Adire Audio HE10.1 User manual

HE10.1 Assembly Instructions 1

HE10.1 Assembly Instructions 1

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

HE10.1 Mark II Instructions

Adire Audio

2006 196th Street SW

Suite 102

Lynnwood, WA 98036

425 778 9663

http://www.adireaudio.com

TABLE OF CONTENTS

1. INTRODUCTION................................................................................................................................................2

2. PARTS.....................................................................................................................................................................2

3. NEEDED TOOLS.................................................................................................................................................2

4. CROSSOVER SCHEMATICS.........................................................................................................................3

4.1. TWEETER CROSSOVER............................................................................................................................3

4.2. WOOFER CROSSOVER..............................................................................................................................3

5. CROSSOVER ASSEMBLY...............................................................................................................................4

5.1. THE BASICS OF CROSSOVER ASSEMBLY......................................................................................................4

5.2. STRIP INDUCTOR INSULATION.......................................................................................................................5

5.3. MOUNT INDUCTORS........................................................................................................................................5

5.4. MOUNT CAPACITORS......................................................................................................................................5

5.5. MOUNT RESISTORS..........................................................................................................................................5

5.6. CONNECT COMPONENT LEADS......................................................................................................................5

5.7. BUILD CONNECTIONWIRES...........................................................................................................................6

5.8. TEST, TEST, TEST........................................................................................................................................6

5.9. SECURE COMPONENTS....................................................................................................................................6

5.10. SOLDER JOINTS...........................................................................................................................................6

5.11. SECURE INSIDE CABINETS.........................................................................................................................6

5.12. ENJOY!..........................................................................................................................................................6

6. SYSTEM TROUBLESHOOTING..................................................................................................................7

7. CABINET PLANS................................................................................................................................................8

7.1. CUT LISTS.........................................................................................................................................................8

7.1.1. Panel cuts...............................................................................................................................................8

7.1.2. Hole/baffle cuts.....................................................................................................................................8

7.2. DRAWINGS........................................................................................................................................................9

