, sometimes resulting in

internal damage. The XARVIS XX is equipped with the following feature to

prevent this.

After applying the brakes, before reversing, the ESC will wait 1 second or more

for the throttle to return to neutral and for the the motor to go from rotating in a

forward direction to coming to a complete stop (it will not go into reverse within

the span of 1 second).

This feature prevents unintentional reversing even if the reverse drive feature is

set ON on the ESC. It prevents damage to the drivetrain of the car and potential

collision with other vehicles, as well as many other possible problems, and is

essential to allow short braking action when turning corners.

① ② ③ ④

Stanby mode at time of shipment

This completes the preparation before driving. Connect the motor and enjoy

driving.

When using lithium polymer batteries, set the cutoff voltage before driving to 3.2V/cell (1

recommended)(P.16)

Verifying the transmitter positions have been correctly set to their initial settings

The standby LED (see below) should be the only one illuminated when the throttle is in

the neutral, maximum forward, and maximum reverse (brake) positions. If the Stanby

LED is unlit in all other positions, the initial setup has been completed properly.

(The standy LED is the only LED that alternately illuminates and goes out when

adjusting the throttle)

If the standby LED does not follow this lighting pattern, the initial setting was not

completed properly. Make sure the throttle related adjustment on the transmitter

are initialized and the RX cable is properly connected to the receiver. Then, retry

the initial setting procedure.

※Depending on the configuration of the vehicle, the car may move in reverse when the throttle

is operated in the forward direction. If your car displays this behavior, change the rotation

direction of the motor (P.16 ).

Neutral positionMax. forward position Max. reverse position

Standby LED lit unlit Standby LED lit unlit Standby LED lit

Note, this safety feature cannot be disabled. However, as detailed in [Reverse

drive ON/OFF and motor rotating selection](P.16), when configuring to

crawleroriented settings, vehicle movement that occurs once the throttle is

placed in the brake position will be specialized for reverse driving (the brake

will not work), thus disabling this function.

①

※

LED<green> : Factory shipped condition = unlit

If the battery voltage becomes lower than the cutoff voltage (P.16) while

driving, the green LED will blink and the car will drive at extremely low

speeds. If this occurs, replace the battery.

②LED<blue> : Factory shipped condition = lit

Standby LED when setting mode (P.10) is in ESC mode. Unlit during Link

mode.

※Under "ESC Mode", <blue> LED will be blinking if the program selected

(P.12) is "Boost/Turbo Disabled", or both "Full Boost Timing"(P.17) and "Full

Turbo Timing" (P.19) are disabled.

②LED<red> : Factory shipped condition = unlit

Standby LED when setting mode is in Link mode. Unlit during ESC mode.

※Under "Link Mode", <red> LED will be blinking if the program selected (P.12)

is "Boost/Turbo Disabled", or both "Full Boost Timing"(P.17) and "Full Turbo

Timing" (P.19) are disabled.

②LED<orange> : Factory shipped condition = lit

Illuminated when the reverse drive feature (P.16) is set to ON. Unlit when set to

OFF.

※

※

※

If the ESC heats up to temperature limits while driving, the motor will remain

at low speed and the Orange LED will blink. If this situation occurs,

discontinue operation until the ESC temperature drops back to ambient

temperature. If the Orange LED starts blinking after driving for only a brief

period of time, check to see if the gear ratio settings are overloading the

motor.

