Advance Appliances EG6 User manual

INSTALLATION AND

USER GUIDE

6, 9 & 12kW

ELECTRIC BOILER

PLEASE RETAIN FOR REFERENCE

ISSUE 2

1220

INTRODUCTION

Please read and understand these instructions prior to installation and commissioning.

These instructions should be left with the customer once the unit is commissioned and

running satisfactorily.

The boiler is available in three output versions, 6kW, 9kW and 12kW and can be specified

for standard central heating circuits with an 80 degree flow or underfloor circuits with a

60 degree flow.

The unit is intended for domestic central heating systems and can be connected to single

phase domestic electricity supplies, please see the Technical Specification for more

information.

Advance eGlow boilers are compact and quiet in operation, require no fluing and can be

located anywhere within the property. A pump is fitted in the eGlow making installation

very straight forward.The pump has an over run facility and there is an automatic by pass

fitted. The eGlow should be installed as a sealed system boiler. A sealed system kit is

available for easy installation with an 8 litre expansion vessel.This can be sited anywhere in

the circuit giving the installer flexibility.

The eGlow is controlled externally with a programmer and room thermostat arrangement

with voltage free switching (not supplied).There is a connector in the boiler casing for

this purpose. Standard central heating programmers and room thermostats can be used.

The boiler is fully modulating and soft switched on start up.This enhances the life of the

heat exchangers as well as reducing the loading on domestic electricity. A single LED

highlights running and fault modes.

A flow switch prevents the boiler running in dry conditions and there are two levels of

overheat protection.

The Advance eGlow boiler is guaranteed for two years against faulty manufacture, subject

to terms and conditions, and a technical help desk service is offered during office hours.

The unit requires no maintenance in ordinary operating conditions. Stainless steel heat

exchangers are fitted for long life and reliability.

2

PRODUCT CODES

CODE TYPE SIZE WEIGHT FULL KG

EG6 6KW CENTRAL HEATING BOILER 510h x 400w x 167d 15KG

EG6-U 6KW UNDERFLOOR HEATING BOILER 510h x 400w x 167d 15KG

EG9 9KW CENTRAL HEATING BOILER 510h x 400w x 167d 15KG

EG9-U 9KW UNDERFLOOR HEATING BOILER 510h x 400w x 167d 15KG

EG12 9KW CENTRAL HEATING BOILER 510h x 400w x 167d 15KG

EG12-U 9KW UNDERFLOOR HEATING BOILER 510h x 400w x 167d 15KG

3

POWER RATING 6kW 9kW 12kW

FLOW AND RETURN 22MM BOTTOM ENTRY 22MM BOTTOM ENTRY 22MM BOTTOM ENTRY

ELECTRICAL SUPPLY SP 240 VAC 50hz 30A SP 240 VAC 50hz 40A SP 240 VAC 50hz 50A

PROTECTION 32 AMPS 45 AMPS 63 AMPS

PUMP 15/50 15/50 15/50

PUMP SETTING AUTO AUTO AUTO

OUTPUT TEMP (MAX) 80°C 80°C 80°C

UNDERFLOOR UNITS

OUTPUT TEMP (MAX) 60°C 60°C 60°C

HIGH LIMIT TEMP

CONTROL 2 STAGE 90°/95°C 90°/95°C 90°/95°C

NOM HEAT OUTPUT 20,000 BTU 30,000 BTU 40,000 BTU

AUTO AIR VENT FITTED FITTED FITTED

FLOW SWITCH FITTED FITTED FITTED

AUTO BY PASS FITTED FITTED FITTED

MIN PRESSURE COLD FILL 0.6 BAR 0.6 BAR 0.6 BAR

MAX PRESSURE HOT 3 BAR 3 BAR 3 BAR

HEAT EXCHANGERS STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL

3Kw PODS x 2 3Kw PODS x 3 3Kw PODS x 4

IPX RATING 1 1 1

OPTIONAL SEALED SYSTEM KIT AA 0400

TECHNICAL SPECIFICATIONS

KIT INCLUDES:

COLD FILL HOUSE WITH DOUBLE ISOLATION

3 BAR PRESSURE RELIEF VALVE 1/2”

EXPANSION VESSEL 8 LITRES

PRESSURE GAUGE

4

MOUNTING THE BOILER

Please ensure that all current local by laws and national building regulations are consulted

prior to installation along with current codes of practice.

