Aemulus AMOEBA 4200 Series User manual

Aemulus

DM482e

User Manual

Version 1.2, 10-2013

AEMULUS 1

Table of Contents

TABLE OF CONTENTS .............................................................................................................................. 1

SAFETY PRECAUTIONS............................................................................................................................ 2

A. GENERAL INFORMATION ................................................................................................................ 2

B. IDENTIFICATION AND DISCOURAGEMENT OF HAZARDOUS APPLICATIONS .................................................. 3

C. IDENTIFICATION OF AUTHORIZED PERSONNEL .................................................................................... 4

SECTION 1: QUICK START ........................................................................................................................ 6

1.1 PRODUCT START-UP CONFIGURATION..................................................................................................... 6

1.2 PRODUCT SOFTWARE &HARDWARE INSTALLATION ................................................................................... 7

SECTION 2: OPERATION ..........................................................................................................................8

2.1 FRONT PANEL CONNECTORS.................................................................................................................8

2.2 SOFT FRONT PANEL.......................................................................................................................... 12

2.2.1 General Functions ................................................................................................................................ 12

2.2.2 MIPI Functions ......................................................................................................................................17

2.3 REMOTE OPERATION......................................................................................................................... 20

SECTION 3: BRIEF TECHNICAL DESCRIPTION ......................................................................................... 21

3.1 BASIC OPERATION ............................................................................................................................ 21

3.1.1 Per Pin Parametric Measurement Unit (PPMU) Functions .................................................................... 21

3.1.2 Pin Electronics (PE) Functions .............................................................................................................. 23

3.1.3 Vector Engine Functions....................................................................................................................... 25

3.1.4 Triggers................................................................................................................................................ 27

3.1.5 MIPI ................................................................................................................................................... 28

3.2 SIGNAL CONNECTION ........................................................................................................................ 30

SECTION 4: MAINTENANCE ................................................................................................................... 31

4.1 CLEANING....................................................................................................................................... 31

4.2 CALIBRATION .................................................................................................................................. 31

4.3 SERVICING ...................................................................................................................................... 31

SECTION 5: WARRANTY......................................................................................................................... 32

SECTION 6: REVISION HISTORY............................................................................................................. 33

SECTION 7: CONTACT US....................................................................................................................... 34

DM482e User Manual

AEMULUS 2

Safety Precautions

A. General Information

Refer to the User Manual prepared by the manufacturer for proper usage of the

instrument.

If the product is used in a manner not specified, the protection provided by the

instrument warranty may be impaired.

Return the instrument to Aemulus for service and repair to ensure that safety

features are maintained.

The WARNING heading explains hazards that might

occur if an operating procedure, practice, or the like

that, if not correctly performed or adhered to might

result in personal injury or death. Always read the

associated information very carefully and make sure

the indicated information is met before performing the

indicated procedure.

The CAUTION heading in the user documentation

explains hazards that could damage the instrument.

Such damage may invalidate the warranty.

WARNING

CAUTION

DM482e User Manual

AEMULUS 3

B. Identification and Discouragement of Hazardous Applications

Main Power

Ensure that the mains power is turned off before plugging

or removing the PXI module into or from the chassis.

Make sure the power cord is plugged properly to the

chassis before applying power.

The chassis that carries the instrument has to be plugged

into a grounded (earthed) power outlet. By not doing so, it

will defeat the power cord safety ground feature.

Ensure that the power is removed from the product before

connecting/disconnecting the cables to the product

connectors.

Instrument Cables /

Connectors

Inspection of the connecting cable and test leads for

possible wear, cracks, or breaks must be done before each

use.

Make sure the cables used for the product are rated to the

specified voltage and current level.

Instrument Output

Extreme caution is to be practiced when a shock hazard is

present. Lethal voltage may be present on cable connector

jacks.

When power is applied to the circuit under test, do not

touch the product and test cables or test leads.

Do not touch the connector jacks or cables when the

output of the product is turned on.

If the DM482e has been in use, it might exceed safe handling

temperatures and cause burns. Allow some cooling time

before removing the DM482e from the chassis.

Hot Surface

WARNING

CAUTION

WARNING

WARNING

DM482e User Manual

AEMULUS 4

Operating

Temperature

The fan speed of the chassis that carries the instrument

has to be in HIGH speed to allow proper heat ventilation.

Make sure the product temperature is under 46˚C before

operating the product.