10 11

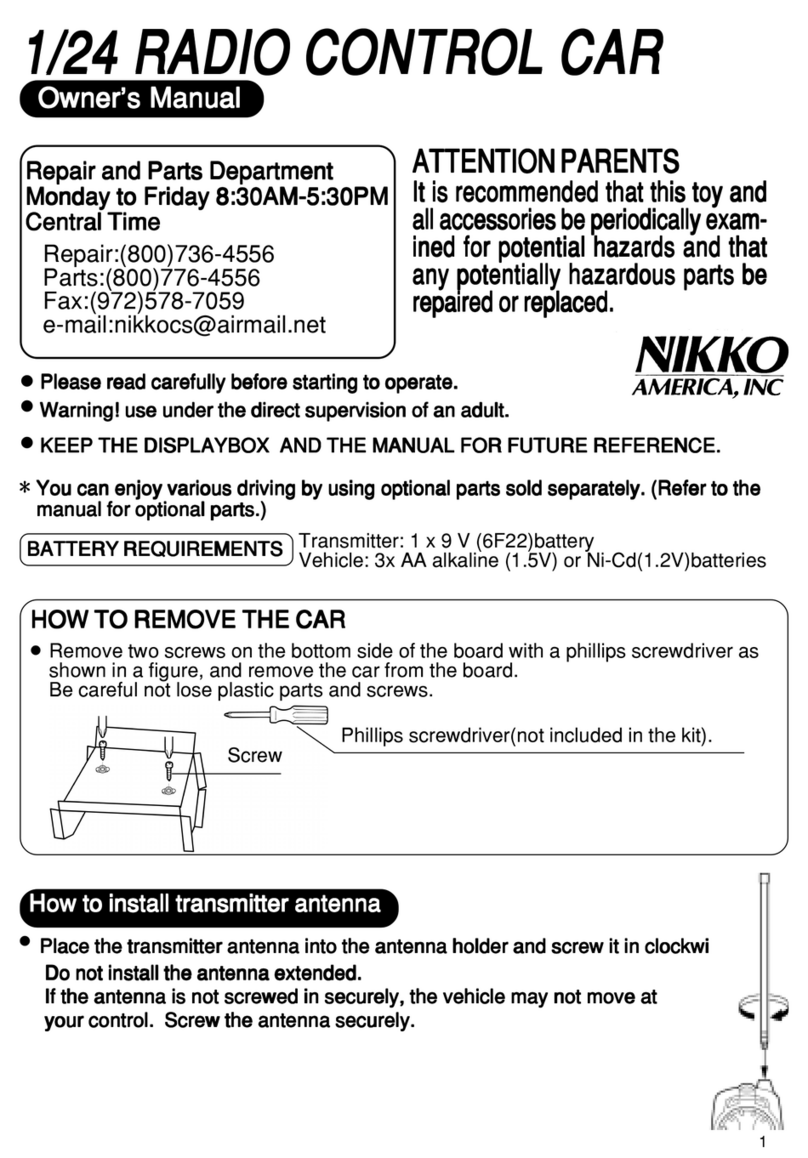

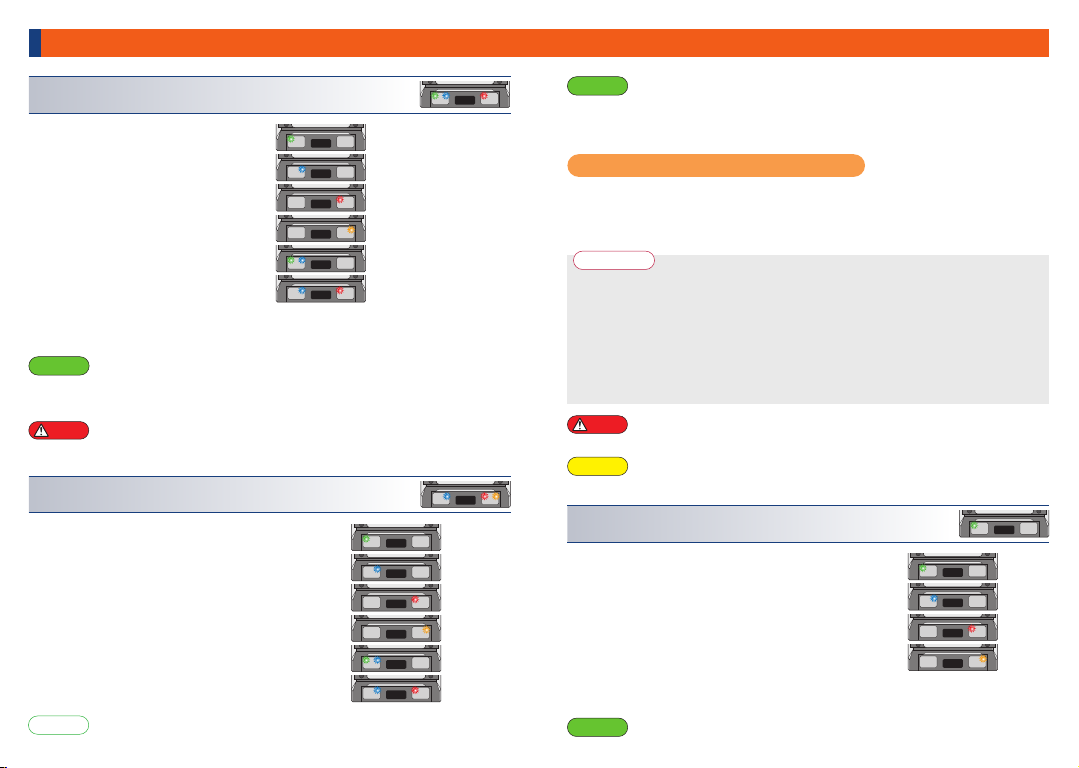

Selecting setting modes

Flow for changing setting and ESC mode

First, select either [ESC mode] or [Link mode].Select ESC mode to adjust various

features on the ESC, or Link mode to change function settings for the effector. At

time of shipment, ESC is set to ESC mode.

Select mode (when Setting mode = ESC mode

In Standby mode (P.8), quickly press the set button once.