HE10.1 Assembly Instructions 2

HE10.1 Assembly Instructions 2

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

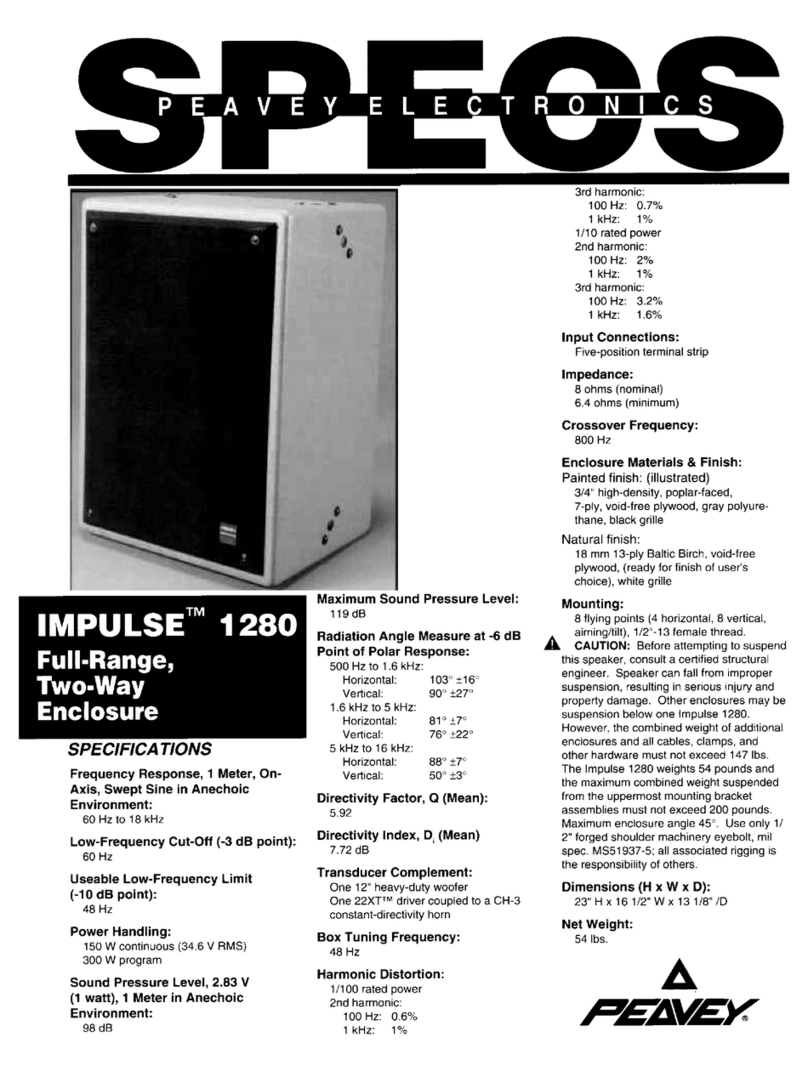

1. Introduction

Welcome to Adire Audio’s HE10.1 Mark II loudspeaker system. The HE10.1 Mark II is a high-

performance high efficiency coaxial driver system, designed for use where high efficiency is required, such

as PA monitors and use with low-power amplifiers (specifically SET amplifiers). It features a 10” paper

cone driver with a coaxially mounted compression driver loaded into a 90°conical constant directivity

horn, which yields an in-room system sensitivity of 95 dB SPL @ 2.83 Vrms. The Mark II model includes

an upgraded compression driver for even quicker decay and flatter response.

2. Parts

Your kit should include the following parts (quantities given are for a pair):

Part Qty Use

3.6 uF 250VDC polypropylene capacitor 4C1011, C1031

12 uF 250VDC polypropylene capacitor 2C2021

10 uF 250VDC polypropylene capacitor 2C2041

6.2 uF 160VDC polypropylene capacitor 2C2061

0.24 mH 20 GA perfect lay air core coil 2L1021

0.62 mH 20 GA perfect lay air core coil 2L2021

1.3 mH 16 GA perfect lay air core coil 4L2031, L2051

2.4 Ohm 10W sandcast resistor 2R1011

20 Ohm 10W sandcast resistor 2R2021

12 ounce polyfill 2Stuffing in the boxes

4”ID by 4.4”L vent 2Vents

BETA 10CX 10” midrange/woofer 2Woofers

ACD1 1” compression driver 2Tweeters

SIC single input cup 2Single pair input cup

14GA/2C 14GA twin conductor cable 10 Internal wiring

0.25” female FAST-ON connector 16 Terminal connectors

21cm long wire tie wrap 28 Crossover assembly

Large T-nut/socket cap screw set 16 Woofer mounting

If any parts are missing, please contact the factory as soon as possible, and we’ll correct the shortage.

3. Needed Tools

You’ll need to supply the following parts and tools to assemble the HE10.1:

-Mounting board (hardboard, plywood, or any other material suitable for crossover mounting)

-Electrical tape

-Masking tape

-Pliers

-Razor blade or sandpaper

-Wire cutters

-Soldering iron

-Solder

HE10.1 Assembly Instructions 3

HE10.1 Assembly Instructions 3

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

4. Crossover Schematics

4.1. TWEETER CROSSOVER

4.2. WOOFER CROSSOVER

NOTE: The resistors shown in series with inductors are representative of the series resistance of the

inductor itself; the only actual resistor is R2021 (20 Ohms) – all other resistors are series resistance.

HE10.1 Assembly Instructions 4

HE10.1 Assembly Instructions 4

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

5. Crossover Assembly

5.1. The Basics of Crossover Assembly

Crossover assembly is one of the most critical aspects of loudspeaker construction. A poorly built

crossover can seriously degrade the sonic performance of a kit. Additionally, poor construction can lead to

early failure of components!

The key to good crossover assembly is to go slow. Take your time. Best to double-check every connection

and step twice before proceeding. Remember, each part of a crossover interfaces with others. Mess up one

connection, and that will ripple through the entire crossover.

We recommend that you start by reading over these instructions a few times prior to actual construction.

This way, you’ll know what comes when, and will have a somewhat “intuitive” feel for the process.