WARNING

DM482e User Manual

AEMULUS 5

C. Identification of Authorized Personnel

End user

Individual or group who is responsible for the use and maintenance

of the product, as well as being responsible for ensuring that the

product is operated within its specifications. Knowledge on

electrical safety procedures and proper use of the product are

prerequisite before operating the product.

Maintenance

personnel

Individual or group who is responsible for performing routine

procedures on the product to keep it operating properly. Any service

should only be done by qualified service personnel.

Service

personnel

Installation and service procedures may only be carried out by

properly trained service personnel. Knowledge on working with live

circuits, performing safe installations, and repairing the products are

prerequisite for this individual or group.

DM482e User Manual

AEMULUS 6

Section 1: Quick Start

1.1 Product Start-up Configuration

Each product is carefully inspected before it leaves the factory. Upon receipt and before

unpacking the product, please inspect the unit for any obvious damage that may occur during

shipment. If any damage is found, notify the instrument manufacturer immediately.

Please verify that the following items are included in the original packing of this product.

Contact the instrument manufacturer immediately if any of these items are found missing.

Reference / Drivers CD-ROM

The product is designed to be used in an indoor environment, an area with low condensation

and a temperature of between 23°C ± 10°C. Ensure that the area where the product is installed

is free from the presence of any explosive or flammable fumes or gases.

The product is shipped in materials that prevent static damage to the

module. The module should only be removed from the packaging in an

anti-static area ensuring that correct anti-static precautions are taken.

Store all modules in anti-static envelopes when not in use.

CAUTION

DM482e User Manual

AEMULUS 7

1.2 Product Software & Hardware Installation

Refer to installation guide.

DM482e User Manual

AEMULUS 8

Section 2: Operation

2.1 Front Panel Connectors

1 OUTPUT (VHDCI, 68-Position, Receptacle)

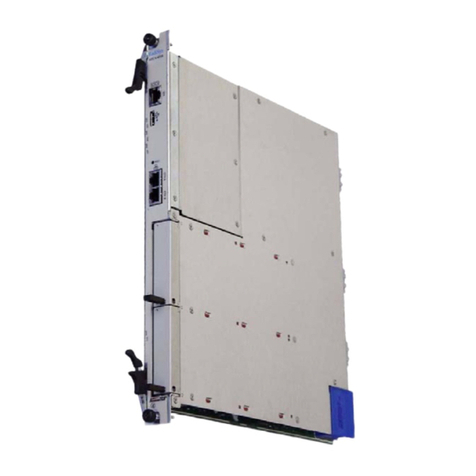

Figure 1: DM482e Front Panel

DM482e User Manual

AEMULUS 9

Pin

Signal Name (Primary)

Signal Name (MIPI)

Description

1

HV3

High Voltage Driver 3

2

HV4

High Voltage Driver 4

3

HV5

High Voltage Driver 5

4

-

-

5

-

-

6

-

-

7

PIN11_SH

Pin 11 Sense-High

8

PIN10_PIN11_L

VIO3_GND

Pin 10-11 Low

9

PIN11_FH

VIO3

Pin 11 Force-High

10

PIN8_PIN9_L

SCLK3_GND

Pin 8-9 Low

11

PIN9_FH

SCLK3

Pin 9 Force-High

12

PIN9_SH

Pin 9 Sense-High

13

PIN7_SH

Pin 7 Sense-High

14

PIN6_PIN7_L

SDATA2_GND

Pin 6-7 Low

15

PIN7_FH

SDATA2

Pin 7 Force-High

16

-

-

17

-

-

18

HV0

High Voltage Driver 0

19

HV1

High Voltage Driver 1

20

HV2

High Voltage Driver 2

21

EXT_TRIGIN0

External Trigger Input 0

22

GND

Ground

23

EXT_TRIGOUT0

External Trigger Output 0

24

GND

Ground

25

PIN5_SH

Pin 5 Sense-High

26

PIN4_PIN5_L

SDATA1_GND

Pin 4-5 Low

27

PIN5_FH

SDATA1

Pin 5 Force-High

28

PIN2_PIN3_L

VIO1_GND

Pin 2-3 Low

29

PIN3_FH

VIO1

Pin 3 Force-High

30

PIN3_SH

Pin 3 Sense-High

31

PIN1_FH

SDATA0

Pin 1 Force-High

32

PIN0_PIN1_L

SDATA0_GND

Pin 0-1 Low

33

PIN1_SH

Pin 1 Sense-High

34

-

-

Table 1: I/O Pin-out (Pins 1-34)