The green LED will start blinking indicating the ESC is in

Select mode. (While in Select mode, the motor will not rotate

even if the transmitter throttle is operated.)

In Select mode, set the LED to the item you want to the check the value of,

after 2 seconds the LED representing the item & the LED representing the

value of the item will blink alternatively. ( The LED indicate the item

selected> <The LED indicate the value of the selected item)

Pressing the SET button once returns to the Select mode.

Refer to P.12 to 20 for the meaning of each displayed values.

With "Load Program", the value LEDs won't always be displayed.

Each time the SET button is pressed briefly, the flashing LED is switched to

indicate the currently selected setting item (see the setting items below for

details). Also, pressing the SET button twice shortly will return to the previous

item.

1

2

Selecting

Setting Modes

Repeating the same procedure alternates between [ESC mode](blue) and [Link

mode](red).

Important

The numerical setting ranges and unit of adjustment differ depending on the mode

selected (P.12 to 20). Refer to the following section for setting procedure in ESC

mode, or the instruction manual supplied with the programming card for setting

procedures in Link mode.

Select the setting to change

Select mode (P.11)(Driving disabled)

Select the save

destination

(P.20)(Driving disabled)

Change the value in the selected item

Select mode > Save destination selection

Quickly press the set button 4 times in

rapid successions.

Standby mode > Select mode

Quickly press the set button

once

Select mode > Standby mode

Quickly press the set button 3

times in rapid succession.

Save destination selection mode > Standby mode.

After selecting the save destination, press the set button

for 2 seconds or longer

Select mode > Setting mode

After selecting the item you wish to change,

press and hold the set button for 2 seconds

or longer

Select mode > Setting mode

Set to desired value, then press and hold

the set button for 2 second or longer.

Select mode

(blinking green LED)

Neutral brake power adjustment is selected

(Blinking orange LED)

(For details of each item, see the following pages)

Description of each blinking LED pattern

[Verifying your current settings]

TUNING THE DRIVING EXPERIENCE

(Ex.)

In standby mode, press and hold

the set button for 4 seconds or longer.

The LEDs (blue & red) alternately blink

indicating the setting mode is now active.

Press the set button

For 4 seconds or longer

Press the SET

Button once

Standby mode

※If the initial settings have not been completed, the following procedure cannot be performed.

[Green flashing twice] Load Program

[Blue flashing twice]Drive Frequency

[Red flashing twice]Neutral Brake Frequency

[Orange flashing twice]Brake Frequency

[Green+Blue flashing twice]Initial Speed

[Green+Red flashing twice]Neutral Brake Power

[Green+Orange flashing twice]Initial Brake Power

[Blue+Red flashing twice]Full Brake Power

[Grn+Blu+Red flashing twice]Operation mode

[Blu+Red+Org flashing twice]Cutoff Voltage

[Green flashing 4 times]Full Boost Timing

[Blue flashing 4 times]Boost Start RPM

[Red flashing 4 times]Boost Stop RPM

[Grn+Red flashing 4 times]Full Turbo Timing

[Blu+Red+Org flashing 4 times]Turbo Start Time

Green Orange

(p.8)(Driving enabled)

Changes will not be saved.

※

※

※

※

Setting mode (P.12)(Driving disabled)

12 13

Setting mode (in ESC setting mode)

While in Select mode (P.11), move the LED to the setting to be changed using the

SET button. Press and hold the SET button 2 seconds or longer. This activates

the Settings mode. (While in Settings mode, the motor will not rotate even if the

transmitter throttle is operated.)

②

Changing to Setting mode

In the select mode(green blinking twice), press

the SET button for 2 seconds or more to enter

the setting mode . Each time the SET button is

pressed briefly, the LED pattern changes and

the program changes accordingly as shown

on the right. Align the LED with your favorite

program, and press the SET button for 2

seconds or more. The program is now set and

the LED returns to the select mode (green

blinking). It is also possible to call the preset

program and change each function to the

setting of your choice.

①

Important

When "boost / turbo disabled" is selected, boost and turbo function (item (11) and

later described below) can not be used. In this case, ⑪to ⑮are skipped in select

mode. Also, the timing angle is fixed at 0 °.

Caution If the power is turned off without saving to a user program, the settings will be lost.

Drift

Boost / Turbo Disabled

Touring

Offroad 2WD

Offroad 4WD

User program①

User program②

TUNING THE DRIVING EXPERIENCE

In select mode, the blue LED blink twice, press the SET button for 2 seconds or more to

enter the setting mode. Each time the SET button is pressed once, the lighting LED

changes and the drive frequency changes as shown on the right.

Adjust the LED to the setting of your choice and press the

SET button for 2 seconds or more. The set value is

validated and it returns to select mode. The changed value

will be reset if the power is turned off without saving.

Please save your settings before tunring your unit off

( P. 2 0 ) .