The unit must be mounted in a vertical position accessible for servicing. Effectively this

means allowing front facing access to remove the outer door casing to access the eGlow.

Please check load bearing and ensure correct fixing is used.There are four holes in the

casing for this purpose.

The 22mm flow and return pipes are at the bottom of the boiler, and should be connected

using compression fittings. Do not solder connections within 600mm of the boiler. Flow is

the left pipe, marked red, return is the right pipe, marked blue.We suggest you install the

means to isolate and drain the boiler independently.

SAFETY

No special precautions are required, however due care should be taken in installing,

commissioning and servicing to prevent electric shock or water leakage.

INSTALLATION

Only persons competent to do so may fit this appliance.

Calculate space heating requirements and allow an extra 3kW for hot water provision if an

indirect cylinder is to be installed. Advance recommend an Advance Appliances stainless

steel pre-plumbed unvented cylinder and would always advise customers to consider

renewable energy such as solar to contribute toward the generation of domestic hot water.

Using a direct (electric) Advance Appliances unvented cylinder will reduce installation cost.

Controls such as room thermostats and programmers or timers must be installed to comply

with current Part L requirements.

Ensure that the correct appliance is fitted, for example by sizing to meet demand and by

choosing underfloor or central heating models.

The system must be properly flushed and have inhibitor added according to manufacturer’s

specifications.Always choose a recognised brand and inhibit to the correct dilution.Always

flush out completely as any chlorine based chemicals can attack stainless steel components.

After drain down, even a partial one, inhibitor levels must be topped up.

Y,W or S plan systems may be used with the eGlow.

Primary pipe work in enclosed spaces such as boiler cupboards should be insulated. Fit

isolation valves.

It is important to have a locked open radiator or open towel rail in the system.

Thermostatic radiator valves are recommended. Use a twin pipe 22mm system with 15mm

tee off to radiators.

5

INSTALLATION SCHEMATICS

The eGlow boiler can only be configured into a sealed system.A sealed system kit can be

purchased from Advance Appliances to make the job simple.An 8 litre expansion vessel is

supplied with each kit but it should be noted that systems with high water content may

require larger vessels. All heating systems must be isolated from the mains water supply

after the system is filled.

eGlow Boiler

Guage

Filling Loop

3 Bar Expansion Valve

RETURN

FLOW

Expansion

Vessel

SEALED SYSTEM

Sealed System Kits are available from

Advance Appliances and can be sited

anywhere in the open pipework of

the system

ELECTRICAL CONNECTIONS

THIS APPLIANCE MUST BE EARTHED

The appropriate current regulations and best practices must always be followed. Installation

must be carried out by a competent and qualified tradesman. Use off peak supplies where

possible to reduce running costs.

Check the incoming supply meets the minimum requirements of the appliance and utilise a

double pole RCD capable of breaking the full current load. Remember that the full house

loading must be taken into consideration when calculating mains demand. Refer to IEE

regulations for wiring size to the appliance. The mains feed goes directly to the terminal

block identified on the schematic (on page 8) and the boiler itself. The earth must be

connected to the marked point.

Standard switching is maintained through the controls, zero voltage switching is used and a

separate power supply for programmer and room thermostat (if digital) should be used. In

some cases this may be a battery or a mains charger with rechargeable cells in the

programmer.This control circuit is identified on the schematic (on page 8) and will switch

the boiler internally.

In the case of a combined hot water and heating system a Y plan or similar can be used

with a three port motorised valve, in which case a separate mains supply will be required

to operate the valve which will be switched via a suitable programmer NOT the boiler PCB.

Use a relay if any voltage is present.

Always consult manufacturer’s requirements and recommendations for controls,the above

advice is of a general nature only.

6

ELECTRICAL CONNECTIONS continued

Check after installation

•Polarity

•Short circuit

•Earth continuity

•Resistance to earth

•Visual check for stray wiring strands etc

•Mechanical check for integrity of connections

Do not switch on until the unit is full of water and air has been purged from the system.

IMPORTANT

The switching in the boiler is zero voltage and cannot be used for mains switching e.g. three

port valves.

We recommend hot water is provided by an independent electric/solar cylinder for

optimum efficiency.

COMMISSIONING

Fill the system by opening isolating valves to the feed and expansion tank or to the filling

loop of a sealed system. Charge sealed systems from 0.75 bar to 1 bar.

When the system is full, and has been thoroughly checked for leaks it should be flushed

out to remove any debris.