DM482e User Manual

AEMULUS 10

Pin

Signal Name (Primary)

Signal Name (MIPI)

Description

35

-

-

36

-

-

37

-

-

38

-

-

39

-

-

40

-

-

41

PIN10_SH

Pin 10 Sense-High

42

PIN10_PIN11_L

SDATA3_GND

Pin 10-11 Low

43

PIN10_FH

SDATA3

Pin 10 Force-High

44

PIN8_PIN9_L

VIO2_GND

Pin 8-9 Low

45

PIN8_FH

VIO2

Pin 8 Force-High

46

PIN8_SH

Pin 8 Sense-High

47

PIN6_SH

Pin 6 Sense-High

48

PIN6_PIN7_L

SCLK2_GND

Pin 6-7 Low

49

PIN6_FH

SCLK2

Pin 6 Force-High

50

GND

Ground

51

EXT_TRIGOUT1

External Trigger Output 1

52

GND

Ground

53

EXT_TRIGIN1

External Trigger Input 1

54

-

-

55

-

-

56

-

-

57

-

-

58

-

-

59

PIN4_SH

Pin 4 Sense-High

60

PIN4_PIN5_L

SCLK1_GND

Pin 4-5 Low

61

PIN4_FH

SCLK1

Pin 4 Force-High

62

PIN2_PIN3_L

VIO0_GND

Pin 2-3 Low

63

PIN2_FH

VIO0

Pin 2 Force-High

64

PIN2_SH

Pin 2 Sense-High

65

PIN0_FH

SCLK0

Pin 0 Force-High

66

PIN0_PIN1_L

SCLK0_GND

Pin 0-1 Low

67

PIN0_SH

Pin 0 Sense-High

68

-

-

Table 2: I/O Pin-out (Pins 35-68)

DM482e User Manual

AEMULUS 11

Signal Name

Description

HVx

High voltage driver capable of generating up to 13.5V.

PINx_FH

The I/O for a pin for all operating modes (PMU, VECTOR, DIO,

CLOCK, INVERTED_CLOCK). Refer to programming manual for

details.

PINx_SH

The remote sense line when operating in PMU mode.

PINx_PIN(x+1)_L

The ground reference level for a pin. 2 pins (PINx and PIN(x+1))

share the same reference level, and these 2 pins can be configured

as a differential pins.

EXT_TRIGOUTx

External trigger output from the module.

EXT_TRIGINx

External trigger input to the module.

SCLKx

SCLK pin for MIPI.

SDATAx

SDATA pin for MIPI.

VIOx

VIO pin for MIPI.

SCLKx_GND

SDATAx_GND

VIOx_GND

GND pin for MIPI. User should short all the GND pins together.

Table 3: Pin Function Description

DM482e User Manual

AEMULUS 12

2.2 Soft Front Panel

The soft front panel provides a graphical interface for operating the module. It is intended for

testing and diagnosing, for demonstration and training, and for basic operation of the module.

It represents most of the functions available in the instrument driver. It is not however a

comprehensive application suitable for measurements; for this, remote programming the

module.

2.2.1 General Functions

Figure 2: DM482e Soft Front Panel

1

2

3

4

7

6a

6

5

7a

8

DM482e User Manual

AEMULUS 13

Item

Description

1

Select the PXI address of the module. A list of addresses is shown for all detected

modules in the chassis.

2

Select the pin group.

3

Set the number of power line cycle, in second.

4

Set the frequency of the power line (50Hz or 60Hz).

3

Initialize the selected module. This includes opening a session to communicate with

the module, and then reset the module in its default state

5

Un-initialize the selected module. This includes closing the current communication

session to the module.

6

Per Pin Parametric Measurement Unit (PPMU) function:

a

Output Function

DC DVCI: Drive-Voltage Clamp-Current operation.

Continuous mode.

DC DICV: Drive-Current Clamp-Voltage operation.

Continuous mode.

b

Voltage Level

Voltage level

c

V Range

Range of the voltage level

d

Current Level

Current level (Current level setting is not required

in DVCI mode. “I Range” will decide the

compliance value)

e

I Range

Range of the current level

f

Sense

Select either Remote or Local sense connection

6a

Click the “Start” button for the selected pin to execute PMU commands. The

button will immediately turn to “Stop”. Press it to exit from PMU functions.