Commentary

The lower the value = strong initial punch/lowered

smoothness. The higher the value = small initial

punch/ increased smoothness

4KHz

8KHz

16KHz

24KHz

2KHz

4KHz

8KHz

16KHz

③

In the select mode with the red LED flashing twice, press

the SET button for 2 seconds or more to enter the setting

mode. Each time the SET button is pressed once, the LED

pattern changes and the neutral brake frequency changes

as shown on the right. Adjust the LED to the setting of your

choice and press the SET button for 2 seconds or more.

The set value is validated and it returns to select mode. The

changed value will be reset if the power is turned off

without saving. Please save your settings before tunring

your unit off (P.20).

Commentary

The lower the value = quicker braking

The higher the value = smoother braking

This is the area to store each set item on this unit. There are two storage areas (user

programs ①and ②) on this unit, but if you need to store more programs, please use TAO II

(sold separately).

Additionally, once all your settings have been adjusted, you can save into a user program.

④

Device frequency (blue flashing twice)

Load program (green flashing twice) Neutral brake frequency (red flashing twice)

Brake frequency (orange flashing twice)

In the select mode with the orange LED flashing twice,

press the SET button for 2 seconds or more to enter the

setting mode. Each time the SET button is pressed once,

the LED pattern changes and the brake frequency changes

as shown on the right. Adjust the LED to the setting of your

choice and press the SET button for 2 seconds or more.

The set value is validated and it returns to select mode. The

changed value will be reset if the power is turned off

without saving. Please save your settings before tunring

your unit off (P.20).

Commentary

The lower the value = quicker braking

The higher the value = smoother braking

2KHz

4KHz

8KHz

16KHz

About user program

14 15

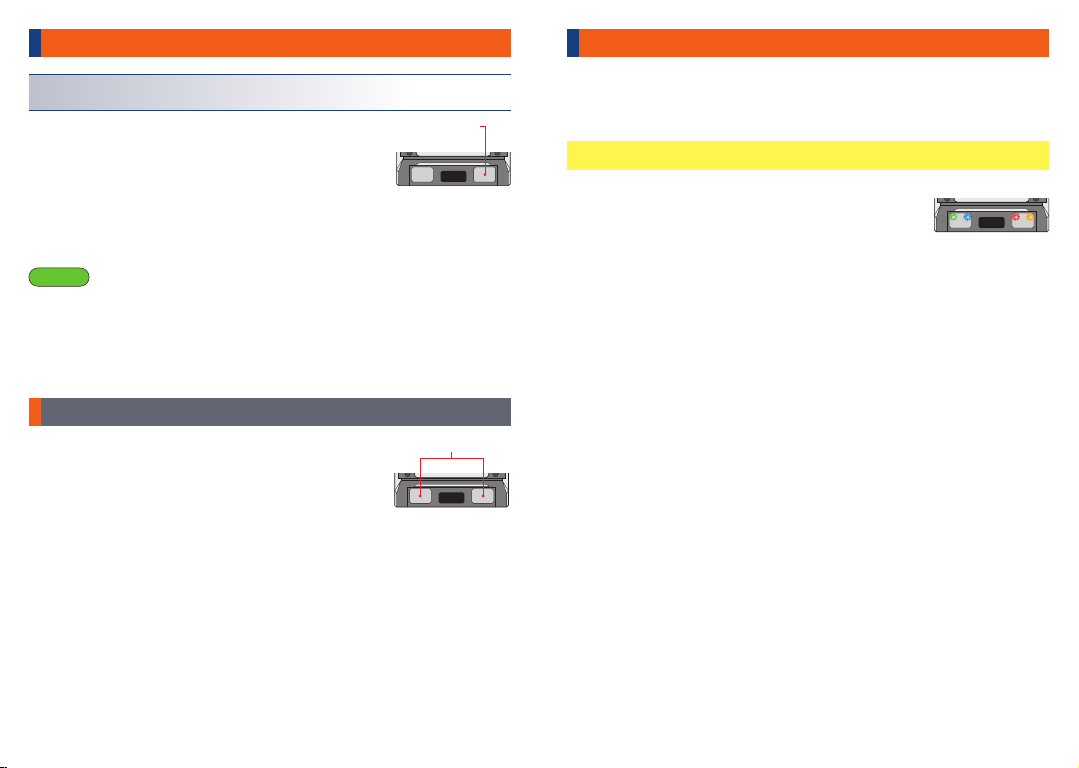

TUNING THE DRIVING EXPERIENCE

Advice

The braking force of the

brake when the throttle is

in the middle range is

linked with the initial

brake power (item ⑦) and

the full brake power (item

⑧) as shown on the right.