Refill, add system cleanser and switch on the boiler.

The boiler controls are fully automatic.The LED will turn green showing that the boiler is

powered up and awaiting demand.When heating demand is on (set the programmer and

room thermostat to call for demand) the pump will be energised for 5 seconds in order

for the flow switch to sense flow in the boiler.If it does not sense flow the boiler will switch

off, the LED will show red (continuously) indicating that the circuit contains air (no flow).

Check that all air is purged and try again. The boiler can be switched back on again by

turning the programmer/room thermostat off and on. It is usual for this process to take a

little time in all heating circuits.

TIP:

Run the boiler with pods disconnected until air is purged.You may need to increase the

pump speed to do this.

NEVER link the flow switch out – it is dangerous and will damage the heater pods.This

action will void guarantees.

Allow the boiler to run for 30 minutes to ensure that it is operating correctly and flush

again.

Refill the system adding inhibitor following manufacturer’s instructions and switch on.

7

USER INSTRUCTIONS

Set the programmer to match your own preferences for heating periods. The room

thermostat should be set at a comfort level, usually 20°C.The room thermostat should be

in a room where the radiator is locked on e.g. a hallway, study etc rather that a living room

or bedroom.The boiler is automatic and should give a trouble free life.

The green LED means that there is power to the boiler; it doesn’t mean that the boiler is

actually heating the system. It does this when there is demand for heating through the

programmer and room thermostat.

If there is insufficient water in the system the red LED will be on continuously. Switch the

room thermostat off and on (making sure that the programmer is on) to start the boiler

up again, air may be present in the system. If the fault persists the system may need

recharging – consult your installer.

The case can be kept clean with a damp cloth.

FAILURE

The LED may flash red, indicating overheat.The unit is protected by the PCB controller in

addition to a thermomechanical device.The appliance will reset itself when it cools. If the

overheat recurs please ensure that the connection from the thermistor (on page 8) to the

PCB is soundly made. Check circulation is free in your heating system. A continuous red

LED relates to a no flow condition and air must be purged from the heating circuit or low

pressure, please charge system. Consult problem solving on page 9 if failure persists.

PROTECTION

In situations where this appliance may be subject to temperatures below 5°C (e.g. holiday

lets not occupied in winter etc) a frost thermostat can be linked to the control circuit.The

unit should always be installed in the main envelope of the property, never outside.

The eGlow can be safely installed in most situations, however, excessive moisture or

temperature extremes should be avoided.