Following results are shown for each pin:

a. Voltage (V)

b. Current (A)

c. On-board temperature

DM482e User Manual

AEMULUS 14

7

Pin Electronics (PE):

Generic Setting:

a

DPIN Force

Sets the operation mode:

Mode

Description

VECTOR

Vector engine

DIO

General purpose I/O

CLOCK

Drive clock signal

INVERTED_CLOCK

Drive inverted clock

signal. This is when 2 pins

are selected as differential

outputs

b

DPIN Level

Set the levels for each pin.

c

DPIN On

Turn on/off the selected pin.

d

DPIN PE Attribute

Enable/disable active load and input termination

Vector:

a

DPIN Period

Specifies the timing set to be used, as well as its

period setting

b

DPIN VecLoad

Load the specified vector set in the vector file to

the module

c

DPIN RunVec

Run the specified vector set.

Clock/Invert Clock:

a

Configure Clock

Frequency

Configure the clock frequency when mode

“CLOCK” or “INVERTED_CLOCK” is selected.

DIO:

a

Set Pin Direction

Specifies the direction of the selected pin.

b

Set Port Direction

Specifies the direction of the selected pin group.

DM482e User Manual

AEMULUS 15

c

Drive/Read

Select Pin

Specifies the pin

Drive Pin Value

Specifies the logic level of the

pin to be driven

Drive Port Value

Enter the port value (in HEX) if

you want to drive to the whole

pin group

Select Function

Select from a list of available

DIO functions:

- Drive Pin

- Drive Port

- Read Pin

- Read Port

Click the “Start” button for the selected pin to execute the command.

The results for read functions for each pin will be displayed as either “H”

(logic high), “L” (logic low) or “Z” (undefined).

8

Display the actions taken in the background.

Table 4: Soft Front Panel Control

DM482e User Manual

AEMULUS 16

Quick steps to configure the module:

1. Select PXIe address of the targeted module from the drop-down list.

2. Select the targeted pin group. In this example, select “All Groups (PIN0-11)”.

3. Press “Initialize”.

4. The module is set to drive 1V and its current compliance is set to 25mA, in DVCI

mode.

5. Press “Start” to execute the commands. The button will immediate to “Stop”.

6. Both voltage and current are measured.

7. Press “Stop” to exit from PMU mode.

8. Press “Un-Initialize” to turn off the whole module.

Figure 3: PMU Operation

DM482e User Manual

AEMULUS 17

2.2.2 MIPI Functions

Figure 4: MIPI SFP

Item

Description

1

Tick to enable loop-back1operation

2

Display the address of the module connected. A list of addresses is shown for all

detected modules in the computer.

3

Set/ display the voltage supply of the module

4

Set/ display the frequency of the MIPI operation

5

Initialize or un-initialize the module

6

Data to be written into the module

DM482e User Manual

AEMULUS 18

7

Channel 0 control panel:

a

Start

Execute the operation

b

Command

The command to be sent to module for different

MIPI operation

c

Select Feature

Select either DM482e_MIPI_RFFE_WR,

DM482e_MIPI_RFFE_RD and

DM482e_MIPI_RFFE_RETRIEVE

d

Reset

Reset all ports to input, drive logic low. Reset all

internal registers

8

Channel 1 control panel:

a

Start

Execute the operation

b

Command

The command to be sent to module for different

MIPI operation

c

Select Feature

Select either DM482e_MIPI_RFFE_WR,

DM482e_MIPI_RFFE_RD and

DM482e_MIPI_RFFE_RETRIEVE

d

Reset

Reset all ports to input, drive logic low. Reset all

internal registers

9

Display the data after read operation, together with its corresponding parity check

bit.

10

Counter to display the number of data byte read

Table 5: MIPI Soft Front Panel Control

Note:

1. Loop-back –is an operation whereby the routing of signals or flows of items back to

their originating devices or facilities without intentional processing or modification.

This is used to test the transmission or transportation infrastructure.

DM482e User Manual

AEMULUS 19

Quick steps to configure the module:

1. Select PXIe address of the targeted module from the drop-down list.

2. Set the desired voltage level.

3. Set the desired frequency.

4. Press “Initialize”.

5. Set desired operation from the feature in channel 0 or channel 1. For example,

DM482e_MIPI_RFFE_WR.

6. Set the desired operation command, for example, 0x0202.

7. Set the data that should be written to the module at part (6). Refer to Figure 4.

8. Press “Start” to execute the command.

9. Press “Un-Initialize” to turn off the whole module.

Note:

Retrieve result and counter will be displayed after the operation of

DM482e_MIPI_RFFE_RETRIEVE.

This manual suits for next models

1

Table of contents