Braking force

Throttle

position

Brake high point

0

MAX

Initial brake power

(The instant that the throttle lever is placed in the brake position)

Full brake power

Commentary

Commentary

It is the brake power that is applied once the throttle

is placed in the brake position. The higher the value

= stronger initial braking force

⑤

In the select mode with the green+blue LED flashing

twice, press the SET button for 2 seconds or more to

enter the setting mode. Each time the SET button is

pressed once, the LED pattern changes and the initial

speed value changes as shown on the right. Adjust the

LED to the setting of your choice and press the SET

button for 2 seconds or more. The set value is validated

and it returns to select mode. The changed value will be

reset if the power is turned off without saving. Please

save your settings before tunring your unit off (P.20).

It is the amount of speed as soon as you begin to pull your throttle lever. The higher

the value = higher speed at the beginning of your throttle. Excessive initial speed

can cause tire spin or chip gears. Choose your setting carefully.

Commentary

⑥

In the select mode with the green+red LED flashing

twice, press the SET button for 2 seconds or more to

enter the setting mode. Each time the SET button is

pressed once, the LED pattern changes and the

neutral brake power value changes as shown on the

right. Adjust the LED to the setting of your choice and

press the SET button for 2 seconds or more. The set

value is validated and it returns to select mode. The

changed value will be reset if the power is turned off

without saving. Please save your settings before

tunring your unit off (P.20).

It is the amount of braking force applied when the

throttle is returned to neutral. The higher the value =

increased braking force

Commentary

⑧

In the select mode with the blue+red LED flashing

twice, press the SET button for 2 seconds or more to

enter the setting mode. Each time the SET button is

pressed once, the LED pattern changes and the full

brake power value changes as shown on the right.

Adjust the LED to the setting of your choice and press

the SET button for 2 seconds or more. The set value is

validated and it returns to select mode. The changed

value will be reset if the power is turned off without

saving. Please save your settings before tunring your

unit off (P.20).

It is the brake power that is applied when the throttle is in fully braked position.The

higher the value = stronger braking force at full braking

0%

8%

14%

0%

4%

8%

10%

12%

14%

16%

32%

⑦

Initial speed (green+blue flashing twice)

Neutral brake power (green+red flashing twice)

Full brake power (blue+red flashing twice)

Initial brake power (green+orange flashing twice)

In the select mode with the green+orange LED flashing twice, press the SET

button for 2 seconds or more to enter the setting mode. Each time the SET button

is pressed once, the LED pattern changes and the initial brake power value

changes as shown on the right. Adjust the LED to the

setting of your choice and press the SET button for 2

seconds or more. The set value is validated and it

returns to select mode. The changed value will be

reset if the power is turned off without saving. Please

save your settings before tunring your unit off (P.20).

6%

12%

16%

26%

70%

80%

90%

100%

16 17

TUNING THE DRIVING EXPERIENCE

It is a function that increase the electronic timing in

conjunction with the motor rpm to further increase motor

rpm.

What is the boost function?

It is a function that increase the electronic timing when in

full throttle to increase motor rpm.

What is the turbo function?

Advice

If "boost/turbo disabled" has been selected in Load program, the "boost function" and

"turbo function"cannot be used.

When using the "boost/turbo disabled"program, zero timing will be activated, and while in

standby, the blue LED will blink in "ESC mode" and the red LED will blink in "Link mode".

This is also known as a "Blinky mode". It allows the user understand at a quick glance that

the ESC is in zero timing mode and that "boost/turbo" is disabled.

The "XARVIS XX" ESC allows to operate either "boost function" or "turbo function"

independently. (When doing so, make sure to use a program other than "boost/turbo

disabled".)

Caution In general,"boost+turbo" function will overload the ESC/motor.Pay close attention

to the heating of the ESC/motor as well as the gear ratio when using these

functions.

When using "boost+turbo"or "boost"only, please use a motor of 8.5T turn or higher.

Damage caused by using a motor with a lower turn count will not be covered by

warranty.

With crawler-oriented settings, the brake will not work and the ESC will switch

between forward and reverse instantly. This function must not be used on

non-crawler vehicles otherwise damage to the ESC, motor, or gears may occur.

Commentary

⑨

In the select mode with the

green+blue+red LED flashing twice,

press the SET button for 2 seconds or

more to enter the setting mode. Each

time the SET button is pressed once,

the LED pattern changes and the

operating mode changes as shown on

the right. Adjust the LED to the setting of

your choice and press the SET button

for 2 seconds or more. The set value is

validated and it returns to select mode.

The changed value will be reset if the

power is turned off without saving.

Please save your settings before tunring

your unit off (P.20).

Switched between normal and reverse motor rotation. Regardless of whether the

initial settings have been completed properly, the car may go into reverse once the

throttle is applied. If this condition occurs, please use Reverse rotation operation

mode. The orange LED will be lit in standby mode when Reverse rotation is

selected.