Also, familiarize yourself with the crossover schematic as best as possible! That way, when you’re

hooking parts up, you’ll recognize bad connections before they become permanent. Get a feel for the flow

of the crossover, and your assembly will go MUCH smoother.

That said, let’s get into the basics of crossover assembly…

Crossover assembly is the process of building the electrical network that goes between the amplifier and

the driver(s). As such, it’s VERY similar to other electrical kit assembly. If you’ve soldered parts together

before, and can read a schematic, you’ll have no problems assembling this kit. On the other hand, if you’ve

never soldered, or don’t understand schematics, you should the time to learn some basics of soldering, and

how to read a schematic, or find a friend with some electronics experience, and you’ll be set. We

recommend any of the “Intro to Electronics” books at Radio Shack, or other electronics/hobbyist stores.

HE10.1 Assembly Instructions 5

HE10.1 Assembly Instructions 5

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

5.2. Strip Inductor Insulation

The first thing you’ll need to do is strip all of the varnish insulation off the inductor leads. This is what the

razor blade or sandpaper is for. If you’re using the razor blade, you’ll need to scrape the insulation. Hold

the razor blade perpendicular to the inductor lead, and scrape. Rotate the lead a bit, and scrape. Repeat as

necessary.

For the sandpaper, you’re best bet is to wrap a small piece of paper around the inductor lead and twist.

This will allow you to sand off the insulation in no time!

5.3. Mount Inductors

Reading Inductor Values: All inductors are labeled with their value, such as 1.2 mH. All are 16 gauge

units, so simply pay attention to the value on the inductor label.

Now mount the inductors. All the locations are shown in section 5.2. Note that we’ve labeled two of the

inductors with a ‘V’. This means to stand the inductor up on end (like a standing tire or inner tube).

Pull the leads through the mounting board. Give them a quick bend to hold the inductors down.

Now use the masking tape to temporarily hold the inductors in place. Go ahead and be liberal with it, and

don’t worry about a perfect mount; we’ll replace the tape with the wire ties later.

5.4. Mount Capacitors

Reading Capacitor Values: All capacitors are marked with their nominal capacitance, such as “6.2 uF”.

All capacitors are 250VDC units, so, don’t worry about matching up the voltage rating. Also, note that all

the capacitors you received are non-polar. You don’t have to worry about connecting the capacitor

“backwards”, like you do with polarized capacitors.

Lay out the capacitors on the board. As with the inductors, pull the leads through the mounting board then

tape the capacitors down with the masking tape.

5.5. Mount Resistors

Reading Resistor Values: Resistors are labeled WWSQP10JXRY, where XRYis the resistor value. X

represents the whole ohm value, andYthe fractional ohm value. For example, a 7.5 ohm resistor would be

7R5, while an 11 ohm resistor would be 11R. The “10J” represents the power handling; all resistors are

rated for 10W, so as with the capacitors, don’t worry about searching the kit for different power ratings on

the resistors.

Lastly, put the resistors on the board. Pull the leads through, and tape down the resistors with the masking

tape.

5.6. Connect Component Leads

Using the pliers, twist the component leads together as needed. You should be able to have all the leads

contact each other as needed. No extra wire is necessary.

Once each connection is made, give it a quick wrap in electrical tape, to avoid shorting out during the

testing phase.

HE10.1 Assembly Instructions 6

HE10.1 Assembly Instructions 6

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

5.7. Build Connection Wires

Now we’ll build the connection wires. For this step, you’ll need to use the wire cutters and the supplied

internal cable and FAST-ON connectors.

For each speaker, you’ll need two 12” long pieces and one 24” piece. Use the 12” pieces to connect the

drivers to the crossovers, and the 24” long piece to connect the input cup to the crossovers. Note that the

positive terminal of the tweeter is marked with a red dot.

Now strip ~0.5” of insulation off all ends of the cable. One end of each cable will ultimately be soldered to

the crossover. The other ends we’re going to attach to the

Twist the raw ends of the cable on to the crossover inputs and outputs. Cover in electrical tape (for

protection while testing the crossover).

