Index Page:

Part 2: Installation Instructions 745-34 Speedpocket

1. Scope of delivery .............................................. 3

2. General notes ................................................ 3

3. Installing the sewing unit

3.1 Transport.................................................... 4

3.2 Removingthesecuringdevices...................................... 5

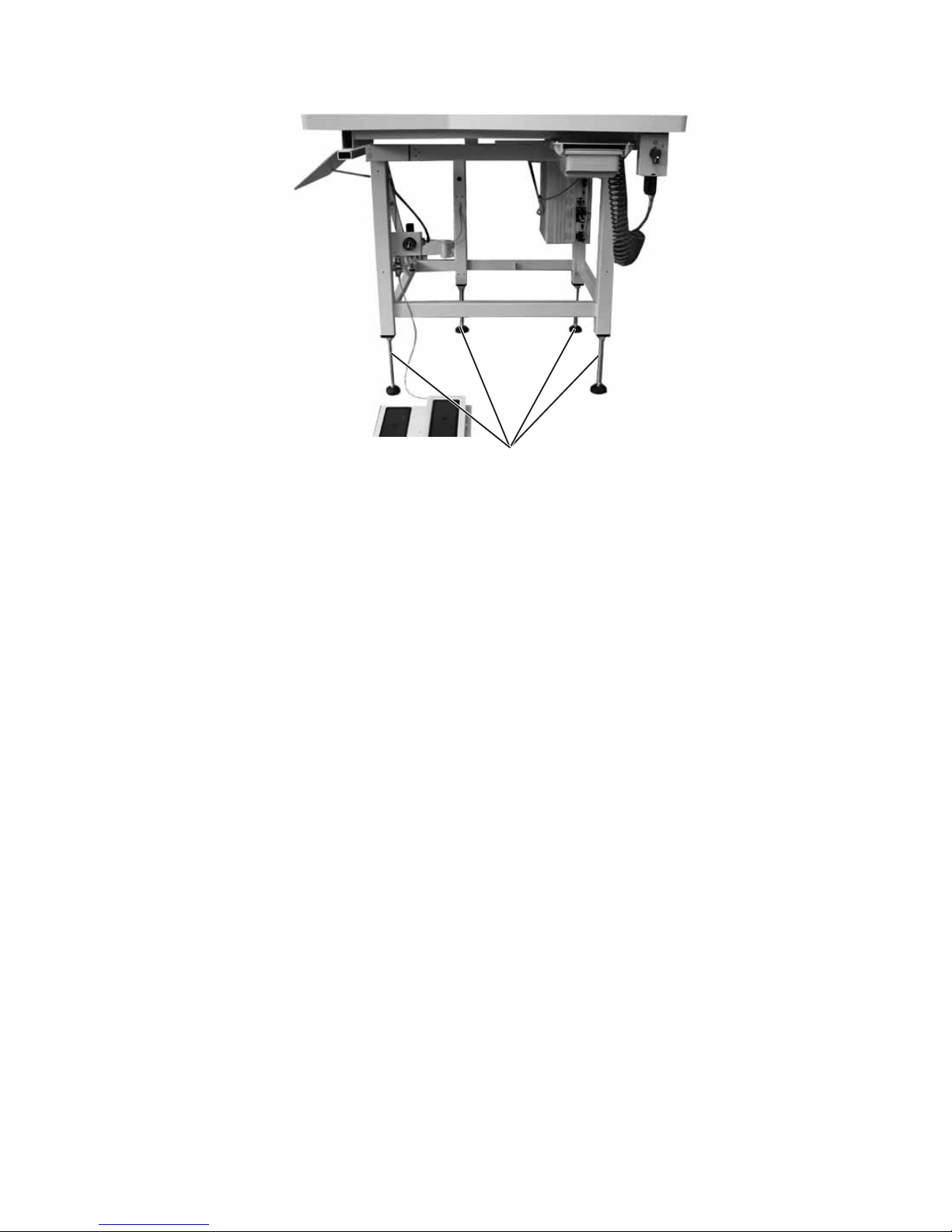

3.3 Settingtheworkingheight ......................................... 6

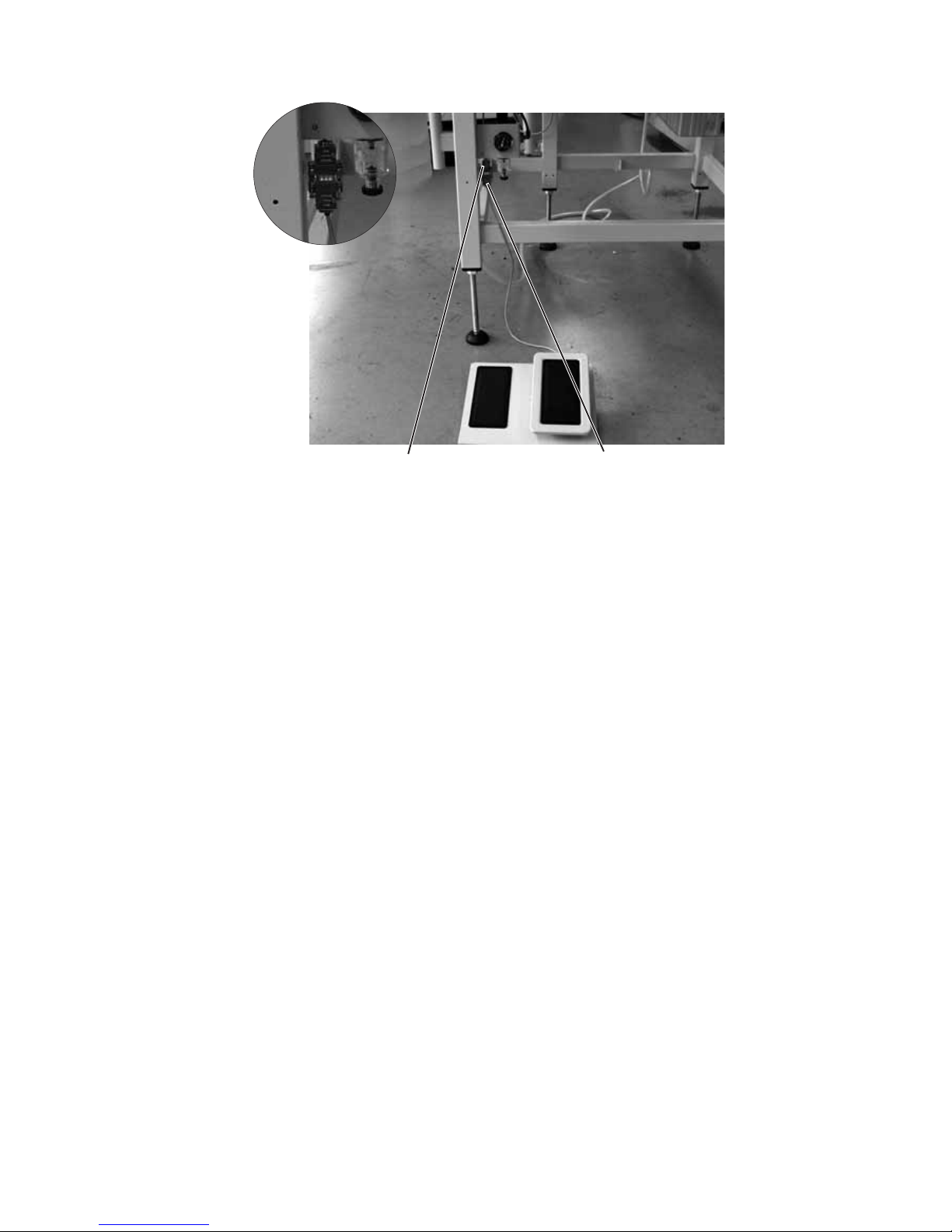

3.4 Connecting the foot pedal.......................................... 7