Commentary

⑩

In the select mode with the blue+red+orange LED

flashing twice, press the SET button for 2 seconds

or more to enter the setting mode. Each time the

SET button is pressed once, the LED pattern

changes and the cutoff voltage value changes as

shown on the right. Adjust the LED to the setting of

your choice and press the SET button for 2

seconds or more. The set value is validated and it

returns to select mode. The changed value will be

reset if the power is turned off without saving.

Please save your settings before tunring your unit

off (P.20).

It is a function to notify the driver of low voltage condition before the unit reaches

critical voltage and performance decrease. When the voltage reaches the cutoff

voltage while driving, the green LED will flash and the vehicle will travel very

slowly. When disabled is selected, this function will not work. Please be careful

about your runtime and other conditions.

Commentary

⑪

Operation mode (grn+blu+red flashing twice)

Cutoff voltage (blu+red+org flashing twice)

Full boost timing (green flashing 4 times)

In the select mode with the green LED flashing 4 times,

press the SET button for 2 seconds or more to enter

the setting mode. Each time the SET button is pressed

once, the LED pattern changes and the boost timing

value changes as shown on the right. Adjust the LED

to the setting of your choice and press the SET button

for 2 seconds or more. The set value is validated and it

returns to select mode. The changed value will be

reset if the power is turned off without saving. Please

save your settings before tunring your unit off (P.20).

This determines the maximum value (terminal value) for timing increased through

boost.

Disabled

2.8V/Cell

3.0V/Cell

3.1V/Cell

3.2V/Cell

3.4V/Cell

0deg

15deg

25deg

45deg

Because the number of cell is automatically recognized, select the voltage per cell.

If set to disabled, pay close attention to your runtime.

Reference

About Boost / Turbo Function

Forward rotation

Forward+Brake

Forward rotation

Forward+Brake+Reverse

Forward rotation

Forward+Brake (for crawlers)

Forward rotation

Forward+Brake

Forward rotation

Forward+Brake+Reverse

Forward rotation

Forward+Brake (for crawlers)

Warning

Warning

18 19

TUNING THE DRIVING EXPERIENCE

Commentary

This determines the motor rpm at which the boost will begin to operate. As this rpm

value is set lower, boost will operate from a lower speed/rpm point.

⑫

In the select mode with the blue LED flashing 4

times, press the SET button for 2 seconds or more

to enter the setting mode. Each time the SET

button is pressed once, the LED pattern changes

and the boost start rpm value changes as shown

on the right. Adjust the LED to the setting of your

choice and press the SET button for 2 seconds or

more. The set value is validated and it returns to

select mode. The changed value will be reset if the

power is turned off without saving. Please save

your settings before tunring your unit off (P.20).

5,000rpm

10,000rpm

15,000rpm

20,000rpm

Caution When set low, it is necessary to lighten the drive load and adjust your gear ratio.

Commentary

This determines the motor rpm at which the boost will end. As this rpm value is set

higher, boost will operate to a higher speed/rpm point.

⑬

In the select mode with the red LED flashing 4

times, press the SET button for 2 seconds or more

to enter the setting mode. Each time the SET

button is pressed once, the LED pattern changes

and the boost end rpm value changes as shown

on the right. Adjust the LED to the setting of your

choice and press the SET button for 2 seconds or

more. The set value is validated and it returns to

select mode. The changed value will be reset if the

power is turned off without saving. Please save

your settings before tunring your unit off (P.20).

15,000rpm

20,000rpm

30,000rpm

40,000rpm

50,000rpm

Caution Please make sure to set the boost end rpm higher than the value of your boost

start rpm. The sudden jump in timing may overload the ESC, therefore it is advised

to start with a much higher boost end rpm and progressively lower timing as you

get comfortable with your gearing.

Commentary

This determines the amount of turbo timing added at full throttle.

⑭

In the select mode with the green+red LED

flashing 4 times, press the SET button for 2

seconds or more to enter the setting mode. Each

time the SET button is pressed once, the LED

pattern changes and the full turbo timing value

changes as shown on the right. Adjust the LED to

the setting of your choice and press the SET

button for 2 seconds or more. The set value is

validated and it returns to select mode. The

changed value will be reset if the power is turned

off without saving. Please save your settings

before tunring your unit off (P.20).

0deg

12deg

20deg

30deg

Important

When using both boost and turbo function at the same time, make sure the total

value of full boost timing and full turbo timing are less than 60°

Commentary

This function limits the output of the motor so that the rpm does not exceed the set

value.