5.8. TEST, TEST, TEST

Connect the connection wires to the drivers. Now mount the crossovers in the cabinets; lay them down on

any suitable brace, or strap them to the wall of the cabinet with masking or duct tape.

Mount the drivers into the cabinets. Now connect the crossover input wires to the terminal cup. Connect

the terminal cup to your amp, and TURN THE VOLUME ALL THE WAY DOWN.

Start playing some music. Turn the volume up VERY slowly. Put your ear in front of the tweeter, to make

sure no bass is coming from it. Likewise, listen to EACH woofer to make sure no really high frequencies

are coming from them.

SLOWLY increase the volume a bit more. Listen to the soundstage, frequency response, and general

timbre of the speaker. If all sounds OK, then continue on to the next step. Otherwise, see section6for

details on tracking down a potential crossover problem.

5.9. Secure Components

Now comes the fun part: strapping down all the components! Start by removing the crossovers from the

speaker. Then use the supplied wire ties to strap the crossover components tight to the mounting board.

Use one wire tie for each capacitor and resistor. Use two wire ties for the inductors, as they’re pretty

heavy. Go ahead and pull fairly tight; you don’t want the components moving around. Don’t pull so tight

as to crush the capacitors, though – that can damage the components. Just pull the ties tight enough that it

takes a good amount of effort to get the components to move.

5.10. Solder Joints

Unwrap the electrical-taped joints. Solder each joint, and inspect for cold solder joints. Then re-wrap each

joint with electrical tape.

5.11. Secure Inside Cabinets

Mount the crossovers inside the cabinets. Typically a pair of drywall screws are used to hold the crossover

to a brace or side panel. Make sure you do NOT put a screw through a wire, or through the center of an

inductor!

5.12. Enjoy!

We trust this step is self-explanatory…J

HE10.1 Assembly Instructions 7

HE10.1 Assembly Instructions 7

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

6. System Troubleshooting

So you encountered a few problems in testing the crossover. Here are some common tips to check over:

1. Double-check all component values. The resistors all look the same, and can only be differentiated by

the markings! Likewise, check the capacitors and inductors.

2. Make sure the polarity of the drivers is observed. Reverse connections will create a deep suck-out in

the midrange.

3. Triple-check all component values.

4. Make sure all joints are electrically isolated from each other.

5. Make sure the drivers are wired to the outputs of the crossover

6. Quadruple-check all component values.

7. Contact us! We try to answer all questions within one business day. You can reach us at

HE10.1 Assembly Instructions 8

HE10.1 Assembly Instructions 8

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

7. Cabinet Plans

The vented Cabinet HE10.1 is a net 29 liters, stuffed with 12 ounces of polyfill. It is tuned to 60 Hz with a

4” OD by 4.5”L vent. This alignment is designed to provide bass extension to 65 Hz anechoic and will

yield typical in-room extension into the 50 Hz range.

Maximum in-room SPL - driven with 10W - will be in excess of 100 dB SPL (at 1 meter) from 45 Hz and

up; driven with 100W, the system is capable of more than 110 dB SPL in-room.

7.1. Cut Lists

The following cut lists are for one cabinet only; adjust the cut count according to the number if

loudspeakers built (double for two loudspeakers, triple for 3, etc.).

7.1.1. Panel cuts

QTY SIZE USE

412” x 16” Sides, baffle and back

212” x 13.5” Top and bottom

7.1.2. Hole/baffle cuts

QTY SIZE USE

19 1/16” diameter Driver cutout; in baffle

14” diameter Vent cutout; in baffle

13” diameter Single Input Cup cutout; in back

HE10.1 Assembly Instructions 9

HE10.1 Assembly Instructions 9

Copyright 2001-2004 Adire Audio. All Rights Reserved. This design is for private, non-retail/non-

commercial use only. Any use of this design for profit, in any way shape or form, without the express

written consent of Adire Audio is strictly prohibited.