PART NUMBERS

3Kw HEATER PODS AA0401

PCB ASSEMBLY AA0402

FLOW SWITCH AA0403

AUTO AIR VENT AA0404

AUTO BY PASS AA0405

THERMISTOR AA0406

PUMP AA0407

CONTACTOR AA0408

HIGH LIMIT THERMOSTAT AA0409

8

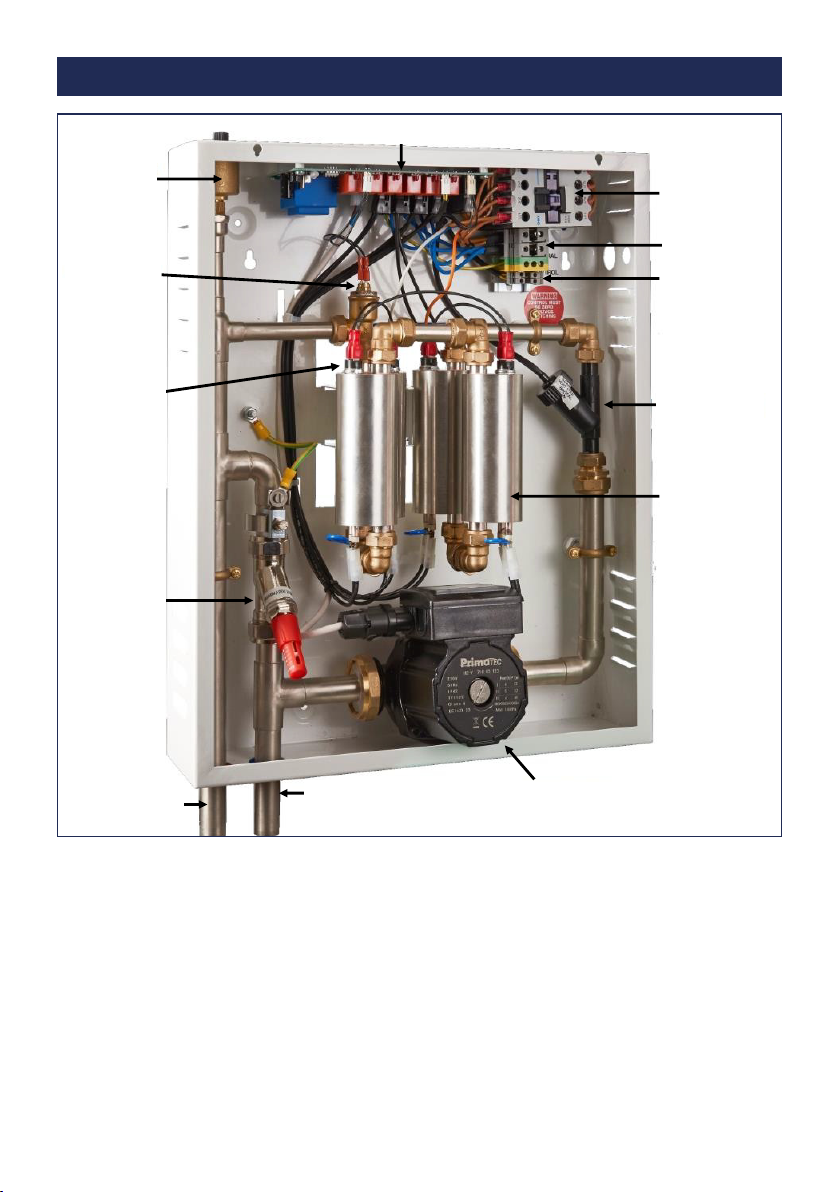

SCHEMATIC

AUTO AIR

VENT

HIGH LIMIT

THERMOSTATS

THERMISTER

RETURN

CONTACTOR

MAINS

FLOW SWITCH

3 KW PODS

A RATED PUMP

FLOW

AUTO BYPASS

CONTROL

PCB

EGLOW PROBLEM SOLVING

9

Note: Main fault modes LED7 Red Cont – Flow Switch

Red Flashing – overheat Green – All ok

Check voltage input at the terminal is between 207v-

245v. Note voltage during commissioning should be

checked when the pods are acve to ensure the voltage

does not go below the minimum level.

Yes

No

Check voltage input R/H

contactor

Yes

No

Go back to source and

check wiring

Faulty wires from block to

contactor

Check ZERO voltage demand and

switch on. Contactor should

switch on

Yes

No

Check the wires from the

demand terminal to the board. If

ok replace contactor

LED 6 lit on PCB

Yes

No

Check fuse 3.15A fast

acng 20 mm

Check for 12v D.C as below

Yes

No

Replace board

EGLOW PROBLEM SOLVING continued

10

Check connuity on

buon stat(s) on pods

Yes

No

Replace buon stat(s)

Is the pump running?