⑮

Boost start rpm (blue flashing 4 times)

Boost end rpm (red flashing 4 times)

Full turbo timing (green+red flashing 4 times)

Rev-Limiter rpm (blu+red+org flashing 4 times)

In the select mode with the blue+red+orange LED

flashing 4 times, press the SET button for 2

seconds or more to enter the setting mode. Each

time the SET button is pressed once, the LED

pattern changes and the rev-limiter rpm value

changes as shown on the right. Adjust the LED to

the setting of your choice and press the SET

button for 2 seconds or more. The set value is

validated and it returns to select mode. The

changed value will be reset if the power is turned

off without saving. Please save your settings

before tunring your unit off (P.20).

OFF

15,000rpm

30,000rpm

50,000rpm

20 21

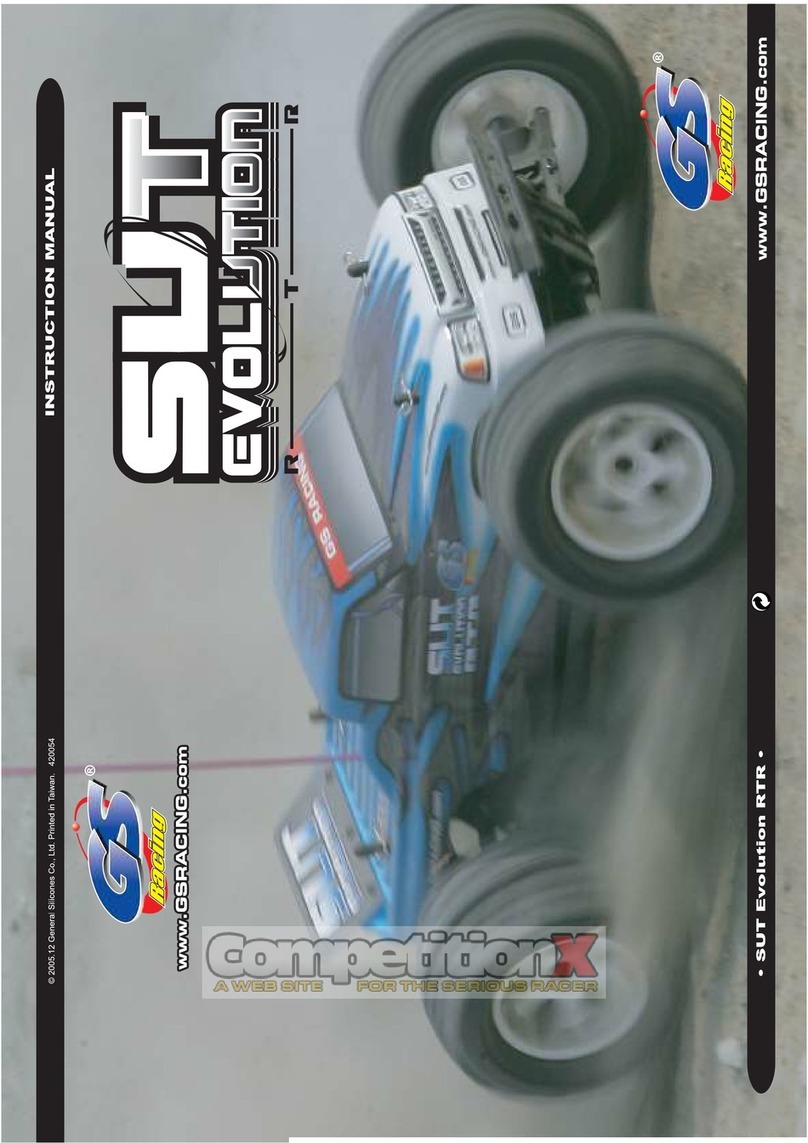

TUNING THE DRIVING EXPERIENCE Error signal during driving (LED flashing pattern)

When shipped from the factory, the unit is preset with the [Drift] program (see the

table above for the setting values of each item). Please change each set of value

according to your preference (For changing method, see P.10 to P.19).

About the factory preset program

In SELECT mode, pressing the SET button 4 times

quickly causes all LEDs to flash, and then automatically

switches to the display that selects the save destination of

the user program. The green LED is the user program ①,

the orange LED is the user program ②. Each time you

press the SET button, the save destination is switched.

After selecting the save destination, press the SET button

for 2 seconds or more to save it and return to the standby

mode.

Switching of BEC output voltage

In standby mode, press and hold the POWER button and

SET button simultaneously for about 2 seconds.

The green LED status changes to OFF or ON, and the BEC

output voltage changes.

Regardless of the setting mode, the BEC output voltage can be switched using

this procedure.

Press the SET button

Quickly 4 times

Saving user program (current value)

Commentary

The saved user programs can be called up by the program load function mentioned

earlier.

press and hold

All LEDs blinking

[LED green is OFF during standby] BEC output voltage 6.0V

[LED green is ON during standby] BEC output voltage 7.4V

When the sensor signal is interrupted or becomes unstable

for some reason, the motor stops with all the LEDs blinking.

When all the LEDs are blinking, no button operation is

accepted, so remove the battery and turn off the power.