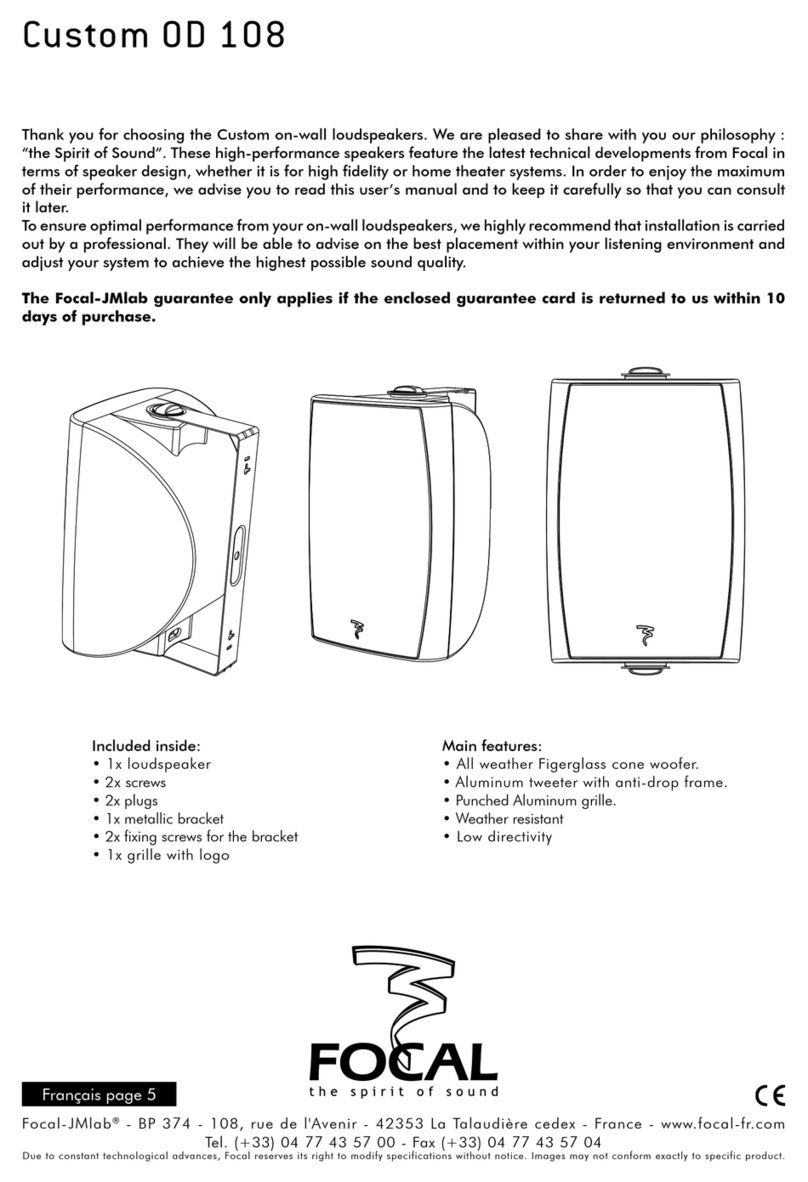

7.2. Drawings

TITLE

DWG NOSIZE REV

SHEETSCALE

CAGE CODE

A

HE10.1 CABINET

1200-0121 -

N/A DRAWN BY DCWN/A 1 of 1

Black solid lines are viewable edges

Grey lines are normally hidden from view

Red lines are for dimensions

Blue lines are for construction/reference

Green lines are text/labels

LEGEND:

Copyright (C) 2001 Adire Audio.

All Rights Reserved. Commercial use or

reproduction of this design without the

express written consent of Adire Audio

is strictly prohibited, and punishable by law.

CONSTRUCTION NOTES

6 in 6 in

12 in

7 in7.5 in3 in 17.5 in

13.5 in

3.75 in4.5 in 9.25 in

3.75 in3.75 in 3 in

3.75 in Ø9.06 in

12 in

16 in

DIMENSIONS: 12"W x 13.5"D x 17.5"H (external)

CONSTRUCTED OF 3/4" THICK STOCK (mdf or better)

DRIVER IS NOT RABBETED

INPUT CUP MOUNTED IN REAR

12 OUNCES STUFFING USED

VENT IS 4" OD BY 4.5" LONG

Ø4.00

4.50

Table of contents