Adrian Steel SA-20 User manual

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE

Assembly/Installation Instructions and Owners Manual

SA-20

STOWALL, DOUBLE

SHOWING SINGLE AND STACKED CONFIGURATION

COVER

TYPICAL STACKED STOWALL

INSTALLATION

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 2

CAUTION

THE USE AIR IMPACT TOOLS CAN

OVER-TORQUE FASTENERS AND

CAUSE FASTENER FAILURE!

CAUTION

ALL INSTALLATION HOLES SHOULD BE SEALED

WITH SILICON OR BUTYL SEALANT TO PREVENT

EXHAUST FUMES FROM ENTERING THE VEHICLE!

- PRECAUTIONS -

DANGER

INSPECT FOR FUEL TANK, FUEL LINES, BRAKE LINES, HIGH

VOLTAGE BATTERIES AND ELECTRICAL LINES PRIOR TO

DRILLINGTO AVOID DAMAGING CRITICAL VEHICLE SYSTEMS

OR INJURY TO INSTALLER DURING INSTALLATION PROCESS!

CAUTION

TO AVOID DAMAGING THE VEHICLE ALWAYS

USE DRILL STOPS WHEN DRILLING ANY IN-

STALLATION HOLES!

1. SUBSTITUTING ADRIAN STEEL SPECIFIED FASTENERS FOR ASSEMBLY AND/OR INSTALLATION

WILL VOID YOUR PRODUCT WARRANTY.

2. ALL HOLES DRILLED INTO VEHICLE SHOULD HAVE THE RAW METAL EDGES SEALED WITH A SELF

-ETCHING PRIMER TO RESIST CORROSION AND POTENTIAL FASTENER POINT FAILURE.

3. ALL FASTENERS USED IN THE INSTALLATION OF THIS PRODUCT SHOULD BE TIGHTENED TO THE

TORQUE(S) SPECIFIED IN THESE INSTRUCTIONS.

4. THESE INSTRUCTIONS SHOULD BE KEPT WITH THE VEHICLE.

- IMPORTANT WARRANTY REQUIREMENTS -

THE BASIC TOOLS NEEDED FOR MOST INSTALLATIONS

DRILL DRILL BIT WITH

STOP

RATCHET, SOCKETS

AND/OR WRENCHES SCREWDRIVERS MEASURING TAPE

ADDITIONAL TOOLS MAY BE NEEDED FOR THIS INSTALLATION AND THEY WILL BE IDENTIFIED IN THE STEPS THAT FOLLOW.

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 3

Installation and/or Assembly Fasteners

BAG00012-0

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 4

Installation and/or Assembly Fasteners

BAG64491

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 5

VIEW FROM TOP SIDE OUTSIDE CURBSIDE DOOR

BRACKET OREINTATION

Instructions for Step 01

Add the drawer floor mounting brackets

FAS0759 (8) 5/16-18 U-NUT

FAS0438 (8) 5/16-18 SCREW

15616-0—MTG BRKT (4)

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 6

Instructions for Step 02

LOCATE AND SET PLUSNUTS

Place your Stow-all in desired position in vehicle (ref: PDS documenta-

tion). Mark the floor through slots in the Drawer Floor Mount Brackets in prep-

aration for installing the 5/16-18UNC plusnuts. Remove Stow-all from vehicle

and set aside at this time.

NOTE: Before drilling through holes for plusnut installation inspect

for electrical wiring, gas tank location, and/or control lines. Use drill bit

with a stop collar as outlined in first part of this instruction.

Once plusnuts have been installed, reposition Stow-all and align slots in

the Drawer Floor Mount Brackets. Secure in place with the fasteners listed

above and tighten to the recommended torque of 17 ft-lbs +/- 2 ft-lbs.

FAS0091—(8) 5/16-18 PLUSNUT

FAS0091—(8) FLAT WASHER

FAS0098—(8) LOCK WASHER

FAS0092—(8) BOLT X 1.5” LG

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 7

Instructions for Step 03

STACKED STOWALLS—ADD FLOOR MOUNTING BRACKETS USING STEP 1 AS YOUR GUIDE

Place your Upper Stow-all on top of

the previously installed Stow-all as shown in detail views below. Mark the (4)

outer corner floor through slots in the Drawer Floor Mount Brackets in prepa-

ration for installing the 5/16-18UNC plusnuts into the lower Stow-all. Remove

the upper Stow-all from vehicle and set aside at this time.

NOTE: After drilling through the outer wrapper of the lower Stowall,

continue drilling through the inner Rail Channels spot welded to the

upper interior surface of the lower Stow-all wrapper. This will allow

clearance for the plusnut body required for proper seating of the

plusnuts.

Once plusnuts have been installed in the lower Stow-all, reposition upper Stow-all and align slots in

the Drawer Floor Mount Brackets. Secure in place with the fasteners listed above and tighten to

the recommended torque of 17 ft-lbs +/- 2 ft-lbs.

FAS0091—(4) 5/16-18 PLUSNUT

FAS0086—(4) FLAT WASHER

FAS0098—(4) LOCK WASHER

FAS0092—(4) BOLT X 1.5” LG

USE STEP 1 AS YOUR GUIDE

FAS0759 (8) 5/16-18 U-NUT

FAS0092—(8) BOLT X 1.5” LG

FAS0098—(8) LOCK WASHER

FAS0091—(8) FLAT WASHER

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 8

ATTENTION!

It is advised that “all fasteners” that assemble and install your

Stow-all is “checked for tightness” at (2) weeks operation and then

rechecked again at (6) weeks of operation.

Assembly fasteners could loosen due to vibration through your ve-

hicle while on the road or in and out of construction sites.