Below is a summary of the LED signal pattern that occurs when something

abnormal is detected while driving.

Refer to P.8 to P.9 “Checking standby status” for the LED lighting / flashing

pattern in standby mode.

Motor stops with all LEDs blinking 〜 Sensor error

[Possible cause of signal generation]

・An error has occurred in the motor sensor.

・Sensor cable has poor contact

・The sensor cable is affected by radiation noise from the motor cable and

the sensor signal is disturbed.

[Workaround]

・Replacing the motor sensor

・Replacing the sensor cable

・Install the sensor cable and motor cable as far apart as possible

※Disturbance of the sensor signal may cause abnormal heat generation and

damage to the ESC and motor. Do not bundle the sensor cable with the motor

connection cable. Install them as far apart as possible.

MEMO

C B A + -

Error signal during driving (LED flashing pattern)

When the ESC battery terminal voltage drops to the cut-off

voltage set on P.16, the standby LED lights up and flashes,

and the green LED will be flashed and drive speed is going

to low.

LED green blinks and runs at low speed ~ Low voltage cut-off

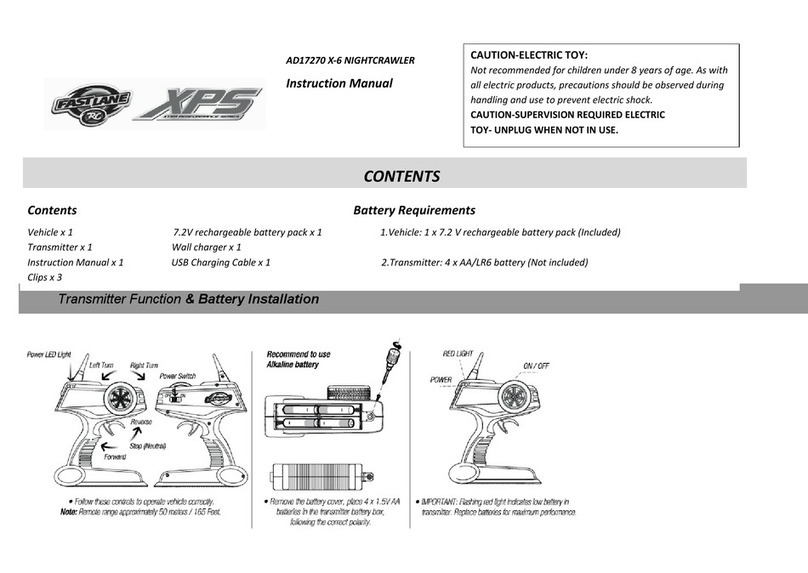

Protection circuit for Battery reverse connection

This product is equipped with a reverse battery protection

circuit, so the ESC circuit is protected if the reverse

connection less than about 10 seconds. (Some heat is

generated when the protection circuit is activated.)

When the battery is connected in reverse, the LED on the

back of the battery terminal will turn red. Remove the

battery immediately and reconnect it correctly.

※The protection circuit is automatically activated

when the battery is reversely connected.

When the ESC overheats due to driving and reaches the

specified temperature, the orange LED blinks in addition to

the standby LED lighting / flashing, and the vehicle runs at

low speed.

In this case, stop driving until the ESC temperature drops.

If the heat protection is activated in a short driving time, the gear ratio setting may be

overloaded. In this case, check each setting status.

LED orange blinks and runs at low speed 〜 Heat protection

22 23

Important

The condition to detect the cut-off voltage is not “Battery voltage” but “ESC battery

terminal voltage”. If the contact condition of the connector to which the battery is

connected and the welded state of the solder bonding the connector are

insufficient, that portion will have a large electrical resistance, and the voltage

detected at the ESC terminal will be far below the battery voltage.

If there is a large difference between the set cut-off voltage and the actual battery

voltage at the time of cut-off operation, the reason may be due to the connector to

which the battery is connected or the solder welding location of the connector.

In such cases, the ESC or motor performance may not be fully achieved. It is

recommended to replace the connector or rework the solder.

Important

This function protects only the ESC circuit board when the battery is reversely

connected. Capacitors connected to ESC such as Chevalier series are not

protected, so be careful when connecting batteries.

Green LED blinking

Orange LED blinking

Alert red LED light

Table of contents

Popular Motorized Toy Car manuals by other brands

INJUSA

INJUSA Porsche 911 Turbo S user manual

Fisher-Price

Fisher-Price X6023 instruction sheet

Team Losi

Team Losi XXX-T Matt Francis Edition owner's manual

Fast Lane

Fast Lane XPS AD17270 X-6 NIGHTCRAWLER instruction manual

Schumacher Racing

Schumacher Racing Eclipse instruction manual

Team Losi

Team Losi LST 3XL-E RTR instruction manual