Yes

No

Check voltage to pump

No

Power

Power

Replace

board

Replace

pump

Test flow switch with the pump

running, there should be

connuity

Yes

No

Ensure system is fully purged

of air. If yes, replace flow

switch

Disconnect all pods. Turn on the boiler. Check

each of the pod leads in pairs for power – note

that the pods come on in sequences, not all at

once

Yes

No

Replace board

2

Disconnect all pods, check for connuity

across terminals, check resistances are 18-21Ω

and check for earth leakages between the pod

terminal and pod case

Yes

No

Replace pod

EGLOW PROBLEM SOLVING continued

11

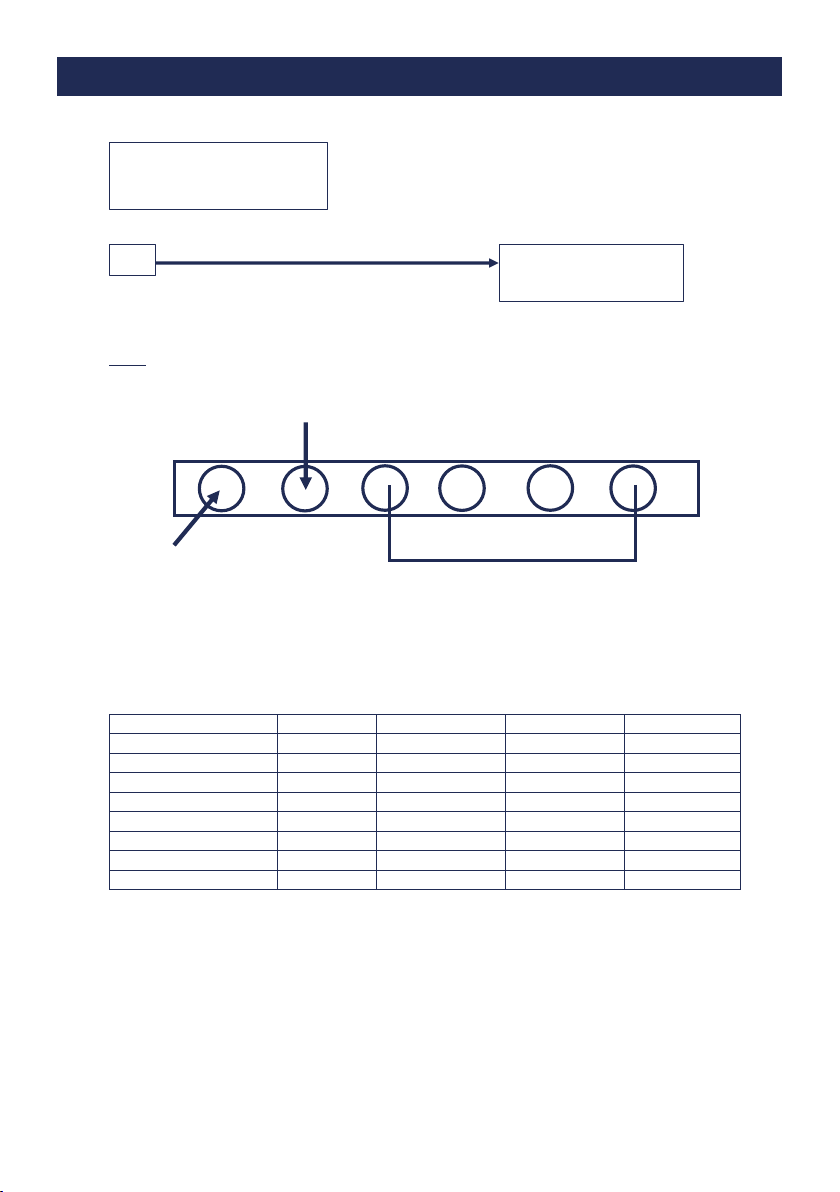

Notes

LED layout

Diagram

X = Any posion

TO CHECK INDIVIDUAL PODS MAKE SURE THERE IS CONTINUITY ACROSS THE TERMINALS AND

THAT THE RESISTANCE IS 21 OHMS

Mode

SW1

SW2

SW3

SW4

Central heang

Off

X

X

X

Under floor

On

X

X

X

3KW

X

Off

Off

X

6KW

X

Off

On

X

9KW

X

On

Off

X

12KW

X

On

On

X

Enable main contactor

X

X

X

On

Disable main contactor

X

X

X

Off

Connect each pod in turn.

Does any one pod, when

connected, turn off the boiler?

Yes

Replace pod

3

Green: ON

Red: off but board powered

Fault: Red Cont= Flow

Red Flash= Overheat

Pump

Pods 1 to 4

12

ADVANCE APPLIANCES GUARANTEE

The eGlow has been manufactured and tested to a high specification and should give years

of trouble free life. If it should go wrong you will be covered for a period of two years from

the date of installation provided that

•You keep proof of purchase/installation date

•Warranty is registered on Advance Appliances Website

•It is installed correctly and the benchmark paperwork is completed

•It is used for its intended purpose

•It is operated properly

•It has not been tampered with or altered in any other way (for example removing the

caps on flow switches)

The foregoing does not affect your statutory rights.

UNIT 4 COPPICE SIDE IND EST BROWNHILLS

For Terms and Conditions go to www.advanceappliances.co.uk

WALSALL WS8 7EX TEL 01543 377723

This manual suits for next models

5

Table of contents

Other Advance Appliances Boiler manuals

Popular Boiler manuals by other brands

Slant/Fin

Slant/Fin Q3-4 Supplemental instructions

Lochinvar

Lochinvar SYNC SB 1000 instructions

Lamborghini Caloreclima

Lamborghini Caloreclima DORA 260 HT User and installation manual

PeerlessBoilers

PeerlessBoilers LC Series Installation, operation & maintenance manual

QHT

QHT BIASI 3 WOOD instructions

ECR International

ECR International Olsen OLSSV-050 Installation, operation & maintenance manual