This is a preventative maintenance step to ensure your Stow-all

give you a long service life.

ATTENTION INSTALLERS! Any seat belt components including not limited to buck-

les and retractors that are removed during installation must be reconnected

(electrically) and secured in the vehicle upon completion. Failure to do so will result

in warning lamps and possible disablement of the air bag system.

DOUBLE-CHECK ALL FASTENER LOCATIONS TO BE

SURE THAT ALL FASTENERS ARE TIGHTENED TO

SPECIFICATIONS!

YOUR INSTALLATION IS NOW COMPLETE! STOW THIS COPY

IN THE VEHICLE FOR FUTURE REFERANCE!

NOTE!

For Stow-all Drawer units that Will Not Open

See the next two sections for Field Fix Options

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 9

STOW-ALL DIVIDER WILL NOT OPEN FILELD FIX OPTION #1

“PUSH-BUTTON CAM (29146-0) TO LATCH BOLT ASM LEVER ARM

( 34102-0) HDW RE-ALIGNMENT”

Figure 1

Latch Bolt Push-button

Figure 2

Figure 3 Figure 4

Figure 5 Figure 6

Figure 7

Figure 1

Nominal push-button cam to latch bolt assembly lever arm configuration for proper opening

and closing of your stow-all.

Figure 2

Shows the push-button cam in the normal “drawer locked position”.

Figure 3

Shows misalignment of hardware, stow-all drawer will not open when pushbutton is depressed.

Figure 4

Realignment begins by inserting the key into the push-button and fully depressing the push-

button mechanism.

Figure 5

While push-button is fully depressed, rotate key 90 deg. Clockwise.

Figure 6

Remove force holding the push-button fully depressed and allow to return to normal position.

Figure 7

Rotate key 90 deg. Counter-Clockwise. This should allow the push-button cam to engage be

hind the latch bolt asm lever arm. When key is returned to the original starting position, the

push-button latch cam and latch bolt lever arm should be as shown in Figure 1. Normal stow-

all drawer operation should be possible at this time. If not, repeat procedure one more time. If

after the second attempt fails, proceed to next section (Field Fix Option #2).

ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 63405 Revision Level: BECN Release: 24871

Assembly/Installation Instructions and Owners Manual

PAGE 10

STOW-ALL DIVIDER WILL NOT OPEN FILELD FIX OPTION #2

“Manual depressing the Latch Bolt through access hole in stow-all

outer housing” (similar to 29529-0)

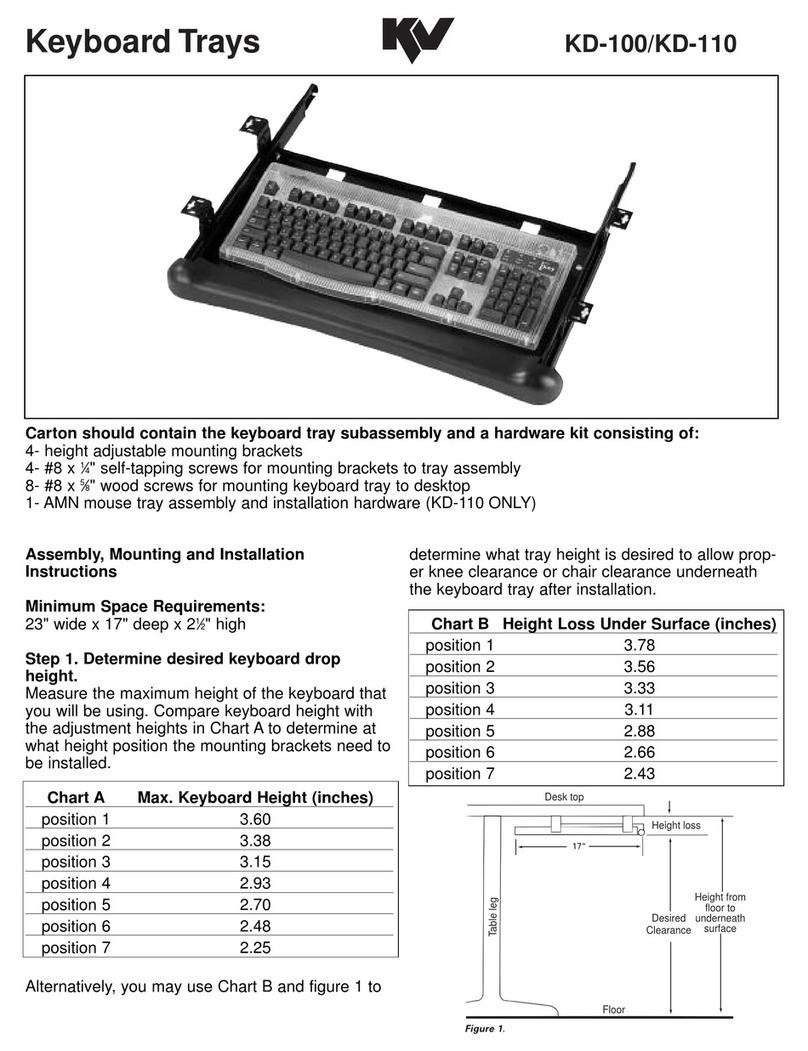

Measure (2) centerlines on top of your Stowall per dimensions shown below

and mark centerline crossing point with a permanent marker. Drill a 0.375” diam-

eter hole through the top surface of the stow-all outer housing.

Stow-all

Drawer

Slam

Stow-all

Square Latch

Bolt

CAP PLUG (21407-0)

DIMENSION “A”

SA-10 / SAJ-10 = 5”

SA-20 / SAJ-20 = 10”

SA-30 / SAJ-30 = 14.812”