4. Attaching the machine parts removed for shipping

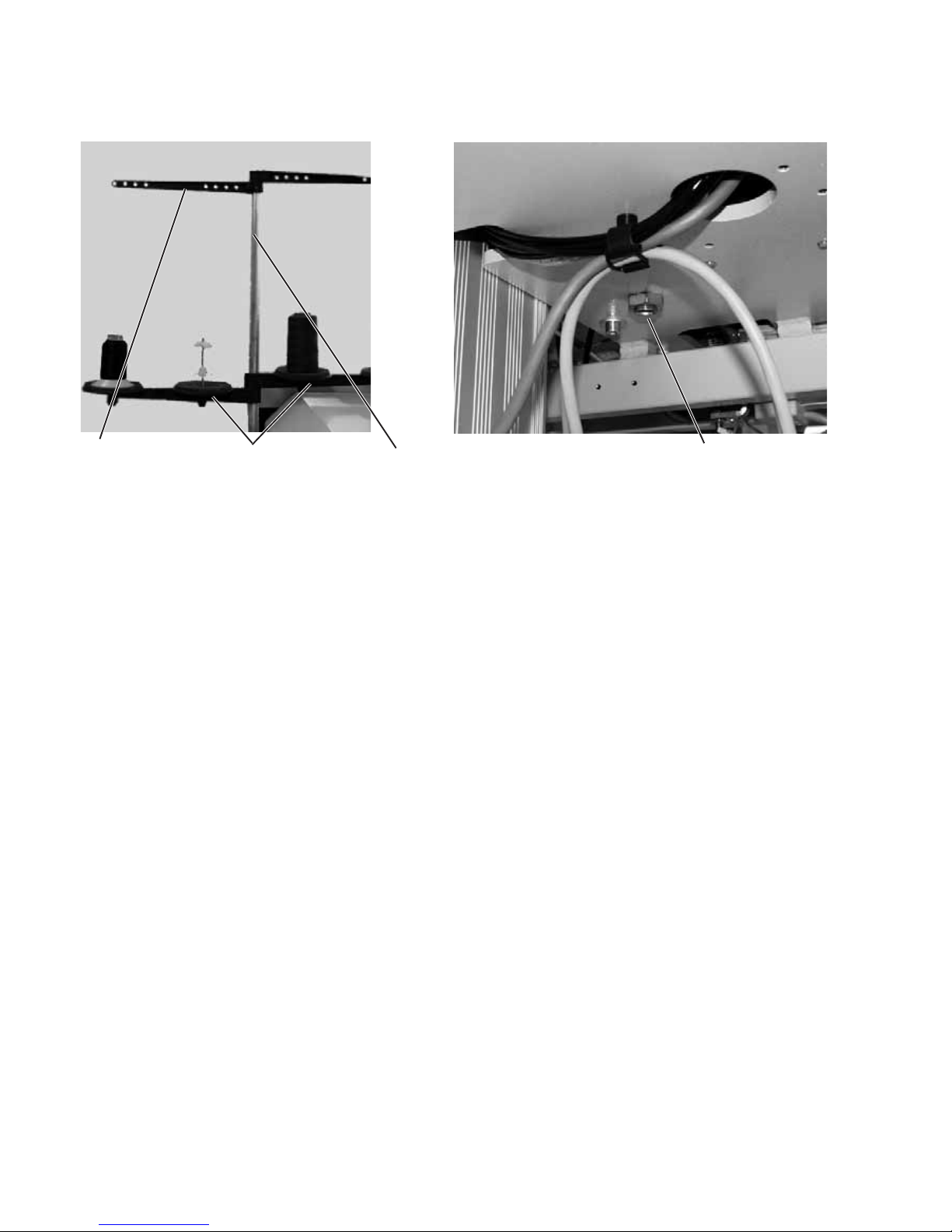

4.1 Threadreelholder.............................................. 8

4.2 Fastening the control panel and the bobbin winder........................... 9

4.3 Pincer stacker (optional equipment) ................................... 10

5. Electrical connection

5.1 Connecting the control panel DAC III C ................................. 11

5.2 Connecting the external bobbin winder .................................. 11

5.3 Making the mains connection ....................................... 11

5.4 Directionofrotationofthesewingmotor................................. 12

6. Pneumatic connection ........................................... 13

7. Oil lubrication ................................................ 14

8. Commissioning ............................................... 15

9. Software installation

9.1 General..................................................... 15

9.2 Loading the program ............................................. 16

9.3 Dongle-Update via Internet ......................................... 17